Patents

Literature

44results about How to "Improve thermal oxidation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-proof reinforced polypropylene material and method for preparing same

The invention discloses a fire-resistance enhancing polypropylene material and a preparing method for the polypropylene material. The material comprises the following components and portions by weight: PP resin 100, halogen-free expanding fire retardant 50-75, enhancing modifier 15-75, and antioxidant 0.2-1.0, wherein, the fire retardant is a self-prepared built halogen-free expanding fire retardant, formed by physically mixing N-P fire retardant and polyorganoxiloxane in 1:0.1-1:0.3 by weight. The invention complexes N-P fire retardant of high fire resistance with a flame-resisting assistant, namely organic silicon, and improves the OI value of material. The product from the material will not frost on surface when storing for a long time, and 5-30% talcum powder or glass fiber can be added, so the invention thoroughly solves the shortcoming of prior product that the surface will frost if storing for a long time and no mineral filler can be added to increase the material strength, truly realizes halogen freedom, environmental friendliness, high strength and usability for a long term. The preparing process of the fire-resistance enhancing polypropylene is simple without adding any complex equipment.

Owner:SHENZHEN KEJU NEW MATERIAL

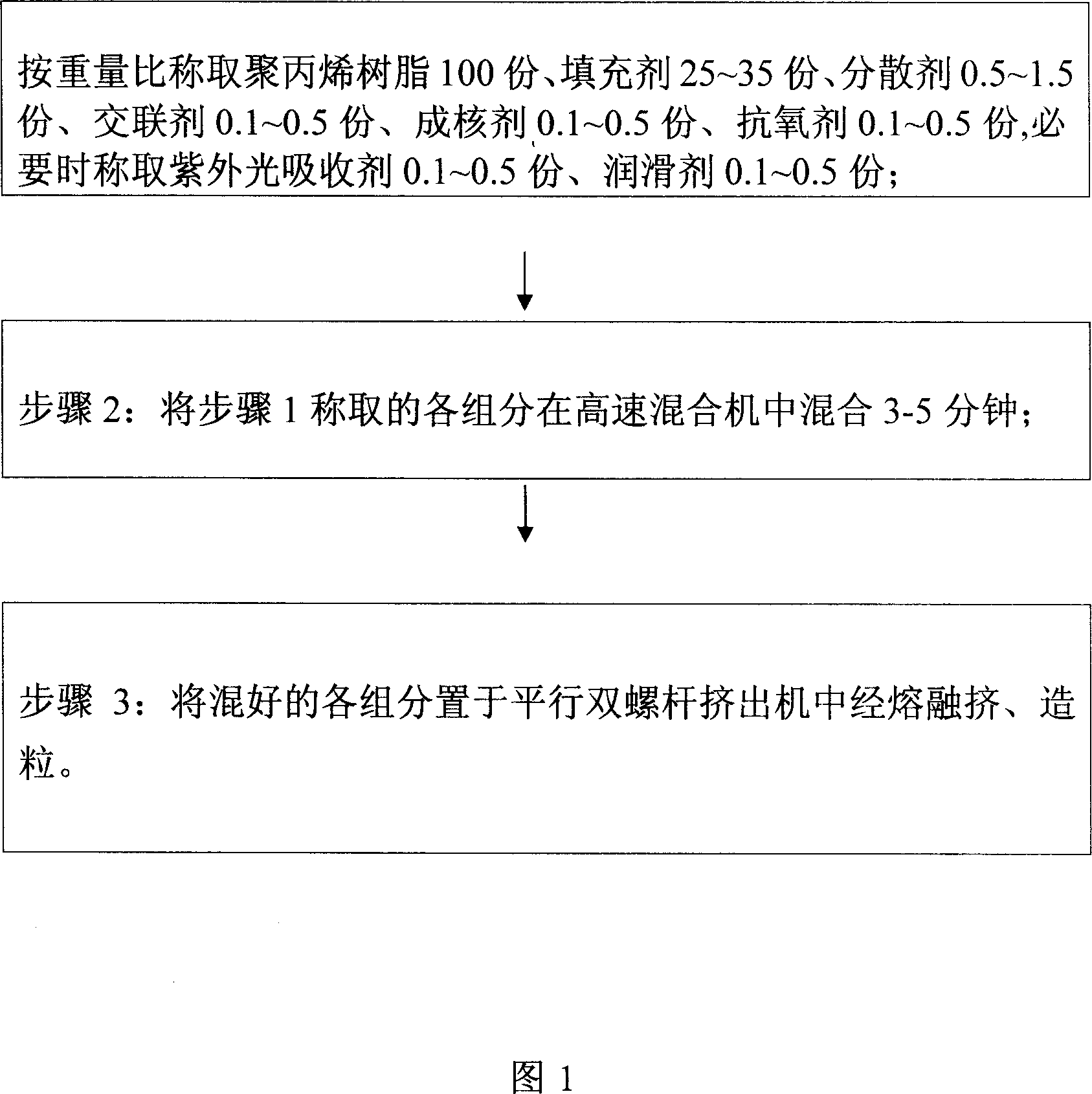

High glaze polypropylene material and preparation method thereof

A high-lustre polypropylene material and its production are disclosed. The material consists of polypropylene resin 100 proportion, filler nanometer calcium carbonate 25-35 proportion, dispersant 0.5-1.5 proportion, cross-linking agent diisopropylzene 0.1-0.5 proportion, beta-crystal nucleation agent 0.1-0.5 proportion, and antioxidant 0.1-0.5 proportion. It costs low, has better toughness and surface brightness on surface.

Owner:SHENZHEN KEJU NEW MATERIAL

Flame-retardant glass fiber reinforced polypropylene composite material for manufacturing coil frame and preparation method thereof

The invention discloses a flame-retardant glass fiber reinforced polypropylene composite material for manufacturing a coil frame and a preparation method thereof. The composite material is mainly prepared from polypropylene, glass fiber, a fire retardant, a compatilizer, a nucleating agent, a dispersing agent and an antioxidant serving as raw materials. The preparation method comprises the following steps of: (1) uniformly mixing the polypropylene, the fire retardant, the compatilizer, the nucleating agent, the dispersing agent and the antioxidant; and (2) performing melt extrusion on the mixed raw materials obtained by the step (1) and the glass fiber in a melt extruder and pelleting to obtain a product. The invention provides the flame-retardant glass fiber reinforced polypropylene composite material for manufacturing the coil frame and the preparation method thereof.

