Antibacterial environment-friendly packaging thin film and preparation method thereof

A packaging film, an environmentally friendly technology, applied in the field of packaging film, can solve the problems of short shelf life and poor antibacterial performance of food, and achieve the effect of improving brittleness, improving antibacterial performance and good practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

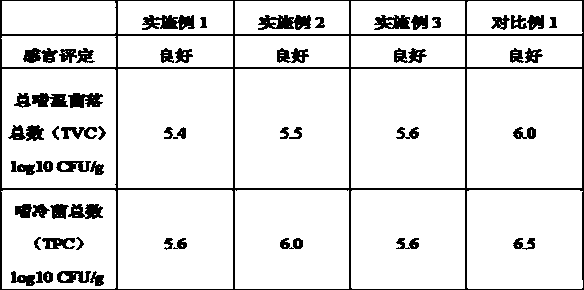

Examples

Embodiment 1

[0027] An antibacterial and environment-friendly packaging film comprises the following components in parts by weight: 7g of microcrystalline cellulose fiber; 10g of antidiarrheal essential oil; 13g of emulsifier; and 70g of polyhydroxybutyrate copolyester.

[0028] A preparation method for an antibacterial environment-friendly packaging film, comprising the following steps:

[0029] 1) Emulsifying and mixing 15g of the essential oil of Chiselwort essential oil and 15g of emulsifier to obtain an emulsified mixture.

[0030] 2) Add 20g of microcrystalline cellulose to 500mL of 0.2mol / L ammonium persulfate solution, stir at 80°C for 16h to dissolve the amorphous area of microcrystalline cellulose, then add 1000mL of water to adjust the pH To 7, after standing for 3 hours, remove the supernatant to obtain a suspension, centrifuge the suspension, remove the supernatant, dilute the precipitate with water, and then repeat the centrifugation until the supernatant obtained by centri...

Embodiment 2

[0034] An antibacterial and environment-friendly packaging film comprises the following components in parts by weight: 7g of microcrystalline cellulose fiber; 6.5g of thyme essential oil; 6.5g of emulsifier; and 70g of polyhydroxybutyrate copolyester.

[0035] A preparation method for an antibacterial environment-friendly packaging film, comprising the following steps:

[0036] 1) Emulsify and mix 10g of thyme essential oil with 10g of emulsifier to obtain an emulsified mixture.

[0037] 2) Add 20g of microcrystalline cellulose to 500mL of 0.3mol / L ammonium persulfate solution, stir at 90°C for 3h to dissolve the amorphous region of microcrystalline cellulose, then add 1000mL of water to adjust the pH To 7.5, after standing for 4 hours, remove the supernatant to obtain a suspension, centrifuge the suspension, remove the supernatant, dilute the precipitate with water, and repeat the centrifugation until the supernatant obtained by centrifugation The liquid turns into a cloudy ...

Embodiment 3

[0041] An antibacterial and environment-friendly packaging film comprises the following components in parts by weight: 7 g of microcrystalline cellulose fiber; 12.5 g of geranium essential oil; 12.5 g of emulsifier; and 80 g of polyhydroxybutyrate copolyester.

[0042] A preparation method for an antibacterial environment-friendly packaging film, comprising the following steps:

[0043] 1) Emulsify and mix 10g of geranium essential oil with 10g of emulsifier to obtain an emulsified mixture.

[0044] 2) Add 20g of microcrystalline cellulose to 600mL of 0.5mol / L ammonium persulfate solution, stir at 85°C for 5h to dissolve the amorphous region of microcrystalline cellulose, then add 1000mL of water to adjust the pH To 8, after standing for 5 hours, remove the supernatant to obtain a suspension, centrifuge the suspension, remove the supernatant, dilute the precipitate with water, and then repeat the centrifugation until the supernatant obtained by centrifugation The liquid turns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com