Patents

Literature

43results about How to "Great improvement in brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber-reinforced flexible SiO2 aerogel heat-insulation material and preparation method thereof

The invention discloses a fiber-reinforced flexible SiO2 aerogel heat-insulation material and a preparation method thereof. Silicon-containing substances such as tetraethyl orthosilicate, tetramethoxysilane, sodium silicate and the like are used as precursors, a fiber felt pad is used as a reinforcing body, fiber / SiO2 composite wet gel is prepared with a sol-gel technology, and the fiber-reinforced flexible SiO2 aerogel heat-insulation material is finally prepared through aging and supercritical drying. The synthesis process is simplified, the preparation cycle is shortened, the cost for synthesis of the SiO2 aerogel composite material is effectively reduced, defects of poor mechanical strength, large brittleness and the like of pure aerogel are overcome, the prepared composite aerogel keeps the excellent performance of the aerogel, the flexibility of the material is obviously improved, the material is better in integrity, capable of being bent at will and very good in heat-insulation effect, the heat conductivity of the material can be decreased to 19 mW / mK, the application range of the aerogel is enlarged, and the material can be applied to actual engineering as an independent bulk composite material.

Owner:四川睿光科技有限责任公司

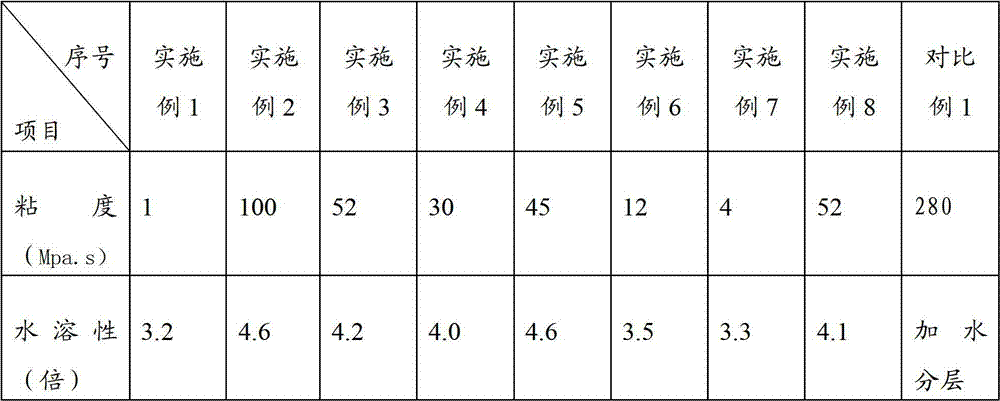

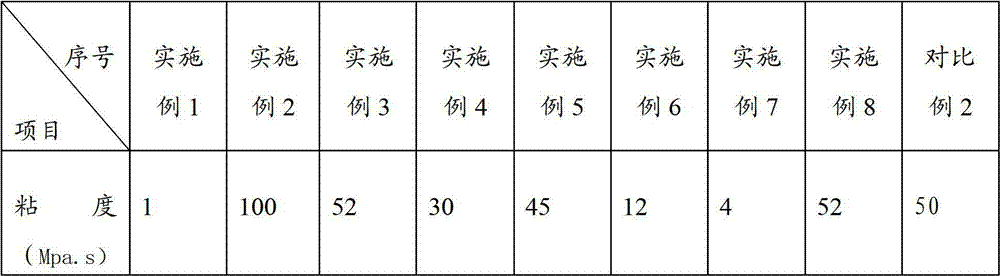

Preparation method of modified phenolic resin

ActiveCN102775568AGood water solubilitySolve the problem of poor water solubility, which is not conducive to on-site constructionCoatingsSolubilityWater soluble

The invention discloses a preparation method of modified phenolic resin, which comprises the following steps of: (a) mixing phenol, cardanol and a sulfonating agent, raising the temperature to 80-95 DEG C under the alkaline condition, reacting for 1-3 hours, then cooling to 50-60 DEG C, adding formaldehyde and reacting for 1-3 hours to obtain a mixture A; (b) mixing lignin with formaldehyde, raising the temperature to 50-100 DEG C under the alkaline condition, maintaining the constant temperature for 3-5 hours to obtain a mixture B, i.e. methylolated lignin; and (c) mixing the mixture A with the mixture B, controlling the temperature to be 70-90 DEG C and maintaining the constant temperature for above 1 hour to obtain the modified phenolic resin. The preparation method has the beneficial effects that as sulfonic acid groups are introduced in cardanol molecules through sulfonation reaction, the polarity of cardanol molecules is improved, so that the water solubility of the cardanol molecules is increased; and the obtained modified phenolic resin can be directly used for the spraying industry.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

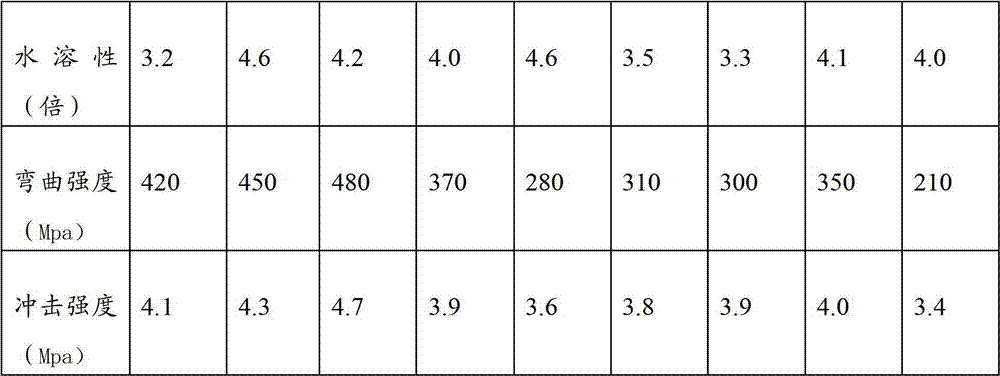

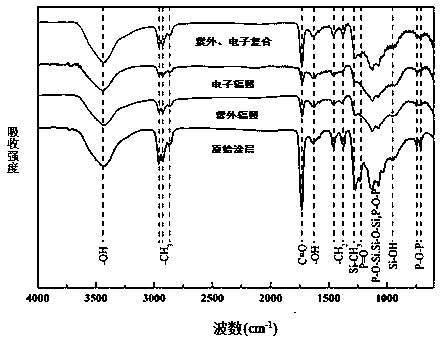

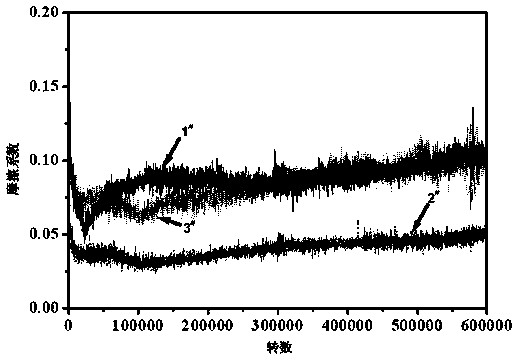

Organic-inorganic composite lubricating protective coating material with excellent space-environment resistance

The invention relates to an organic-inorganic composite lubricating protective coating material with excellent space-environment resistance. According to the invention, an inorganic phosphate modifiedby a polytetrafluoro emulsion is used as a binder, a layered disulfide compound is used as a solid lubricant, antimonous oxide and a rare earth fluoride are used as auxiliary functional fillers, water is used as a diluent, and ball milling and uniform dispersion are performed to obtain the material. Performance detection results show that the coating material is a high-performance bonding solid lubricating coating. A coating prepared from the coating material has good adhesive force, flexibility and impact resistance to a metal base material, the good lubricating protection performance of thecoating material can still be kept under the long-term irradiation of atomic oxygen, ultraviolet and ionizing radiation in a space environment (especially a low-orbit space environment), and the service life of related equipment in the space environment can be effectively prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

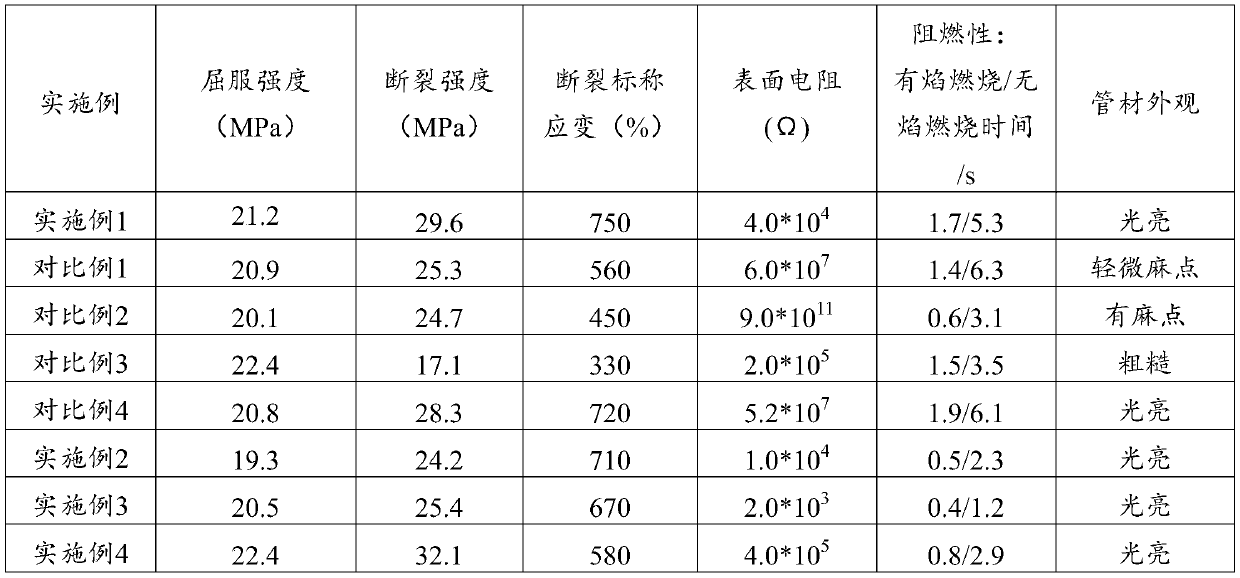

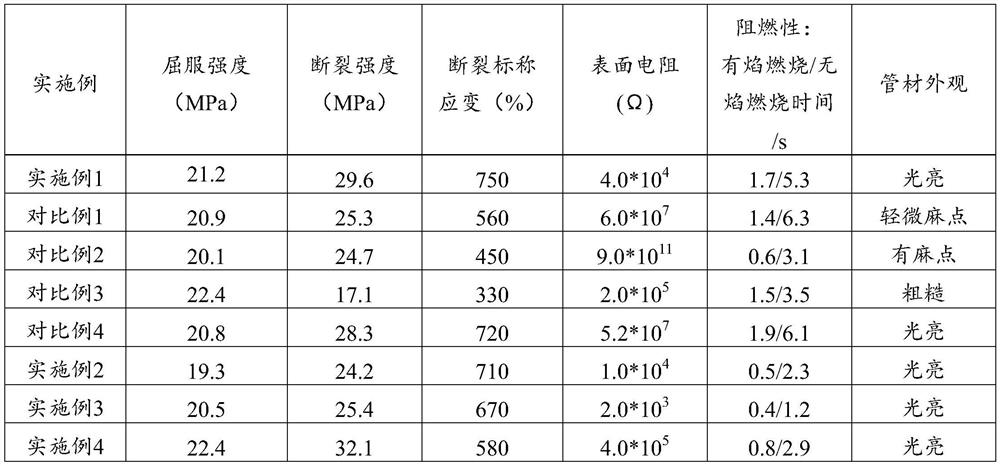

Carbon nanotube-modified polyolefin double-resistant material and preparation method and application thereof

