Thermal insulation raw material, thermal insulation material and multilayered composite material

A technology of multi-layer composite materials and thermal insulation materials, applied in the field of thermal insulation raw materials, can solve the problems of low thermal insulation performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

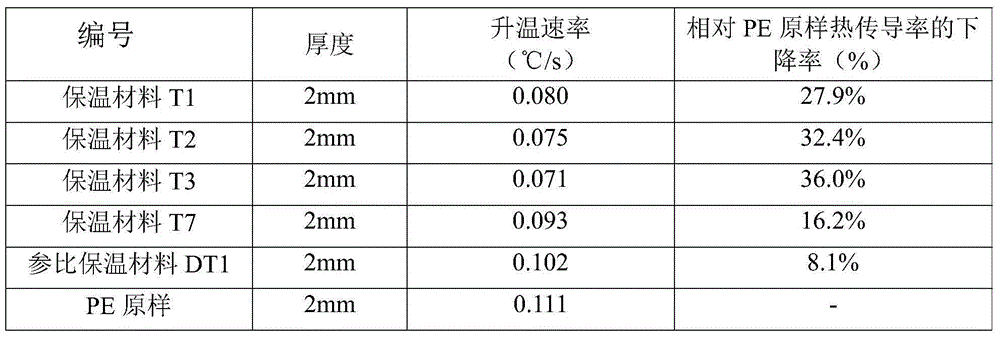

[0028] This preparation example is used to illustrate the insulation raw material and insulation material provided by the present invention and the preparation method thereof.

[0029] Add 6g of silica airgel (average pore diameter of 25nm, porosity of 98%, purchased from Cabot Company) and 24g of polyethylene (purchased from Yanshan Petrochemical, brand LD100ac, the same below) into the cavity of the rheometer , kneaded for 8 minutes under the conditions of a kneading temperature of 180°C and a rotor speed of 30rmp, and obtained thermal insulation material T1 after cooling. The microstructure of the thermal insulation material T1 was observed with a scanning electron microscope, and the results showed that the silica airgel was uniformly dispersed in polyethylene.

preparation example 2

[0031] This preparation example is used to illustrate the insulation raw material and insulation material provided by the present invention and the preparation method thereof.

[0032] Add 7.5g of silica airgel (average pore diameter of 15nm, porosity of 92%, purchased from Cabot Company) and 22.5g of polyethylene into the cavity of the rheometer. Mixed for 8 minutes under the condition of 30rmp, and obtained insulation material T2 after cooling. The microstructure of the thermal insulation material T2 was observed with a scanning electron microscope, and the results showed that silica airgel was uniformly dispersed in polyethylene.

preparation example 3

[0034] This preparation example is used to illustrate the insulation raw material and insulation material provided by the present invention and the preparation method thereof.

[0035] Add 12g of silica airgel (average pore diameter of 40nm, porosity of 93%, purchased from Cabot Company) and 18g of polyethylene into the chamber of the rheometer, at a mixing temperature of 180°C and a rotor speed of 30rmp Mixed for 8 minutes under the conditions, after cooling to obtain insulation material T3. The microstructure of the thermal insulation material T3 was observed with a scanning electron microscope, and the results showed that silica airgel was uniformly dispersed in polyethylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore diameter | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com