HDPE (high-density polyethylene) pipeline modification process

A pipe and modification technology, applied in the field of HDPE pipe modification technology, can solve the problems of low ring stiffness and high brittleness, and achieve the effects of improving aging resistance, improving brittleness and beautifying the appearance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

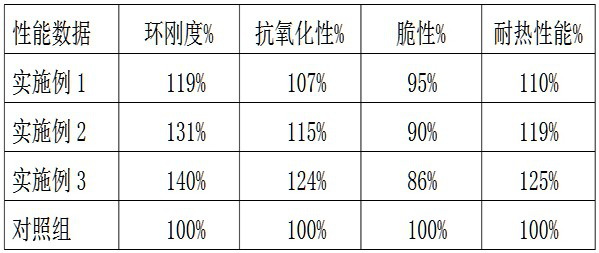

Examples

Embodiment 1

[0018] A process for modifying HDPE pipes, comprising the following steps:

[0019] The composition in parts by mass is as follows:

[0020] S1, cleaning: put 70 parts of HDPE raw materials and 8 parts of cleaning agent into the cleaning tank for cleaning; S2, drying: take out the HDPE raw materials cleaned in step S1, put it into a dryer to dry for 30min; S3, mix: put S2 In the step, 70 parts of dried HDPE raw materials, 1 part of toughening agent, 2,6-tertiary butyl-4-methylphenol, bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide A total of 0.2 parts and 0.5 parts of the plastic high-efficiency defoamer water-absorbing masterbatch are put into the mixer for mixing, the set temperature is 105 ° C, and the mixing is 60 minutes, so that the ingredients are stirred and mixed evenly; S4, extrusion: when the mixer The temperature is lowered to 40°C, the mixture is taken out and dried at 70°C for 2 hours, fed into the extruder by a vacuum feeder, and the HDPE pipe is extruded and f...

Embodiment 2

[0022] A process for modifying HDPE pipes, comprising the following steps:

[0023] The composition in parts by mass is as follows:

[0024] S1, cleaning: put 70 parts of HDPE raw materials and 8 parts of cleaning agent into the cleaning tank for cleaning; S2, drying: take out the HDPE raw materials cleaned in step S1, put it into a dryer to dry for 30min; S3, mix: put S2 In the step, 70 parts of dried HDPE raw materials, 1 part of toughening agent, 2,6-tertiary butyl-4-methylphenol, bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide , 0.2 part of tetra[beta-(3,5-tertiary butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, and 0.5 part of water-absorbing master batch of high-efficiency plastic defoamer are put into the mixer to mix, set The temperature is 105°C, and the material is mixed for 60 minutes; S4, extrusion: when the temperature in the mixer drops to 40°C, the mixture is taken out and dried at 70°C for 2 hours. The machine extrudes the HDPE pipe; S5. Cooling...

Embodiment 3

[0026] A process for modifying HDPE pipes, comprising the following steps:

[0027] The composition in parts by mass is as follows:

[0028] S1, cleaning: put 70 parts of HDPE raw materials and 8 parts of cleaning agent into the cleaning tank for cleaning; S2, drying: take out the HDPE raw materials cleaned in step S1, put it into a dryer to dry for 30min; S3, mix: put S2 In the step, 70 parts of dried HDPE raw materials, 3 parts of toughening agent, 2,6-tertiary butyl-4-methylphenol, bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide A total of 0.5 parts and 1 part of the high-efficiency plastic defoamer water-absorbing masterbatch are put into the mixer for mixing, the set temperature is 105 ° C, and the mixing is 60 minutes; S4, extrusion: When the temperature in the mixing machine drops to 40 ° C, mix The material is taken out and dried at 70°C for 2 hours, and is fed into the extruder by a vacuum feeder, and the HDPE pipe is extruded and formed by the extruder; S5, cooling:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com