Hyperbranched bifunctional star-shaped compound, polymer electrolyte material, preparation of hyperbranched bifunctional star-shaped compound and polymer electrolyte material, and application of hyperbranched bifunctional star-shaped compound

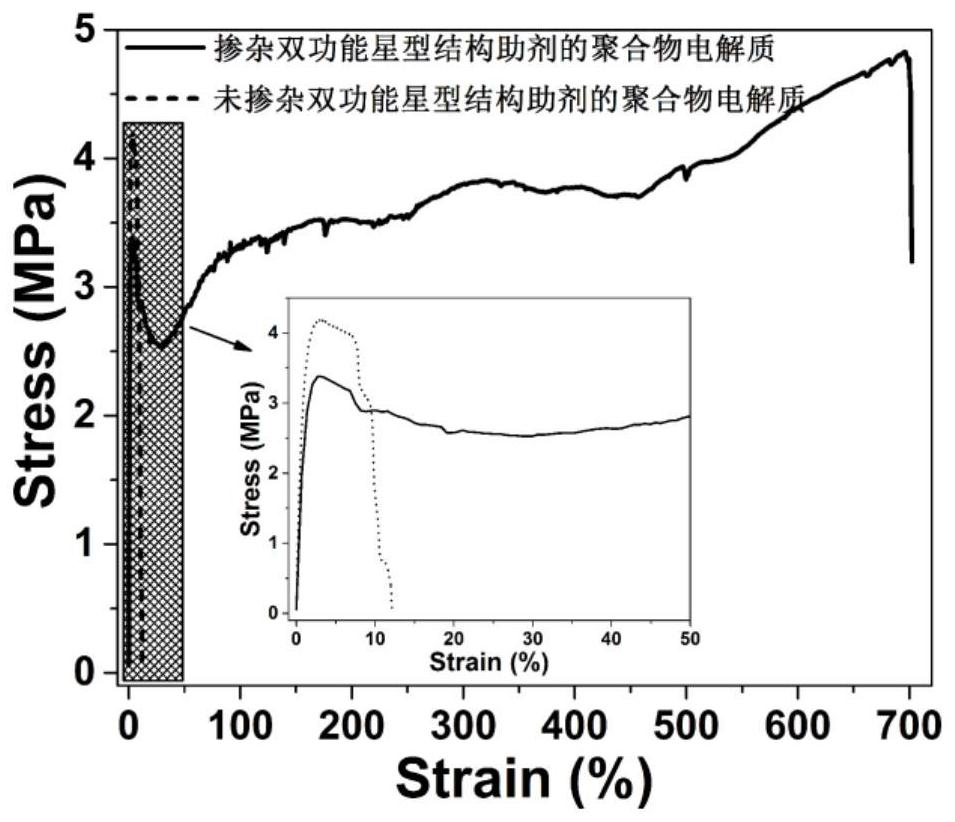

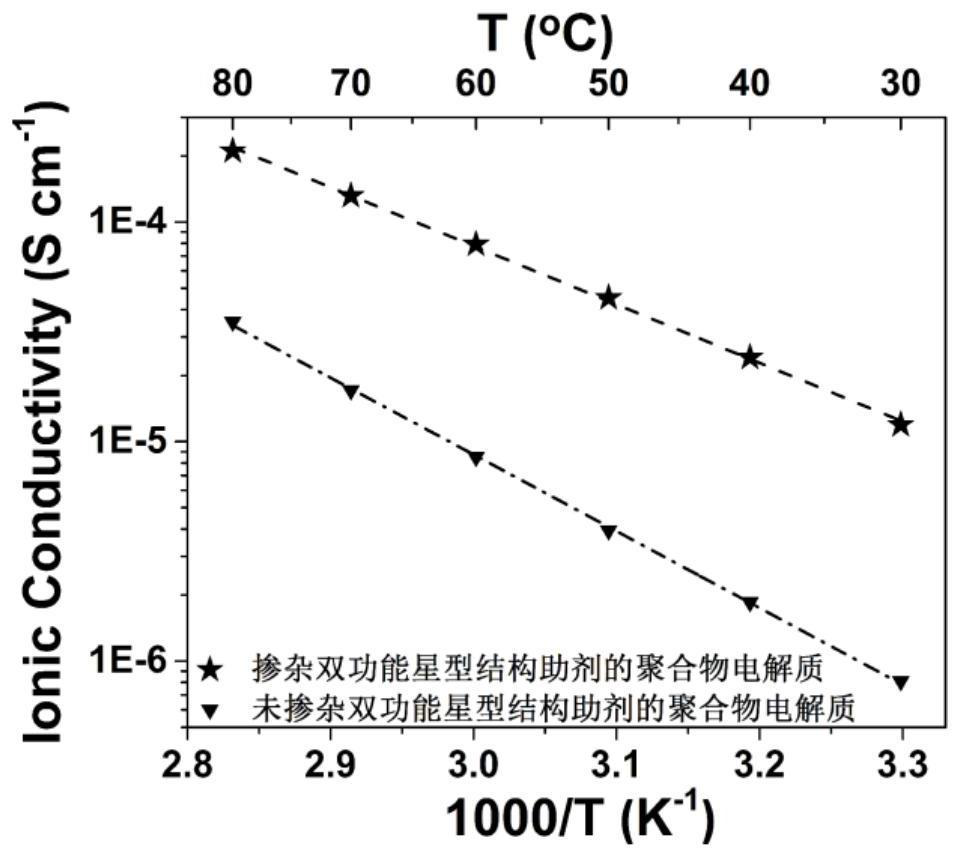

A technology for electrolyte materials and compounds, which is applied in the field of polymer electrolyte materials, preparation and application, hyperbranched bifunctional star compounds, and can solve the problems of high brittleness, poor film formation of electrolyte materials, and low ionic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Take by weighing 0.0949g photoinitiator benzophenone, 0.3985g trimethylolpropane three (3-mercaptopropionate) and polyethylene glycol of 1.5g number average molecular weight 300g / mol in oil bath Methyl ether methacrylate, and then put the above-mentioned blending system in an oil bath at 40°C for 4h under stirring conditions; among them, trimethylolpropane tris(3-mercaptopropionate) and polyethylene glycol methyl ether methacrylate The molar ratio is 1:5, and the amount of photoinitiator is 5wt.% of the total amount of trimethylolpropane tris (3-mercaptopropionate) and polyethylene glycol methyl ether methacrylate;

[0053] (2) Place the homogeneous slurry obtained in step (1) in a PTFE mould, and then irradiate the slurry required for the polymerization reaction under ultraviolet light for 5 minutes to promote the reaction between polyhydric mercapto propionate and polyethylene glycol methacrylate Polymerization to obtain a hyperbranched bifunctional star compound;...

Embodiment 2

