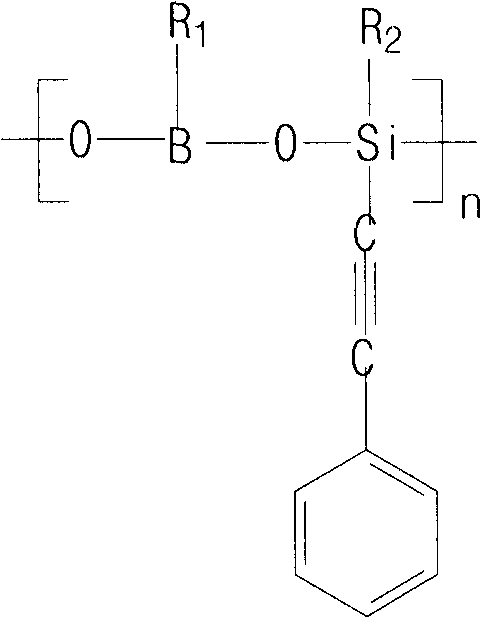

Polyphenylacetylene silicon oxide borane and preparation method thereof

A technology of polyphenylethynylsiloxaborane and alkylboronic acid, which is applied in the field of polyphenylethynylsiloxaborane and its preparation, can solve problems such as difficult molding of high temperature resistant materials, achieve improved thermal oxidation performance, good resistance Thermal oxidation performance, effect of improving thermal oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

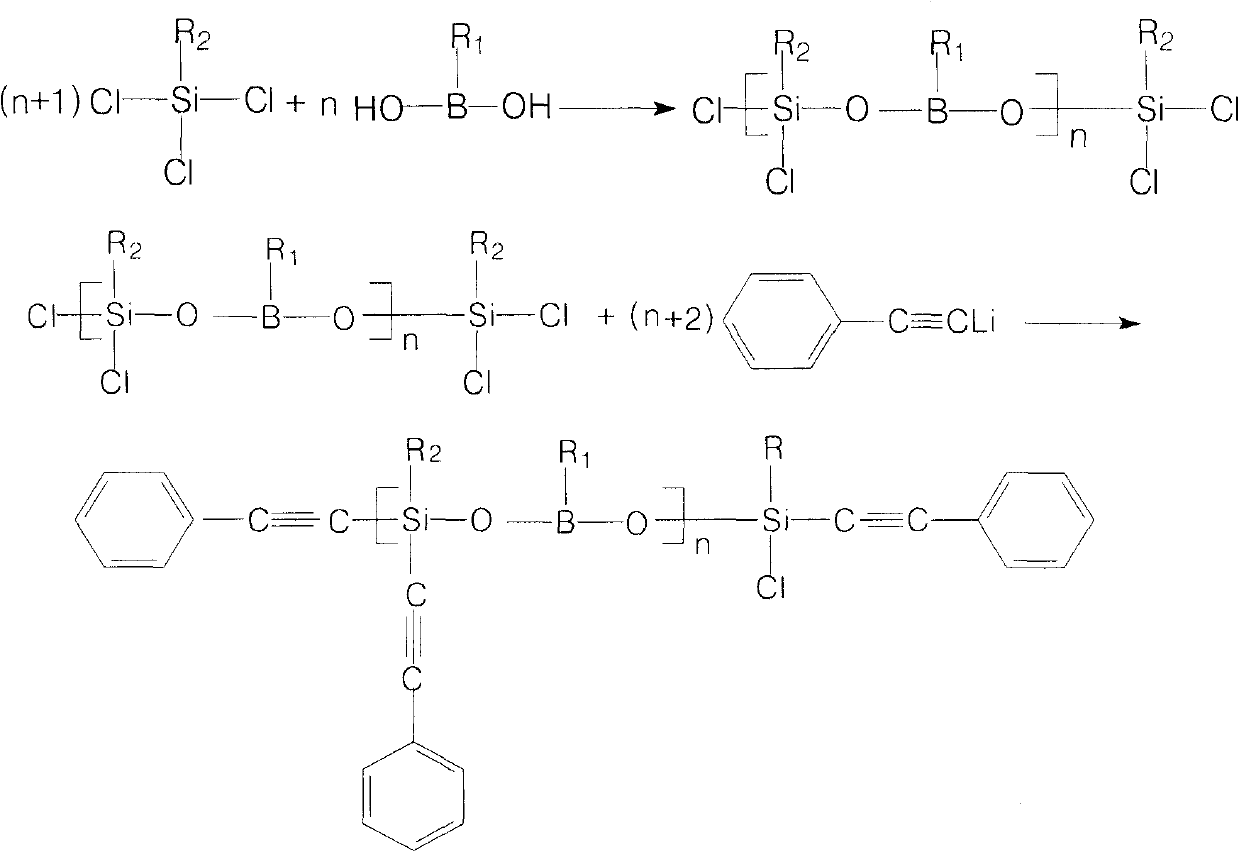

[0020] Embodiment 1: prepare polyphenylethynylsiloxaborane (wherein, R 1 , R 2 C respectively 6 h 5 、C 6 h 5 )

[0021] Under the protection of nitrogen, add 0.025mol phenylboronic acid (3.05g) and 15ml N,N-dimethylformamide to a 100ml three-necked flask, and heat up to 40°C under stirring to completely dissolve phenylboronic acid in the solvent; mol phenyltrichlorosilane (5.3g) and 20ml N, N-dimethylformamide mixed solution dropwise into the solution of phenylboronic acid, the temperature of the system is kept at 100°C ± 5°C; after the dropwise addition, the temperature of the system is controlled at 150℃±5℃, react for 48h. Add a mixed solution of 0.025mol phenylethynyllithium and tetrahydrofuran (the volume ratio of phenylethynyllithium to tetrahydrofuran is 1:5) dropwise into the reaction system, the dropping temperature is controlled at 0°C ± 5°C, and the dropwise addition is completed. The temperature of the system was controlled at 20°C±5°C, and the reaction was c...

Embodiment 2

[0022] Embodiment 2: Preparation of boron-containing phenylethynyl siloxane (wherein, R 1 , R 2 C respectively 6 h 5 、CH 3 )

[0023] Under nitrogen protection, add 0.025mol phenylboronic acid (3.05g) and 15ml n-butyl ether into a 100ml three-necked flask, and heat up to 40°C under stirring to completely dissolve phenylboronic acid in the solvent; 0.03mol methyltrichlorosilane (4.5g) and 25ml of butyl ether mixed solution was dropped into the phenylboronic acid solution, and the system temperature was kept at 90°C±5°C; after the addition, the system temperature was controlled at 65°C±5°C, and the reaction was carried out for 60 hours. Add a mixed solution of 0.04mol phenylethynyllithium and tetrahydrofuran (the volume ratio of phenylethynyllithium to tetrahydrofuran is 1:5) dropwise into the reaction system, and the dropping temperature is controlled at 0°C ± 5°C. After the addition is complete, The temperature of the system was controlled at 20°C±5°C, and the reaction wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com