The invention relates to a carbon nanotube-modified polyolefin double-resistant material, and a preparation method and application thereof. The polyolefin double-resistance material comprises the following raw materials in parts by mass: 60 to 92 parts of a polyolefin matrix, 2 to 5 parts of carbon nanotubes, 0.5 to 4 parts of a synergistic conductive agent, 0.3 to 2 parts of a carbon nanotube dispersing agent, 4 to 20 parts of a flame retardant, 2 to 8 parts of maleic anhydride-polysiloxane bifunctional grafted polyolefin elastomer and 0.2 to 1.2 parts of an antioxidant. According to the invention, the problem that carbon nanotubes are difficult to disperse in a polymer is solved. The carbon nanotube-modified polyolefin double-resistant material has excellent antistatic properties and flame retardance and good mechanical properties; and a pipeline prepared from the material has the advantages of smooth surface, excellent comprehensive properties and high pressure resistance, and the flame retardancy and antistatic performance of the pipeline satisfy the standard requirements of mining pipelines.

Owner:SHANDONG DONGHONG PIPE IND

High-strength vibration-reduction epoxy mortar with nano improver

The invention discloses high-strength vibration-reduction epoxy mortar with a nano improver. The high-strength vibration-reduction epoxy mortar consists of three components A, B and C, wherein the component A is a substrate mixture; the component B is an auxiliary mixture; the component C is a curing mixture; the component A consists of the following various raw materials in parts by weight: 80-100 parts of modified epoxy resin, 45-70 parts of cement and 100-300 parts of quartz sand; the component B consists of the following various raw materials in parts by weight: 10-50 parts of a nano improver, 3-5 parts of a silane coupling, 0-1 part of a defoaming agent and 10-15 parts of a diluent; the component C consists of the following various raw materials in parts by weight: 40-55 parts of a curing agent and 1-5 parts of a toughening agent; the weight ratio of the component A, the component B to the component C is (80-100):(5-100):(50-600). The high-strength vibration-reduction epoxy mortar disclosed by the invention has the advantages of being high in strength, good in vibration reduction effect, good in binding force with a concrete substrate, good in compatibility and the like, and can be used as a secondary grouting material of complex industrial vibration equipment.

Owner:SINOPEC PETROLEUM ENG & CONSTR ZHONGYUAN

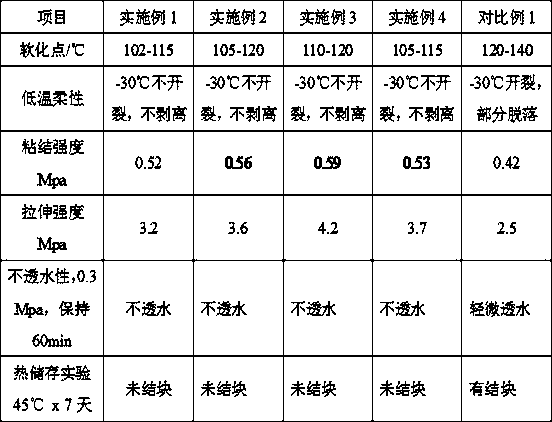

Polyisobutylene modified building asphalt and preparation method thereof

InactiveCN108841187AImprove high and low temperature resistanceGood hydrophobicityBuilding insulationsSilane couplingWeather resistance

The invention relates to a polyisobutylene modified building asphalt and a preparation method thereof. According to the technical solution, the building asphalt comprises the following components in parts by weight: 100 parts of base asphalt, 10-30 parts of epoxidized polyisobutylene, 5-10 parts of reinforcing fibers, 50-80 parts of inorganic filler, 0.5-3 parts of a silane coupling agent, and 0.5-2 parts of an anti-aging agent. The epoxidized polyisobutylene can modify lignin, and the inorganic filler can significantly improve the compatibility, thereby increasing the thermal storage stability of the modified asphalt; meanwhile, the polyisobutylene is used to toughen the asphalt, thereby significantly improving the high and low temperature resistance of the asphalt and solving the problemof high brittleness; and the polyisobutylene has good hydrophobic property, weather resistance and the like, and can significantly improve the weather resistance and the like of the asphalt.

Owner:朱红艳

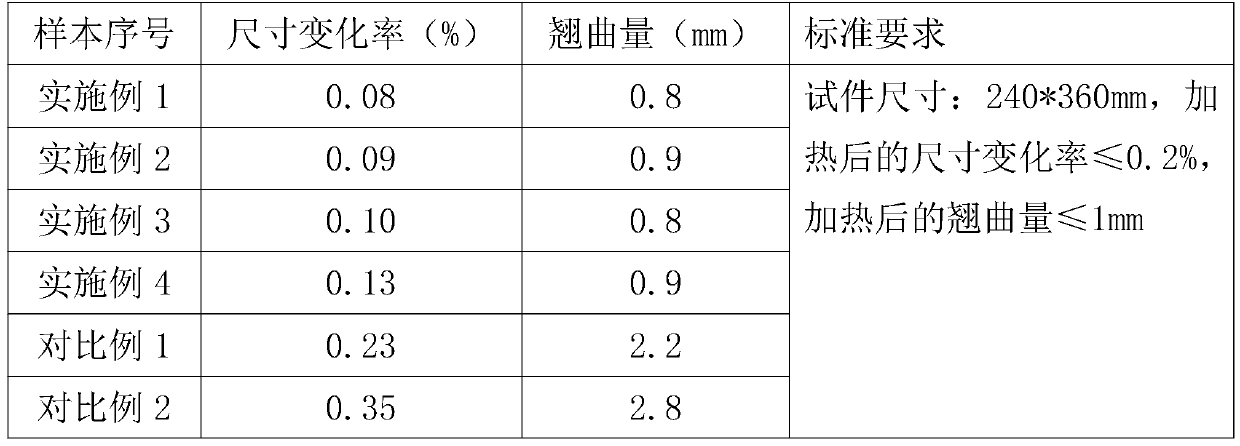

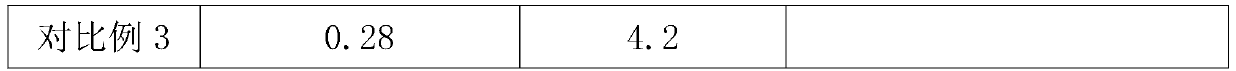

Indoor floor, and preparation technology thereof

ActiveCN109823017AExcellent test performanceExcellent surface static indentation performanceSynthetic resin layered productsFlooringSurface layerPlasticizer

The invention belongs to the technical field of indoor floor, and more specifically relates to an indoor floor and preparation technology thereof. The indoor floor is composed of a SPC surface layer and a bamboo plastic foamed core layer; the SPC surface layer is prepared through raw material mixing, extrusion, and thickness determination; the bamboo plastic foamed core layer is prepared through injection of raw materials into a torque rheometer for banburying and injection moulding using an injection machine; and at last combination is carried out so as to obtain the indoor floor. The invention also discloses preparation methods of modified bamboo powder and a modified plasticizer; bamboo powder is modified with the modified plasticizer, the hot melt fluidity is improved, sheet material plasticizing torsion force is reduced effectively, energy consumption is reduced, and cost is reduced. The indoor floor is excellent in flexibility, size stability, and warping resistance, and the market prospect is better than that of conventional sheet materials.

Owner:ANHUI SENTAI WPC GRP CO LTD

Low-temperature solder alloy powder and preparation method thereof

ActiveCN109158795AImprove antioxidant capacityHigh strengthWelding/cutting media/materialsSoldering mediaMetallurgySolder alloy

The invention provides low-temperature solder alloy powder. The low-temperature solder alloy powder is characterized by comprising the following components of, by weight, 3-3.5% of Ag, 0.02-1% of P, 0.02-1% of RE, 1-1.5% of Co, 2-3% of Pd, 40-60% of Bi and the balance Sn.

Owner:EUNOW ELECTRONICS TECH CO LTD SUZHOU

Special high-performance polyvinyl chloride composite material for cable

InactiveCN106221055AHigh impact strengthHigh tensile strengthPlastic/resin/waxes insulatorsPolyvinyl chlorideCerium

The invention discloses a special high-performance polyvinyl chloride composite material for a cable. The composite material comprises the following raw materials: polyvinyl chloride, nitrile rubber, acrylonitrile-butadiene-styrene copolymer, trimethylol-propane trimethacrylate, 2,5-diphenyl-1,3,4-oxadiazole, kaolin, magnesium hydroxide, nanometer calcium carbonate, organic montmorillonite, graphite nanosheets, cerium carbonate, tribasic lead sulfate, bisphenol A diglycidyl ether, maleic acid monoester of lanthanum, cerium citrate, glycerol, glyzinc, dibutyltin dilaurate, xylitol, a lubricant, a plasticizer and a flame retardant, wherein the flame retardant is composed of ammonium heptamolybdate, hydrotalcite, zinc borate, bisphenol A bis(diphenylphosphate), silicone powder and alpha-zirconium phosphate. The special high-performance polyvinyl chloride composite material for the cable in the invention has the advantages of excellent heat resistance, good flame retardant performance, high strength, shock resistance and long service life.

