Mirror back coating adhesion promoter and preparation method thereof

A technology of adhesion promoter and coating, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as damage to mirror metal reflective layers, and achieve the effects of superior coating adhesion, improved peeling resistance, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

Different from Example 1, the phosphoric acid solution was not included in the raw material.

[0040] performance test

Detection method / test method

Add equal amounts of the adhesion promoters in Examples 1-12 and Comparative Examples 1-3 to the same amount of coating respectively, then use the method of curtain coating to pour on the mirror back, and carry out the coating on the mirror back. The following detections:

Adhesion test: Adhesion test is carried out in accordance with the provisions of "Paints and Varnishes-Cross-cut Test of Paint Film" GB / T 9286-2021; Corrosion performance and CASS test: According to "Test method for environmental corrosion resistance of silver-coated glass mirrors" 》GB / T 32026-2015 provides for corrosion performance and CASS experiments;

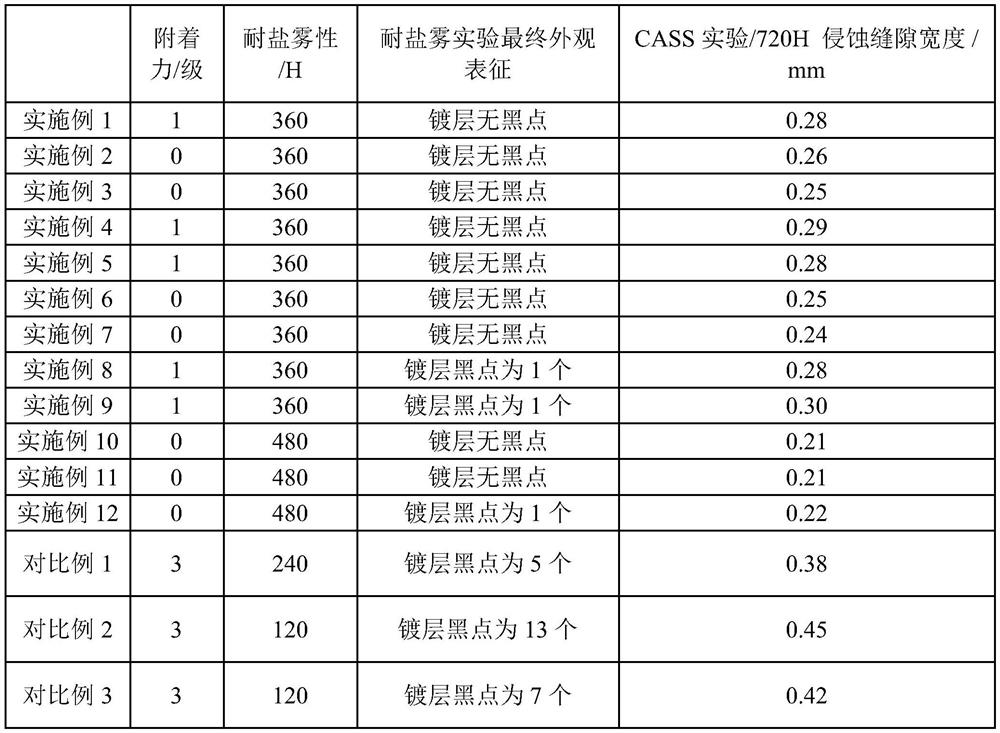

The performance testing results are shown in Table 2.

[0041] Table 2 performance test results

[0042] In conjunction with Examples 1-6 and Comparative Examples 1-3, and in conjunction with Table 2, ...

preparation example 1

preparation example 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com