Integrated forming method and integrated forming device for large complex thin-walled fine grain casting

A molding method and molding device technology, applied in the direction of casting equipment, indicating equipment/measurement equipment configuration, manufacturing tools, etc., can solve the problem of hindering crystal growth and strong grain refinement, difficulty in forming large complex thin-walled castings, and metallurgical quality Low-level problems, to achieve the effect of improving formability and density, broadening the scope of use, and achieving remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

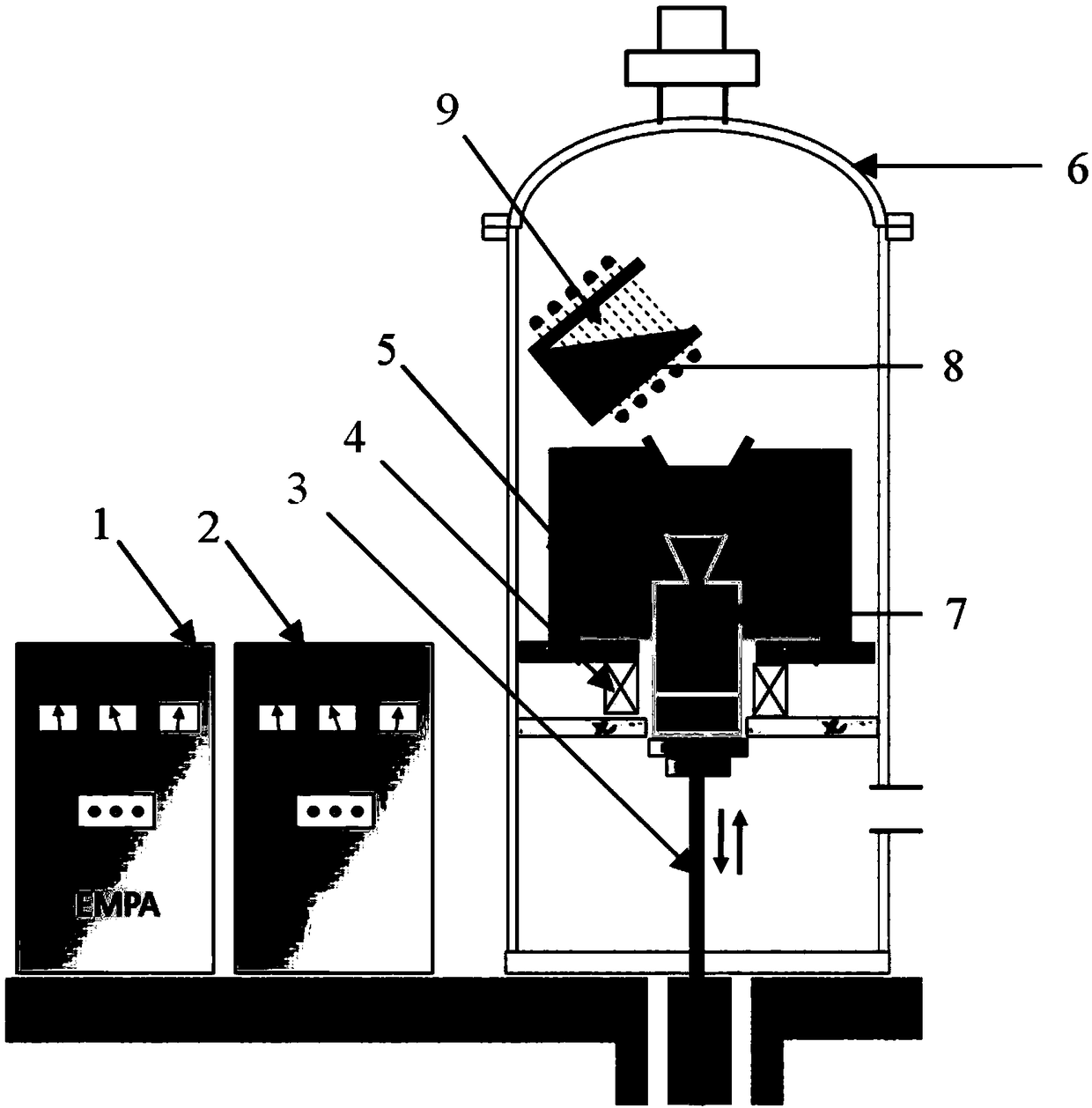

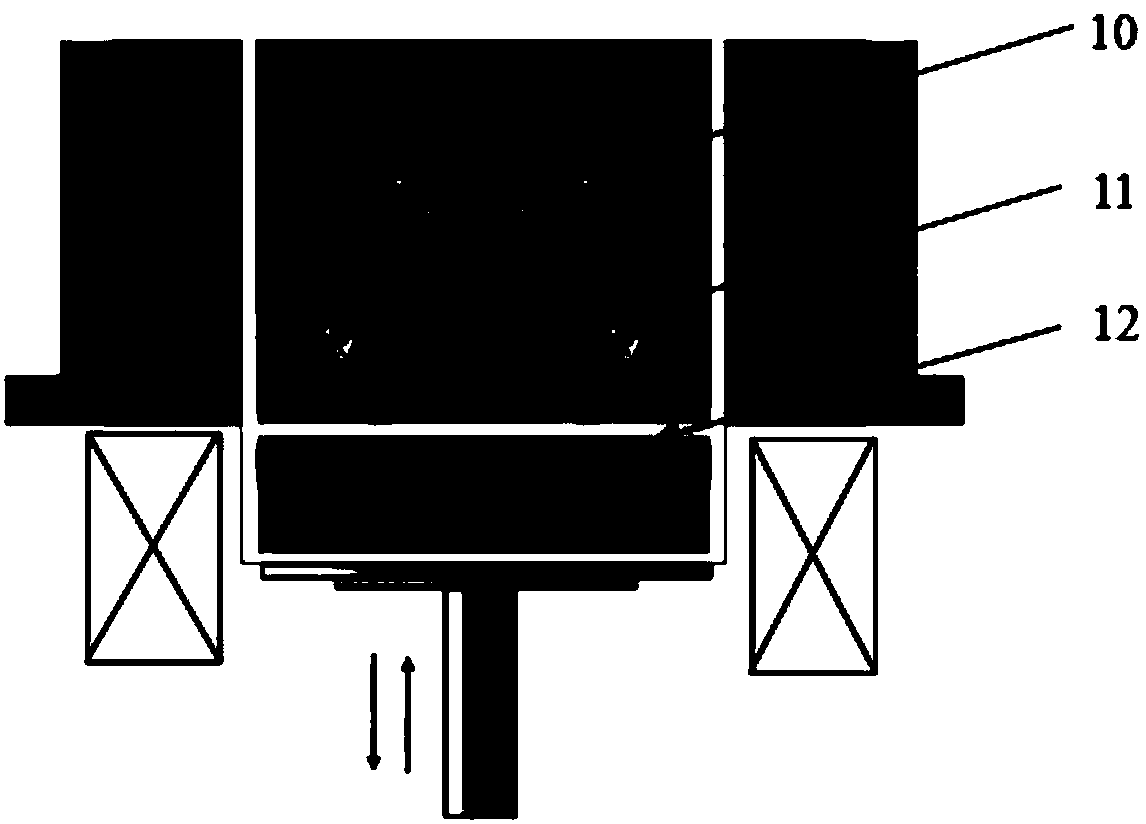

Method used

Image

Examples

Embodiment 1

[0043] In this example, the K4169 nickel-based superalloy was melted to 1500°C in a vacuum induction melting furnace and refined for 5 minutes, then cooled to 1420°C (superheat degree 60°C), and poured into the mold shell placed in the mold temperature control system (upper temperature 1360°C, lower temperature 1260°C), the ingot drawing system is turned on, and the mold shell is slowly drawn away from the hot zone at a pulling speed of 10mm / min; the magnetic pulse disturbance system is turned on to make the melt under the action of an electromagnetic field Sequential solidification, control the strength and frequency of the pulsed magnetic field, the magnetic field strength is 0.2T, the frequency is within 5Hz, and the action time is 30 minutes. The filling of the casting is complete, the grain size is less than 3mm, and the area percentage of loose defects is controlled below 0.03%.