Owner:ANHUI ELECTRIC GRP SHARES

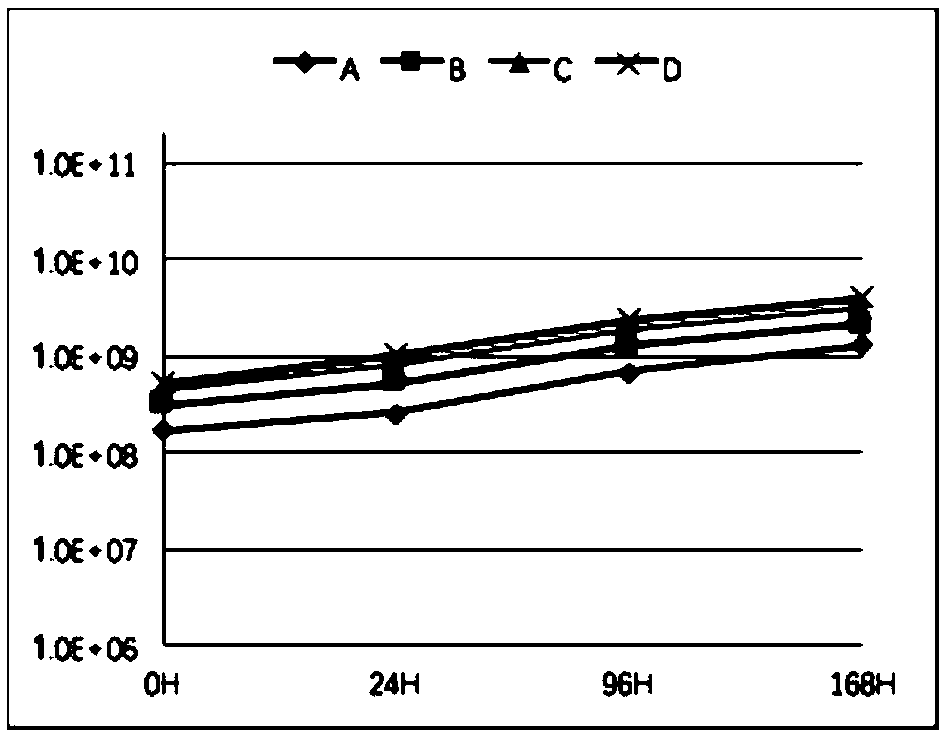

Antibacterial environment-friendly packaging thin film and preparation method thereof

InactiveCN108102322AImprove mechanical propertiesImprove thermal stabilityFiberBiocompatibility Testing

The invention provides an antibacterial environment-friendly packaging thin film and a preparation method thereof. The antibacterial environment-friendly packaging thin film is prepared from the following components in parts by weight: 5 to 10g of microcrystalline cellulose fiber, 5 to 10g of plant essential oil, 8 to 15g of an emulsifier and 60 to 80g of polyhydroxybutyrate-hydroxyvaleratepoly(3-hydroxybutyrate-co-3-hydroxyvalerate. The antibacterial environment-friendly packaging thin film provided by the invention is provided with the plant essential oil so that the antibacterial effect canbe realized and the shelf life of foods is prolonged; the poly(3-hydroxybutyrate-co-3-hydroxyvaleratepolyhydroxybutyrate-hydroxyvalerate with excellent performance including biocompatibility, high crystallization degree, low toxicity and the like is used as a matrix and the microcrystalline cellulose fibers are used as filler, so that the defects that the poly(3-hydroxybutyrate-co-3-hydroxyvaleratepolyhydroxybutyrate-hydroxyvalerate matrix has great brittleness, poor toughness and slow crystallization speed can be improved, and the mechanical performance and the thermal stability of the antibacterial environment-friendly packaging thin film are improved.

Owner:GUANGZHOU MERITECH BIO ENG TECH

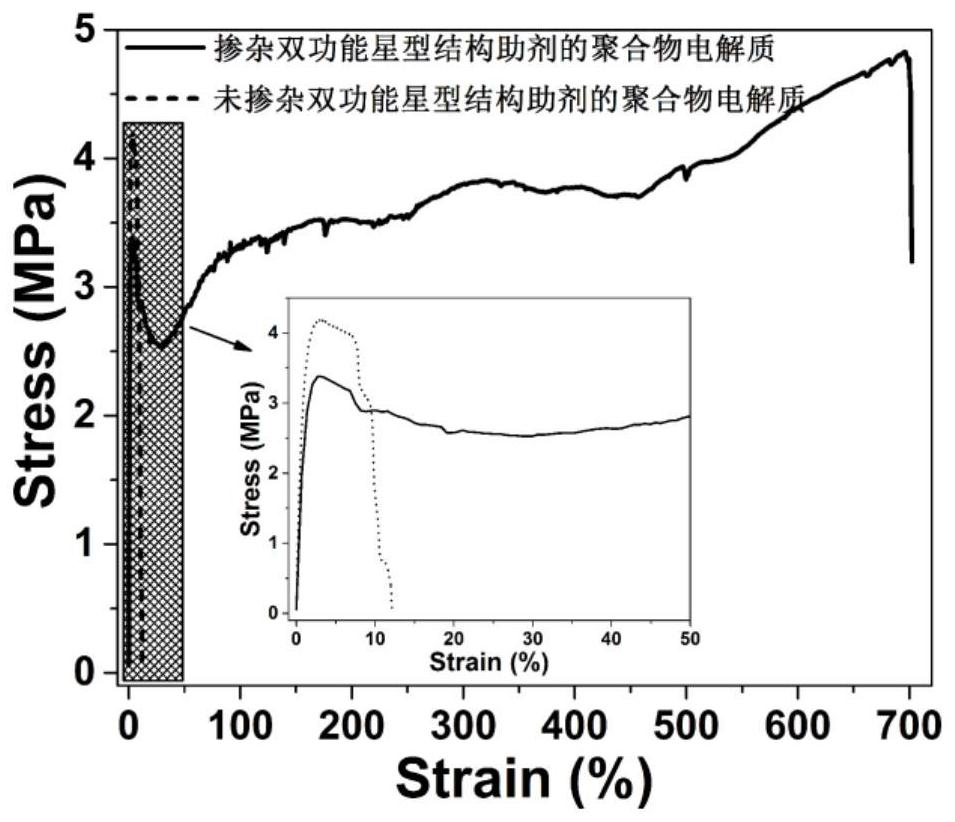

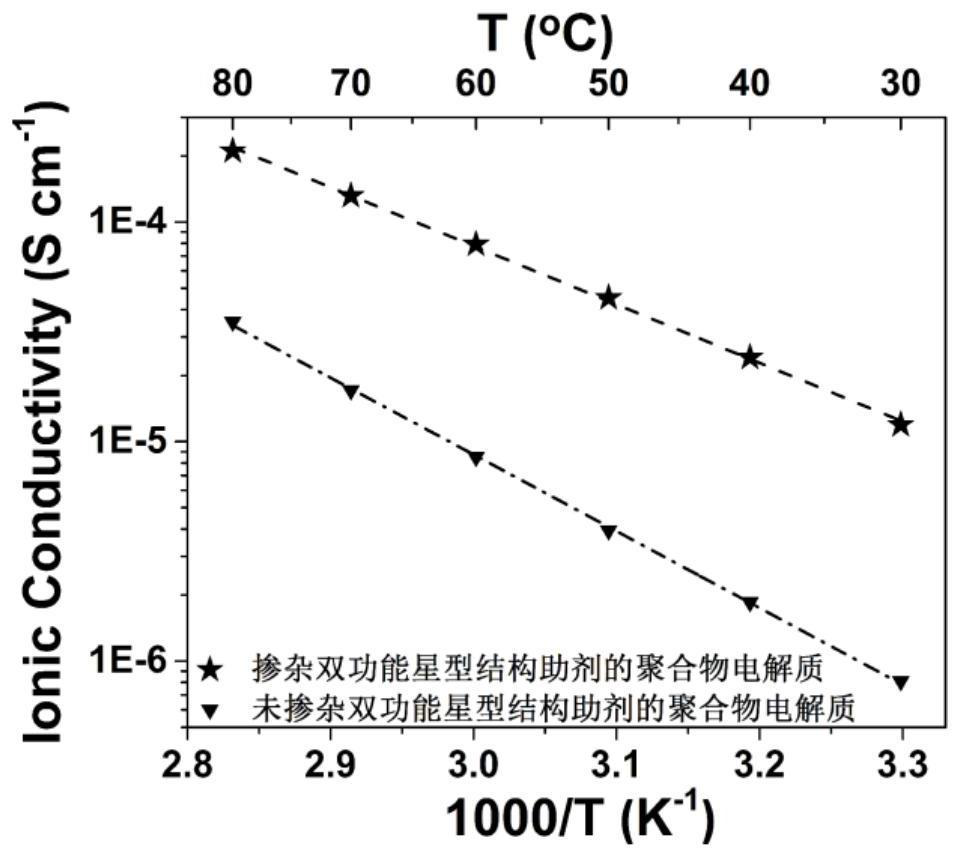

Hyperbranched bifunctional star-shaped compound, polymer electrolyte material, preparation of hyperbranched bifunctional star-shaped compound and polymer electrolyte material, and application of hyperbranched bifunctional star-shaped compound

InactiveCN111848969AFacilitate conductionImprove conductivitySecondary cellsOrganic electrolytesMethacrylatePolymer science

The invention belongs to the field of polymer electrolyte materials of lithium ion batteries, and particularly relates to a hyperbranched bifunctional star-shaped compound, a polymer electrolyte material, preparation of the hyperbranched bifunctional star-shaped compound and the polymer electrolyte material, and application of the hyperbranched bifunctional star-shaped compound. The hyperbranchedbifunctional star-shaped compound is a star-shaped compound with a branched chain extending outwards, and is prepared by subjecting polymercaptopropionate serving as a core and polyethylene glycol methacrylate serving as an arm to photocuring under ultraviolet light to initiate a mercapto-double bond reaction. The hyperbranched bifunctional star compound can be used as a lithium ion polymer electrolyte additive, can improve the ionic conductivity of an electrolyte material and can also be used as a plasticizer to improve the mechanical properties and flexibility of the electrolyte material, and the preparation process of the compound is simple to operate and friendly to environment. The invention also provides the polymer electrolyte material containing the hyperbranched bifunctional star-shaped compound. Thus, a new research thought and method are provided for preparing high-performance lithium ion polymer electrolytes.

Owner:LUOYANG INST OF SCI & TECH

Solder paste composition containing bismuth alloy

ActiveCN109158794AImprove performanceImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaOxidation resistantAlloy

The invention provides a solder paste composition containing bismuth alloy. The solder paste composition comprises soldering flux and tin alloy powder, and the weight ratio of the soldering flux to the tin alloy powder is 9-15%. A protective agent is added into the soldering flux, a layer of protective film can be formed, small molecule precipitation is prevented, in the welding process, pores areformed at the high temperature, small molecules are adsorbed, and damage to human bodies and environment can be prevented. The solder paste composition is environmentally friendly, good in performance, high in oxidation resistance, free of lead, and good in expansibility and welding performance.