[0057] (1) Weigh 0.0919g photoinitiator 1-hydroxycyclohexyl phenyl ketone, 0.3985g trimethylolpropane three (3-mercaptopropionate) and 1.9g number average molecular weight 475g / mol in oil bath Polyethylene glycol methyl ether methacrylate, and then the above blend system was stirred in an oil bath at 45°C for 5 hours; among them, trimethylolpropane tris(3-mercaptopropionate) and polyethylene glycol The molar ratio of methyl ether methacrylate is 1:4, and the amount of photoinitiator is 4wt.% of the total amount of trimethylolpropane tris(3-mercaptopropionate) and polyethylene glycol methyl ether methacrylate ;

[0058] (2) Place the homogeneous slurry obtained in step (1) in a PTFE mould, and then irradiate the slurry required for the polymerization reaction under ultraviolet light for 10 minutes to promote the reaction between polyhydric mercapto propionate and polyethylene glycol methacrylate The cross-linking polymerization of hyperbranched bifunctional star compound is ob...

Embodiment 3

[0062] (1) Weigh 0.0975g photoinitiator 2-hydroxyl-2-methyl-1-phenyl-acetone, 0.3985g trimethylolpropane three (3-mercaptopropionate) and 2.85g in oil bath Polyethylene glycol methyl ether methacrylate with a number average molecular weight of 950g / mol, and then the above-mentioned blending system was placed in an oil bath at 50°C for 8h under stirring conditions; among them, trimethylolpropane tris(3-mercaptopropane The molar ratio of ester) to polyethylene glycol methyl ether methacrylate is 1:3, and the amount of photoinitiator is trimethylolpropane three (3-mercapto propionate) and polyethylene glycol methyl ether methyl 3wt.% of the total amount of acrylate;

[0063] (2) Place the homogeneous slurry obtained in step (1) in a PTFE mould, and then irradiate the slurry required for the polymerization reaction under ultraviolet light for 15 minutes to promote the reaction between polyhydric mercapto propionate and polyethylene glycol methacrylate The cross-linking polymeriza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com