Method for manufacturing two-way threaded-insert type tension spring

A manufacturing method and technology of two-way screw, applied in the field of coiled spring and its manufacturing, can solve the problems of long process, product scrapping, high process control, etc., and achieve the effect of solving the problem of initial tension, solving the difficulty of forming, and simplifying the process program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] The manufacture method of a kind of two-way screw type extension spring of the present invention, its steps are as follows:

[0022] The first step is to select spring steel wire: the selected material grade is 60Si2MnA, and the strength level is 1620-1770Mpa;

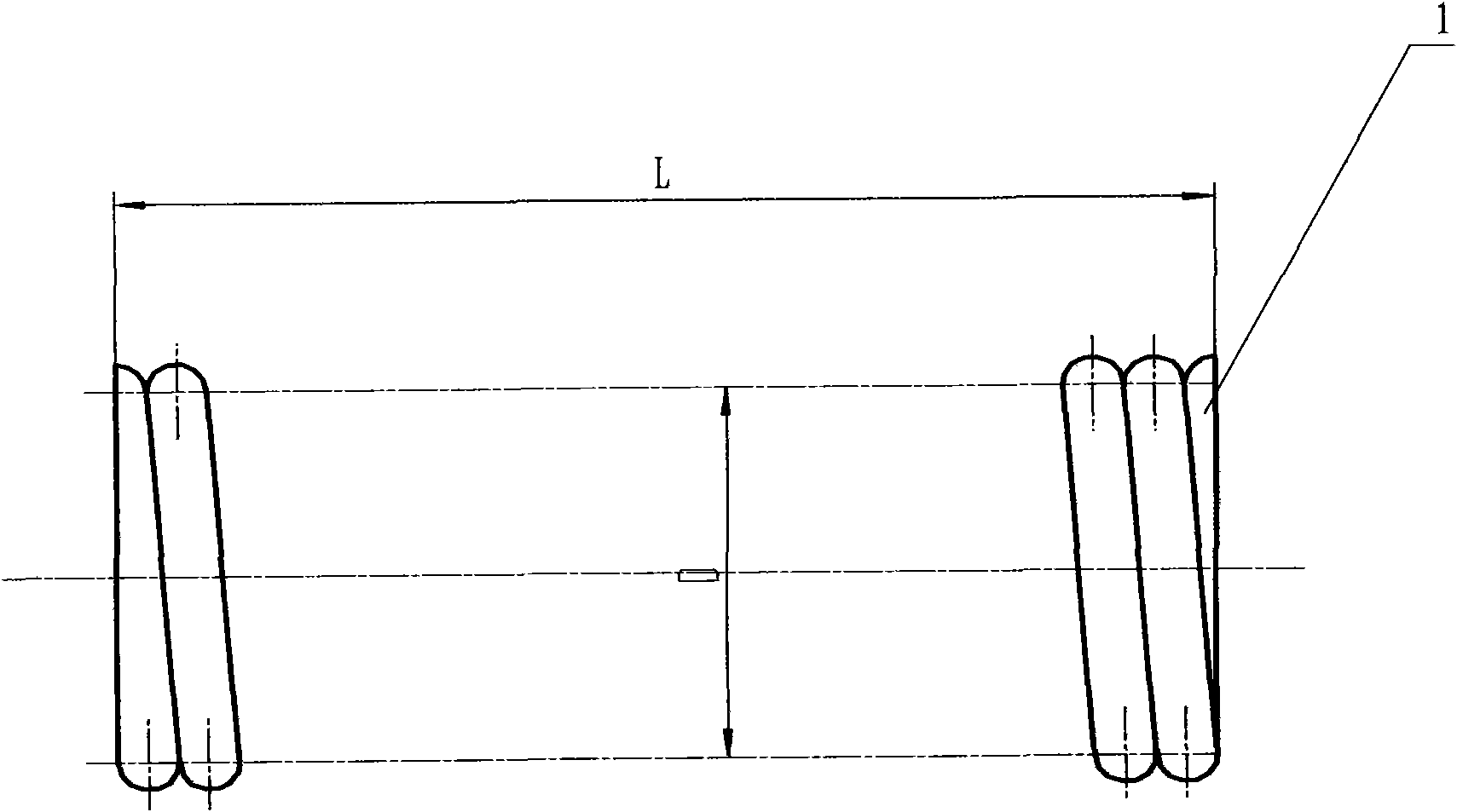

[0023] The second step is to wind the cylindrical helical spring: the selected spring steel wire is tightly wound on the spring coiling machine to make the cylindrical helical spring 1, see figure 1 ;

