Production method of fibrilia automobile ceiling

A production method and hemp fiber technology are applied in the production field of hemp fiber automobile canopies, which can solve the problems of scraps and scrap products that are difficult to recycle, product materials that are not environmentally friendly, and poor impact resistance, and achieve outstanding environmental performance and light weight. , the effect of low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Hemp fiber car roof, its specification is: L1200×W1000mm. The weight of hemp fiberboard is 1200g / m 2 , the thickness is 5mm; the adhesive film is PA mesh film; the fabric is a composite fabric of knitted fabric and non-woven fabric.

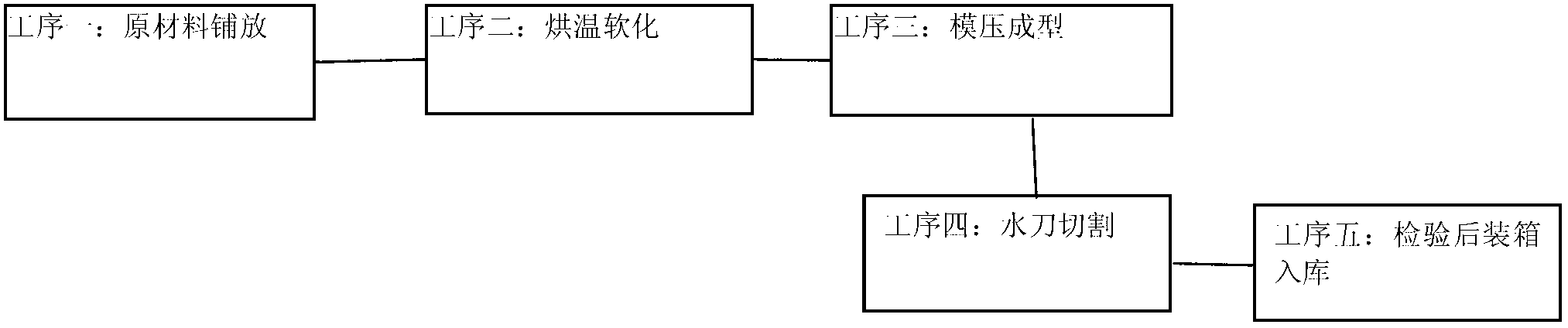

[0019] A kind of production method of hemp fiber car headliner, the steps are as follows:

[0020] (1) Laying of raw materials: Stack the hemp fiber boards with adhesive film on the loading table, and the hemp fiber is transferred to the oven mesh chain by the suction mechanism;

[0021] (2) Baking and softening: put the hemp fiber board on the oven net chain in a rotating net chain oven for drying and softening. The softening temperature is 190°C and the time is 100s; Surface bonding on the feeding mechanism;

[0022] (3) Compression molding: use a rotating network chain to spread the softened material on the mold, and obtain a semi-finished product after holding the pressure; the holding pressure is 100bar, and the holding time is 60...

Embodiment 2

[0027] Hemp fiber car roof, its specification is: L1200×W1000mm. The weight of hemp fiberboard is 1000g / m 2 , the thickness is 5mm; the adhesive film is PA mesh film; the fabric is a composite fabric of knitted fabric and non-woven fabric.

[0028] A kind of production method of hemp fiber car headliner, the steps are as follows:

[0029] (1) Laying of raw materials: Stack the hemp fiber boards with adhesive film on the loading table, and the hemp fiber is transferred to the oven mesh chain by the suction mechanism;

[0030] (2) Oven softening: put the hemp fiberboard on the oven net chain in a rotating net chain oven for oven softening, the softening temperature is 195°C, and the time is 90s; while softening, spread the fabric on the Surface bonding on the feeding mechanism;

[0031] (3) Compression molding: use a rotating network chain to spread the softened material on the mold, and obtain a semi-finished product after holding the pressure; the holding pressure is 90bar...

Embodiment 3

[0036] Hemp fiber car roof, its specification is: L1200×W1000mm. The weight of hemp fiberboard is 1400g / m 2 , the thickness is 5mm; the adhesive film is PA mesh film; the fabric is a composite fabric of knitted fabric and non-woven fabric.

[0037] A kind of production method of hemp fiber car headliner, the steps are as follows:

[0038] (1) Laying of raw materials: Stack the hemp fiber boards with adhesive film on the loading table, and the hemp fiber is transferred to the oven mesh chain by the suction mechanism;

[0039] (2) Baking and softening: put the hemp fiber board on the oven mesh chain in a rotating mesh chain oven for drying and softening. The drying and softening temperature is 200°C and the time is 110s; Surface bonding on the feeding mechanism;

[0040] (3) Molding: Use a rotating network chain to lay the softened material on the mold, and obtain a semi-finished product after holding the pressure; the holding pressure is 110bar, and the holding time is 60s;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com