Owner:ANHUI KEJU NEW MATERIALS

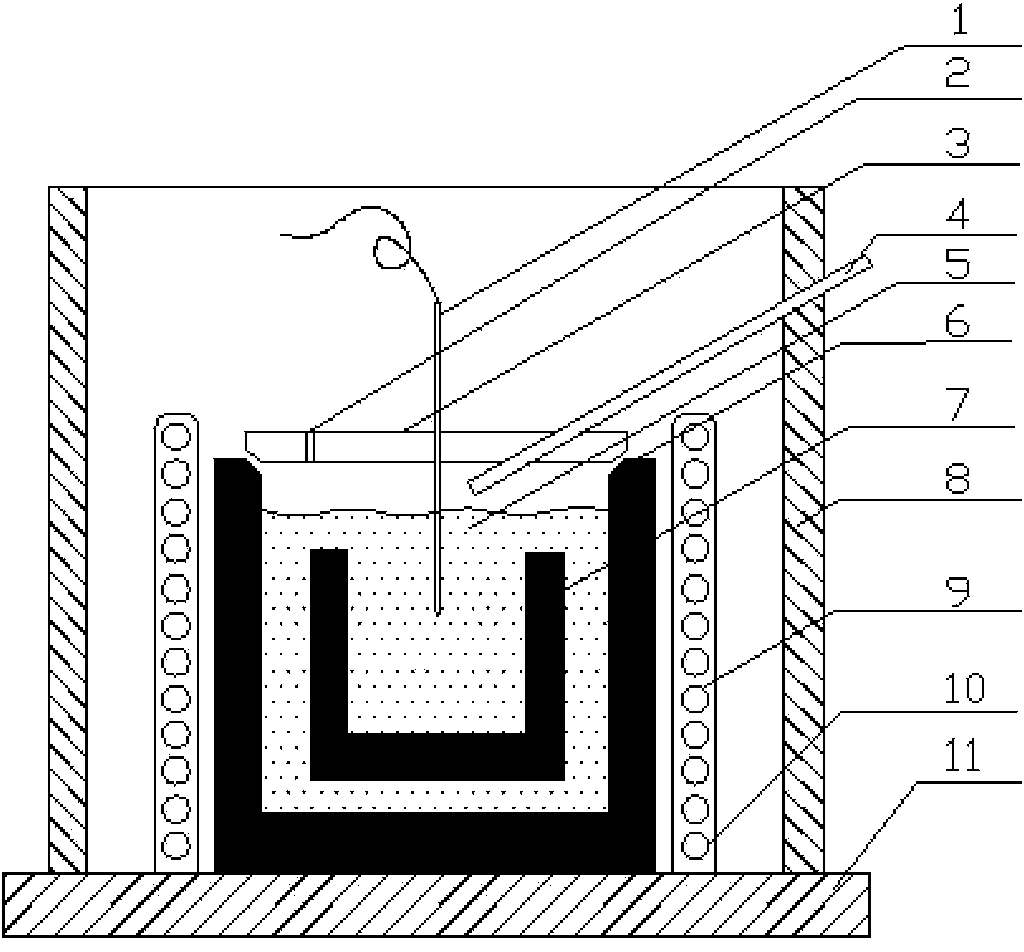

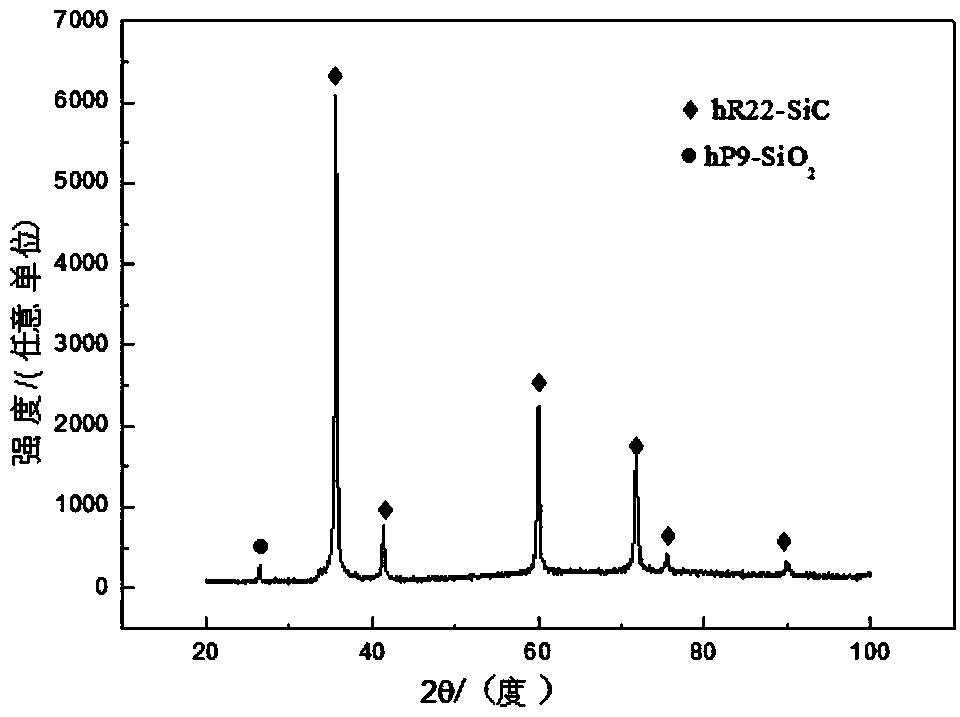

Method for preparing SiC coating on surface of graphite crucible by using in-situ reaction method

The invention provides a method for preparing a SiC coating on the surface of a graphite crucible by using an in-situ reaction method. The method comprises the following steps: burying a graphite crucible for the coating into silicon powder inside a graphite crucible for heating, so as to obtain a pre-action material, putting the pre-action material into a superaudio sensing heating furnace, and reacting for 60-90 minutes at 1,300 DEG C on the presence of inert gases. According to the method, the SiC coating which is uniform in thickness is generated through solid phase on the surface of the graphite crucible through in-site reaction, the method is simple in process, easy to control and beneficial for industrial production. The SiC coating prepared by using the method provided by the invention is solidly combined with a substrate of the graphite crucible, because of the SiC coating, the graphite crucible is effectively prevented from being oxidized, and the oxidation resistance and the thermal impact resistance of the graphite crucible are improved, so that the service life of the graphite crucible is prolonged, and no other impurities are introduced.

