Preparation and sintering of single-aperture blank of oxygen self-supported permanent magnetic ferrite pre-sintering material

A technology of permanent magnet ferrite and pre-sintered material, which is applied in the field of magnetic functional material preparation, can solve the problems of reduced output of ferrite pre-sintered material, unfavorable energy saving and environmental protection, and impact on product performance, so as to avoid the difficulty of forming magnetic parts, Cost-effective, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

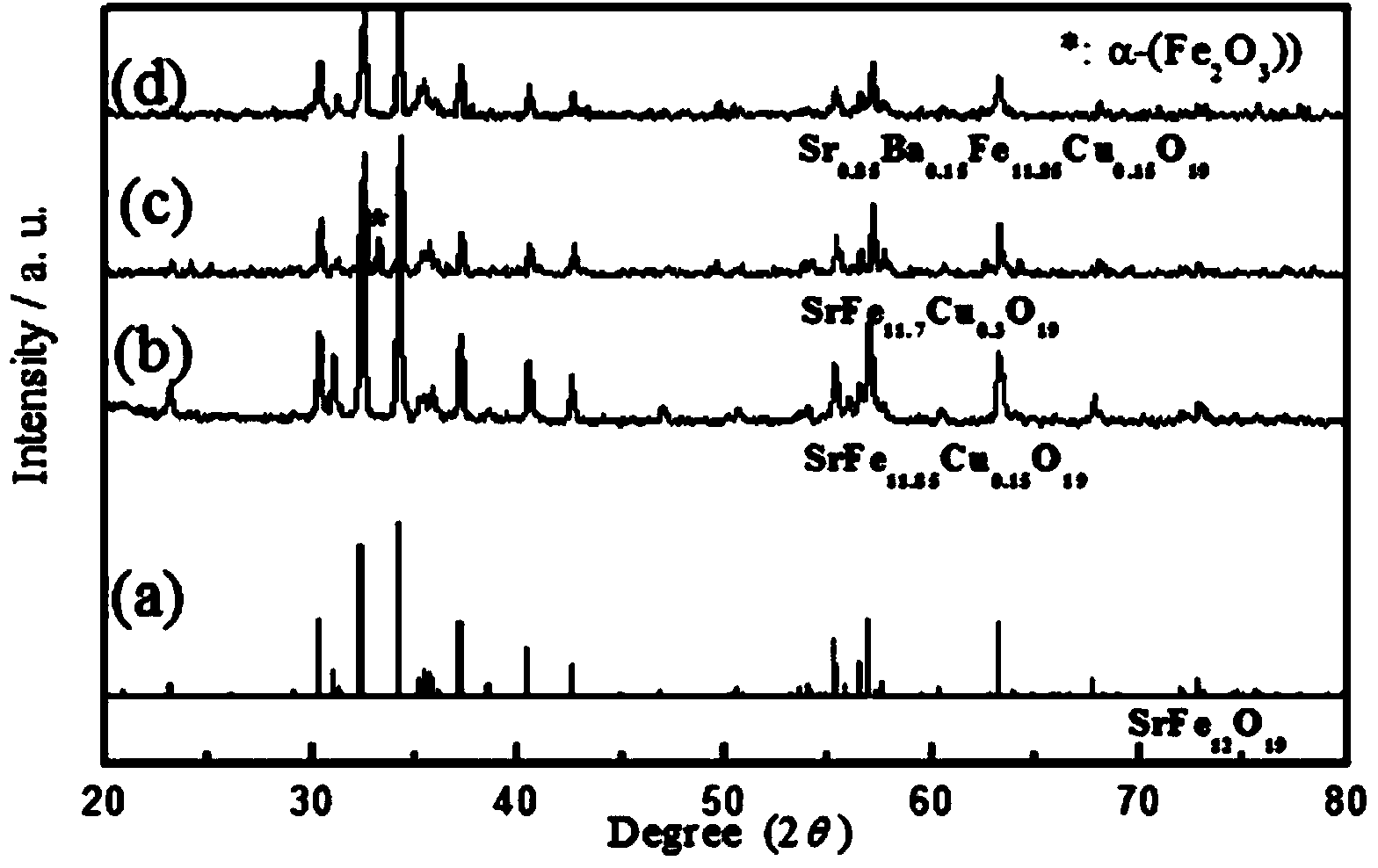

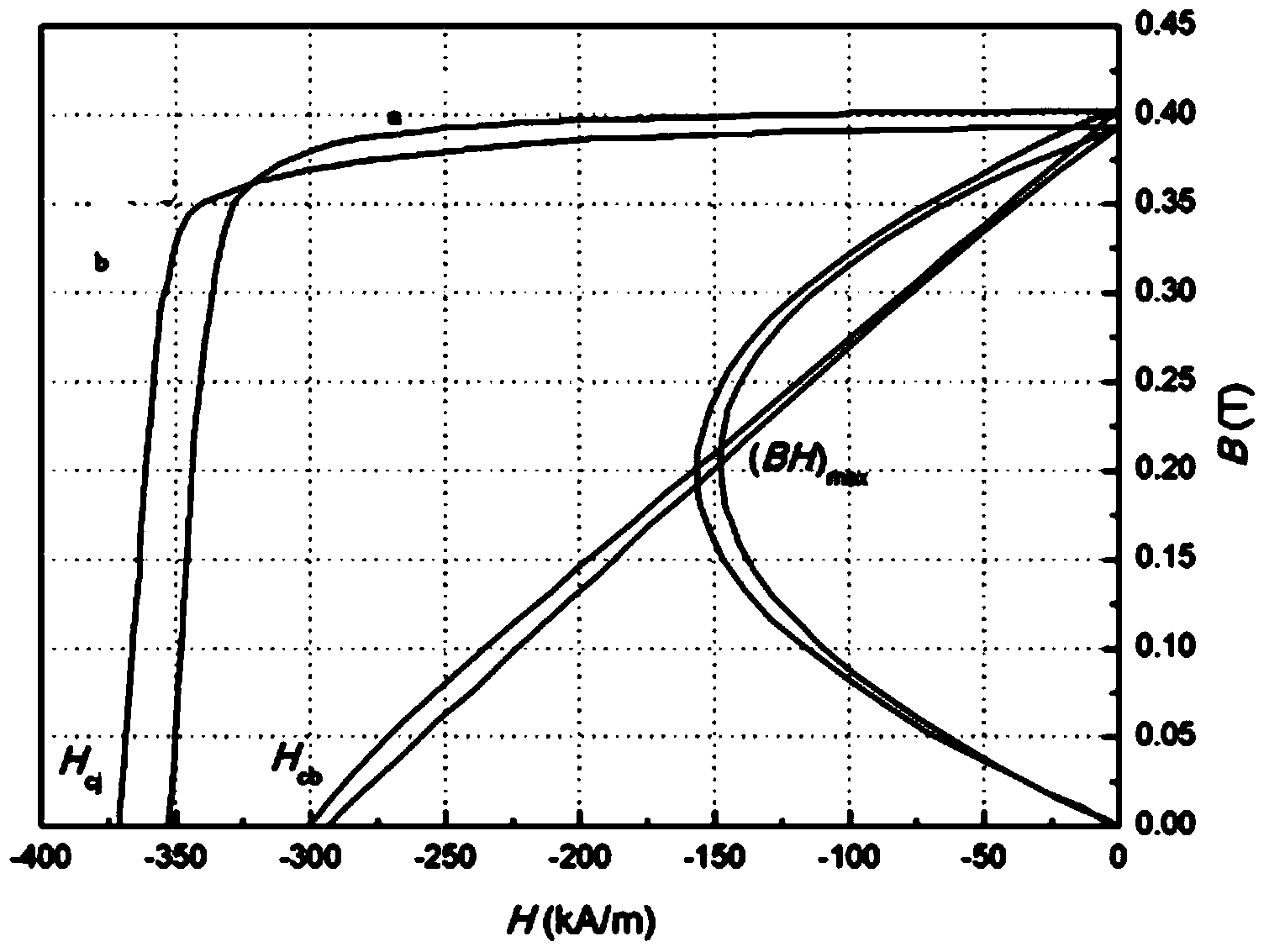

[0026] According to the chemical structure formula Sr 1-x Ba x O nFe (12-y) / n R y / n o 3(x=0.0, n=6.0, y=0.2, R is the composition requirement of Mn, with industrially produced iron red (purity is 99.5%), strontium carbonate (purity is 99.05%) and industrial pure K 2 MnO 4 As raw material, batching is carried out once, and 0.2wt% CaCO is added at the same time 3 , 0.3wt% SiO 2 As a primary additive, mix with water and steel balls according to the weight ratio of material: water: ball = 1: 1.5: 15, and perform primary ball milling for 2 hours to obtain a mixture with an average particle size of suspended particles of 1.0-1.5 μm.

[0027] After the mixed material is filtered, dried and granulated, it is pre-fired at 1290°C and kept for 3 hours to prepare the M-type permanent magnet ferrite pre-fired material;

[0028] Then, in the calcined powder obtained after pulverizing and sieving, add secondary additives, the addition of each component of the additive and the calcined...

Embodiment 2