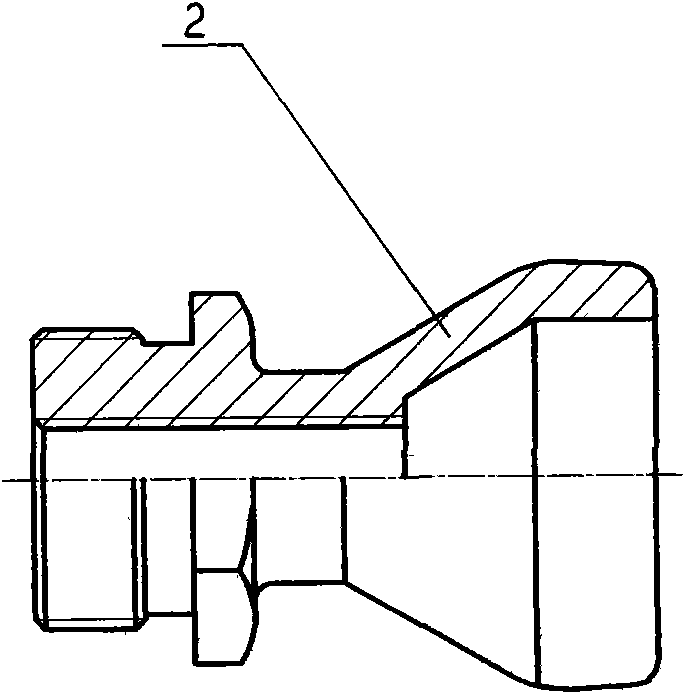

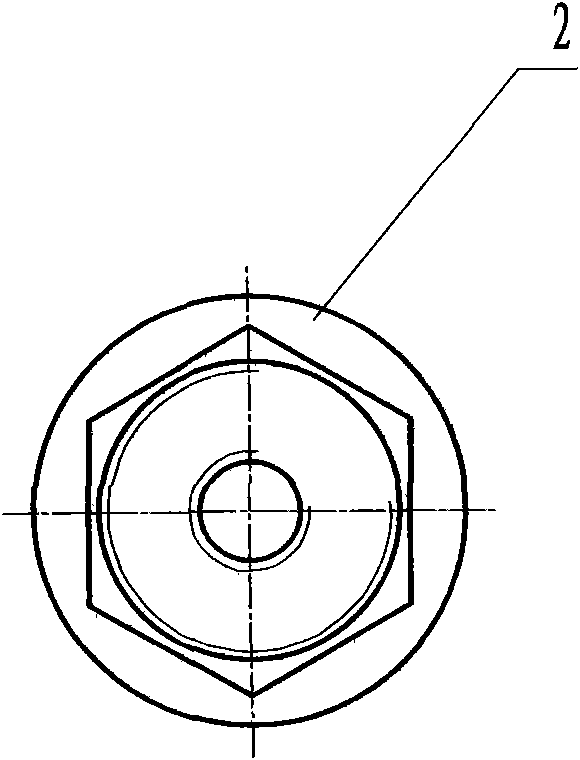

[0024] The third step is to inlay the screw sleeve: inlay the screw sleeve 2 at both ends of the cylindrical coil spring 1 respectively, first install the screw sleeve 2 made of a car into one end of the cylindrical coil spring 1, and perform spinning on the spinning fixture , tighten one end of the cylindrical helical spring 1, so that one end of the cylindrical helical spring fits the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com