Owner:EUNOW ELECTRONICS TECH CO LTD SUZHOU

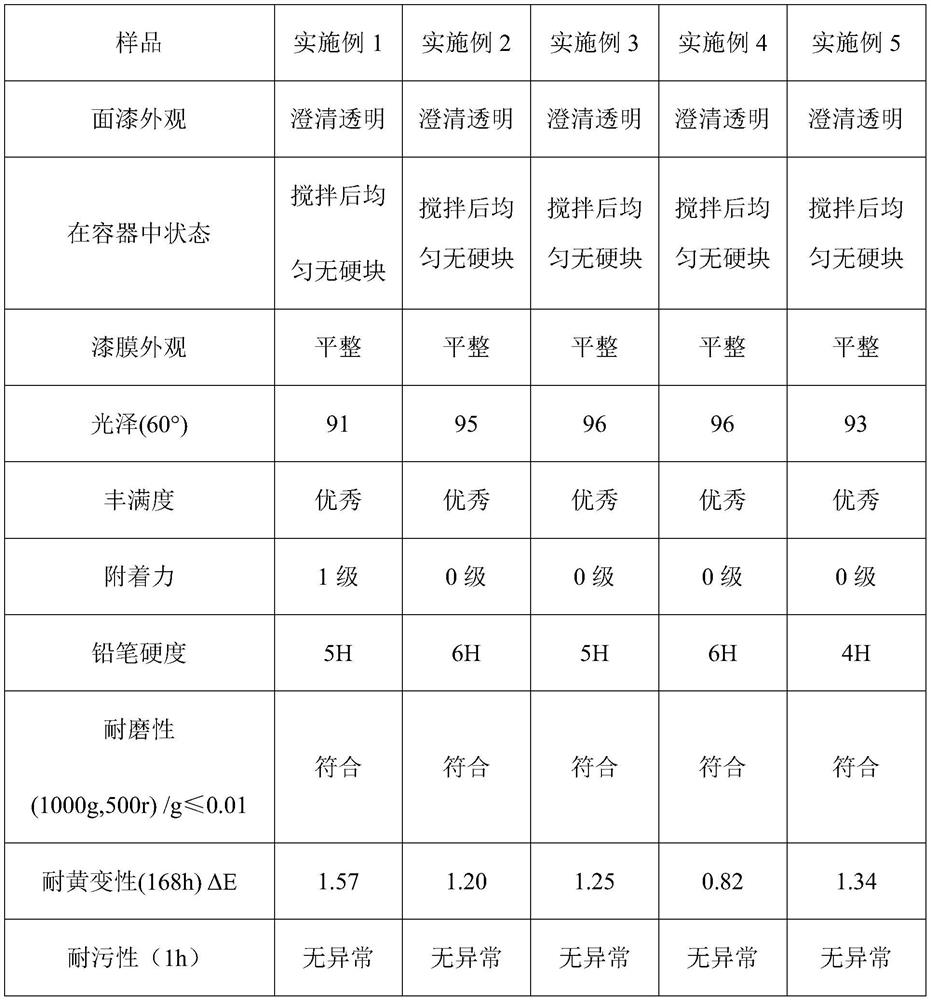

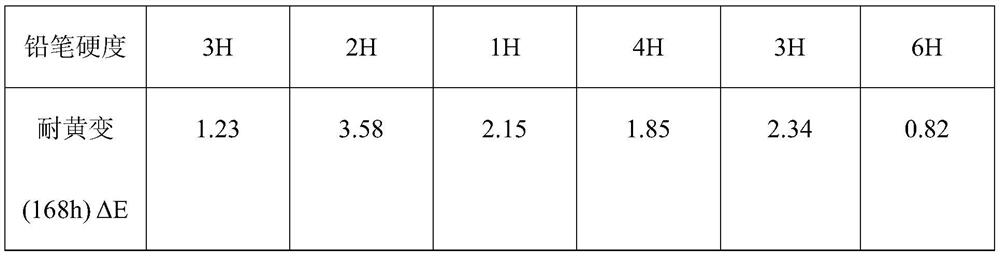

Super-yellowing-resistant high-rigidity UV fully-bright transparent finishing coat and preparation method thereof

ActiveCN111978829AStrong adhesionHigh hardnessAntifouling/underwater paintsPaints with biocidesPolymer science3d printed

The invention belongs to the technical field of UV paints, and provides a super-yellowing-resistant high-rigidity UV fully-bright transparent finishing coat and a preparation method thereof. The super-yellowing-resistant high-rigidity UV fully-bright transparent finishing coat consists of the following raw materials in parts by weight: 20-40 parts of bisphenol A epoxy acrylate, 10-20 parts of amino-modified epoxy acrylate, 20-40 parts of an acrylate monomer, 3-5 parts of a photoinitiator and 0.5-2 parts of additives, wherein the acrylate monomer consists of isobornyl acrylate, neopentyl glycoldiacrylate and tri(2-hydroxyethyl)isocyanurate triacrylate in a mass ratio of (0.1-0.6) to 1 to (0.8-2); and the additives are one or more of a defoamer, a wetting agent, a dispersing agent and an anti-settling agent. The super-yellowing-resistant high-rigidity UV fully-bright transparent finishing coat has good plumpness, adhesive force and pollution resistance, excellent yellowing resistance and high rigidity and can be applied to 3D printing patterns on dining tables, tea tables and the like.

Owner:东莞大宝化工制品有限公司 +1

Filter paper with high filtering efficiency, and preparation method thereof

InactiveCN103437249AFacilitate cross-linkingEvenly distributedSynthetic cellulose/non-cellulose material pulp/paperFiltration separationWaxSodium carboxymethylcellulose

The invention relates to filter paper with high filtering efficiency, and a preparation method thereof. The filter paper with high filtering efficiency disclosed by the invention is composed of the following raw materials by weight: 50-60 parts of jute pulp, 45-50 parts of wood pulp, 20-25 parts of polystyrene fibers, 3-5 parts of sodium carboxymethyl cellulose, 3-4 parts of a nano carbon powder, 1-2 parts of feldspar powder, 1-2 parts of alum powder, 1-2 parts of 4,4'-diphenylmethane diisocyanate, 2-3 parts of diethylene triamine, 2-3 parts of polyamide wax micropowder, 0.8-1 part of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 0.4-0.6 part of an antioxidant DSTP, 0.5-0.6 part of sodium persulfate, 2-3 parts of ethylene glycol, 6-7 parts of rosin, 15-20 parts of absolute ethyl alcohol, 3-4 parts of nano diatomite, 0.8-1 part of polyoxyethylene octyphenyl ether, 0.3-0.4 part of Gamma-(2,3-epoxypropoxy)propyl trimethoxysilane and a proper amount of water. The filter paper produced by the invention has high filtration precision, high filtration efficiency, small air resistance and strong pollutant-holding capacity, and is environment-friendly.

Owner:BENGBU PIONEER FILTER

High-density wear-resistant PPS plastic and preparation method thereof

The invention discloses high-density wear-resistant PPS plastic and a preparation method thereof. The high-density wear-resistant PPS plastic is prepared from, by weight, 100 parts of polyphenylene sulfide, 30-35 parts of metal powder, 8-10 parts of a mineral powder composition, 5-10 parts of a flexibilizer, 1-3 parts of a lubricant and 10-15 parts of a coupling agent. The preparation method comprises the following steps of: firstly, using a coupling agent to carry out surface modification on metal powder and a mineral powder composition, and mixing to obtain a heavy filler; secondly, adding polyphenylene sulfide, a flexibilizer, a lubricant and a heavy filler into a mixing smelting machine, and uniformly mixing to obtain a molten mixture; and thirdly, discharging the molten mixture from the mixing smelting machine, feeding the molten mixture into a double-screw extruder for further mixing and extrusion, and then pelletizing, cooling and packaging to obtain the high-density wear-resistant PPS plastic. The problem that a product is cheap and poor in wear resistance and the surface of the product is easy to wear due to low density and low weight of PPS plastic is solved.

Owner:广州凯杰环保新材料科技有限公司

High-strength bamboo plywood

InactiveCN107053368AHigh economic valueStrong load capacitySynthetic resin layered productsCane mechanical workingCarbon fibersNylon fiber

The invention discloses high-strength bamboo plywood. The high-strength bamboo plywood is formed in the manner that carbon fiber cloth is used as a core layer, bamboo skin curtains and bamboo filament curtains mixed with nylon fiber in a woven manner are alternately stacked and bonded, and hot pressing is conducted, and a production technology of the high-strength bamboo plywood is provided. Phenolic resin glue mixed with micron sized silica aerogel is used as a sizing agent, so that the defects that the phenolic resin glue is large in fragility, poor in creep resistance and the like are relieved. The manufactured bamboo plywood is better than bamboo plywood produced by the adoption of a traditional technology in the aspects of loading capacity, deformation resistance, heat resistance and the like, and the economic value of the bamboo plywood is effectively improved.