Owner:DALIAN UNIV OF TECH

Preparation method of heat-resistant oxygen-resistant polyester film

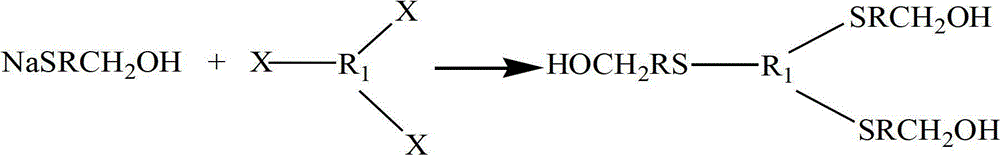

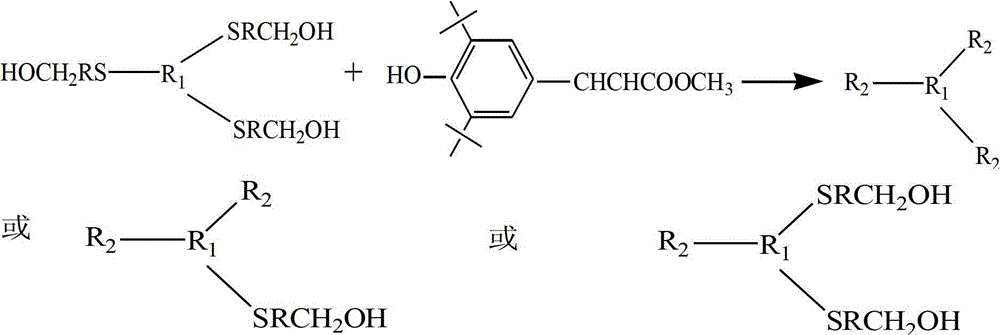

ActiveCN102875980AImprove thermal oxygen resistanceImprove temperature resistanceFlat articlesSulfide preparationOxygenPhenol

The invention discloses a preparation method of a heat-resistant oxygen-resistant polyester film. The preparation method is characterized by including the steps of preparation of hydroxy thiophenol containing compounds, preparation of sulfur-containing hindered phenol antioxidants, polyester synthesis and film processing. The preparation method includes: using 4-hydroxy benzyl thiophenol sodium, 1, 3, 5-trichlorobenzene, 1, 3, 5-tribromobenzene and 2, 4, 6-tri(4-hydroxy benzyl thiophenyl)-1, 3, 5-triazine to synthesize the hydroxy thiophenol containing compounds, namely, 1, 3, 5-tri(4-hydroxy benzyl thiophenyl) benzene and 2, 4, 6-tri(4-hydroxy benzyl thiophenyl)-1, 3, 5-triazine in N, N-dimethyl formamide solvent; synthesizing the 1, 3, 5-tri(4-hydroxy benzyl thiophenyl) benzene, the 2, 4, 6-tri(4-hydroxy benzyl thiophenyl)-1, 3, 5-triazine and 3, 5-di-tert-butyl-4-hydroxy phenylacrylic acid methyl ester to prepare the type A reactive sulfur-containing hindered phenol antioxidant and the type B reactive sulfur-containing hindered phenol antioxidant; and synthesizing the type A reactive sulfur-containing hindered phenol antioxidant, the type B reactive sulfur-containing hindered phenol antioxidant, terephthalic acid and ethylene glycol to prepare heat-resistant oxygen-resistant polyester resin, so that the heat-resistant oxygen-resistant polyester film good in performance is prepared.

