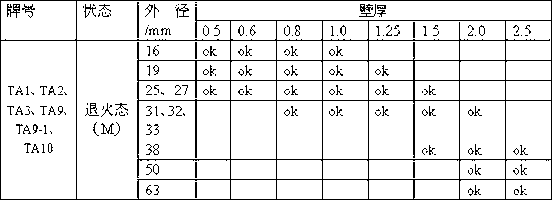

Preparation method of thickness-diameter ratio longitudinal titanium and titanium alloy welded pipe

A titanium alloy, thickness-to-diameter ratio technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as incomplete forming, wavy forming edges, and rebound welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

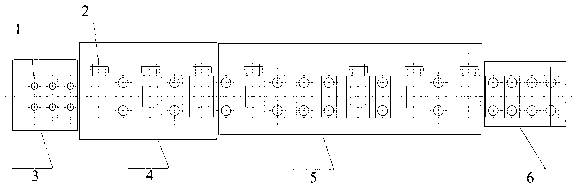

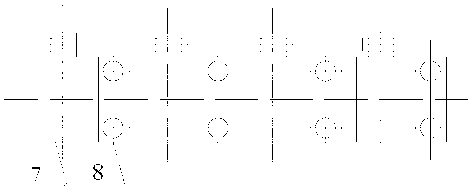

[0031] The raw material is TA2 titanium belt, the width is 122.0~123.5, the wall thickness is 0.68~0.76mm, the continuous cold bending forming roll mold specification is Φ39, and the preparation of Φ39×0.7mm straight seam titanium welded pipe is carried out. The titanium belt passes through the centering device composed of 3 sets of non-powered vertical rollers on the forming unit. The gap between the vertical rollers is 10mm to realize the centering and guiding of the titanium belt. The titanium belt through the centering device enters the rough forming device in the forming unit, and the arrangement is flat roll + vertical roll + flat roll + vertical roll + flat roll. The gap between the flat roll and the vertical roll in the rough forming device is 25mm. The lower rolls of the 3 sets of flat rolls are driven independently with power, and the upper rolls and vertical rolls of the flat rolls are passively driven without power. After the rough forming device, the edge of the ...

Embodiment 2

[0035] The raw material is TA2 titanium belt, the width is 139~140.5, the wall thickness is 0.68~0.76mm, the continuous cold bending forming roll mold specification is Φ39, and the straight seam titanium welded pipe with the specification of Φ44.7×0.7mm is prepared.

[0036] The titanium belt passes through the centering device composed of 3 sets of non-powered vertical rollers on the forming unit. The gap between the vertical rollers is 10mm to realize the centering and guiding of the titanium belt. The titanium belt through the centering device enters the rough forming device in the forming unit, and the arrangement is flat roll + vertical roll + flat roll + vertical roll + flat roll. The gap between the flat roll and the vertical roll in the rough forming device is 25mm. The lower rolls of the 3 sets of flat rolls are driven independently with power, and the upper rolls and vertical rolls of the flat rolls are passively driven without power. After the rough forming device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com