Owner:ANHUI SHUCHENG HUAZHU IND

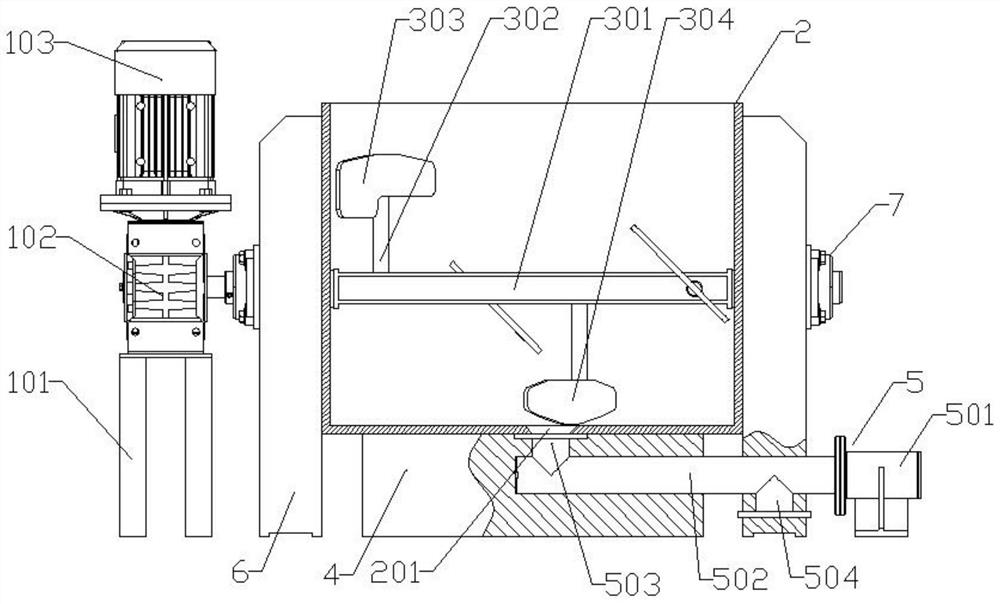

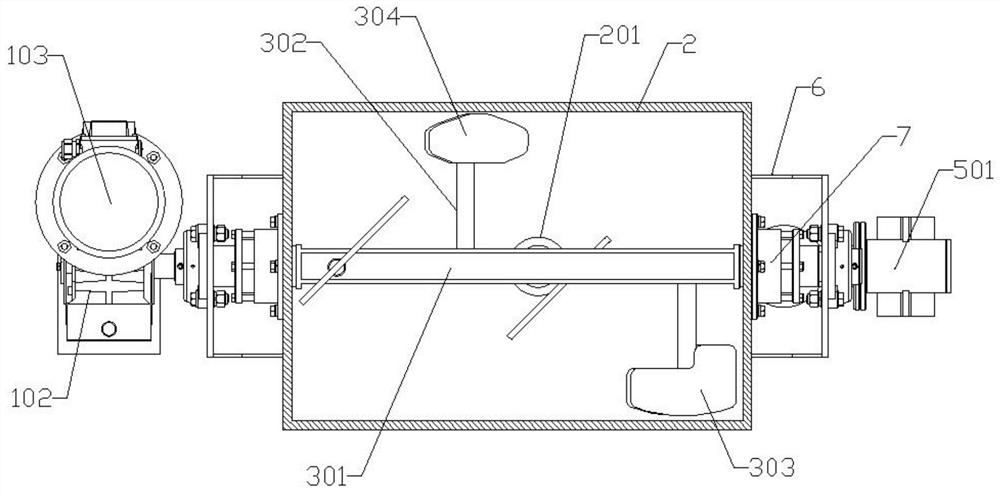

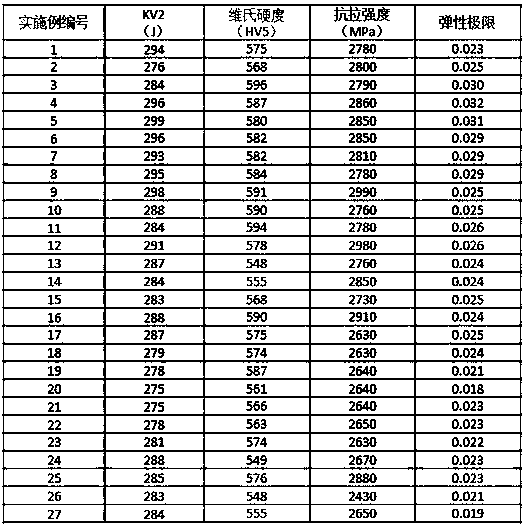

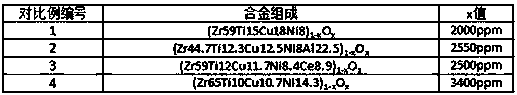

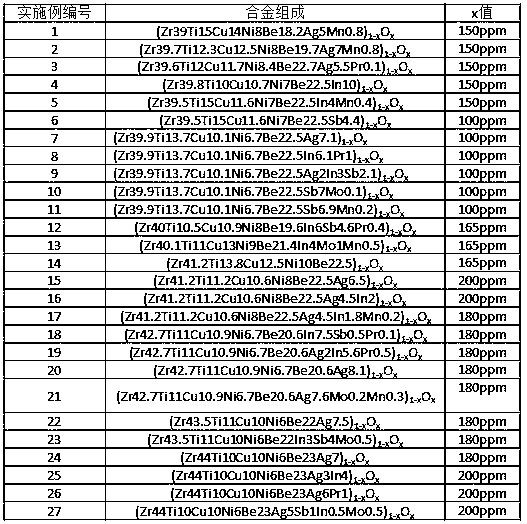

Low-brittleness zirconium-based amorphous alloy and preparation method thereof

The invention discloses a low-brittleness zirconium-based amorphous alloy. The zirconium-based amorphous alloy has the composition of (ZraTibCucNidBeeMfNg)1-xOx, wherein M is one or more of Ag, In andSb, and N is one or more of Mo, Mn and Pr; a, b, c, d, e, f, g and x represent atomic percentages, 39<=a<=44, 10<=b<=15, 10<=c<=14, 6<=d<=15, 18<=e<=23, 0<=f<=10, 0<=g<=1, and 100 ppm<=x<=200 ppm. Through improvement in the composition and the preparation method, the zirconium-based amorphous alloy has high hardness, high tensile strength and formation size; and most importantly, the zirconium-based amorphous alloy has low brittleness, and solves the problem of large brittleness of a zirconium-based amorphous alloy in the prior art.

Owner:SHENZHEN GO ON MATERIAL TECH CO LTD

Aramid fiber reinforced carbon fiber resin prepreg and preparation method thereof

The invention relates to an aramid fiber reinforced carbon fiber resin prepreg and a preparation method thereof. The main components of the product are carbon fibers, epoxy resin and aramid fibers; firstly acetone is used as an organic solvent, the aramid fibers are uniformly dispersed in the epoxy resin, then the epoxy resin added with the aramid fibers is combined with the carbon fibers by a prepreg machine, and the aramid fiber reinforced carbon fiber resin prepreg is prepared by a roll forming process. Compared with a common carbon fiber prepreg, the aramid fiber reinforced carbon fiber resin prepreg has the advantages that a plurality of mechanical properties such as strength and modulus of a carbon fiber reinforced plastic (CFRP) product formed after the product is laminated and cured are greatly improved; meanwhile, the structural stability and the impact resistance of the CFRP can be enhanced, and important significance is provided for overcoming the defects that interlayer resin of the CFRP material is high in brittleness and prone to layering, breaking and damaging.