Embodiment 2

[0045] In this example, the K4169 superalloy was melted to 1500°C in an induction melting furnace and refined for 5 minutes, then cooled to 1450°C (90°C superheat), and poured into a mold shell placed in a mold temperature control system (1380°C , lower part temperature 1260°C), turn on the mold ingot drawing system, and slowly pull the mold shell away from the hot zone at a drawing speed of 12mm / min; turn on the magnetic pulse disturbance system to make the melt solidify sequentially under the action of the electromagnetic field, and control the pulse The strength and frequency of the magnetic field, the magnetic field strength is 0.4T, the frequency is within the range of 5Hz, and the action time is 40 minutes.

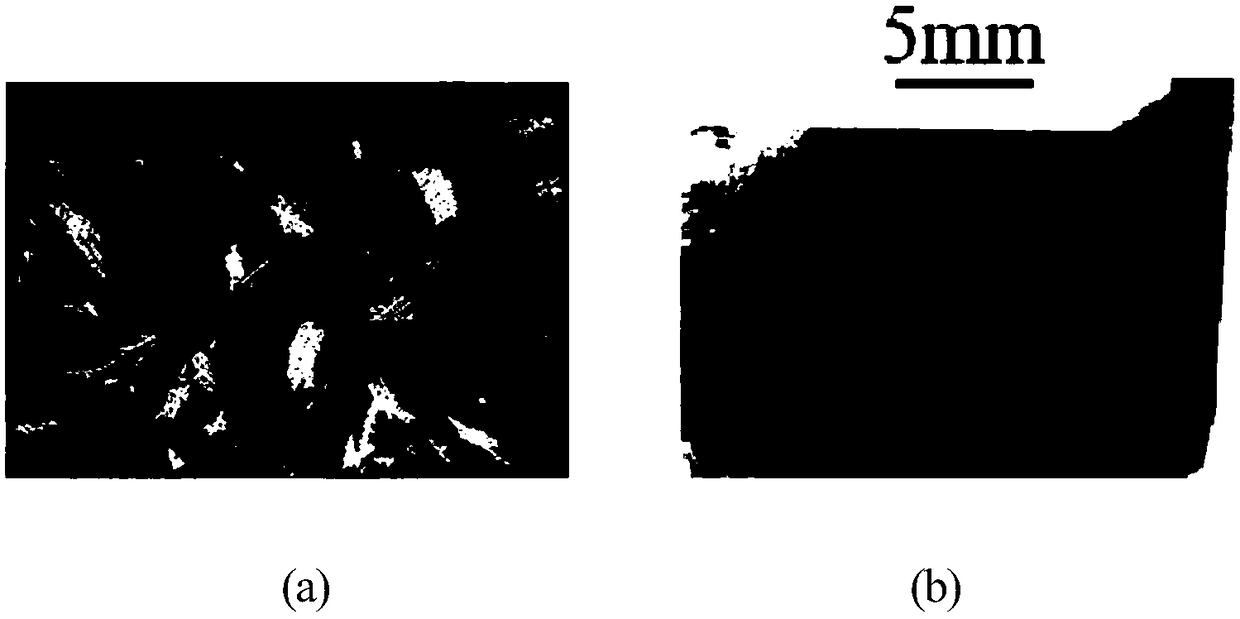

[0046] Such as image 3 Shown, the contrast of alloy microstructure after the solidification of the present invention and ordinary cast K4169 superalloy large complex thin-walled casting. The outer diameter of the casting is 890mm, the thin wall is 2mm, and the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com