Preparation method of porous spinning composite material and lithium extraction application thereof

A composite material and spinning technology, applied in the field of porous spinning composite materials and lithium ion adsorption materials, can solve the problems of unfavorable large-scale industrial operation, low lithium concentration, poor cycle stability, etc., and achieve easy continuous industrial operation and preparation. Simple process flow and the effect of solving poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

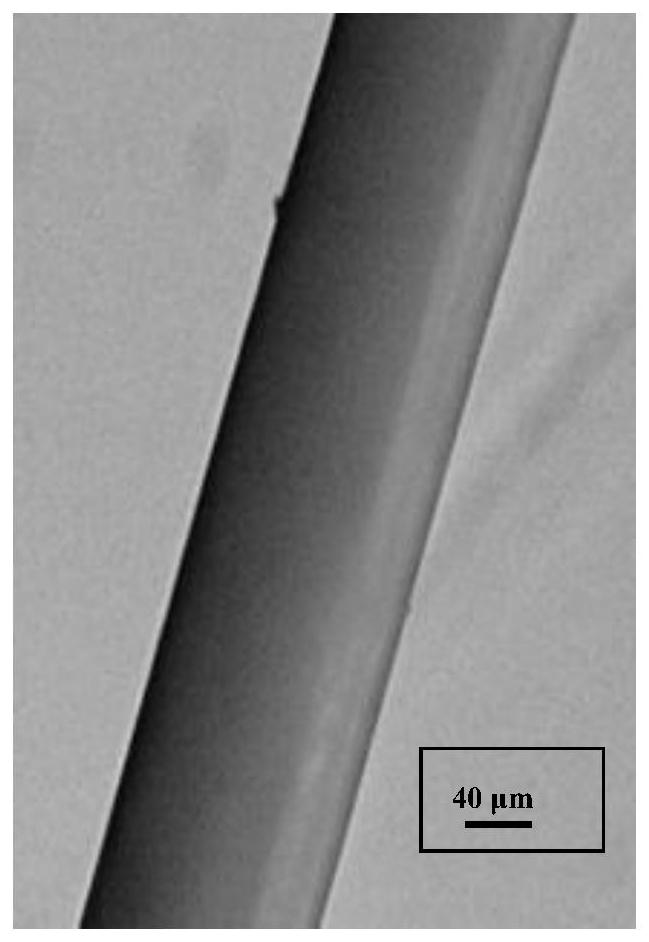

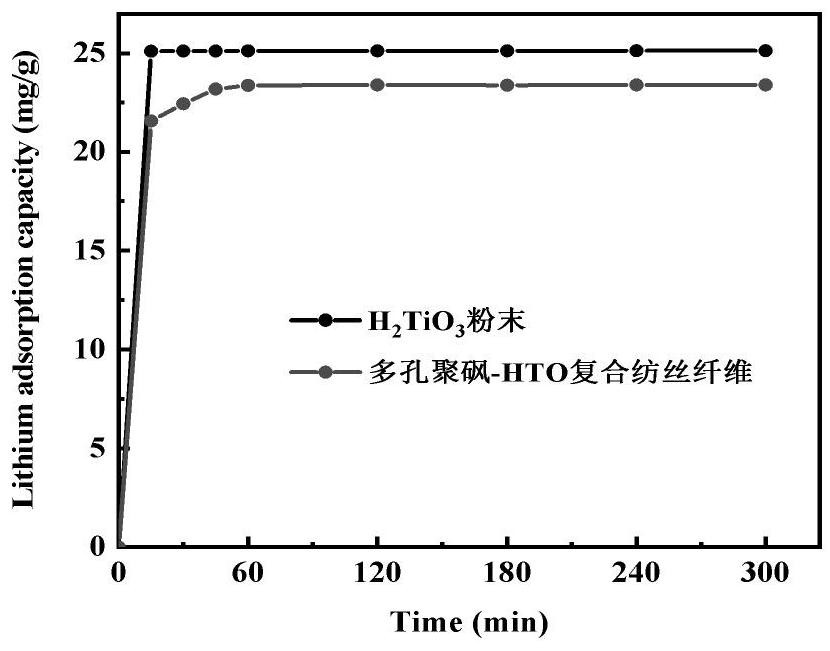

[0044] Example 1: Polysulfone-H 2 TiO 3 Preparation of porous spinning composites and its geothermal extraction of lithium

[0045] Weigh 10 g of polysulfone particles into a beaker, add 90 g of N-methylpyrrolidone into the beaker, and heat and stir with a constant temperature water bath magnetic stirrer until the polysulfone particles are completely dissolved.

[0046] Weigh 10g H 2 TiO 3 Add the powder and 8g of water-soluble porogen PEG-400 into the above polysulfone mixed solution, mix well and stir evenly, and make the H-type lithium ion sieve powder H 2 TiO 3 Uniformly dispersed in polysulfone mixed solution.

[0047] Polysulfone / H 2 TiO 3 Add the composite spinning stock solution to the raw material tank of the wet spinning equipment, adjust the number of spinneret holes to 40, the diameter of the spinneret holes to be 0.07mm, the spinneret speed to be 13m / min, and the drafting and winding speed to be 16m / min , sprayed into the coagulation bath through the spinn...

Embodiment 2

[0051] Example 2: Polyacrylonitrile-H 4 Ti 5 o 12 Preparation of Spinning Composite Materials and Its Geothermal Extraction of Lithium

[0052] Weigh 10 g of polyacrylonitrile powder into a beaker, add 90 g of dimethylformamide into the beaker, and heat and stir with a constant temperature water bath magnetic stirrer until the polyacrylonitrile powder is completely dissolved.

[0053] Weigh 5g H 4 Ti 5 o 12 The powder is added into the above polyacrylonitrile mixed solution, fully mixed and stirred evenly, so that the lithium ion sieve powder is uniformly dispersed in the polyacrylonitrile mixed solution.

[0054] PAN / H 4 Ti 5 o 12 Add the composite spinning stock solution to the raw material tank of the wet spinning equipment, adjust the number of spinneret holes to 50, the diameter of the spinneret holes to be 0.05mm, the spinneret speed to be 10m / min, and the drafting and winding speed to be 110m / min , through the spinneret into the coagulation bath, through phase ...

Embodiment 3

[0056] Embodiment 3: polyacrylonitrile-Li 2 TiO 3 Preparation of Spinning Composite Materials and Its Geothermal Extraction of Lithium

[0057] Weigh 10.5 g of polyacrylonitrile powder into a beaker, add 90 g of dimethylformamide into the beaker, heat and stir with a constant temperature water bath magnetic stirrer until the polyacrylonitrile powder is completely dissolved.

[0058] Weigh 10g Li 2 TiO 3 The powder is added into the above polyacrylonitrile mixed solution, fully mixed and stirred evenly, so that the lithium ion sieve powder is uniformly dispersed in the polyacrylonitrile mixed solution.

[0059] Polyacrylonitrile / Li 2 TiO 3 Add the composite spinning stock solution to the raw material tank of the wet spinning equipment, adjust the number of spinneret holes to 40, the diameter of the spinneret holes to be 0.07mm, the spinneret speed to be 10m / min, and the drafting and winding speed to be 10m / min , spun into the coagulation bath through the spinneret, formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com