Owner:浙江宝旌炭材料有限公司

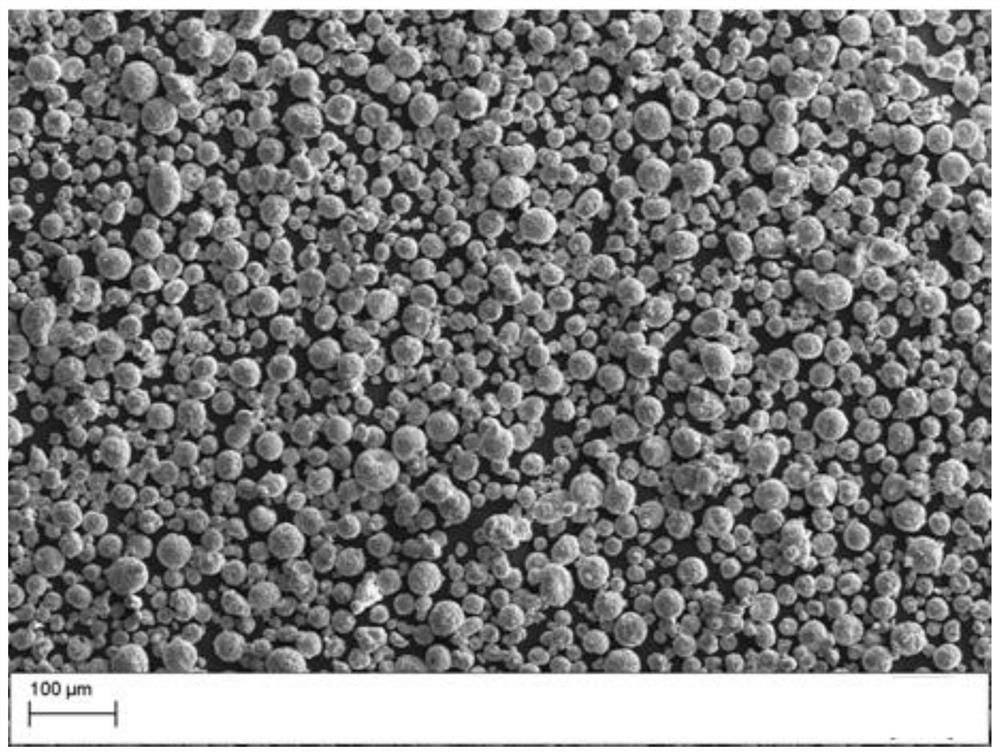

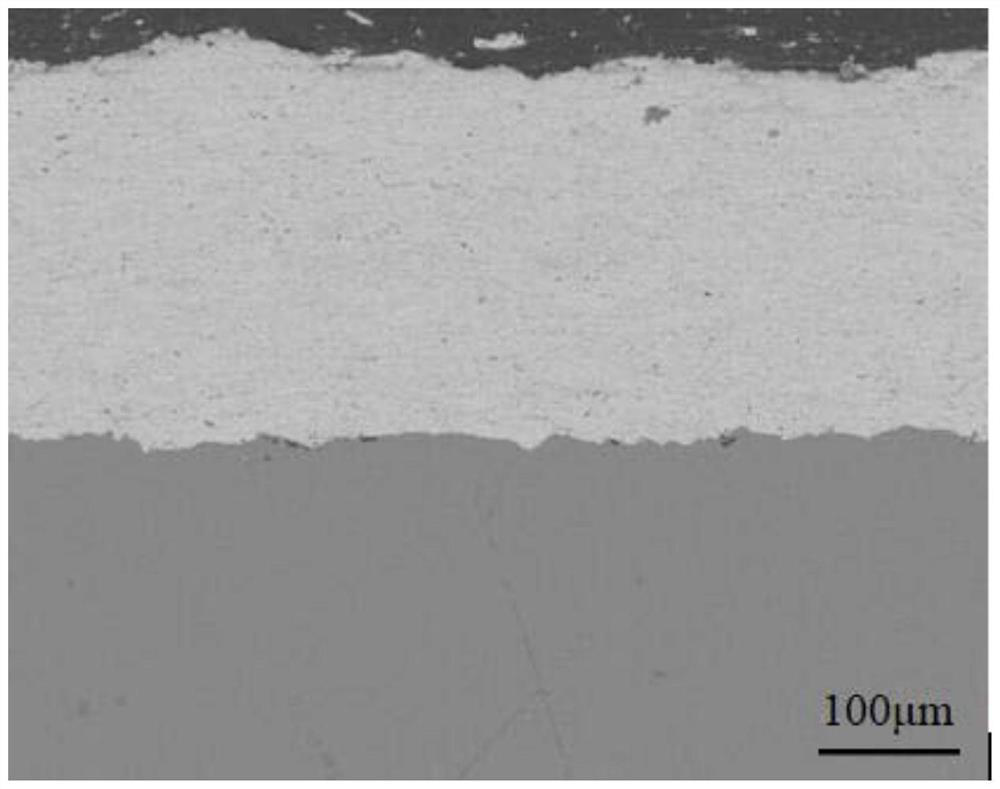

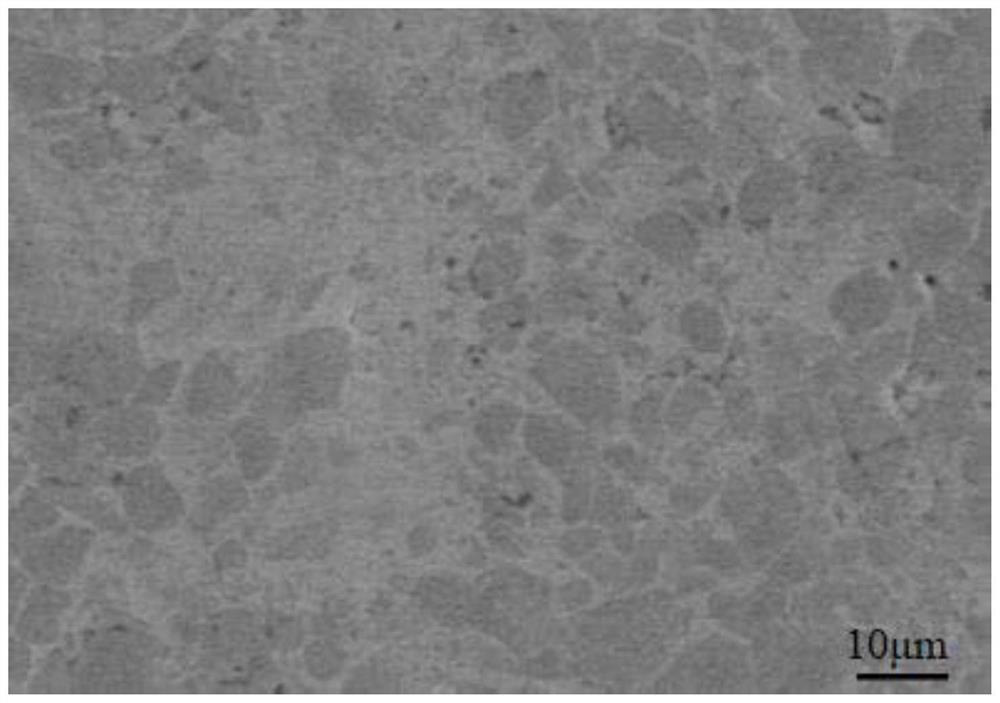

Wear-resistant and corrosion-resistant spray coating on valve flow surface and preparation method thereof

The invention provides a wear-resistant and corrosion-resistant spray coating on the overflow surface of a valve and a preparation method thereof. The spray coating includes the following components: powder, adhesive and dispersant, and the composition of powder, adhesive and dispersant The weight ratio is 100:2-5:2-4; the powder includes the following components in weight percentage: 10-30% of nickel powder, 5-15% of chromium powder, and the balance is composite solid solution powder. The invention also provides a preparation method of the sprayed layer. The process flow of the invention is simple, adding materials or elements with excellent properties to the spray coating material, improving its composition content, making the spray coating structure and particle size distribution uniform, and better fluidity, effectively solving the problem of high brittleness and shedding tendency of the spray coating material Large size, insufficient wear and corrosion resistance and short service life.

Owner:XIHUA UNIV

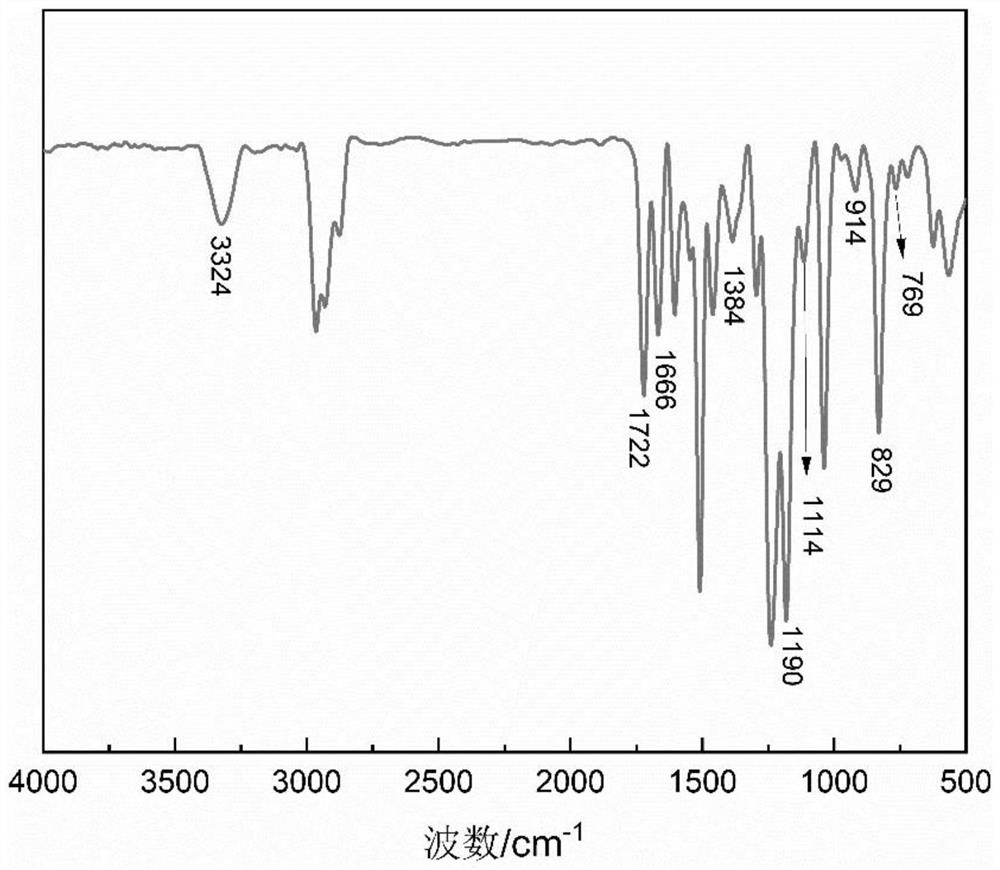

High temperature resistant self-crosslinking waterborne epoxy resin for oil well cement

The invention discloses a high-temperature-resistant self-crosslinking water-based epoxy resin for oil well cement. The preparation method steps are as follows: (1) dissolving the epoxy resin in N,N-dimethylformamide, feeding in nitrogen, and stirring Heat up to 85°C; (2) Dissolve benzoyl peroxide in acetone, then add the acetone solution dropwise to the solution in step (1), raise the temperature to 95°C, and keep the temperature constant for 30 minutes; (3) Add to the reaction solution Slowly add a mixed aqueous solution of 2-acrylamido-2-methylpropanesulfonic acid and acrylamide; constant temperature reaction for 4h; (4) rotary evaporation to remove solvent, use ethyl acetate to repeatedly wash to remove unreacted epoxy resin raw material, to obtain Self-crosslinking waterborne epoxy resin. The self-crosslinking water-based epoxy resin of the invention is added to the cement to simplify the on-site slurry mixing step; it can improve the brittleness characteristics of the oil well cement stone, and effectively improve the macroscopic mechanical properties and compactness of the oil well cement stone.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of water-resistant anti-seismic gypsum-based self-leveling material

The invention provides a preparation method of a water-resistant anti-seismic gypsum-based self-leveling material. The preparation method comprises the following steps: mixing and stirring 100-120 parts by weight of anhydrous phosphogypsum, 10-15 parts by weight of silica fume, 20-30 parts by weight of modified ultrafine steel slag and 1-5 parts by weight of straw powder nano crystals for 10-20 minutes to obtain a solid mixture A; step 2, taking 0.1-0.5 part by weight of a defoaming agent, 0.4-0.8 part by weight of a water reducing agent, 0.2-0.6 part by weight of a water retaining agent, 6-8parts by weight of a composite excitant and 70 parts by weight of water, stirring for 10-20 minutes, and uniformly mixing to obtain a liquid mixture B; and step 3, mixing and stirring the solid mixture A and the liquid mixture B obtained in the step 1 and the step 2 for 5-10 minutes to obtain the anti-seismic gypsum-based self-leveling material. According to the method, the gypsum-based self-leveling material prepared by a specific construction process has good flowability, stability, high strength and high shock resistance.

