A radiation-resistant and anti-corrosion bottom-surface-integrated high-solid coating and preparation method thereof

An anti-corrosion pigment, high solid technology, used in anti-corrosion coatings, epoxy coatings, coatings, etc., to achieve the effect of shortening the coating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0037] Embodiment 1~3 prepares the high solid content coating of anti-radiation anti-corrosion bottom surface integrated

[0038] The specific method is as follows:

[0039] (1) Preparation of Component A

[0040] ① Prepare each component according to the following ratio

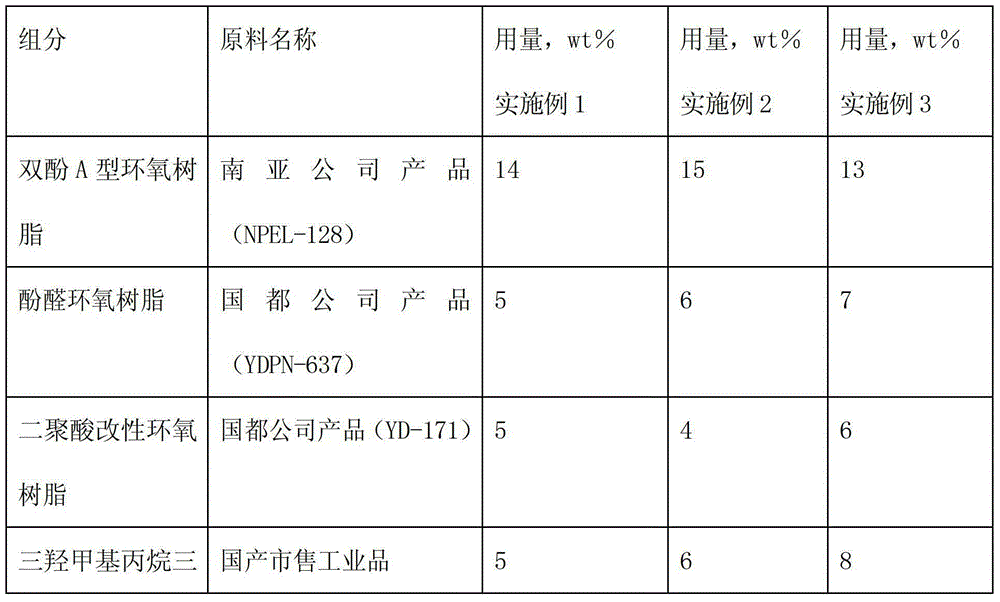

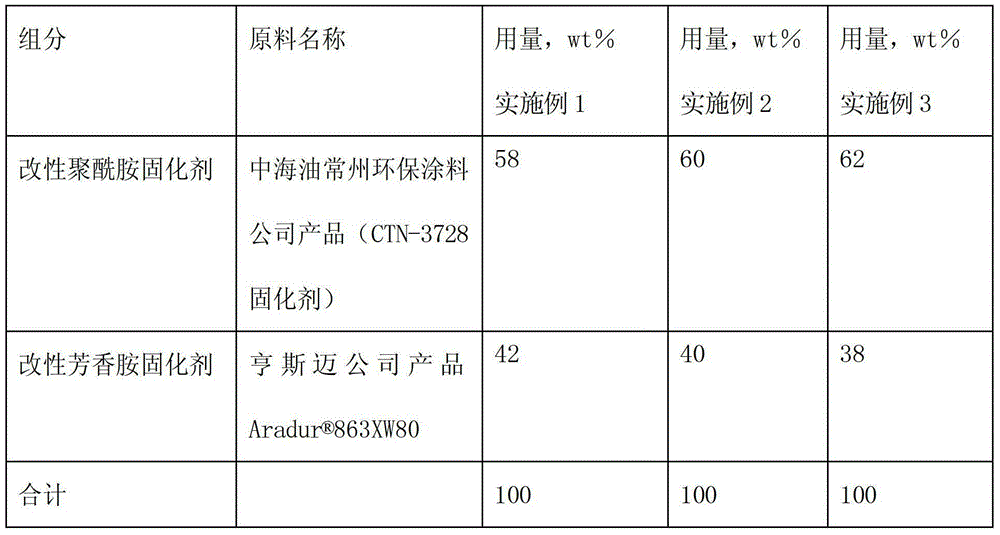

[0041]Component A is composed of the following raw materials in terms of mass fraction: bisphenol A epoxy resin 12-18%, novolak epoxy resin 4-8%, dimer acid modified epoxy resin 4-8%, trihydroxy Methylpropane triglycidyl ether 5-10%, coloring pigment 2-10%, anti-corrosion pigment 15-25%, filler 15-25%, flame retardant 10-20%, defoamer 0.3-0.8%, flow The leveling agent is 0.3-0.8%, the diluent is 5-10%, the sum of the mass fractions of the above components is 100%, and the specific formula is shown in Table 1.

[0042] Table 1

[0043]

[0044]

[0045] ② Specific operation

[0046] Add bisphenol A epoxy resin, novolac epoxy resin, dimer acid modified epoxy resin, trimethylolpropane triglycidyl eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com