Owner:四川东方绝缘材料股份有限公司

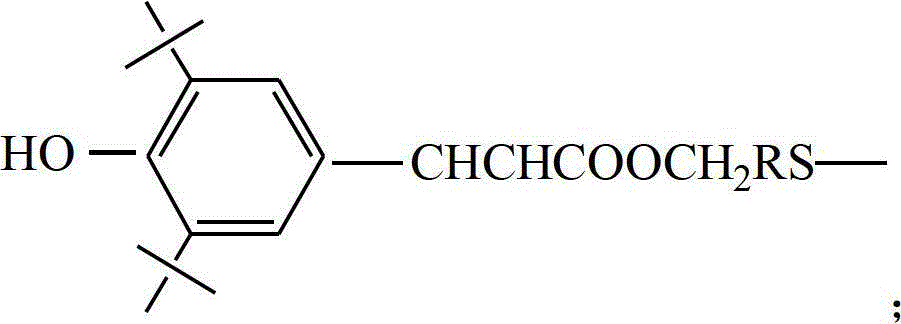

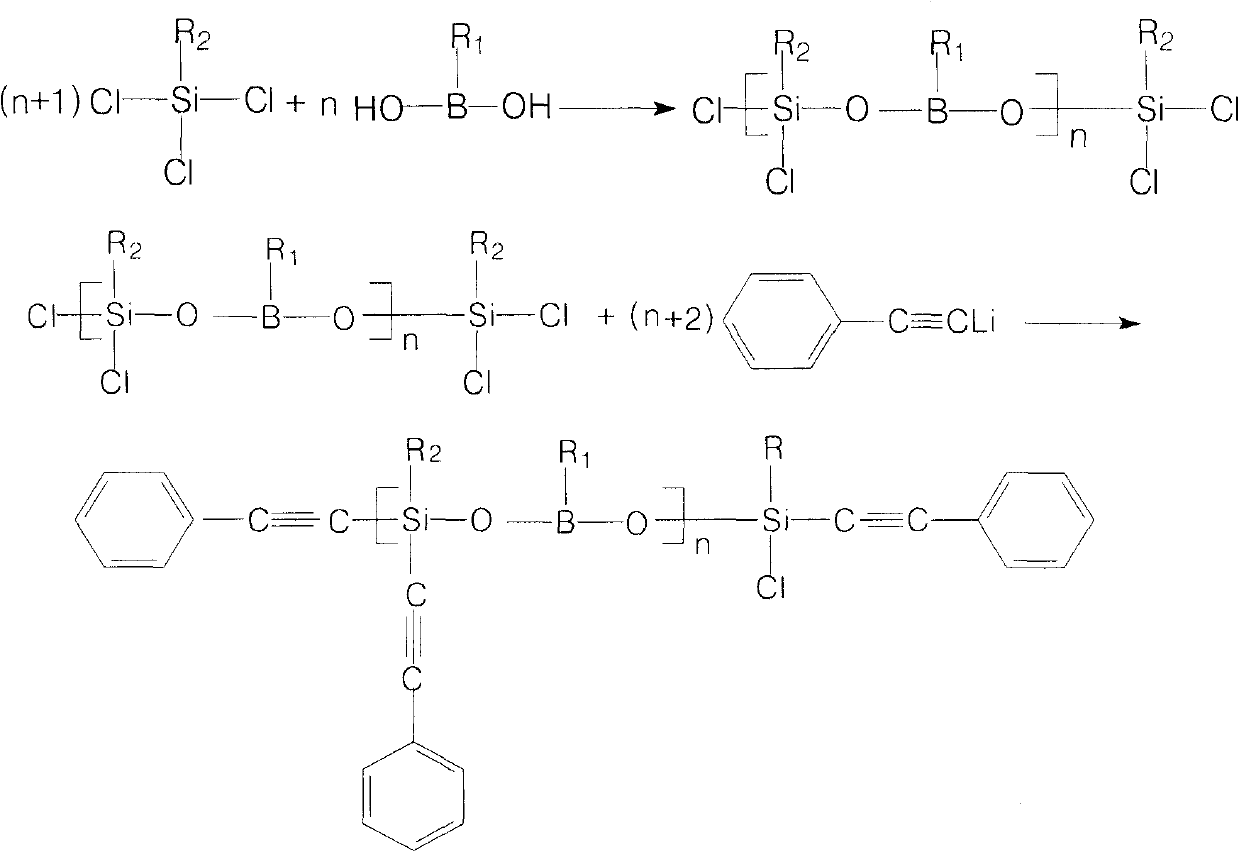

Polyphenylacetylene silicon oxide borane and preparation method thereof

ActiveCN102234375ADoes not affect crosslink densitySolve molding difficultiesBoron carbideSilicon oxide

The invention discloses polyphenylacetylene silicon oxide borane and a preparation method thereof. The structure of the prepared polyphenylacetylene silicon oxide borane is shown as a formula I, wherein R1 and R2 refer to CH3, C6H5, and n is 1-100. The preparation method comprises the following steps of: performing hydrogen chloride removal reaction on trichlorosilane and alkyl boric acid to obtain polychlorosilicon oxide borane; and reacting the polychlorosilicon oxide borane with phenylacetylenelithium to obtain the polyphenylacetylene silicon oxide borane. In the polymer, a repeat unit contains polyphenylacetylene, so the magnitude of the polymerization degree cannot influence the crosslinking density of the polymer. The molecular weight of the polymer can be controlled by proportioning raw materials. In high temperature environment, the surface of a material is vitrified, and a ceramic layer such as a silicon carbide layer or a boron carbide layer is formed, so that the inner material is isolated from heat and oxygen; therefore, the thermal oxidation performance of the structural material is improved. The polyphenylacetylene silicon oxide borane is applied to preparing ceramic precursors, high-performance composite material matrixes, ablation resistant materials, high temperature resistant coatings and the like. The formula I is shown in the specifications.

