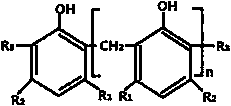

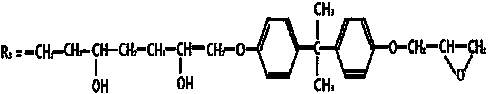

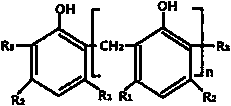

Plant polyene phenol-modified phenolic resin and preparation method thereof

A plant polyenol and phenolic resin technology, which is applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problems of poor peeling resistance, cracking resistance and impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 150g of plant polyenol, 900g of phenol, and 32g of 30% sodium hydroxide into the flask, raise the temperature to 55°C, slowly add 324g of paraformaldehyde several times, react at 70°C for 1 hour, raise the temperature to 90°C for 40 minutes, add 320 Toluene, react at 85°C for 30 minutes, add ethanol and stir evenly, cool down to 75°C, add 80g of E-51 liquid epoxy resin to react for 2 hours, add 1.6g of 2,4,6-tris(dimethylaminomethyl)phenol and stir After 30 minutes, cool down to 40 degrees and discharge.

Embodiment 2

[0024] Add 135g of plant polyenol, 200g of phenol, and 13.4g of 30% sodium hydroxide into the flask, raise the temperature to 55°C, slowly add 324g of paraformaldehyde in multiple times, react at 70°C for 1 hour, heat up to 90°C for 40 minutes, add 320 toluene, react at 85°C for 30 minutes, add ethanol and stir evenly, cool down to 75°C, add 120g of E-51 liquid epoxy resin to react for 2 hours, add 2.4g of 2,4,6-tris(dimethylaminomethyl)phenol and stir After 30 minutes, cool down to 40 degrees and discharge.

Embodiment 3

[0026] Add 180g of plant polyenol, 225g of phenol, and 18g of 30% sodium hydroxide into the flask, raise the temperature to 55°C, slowly add 360g of paraformaldehyde several times, react at 70°C for 1 hour, raise the temperature to 90°C for 40 minutes, add 320 Toluene, react at 85°C for 30 minutes, add ethanol and stir evenly, cool down to 75°C, add 80g of E-51 liquid epoxy resin to react for 2 hours, add 1.6g of 2,4,6-tris(dimethylaminomethyl)phenol and stir After 30 minutes, cool down to 40 degrees and discharge.

[0027] Coat the plant polyenol-modified phenolic resin prepared in Example 1-3 on a 15cm*5cm sandblasted iron plate, place it in an oven at 70°C, and dry it for 30 minutes; The tensile weight is bonded to the product, and pressed with a pressure of 0.35-1.0Mpa. Keep the curing condition at 150°C for 30 minutes, 165°C for 15 minutes, and 200°C for 5 minutes. Cool to room temperature and use PosiTest AT-A to test the tensile strength, as shown in the table below : ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com