Owner:HUBEI UNIV OF TECH

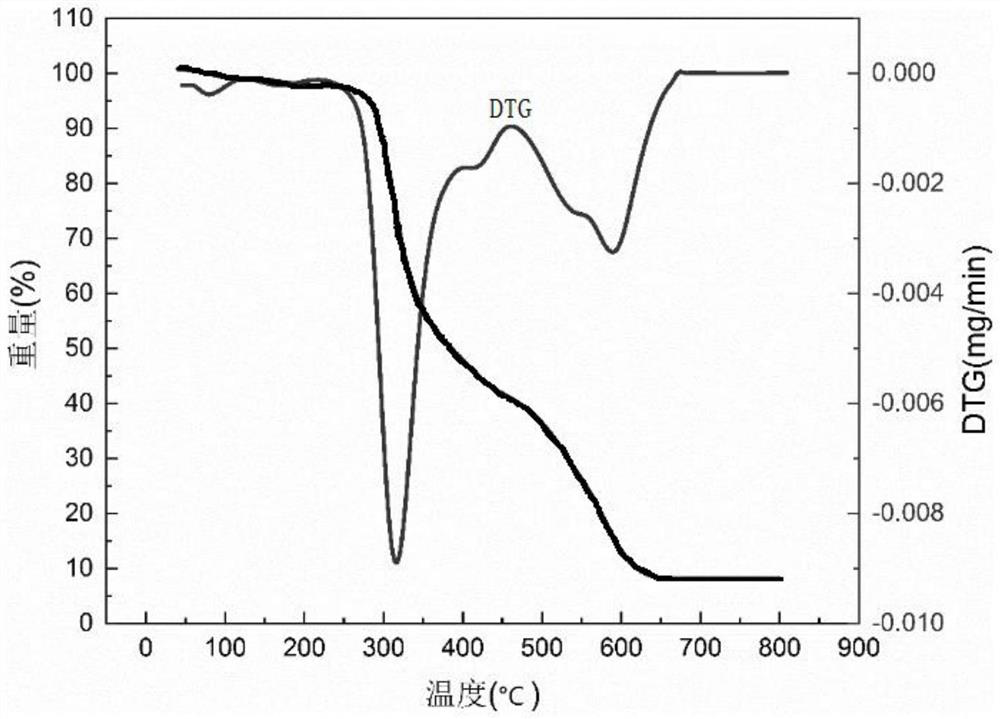

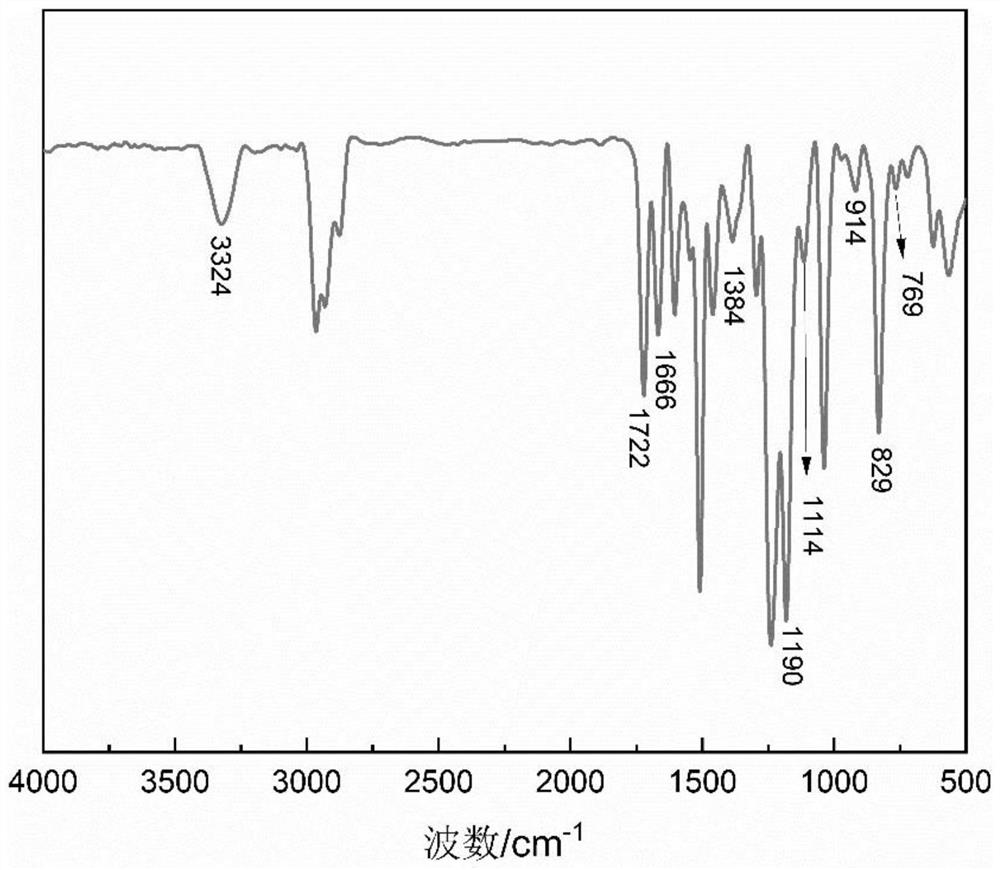

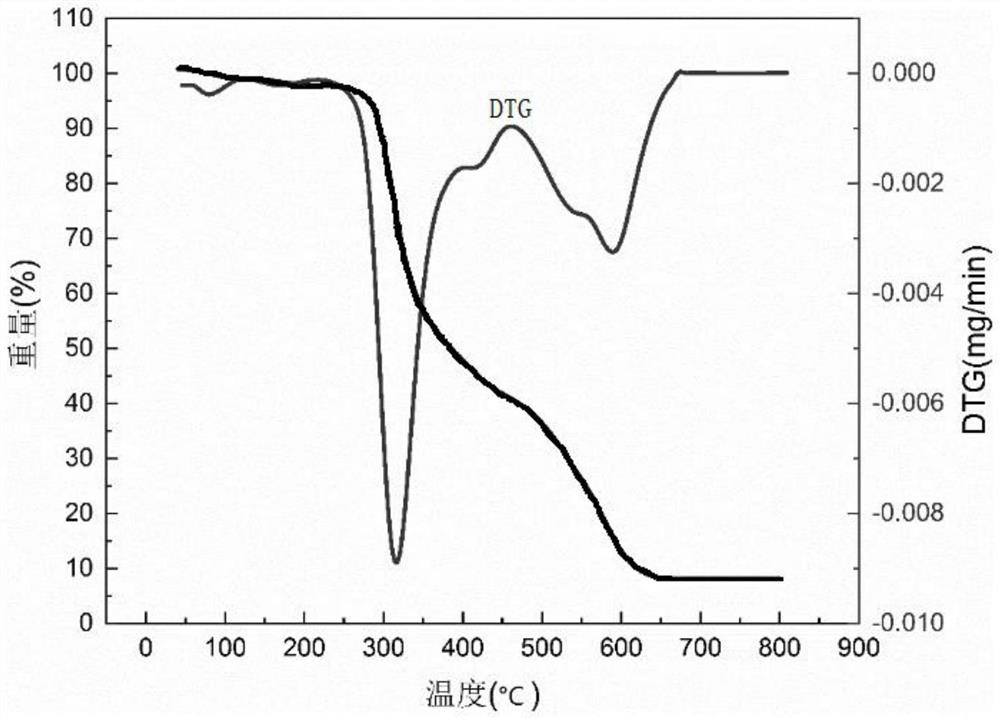

Hydroxyl water-based acrylate polymer and preparation method thereof

InactiveCN111072863AHigh molecular weightGreat improvement in brittlenessGraft polymer adhesivesPolymer chemistryRadical polymerization

The invention discloses a hydroxyl water-based acrylate polymer and a preparation method thereof. According to the hydroxyl water-based acrylate polymer disclosed by the invention, an acrylate monomeris modified by adopting long-chain alkyl silane, so that the problem of high brittleness is improved. The hydroxyl water-based acrylate polymer is prepared by two steps, namely a specific hydroxyl-containing acrylate aqueous dispersion is firstly prepared, and then free radical polymerization is performed by using an acrylate monomer and different initiators, thereby obtaining the hydroxyl-containing water-based acrylate polymer which has the advantages of dispersity and high gloss of the aqueous dispersion, and also has the advantages of low solvent contents and higher molecular weight of the emulsion type water-based acrylate polymer.

Owner:TAICANG YUNTONG BIOCHEM ENG

High-temperature-resistant self-cross-linking waterborne epoxy resin for oil well cement

The invention discloses a high-temperature-resistant self-cross-linking water-borne epoxy resin. The preparation method comprises the following steps: (1) dissolving an epoxy resin in N, N-dimethylformamide, introducing nitrogen, stirring and heating to 85 DEG C; (2) dissolving benzoyl peroxide in acetone, dropwise adding the acetone solution into the solution obtained in the step (1), heating to 95 DEG C, and keeping the temperature for 30 minutes; (3) slowly adding a mixed aqueous solution of 2-acrylamido-2-methylpropanesulfonic acid and acrylamide into the reaction solution, and performing constant-temperature reaction for 4 hours; and (4) carrying out rotary evaporation to remove the solvent, and repeatedly washing with ethyl acetate to remove the unreacted epoxy resin raw material to obtain the self-cross-linking waterborne epoxy resin. According to the invention, the self-cross-linking water-borne epoxy resin is added into cement, so that the on-site slurry preparation step is simplified; and the brittleness characteristic of the oil well set cement can be improved, and the macroscopic mechanical property and compactness of the oil well set cement are effectively improved.