[0033] According to the chemical structure formula Sr 1-x Ba x O nFe (12-y) / n R y / n o 3 (x=0.0, n=6.0, y=0.25, R is the composition requirement of Mn, with industrially produced iron red (purity is 99.5%), strontium carbonate (purity is 99.05%) and industrial pure K 2 MnO 4 As raw material, batching is carried out once, and 0.2wt% CaCO is added at the same time 3 , 0.3wt% SiO 2 As a primary additive, mix with water and steel balls according to the weight ratio of material: water: ball = 1: 1.5: 15, and perform primary ball milling for 2 hours to obtain a mixture with an average particle size of suspended particles of 1.0-1.5 μm.

[0034] After the mixed material is filtered, dried and granulated, it is pre-fired at 1290° C. and kept for 3 hours to prepare the M-type permanent magnet ferrite pre-fired material.

[0035] Then, in the calcined powder obtained after pulverizing and sieving, add secondary additives, the addition of each component of the additive and the calc...

Embodiment 3

[0040] According to the chemical structure formula Sr 1-x Ba x O nFe (12-y) / n R y / n o 3 (x=0.0, n=6.0, y=0.3, R is the composition requirement of Mn, with industrially produced iron red (purity is 99.5%), strontium carbonate (purity is 99.05%), technical pure K 2 MnO 4 As raw material, batching is carried out once, and 0.2wt% CaCO is added at the same time 3 , 0.3wt% SiO 2 As a primary additive, mix with water and steel balls according to the weight ratio of material: water: ball = 1: 1.5: 15, and perform primary ball milling for 2 hours to obtain a mixture with an average particle size of suspended particles of 1.0-1.5 μm.

[0041] After the mixed material is filtered, dried and granulated, it is pre-fired at 1290°C and kept for 3 hours to prepare an M-type permanent magnet ferrite pre-fired sample block;

[0042] Then, in the calcined powder obtained after pulverizing and sieving, add secondary additives, the addition of each component of the additive and the calcined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com