Polyisobutylene modified building asphalt and preparation method thereof

A technology of polyisobutylene and construction asphalt, which is applied in construction, building components, building structure, etc., can solve the problems of high low temperature brittleness, thermodynamic instability, asphalt incompatibility, etc. The effect of obvious, good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

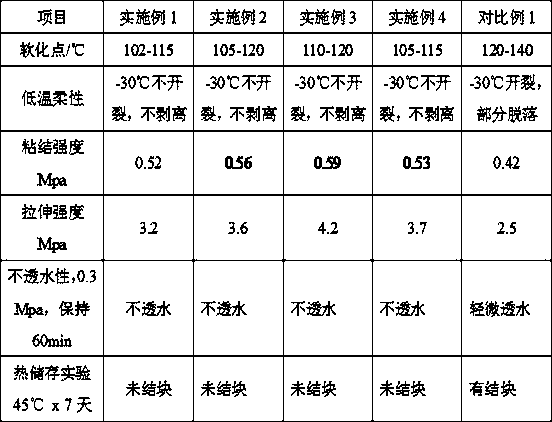

Examples

Embodiment 1

[0040] A polyisobutylene modified construction asphalt is composed of the following components by weight:

[0041] Basic asphalt 100 parts

[0042] 10 parts of epoxy polyisobutylene

[0043] lignin 5 parts

[0044] Inorganic filler 50 parts

[0045] Silane coupling agent 1 part

[0046] Anti-aging agent 0.5 parts

[0047] The base asphalt is selected from straight-run petroleum asphalt.

[0048] The inorganic filler is selected from 15 parts of magnesium hydroxide, 20 parts of barium sulfate and 15 parts of calcium carbonate.

[0049] The silane coupling agent is selected from aminosilane coupling agents, selected from 3-aminopropyltriethoxysilane.

[0050] The anti-aging agent is selected from phenolic antioxidants.

[0051] The preparation method of this polyisobutylene modified construction asphalt is:

[0052] 1) Add magnesium hydroxide, barium sulfate, and calcium carbonate to the planetary grinder, and add ethanol / water (50 / 50

[0053] parts by mass), then add a...

Embodiment 2

[0059] A polyisobutylene modified construction asphalt is composed of the following components by weight:

[0060] Basic asphalt 100 parts

[0061] 20 parts of epoxy polyisobutylene

[0062] Lignin 7.5 parts

[0063] Inorganic filler 60 parts

[0064] 1.5 parts of silane coupling agent

[0065] Anti-aging agent 1 part

[0066] The base asphalt is selected from straight-run petroleum asphalt.

[0067] The inorganic filler is selected from 20 parts of magnesium hydroxide, 20 parts of barium sulfate and 20 parts of calcium carbonate.

[0068] The silane coupling agent is selected from aminosilane coupling agents, selected from 3-aminopropyltriethoxysilane.

[0069] The anti-aging agent is selected from phenolic antioxidants.

[0070] The preparation method of this polyisobutylene modified construction asphalt is:

[0071] 1) Add magnesium hydroxide, barium sulfate, and calcium carbonate to the planetary grinder, and add ethanol / water (50 / 50

[0072] parts by mass), then ...

Embodiment 3

[0078] A polyisobutylene modified construction asphalt is composed of the following components by weight:

[0079] Basic asphalt 100 parts

[0080] 30 parts of epoxy polyisobutylene

[0081] lignin 10 parts

[0082] Inorganic filler 80 parts

[0083] 3 parts of silane coupling agent

[0084] Anti-aging agent 2 parts

[0085] The base asphalt is selected from straight-run petroleum asphalt.

[0086] The inorganic filler is selected from 25 parts of magnesium hydroxide, 25 parts of barium sulfate and 30 parts of calcium carbonate.

[0087] The silane coupling agent is selected from aminosilane coupling agents, selected from 3-aminopropyltriethoxysilane.

[0088] The anti-aging agent is selected from phenolic antioxidants.

[0089] The preparation method of this polyisobutylene modified construction asphalt is:

[0090] 1) Add magnesium hydroxide, barium sulfate, and calcium carbonate to the planetary grinder, and add ethanol / water (50 / 50

[0091] parts by mass), then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com