Preparation method of flexible quick-curing structural adhesive for buildings

A structural adhesive and fast-curing technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as difficult process control, reduced material strength, and reduced service life, and achieve faster bonding strength, The effect of reducing viscosity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

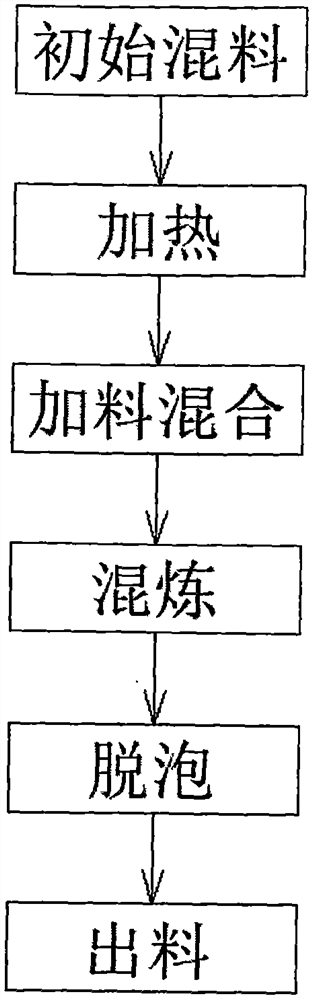

[0020] see figure 1 , the present invention provides a technical solution: a preparation method of flexible fast-curing structural adhesive for construction, the structural adhesive is 100% by weight, the acrylate monomer is 100-120 parts; the adhesive is 25-40 parts 20-40 parts of plasticizer; 30-35 parts of toughening agent; 5-10 parts of curing agent; 5-10 parts of accelerator; 10-15 parts of thinner; 5-15 parts of modified materials and other fillers;

[0021] Acrylic monomer 50-60%; Adhesive 12-20%; Plasticizer 10-20%; Toughener 15-18%; Curing agent 2-5%; Accelerator 2-5%; Thinner 5-8%; modified materials and other fillers 3-8%;

[0022] The plasticizer is one of polybutadiene, dioctyl phthalate and didecyl phthalate, or the two substances are mixed in any proportion;

[0023] Modified materials are selectively added materials;

[0024] The preparation method of flexible fast-curing structural adhesive for construction comprises the following process steps:

[0025] (...

Embodiment 1

[0035] (1), the acrylate monomer of 50% by weight and the filler of 5% are fully mixed by a mixer, and the speed of the mixer is controlled at 20-30r / min;

[0036] The filler in step (1) wherein contains 2% pigment;

[0037] (2) Place the material mixed in step (1) in an oven for heating treatment, the temperature range of the oven is 60-90°C, and the heating time is 30 minutes; during the heating period, stir three times, once every 10 minutes, so that the materials are fully mixed;

[0038] (3), add adhesive material 12-20% respectively in the material after step (2); Plasticizer 10-20%; Toughening agent 15-18%; Curing agent 5%; Accelerator 5%; 5% diluent for initial mixing;

[0039] (4) Use the three-roll mill to mix the mixed material 4-6 times, each time the mixing time is not less than 20min, so that the material is fully mixed, and the temperature of the three-roll machine is controlled at 40-60°C during the period. The material is uniform and free of particles;

[0...

Embodiment 2

[0043] (1) Place 50% by weight of acrylate monomer, 5% of filler and 5% of modified material in an oven for heat treatment, the temperature range of the oven is 60-70°C, and the heating time is 30min; Stir six times during this period, once every 5 minutes, so that the materials are fully mixed;

[0044] (2), add adhesive material 12-20% respectively in the material after step (1); Plasticizer 10-20%; Toughening agent 15-18%; Curing agent 5%; Accelerator 5%; 5% diluent for initial mixing;

[0045](3) Use the three-roll mill to mix the mixed material 5-6 times, each time the mixing time is not less than 30min, so that the material is fully mixed, and the temperature of the three-roll machine is controlled at 40-60°C during the period. The material is uniform and free of particles;

[0046] (4) Place the above mixed material in a vacuum degassing machine for 4-7 minutes at a speed of 2500--3000r / min;

[0047] (5) Forming and discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com