Flame-retardant antifouling cellulose laminated composite board for rail transit interiors and preparation method of flame-retardant antifouling cellulose laminated composite board

A technology of cellulose layer and composite board, which is applied in the direction of sustainable transportation, non-fiber pulp addition, fiber raw material treatment, etc., can solve the problems that cannot meet the application requirements of rail transit interior materials, fire prevention, and antifouling performance. Achieve the effects of improving anti-pollution performance, excellent anti-fouling performance, and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

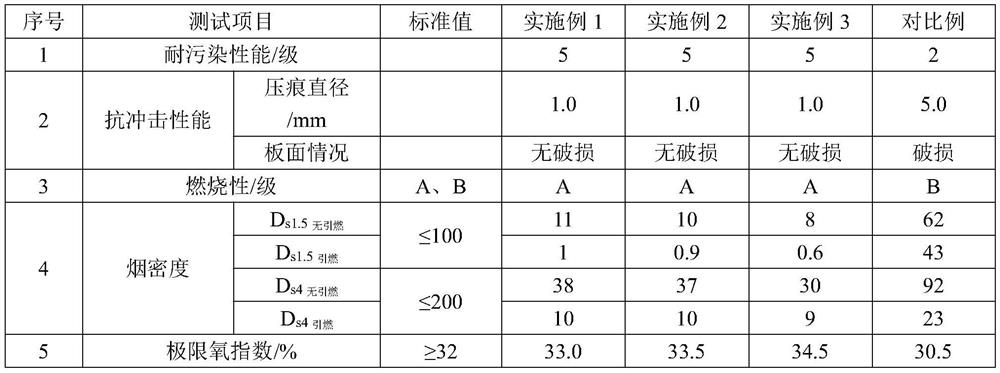

Examples

Embodiment 1

[0029] Embodiment 1: A flame-retardant and anti-fouling cellulose laminated composite sheet for rail transit interior decoration in this embodiment is formed by hot-pressing and curing a laminated surface layer and a core layer; the surface layer is two layers impregnated with modified melamine formaldehyde Resin cellulose paper, the core layer is composed of aramid paper impregnated with modified melamine formaldehyde resin and cellulose paper impregnated with modified melamine formaldehyde resin which are alternately laminated with a total number of 20 layers; wherein aramid The number of paper layers is 10 layers, and the number of cellulose paper layers is 10 layers. The cellulose paper is prepared by chemical-mechanical pulp papermaking and has a grammage of 150g / m 2 cellulose paper, the aramid paper is meta-aramid paper, the weight is 50g / m 2 ;

[0030] The preparation method of the modified melamine formaldehyde resin is as follows: 37wt% formaldehyde solution and 10wt...

Embodiment 2

[0036]Embodiment 2: A flame-retardant and anti-fouling cellulose laminate composite sheet for rail transit interior decoration in this embodiment is formed by hot-pressing and curing the surface layer and the core layer that are stacked; the surface layer is two layers of impregnated modified melamine formaldehyde Resin cellulose paper, the core layer is composed of aramid paper impregnated with modified melamine formaldehyde resin and cellulose paper impregnated with modified melamine formaldehyde resin, which are alternately laminated with a total number of 14 layers; wherein aramid The number of paper layers is 6 layers, and the number of cellulose paper layers is 8 layers. The cellulose paper is prepared by chemical-mechanical pulp papermaking and has a grammage of 120g / m 2 cellulose paper, the aramid paper is meta-aramid paper, the weight is 80g / m 2 ;

[0037] The preparation method of the modified melamine formaldehyde resin is as follows: 37wt% formaldehyde solution an...

Embodiment 3

[0043] Embodiment 3: A flame-retardant and anti-fouling cellulose laminated composite sheet for rail transit interior decoration in this embodiment is formed by hot-pressing and curing the surface layer and the core layer that are stacked; the surface layer is two layers of impregnated modified melamine formaldehyde Resin cellulose paper, the core layer is composed of aramid paper impregnated with modified melamine formaldehyde resin and cellulose paper impregnated with modified melamine formaldehyde resin which are alternately laminated with a total number of 30 layers; wherein aramid The number of layers of paper is 15 layers, and the number of layers of cellulose paper is 15 layers. The cellulose paper is prepared by chemical-mechanical pulp papermaking and has a grammage of 200g / m 2 The cellulose paper, the aramid paper is meta-aramid paper, the weight is 29g / m 2 ;

[0044] The preparation method of the modified melamine formaldehyde resin is as follows: 37wt% formaldehyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com