Owner:EAST CHINA UNIV OF SCI & TECH +1

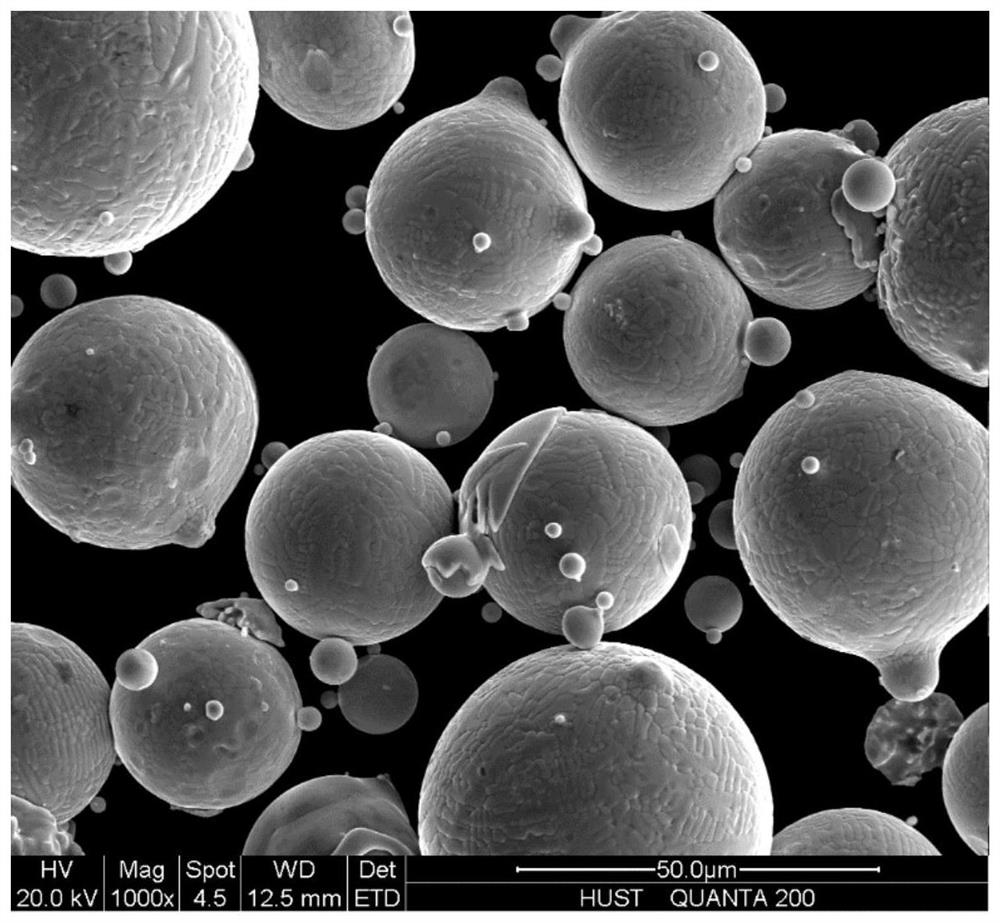

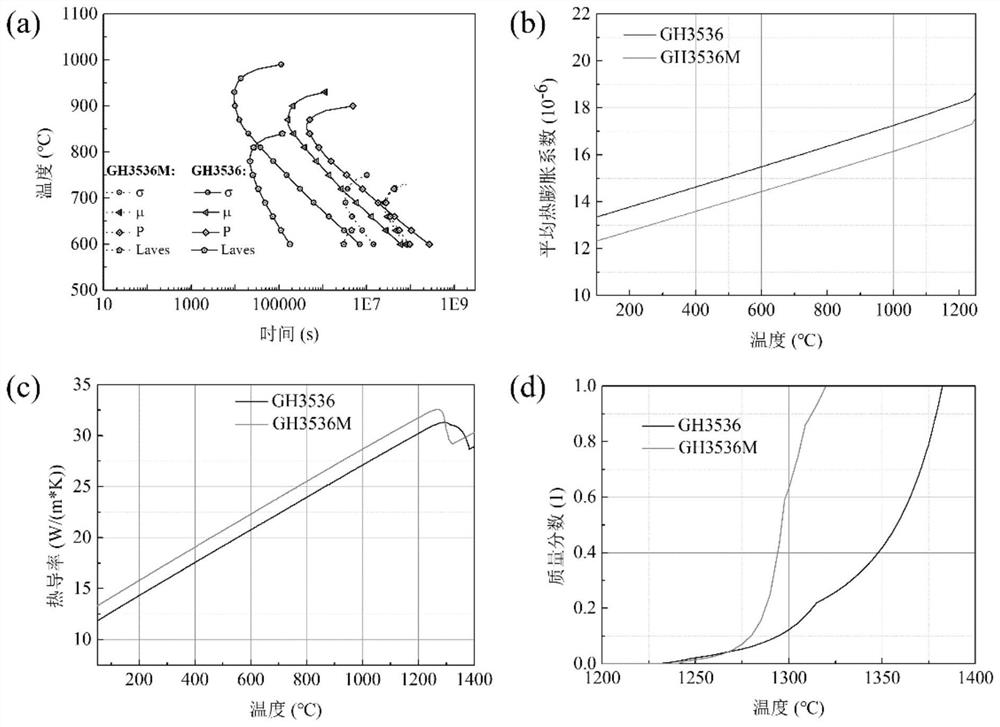

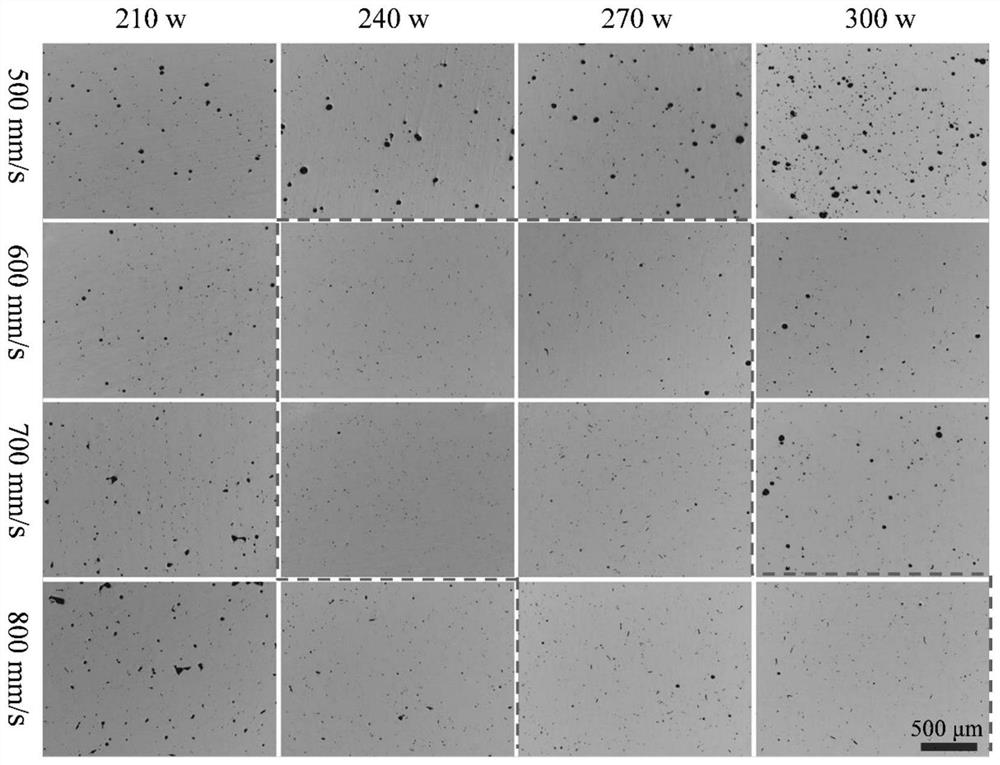

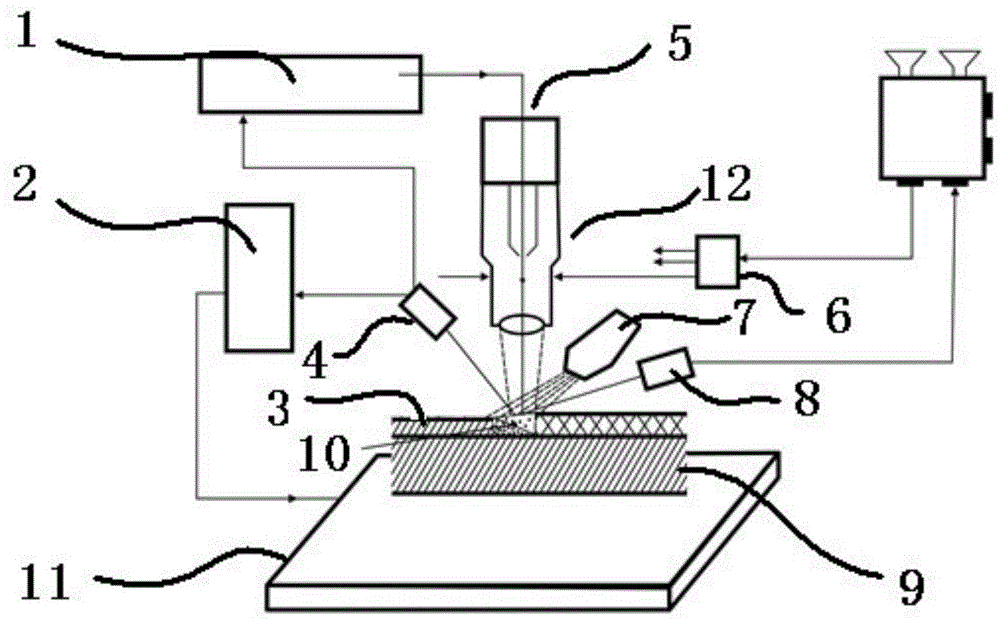

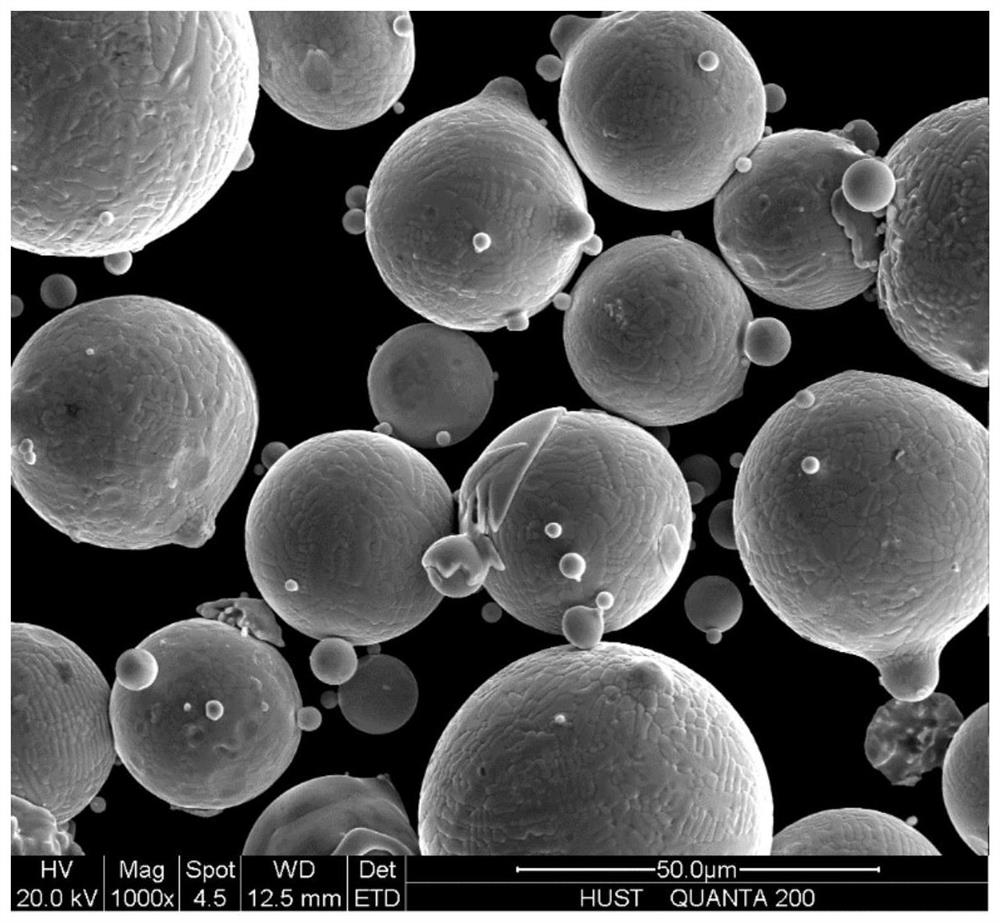

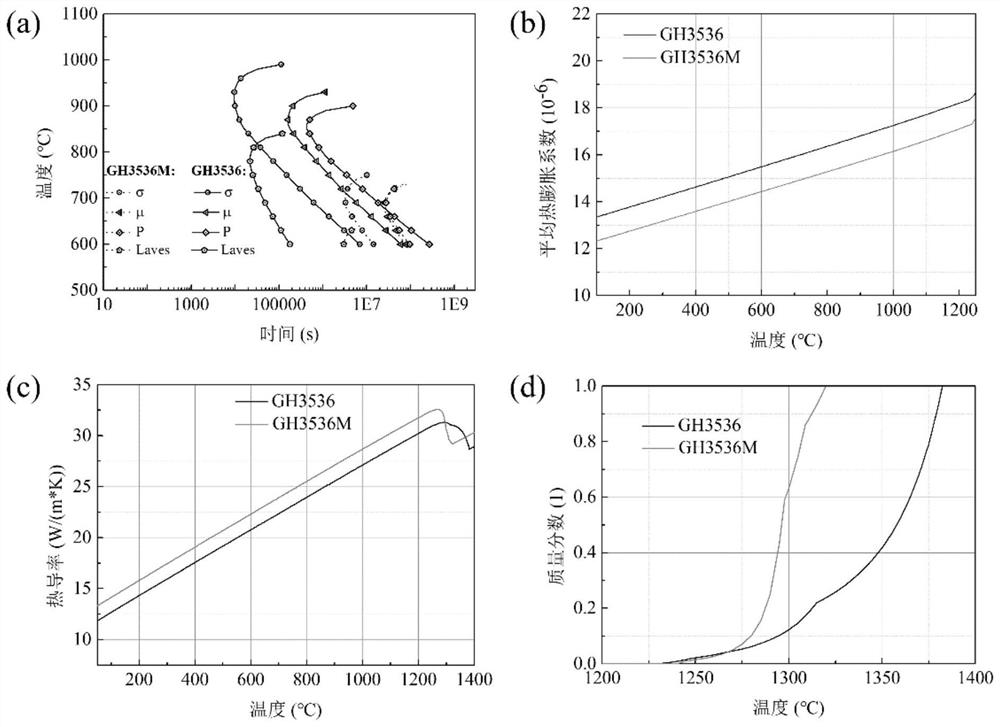

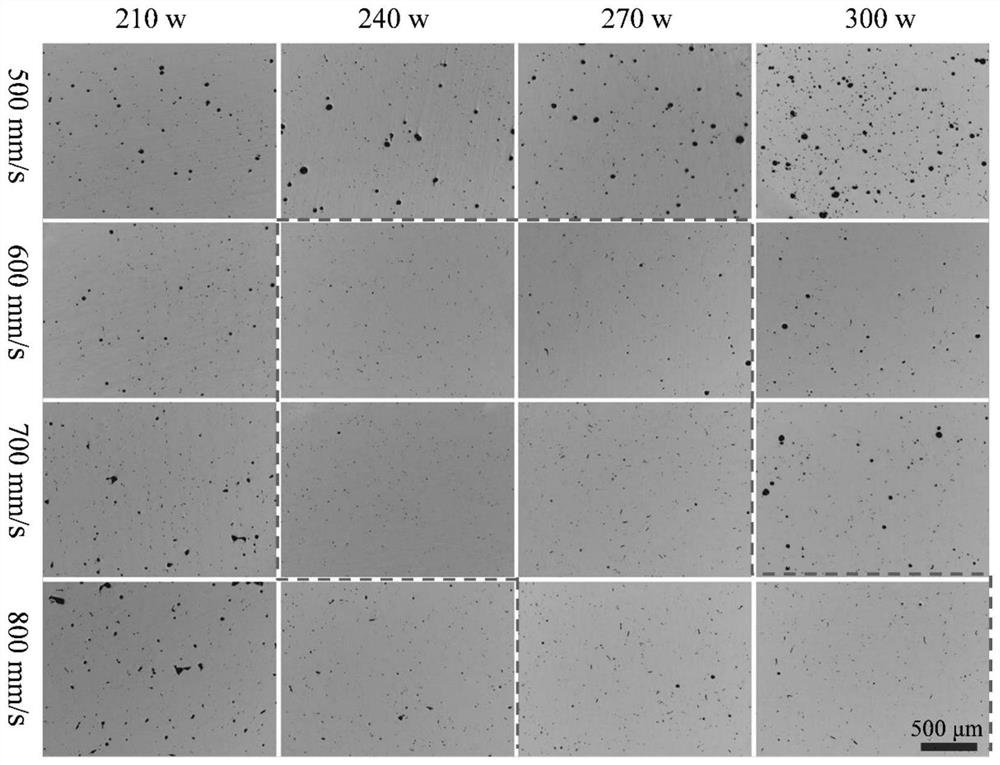

Crack-free nickel-based superalloy and component design method and preparation method thereof

The invention belongs to the field of metal additive manufacturing, and particularly discloses a crack-free nickel-based superalloy and a component design method and a preparation method thereof. The crack-free nickel-based superalloy comprises the following components in percentage by mass: 10.50%-11.00% of Mo, 24.50%-25.30% of Cr, 1.00%-1.50% of W, 4.00%-4.50% of Co, 10.00%-11.00% of Fe, 0.05%-0.08% of C, 0.60%-0.80% of Mn, 0-0.30% of Si and the balance of Ni. According to the nickel-based superalloy, the rapid solidification effect of the selective laser melting forming technology can be fully utilized, the strength of the GH3536 alloy can be remarkably improved, meanwhile, the microcrack defect of a traditional nickel-based superalloy in the selective laser melting forming process is remarkably reduced, and the mechanical property is excellent.