Owner:SOUTHWEST PETROLEUM UNIV

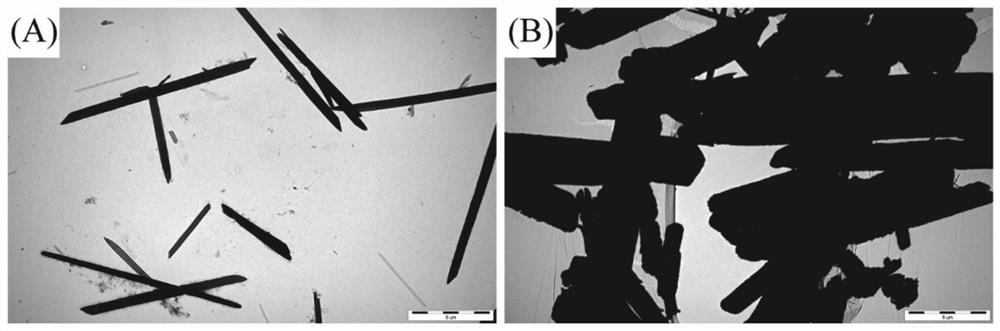

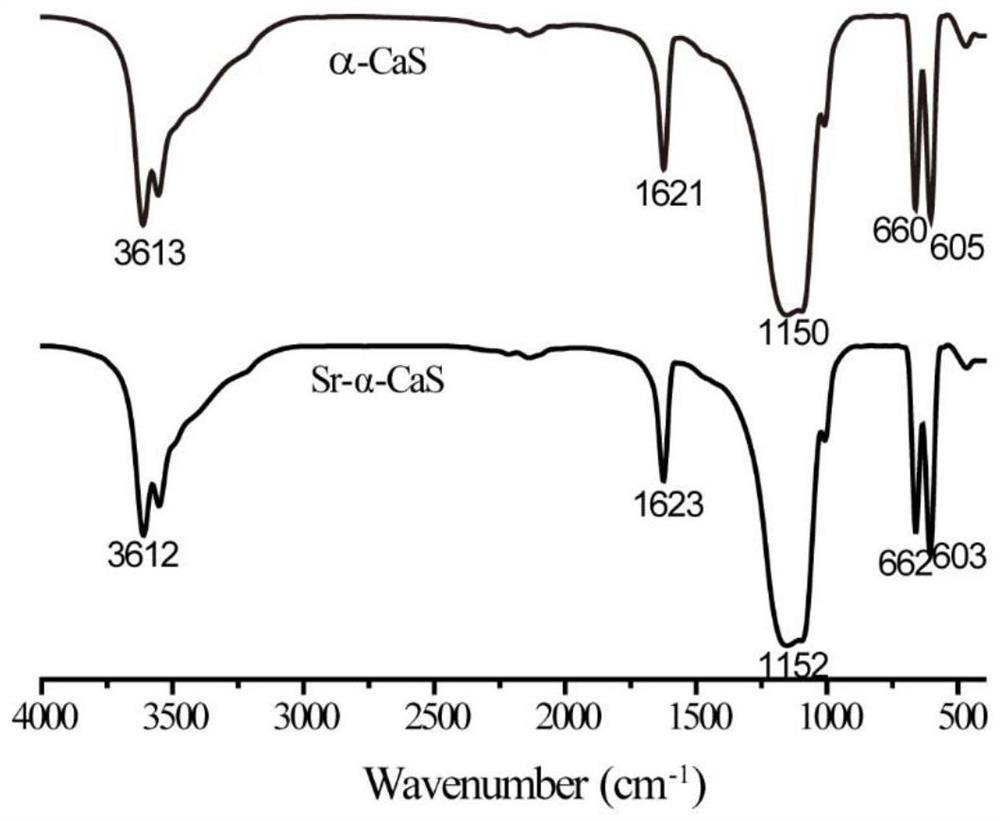

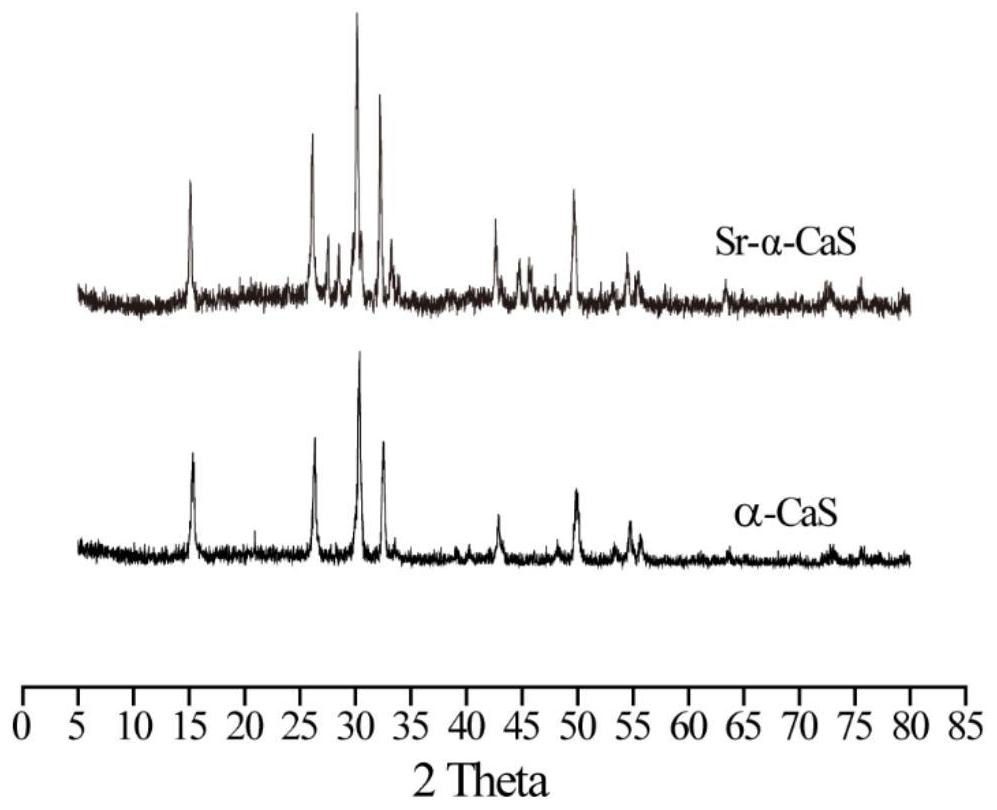

A kind of strontium α-calcium sulfate hemihydrate/nano silver/ginsenoside-loaded sodium alginate microsphere bone substitute material and preparation method thereof

ActiveCN110694107BGood biocompatibilityPromote degradationPharmaceutical delivery mechanismTissue regenerationArtificial bonePharmacology

The invention discloses a bone substitute material, which comprises the following components in parts by weight: 1 part of ginsenoside sodium alginate microspheres and 90-110 parts of strontium-doped calcium sulfate hemihydrate loaded with silver nanoparticles; the ginsenoside alginate In the sodium microspheres, the mass ratio of ginsenoside to sodium alginate is: ginsenoside: sodium alginate = 1:4000-12000. The invention loads ginsenosides into the natural polymer alginic acid microspheres, which can promote the proliferation, migration and osteogenic differentiation of human bone marrow stromal cells. At the same time, sodium alginate microspheres are introduced into calcium sulfate hemihydrate containing strontium, which improves The strontium calcium sulfate hemihydrate material has the problems of high brittleness and sudden release. The prepared bone substitute material is a composite artificial bone material with certain mechanical properties and drug sustained release; nano-silver is added to the bone repair material, which can reduce the Risk of inflammation due to bone infection from surgery or trauma.

Owner:THE EIGHTH AFFILIATED HOSPITAL SUN YAT SEN UNIV

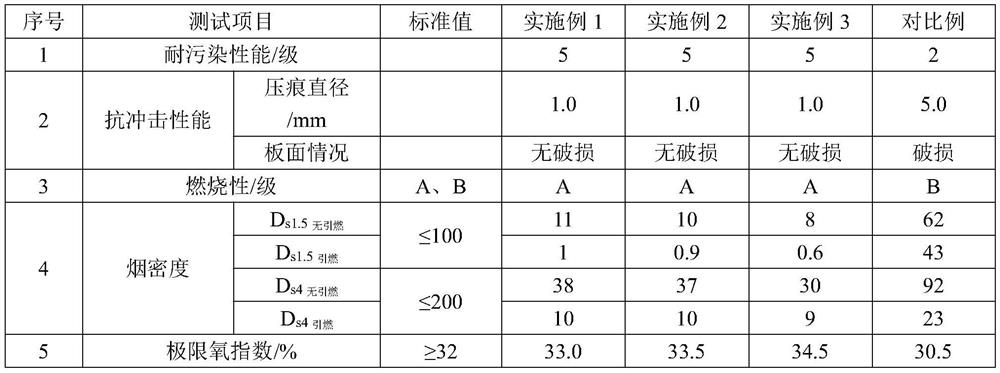

Flame-retardant antifouling cellulose laminated composite board for rail transit interiors and preparation method of flame-retardant antifouling cellulose laminated composite board

ActiveCN113463440AHigh mechanical strengthImprove impact resistanceNon-fibrous pulp additionMechanical working/deformationCellulosePolymer science

The invention discloses a flame-retardant antifouling cellulose laminated composite board for rail transit interiors and a preparation method of the flame-retardant antifouling cellulose laminated composite board. The invention belongs to the field of rail transit interiors. The invention aims to solve the technical problems that the existing cellulose laminated composite material has poor fireproof and antifouling properties and cannot meet the application requirements of rail transit interior materials. The flame-retardant antifouling cellulose laminated composite board for the rail transit interior decoration is formed by hot-pressing and curing a surface layer and a core layer which are laminated, the surface layer is a plurality of layers of cellulose paper impregnated with modified melamino-formaldehyde resin, and the core layer is formed by compounding a plurality of layers of aramid paper impregnated with modified melamino-formaldehyde resin and cellulose paper impregnated with modified melamino-formaldehyde resin, which are alternately laminated. The composite board provided by the invention is formed by hot-pressing a plurality of cellulose materials impregnated with modified melamine formaldehyde resin with rapid infiltration and flame retardant properties. The limit oxygen index reaches 36.5; the combustion performance reaches grade A; the anti-pollution performance can reach level 5, and excellent anti-pollution and flame-retardant performance is achieved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

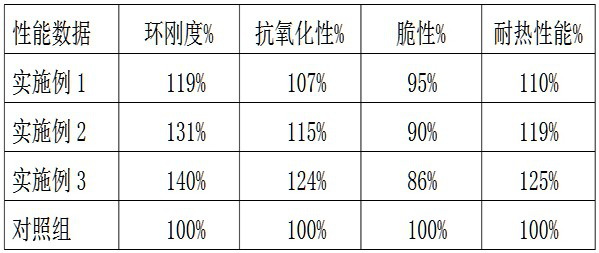

HDPE (high-density polyethylene) pipeline modification process

PendingCN114456465AGreat improvement in brittlenessIncrease stiffnessTubular articlesAntioxidantEngineering

The invention discloses an HDPE (high-density polyethylene) pipeline modification process, and belongs to the technical field of HDPE pipelines, the HDPE pipeline modification process comprises the following steps: S1, cleaning: putting an HDPE raw material and a cleaning agent into a cleaning pool together for cleaning; s2, drying: taking out the HDPE raw material cleaned in the step S1, and drying the HDPE raw material in a drying machine for 30-40 minutes; s3, mixing: putting the HDPE raw material dried in the step S2, a toughening agent, an antioxidant and a defoaming agent into a mixer for mixing, setting the temperature to be 105-110 DEG C, and mixing for 60-80 minutes; s4, extruding: when the temperature in the mixer is reduced to 40 DEG C, taking out the mixed material, drying at 70-80 DEG C for 2 hours, feeding into an extruder by using a vacuum feeding machine, and extruding and forming the HDPE pipeline by using the extruder; s5, cooling is conducted, specifically, the formed HDPE pipeline is cooled, and fixed-length cutting is conducted; and S6, warehousing is conducted, specifically, the HDPE pipelines subjected to fixed-length cutting are sequentially inspected, printed with marks and warehoused as finished products. According to the invention, the problems of high brittleness and low ring stiffness of the cooled HDPE pipeline are effectively improved, the product performance is improved, and the service life of the HDPE pipeline is prolonged.

Owner:河北再美高分子材料有限公司

A carbon nanotube modified polyolefin double resistance material and its preparation method and application

Owner:SHANDONG DONGHONG PIPE IND

A kind of bismuth-based alloy solder paste composition

ActiveCN109158794BImprove antioxidant capacityHigh strengthWelding/cutting media/materialsSoldering mediaAntioxidant capacityOxidation resistant

The invention provides a bismuth-based alloy solder paste composition, which comprises solder flux and tin alloy powder, and the weight ratio of the solder flux to tin alloy powder is 9%-15%. The inventor added a protective agent to the soldering paste, which can form a protective film to prevent the precipitation of small molecules. During the soldering process, high temperature leaves holes to absorb small molecules, so as to avoid harm to the human body and the environment. The solder paste prepared by the invention is environmentally friendly, has excellent performance, strong oxidation resistance, is lead-free, and has excellent expansion performance and soldering performance.

Owner:EUNOW ELECTRONICS TECH CO LTD SUZHOU

High-rigidity high-abrasion-resistance PPO/sPS carbon fiber reinforced composite alloy material and preparation method thereof

The invention relates to the technical field of composite alloy materials, in particular to a high-rigidity high-abrasion-resistance PPO / sPS carbon fiber reinforced composite alloy material and a preparation method thereof. The composite alloy material is prepared from, by weight, 40-60% of PPO resin, 15-30% of alpha-crystal-form sPS resin, 8-15% of syndiotactic polypropylene, 5-10% of reinforcedglass fibers, 0.1-0.5% of a TiCl4+Al(C2H5)3 catalyst, 0.1-0.5% of an initiator, 1-3% of a lubricating agent and 2-5% of an antioxidant. The composite alloy material has advantages of high rigidity andhigh abrasion resistance. The preparation method of the composite alloy material includes that hydroxyl-terminated PPO resin and a cross-linked material of alpha-crystal-form sPS resin and syndiotactic polypropylene are prepared respectively and then subjected to combined screw granulating to prepare the composite alloy material.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

A kind of basalt fiber reinforced recycled micropowder geopolymer and its preparation method

ActiveCN111646713BImprove performanceImprove toughnessCement productionPolymer scienceResource consumption

The invention relates to a basalt fiber reinforced regenerated micropowder geopolymer and a preparation method thereof, which comprises 100-500 parts of regenerated micropowder, 500-900 parts of metakaolin, 700-1000 parts of alkali activator, and 5-10 parts of high-efficiency activator , 3~18 parts of basalt fiber, 1~5 parts of fiber dispersant, 150~200 parts of deionized water. The present invention uses building solid waste to replace cement, which improves the recycling rate of resources, reduces the burden on the environment, reduces costs, and reduces resource consumption; the present invention uses basalt fiber to reinforce regenerated micro-powder geopolymers to solve the problem of poor toughness of geopolymers, The problem of large early shrinkage and easy cracking can be obtained by obtaining geopolymers with high strength and high toughness, which is conducive to the popularization and application of geopolymers in the field of engineering in my country.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com