Owner:HUAZHONG UNIV OF SCI & TECH

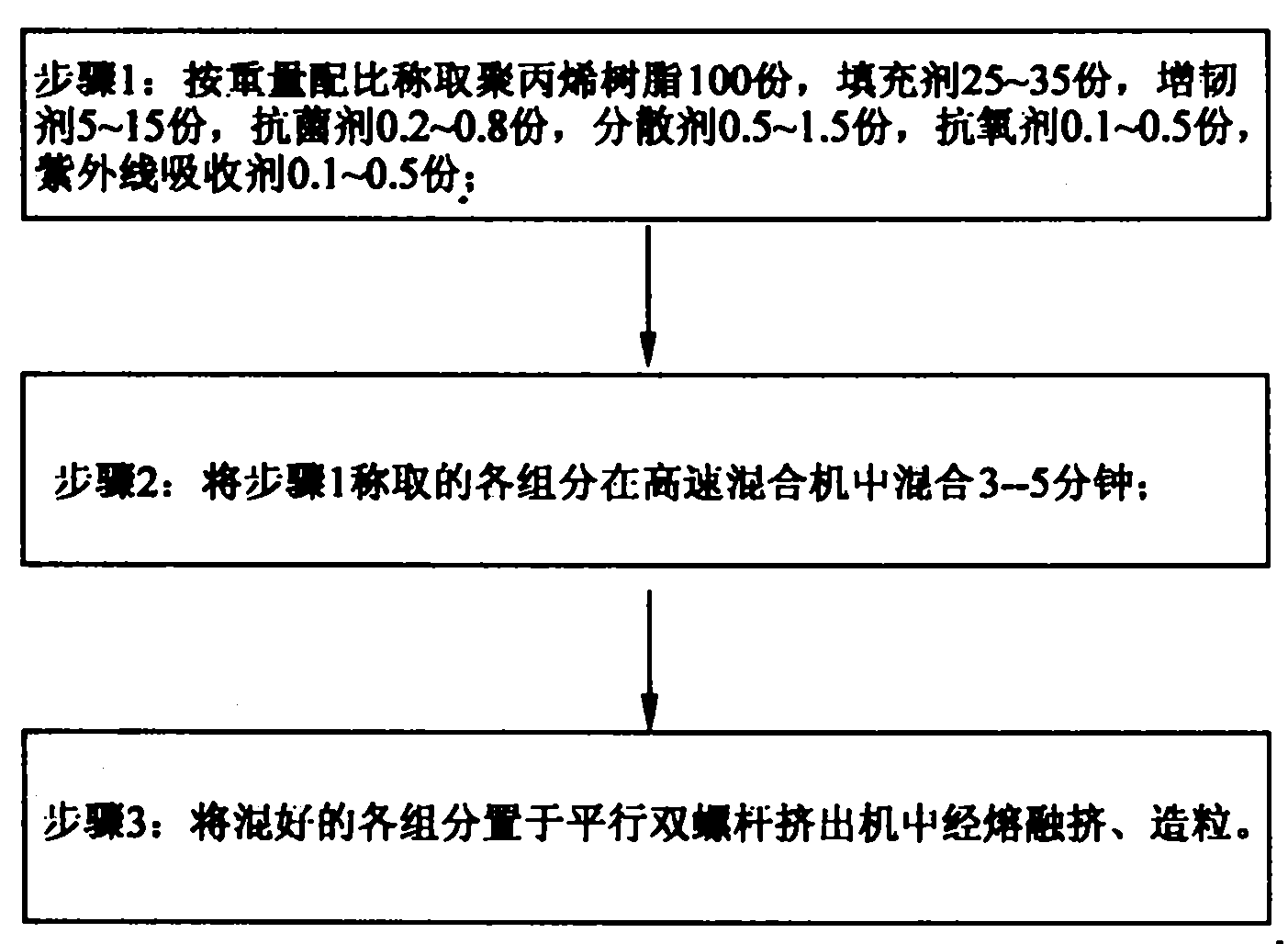

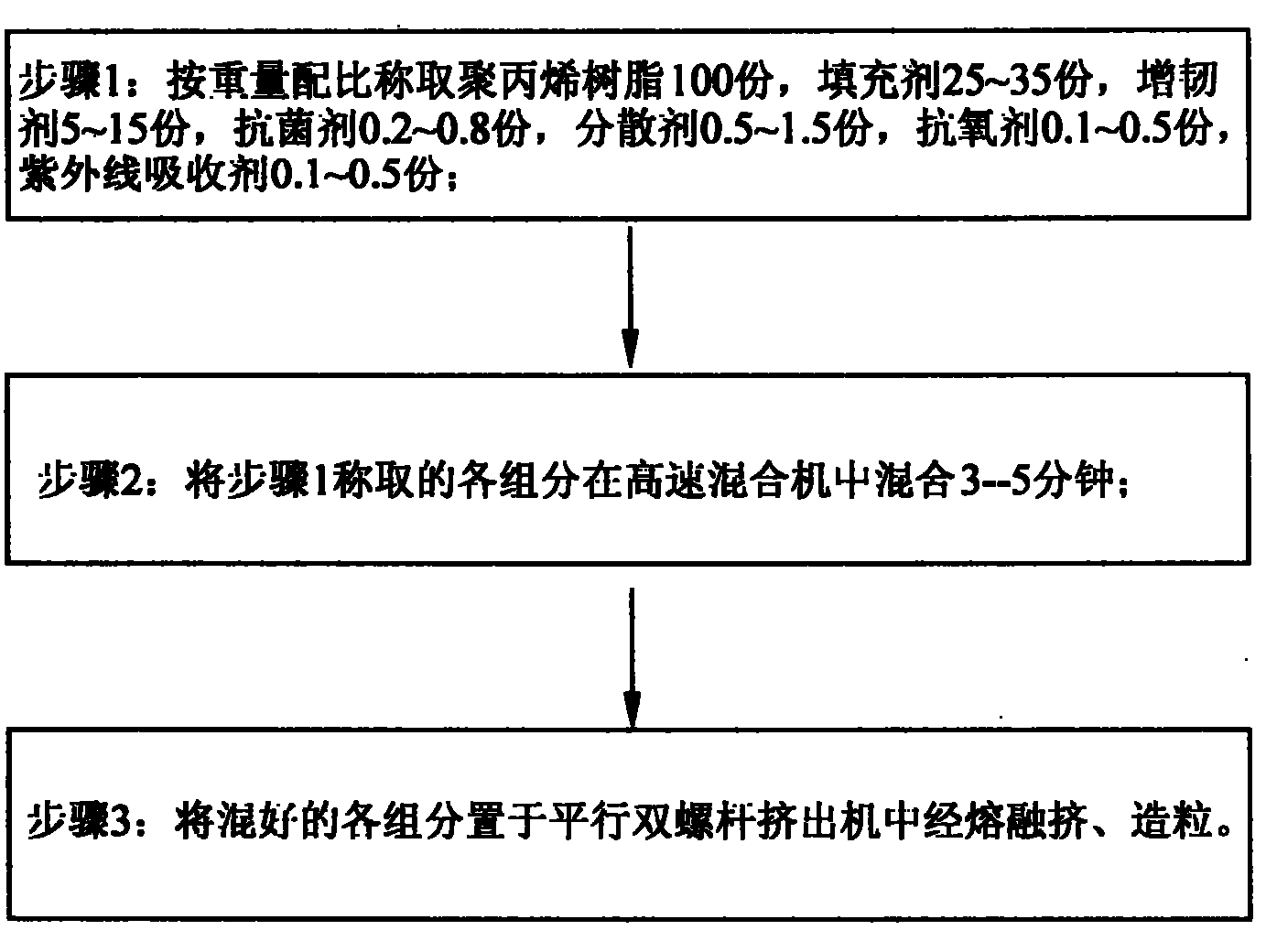

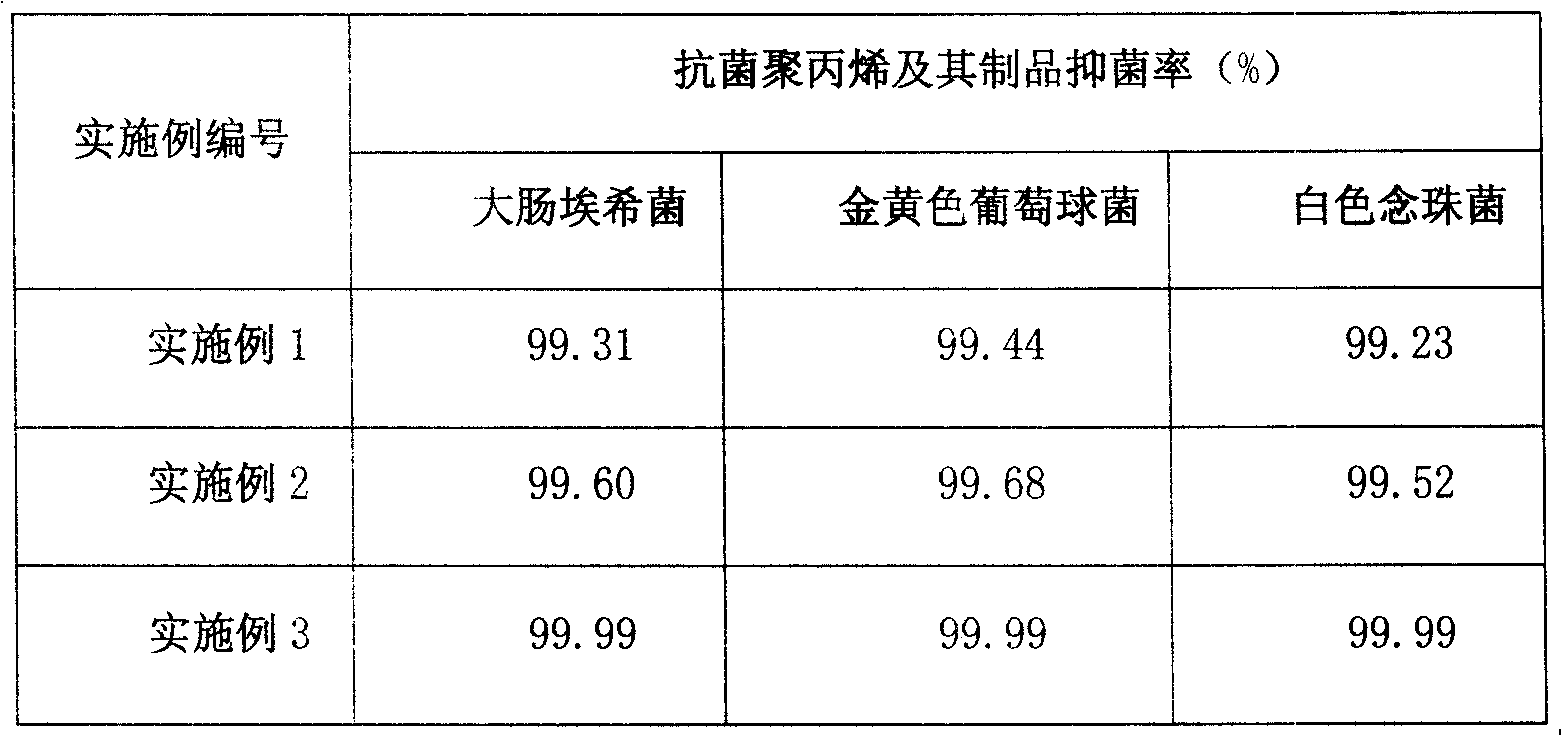

Antibacterial polypropylene material and its preparation process

InactiveCN101089038BReduce manufacturing costHigh surface glossBiocideAnimal repellantsUltravioletPolypropylene

The antibacterial polypropylene material consists of polypropylene resin 100 weight portions, stuffing 25-35 weight portions, toughening agent 5-15 weight portions, antiseptic 0.2-0.8 weight portion, dispersant 0.5-1.5 weight portions, antioxidant 0.1-0.5 weight portion and ultraviolet absorber 0.1-0.5 weight portion. The polypropylene resin is homopolypropylene, and the antiseptic is compounded with nanometer silver and organosilicon antiseptic. The present invention also provides the preparation process of the antibacterial polypropylene material with low production cost, excellent antiseptic performance.

Owner:SHENZHEN KEJU NEW MATERIAL

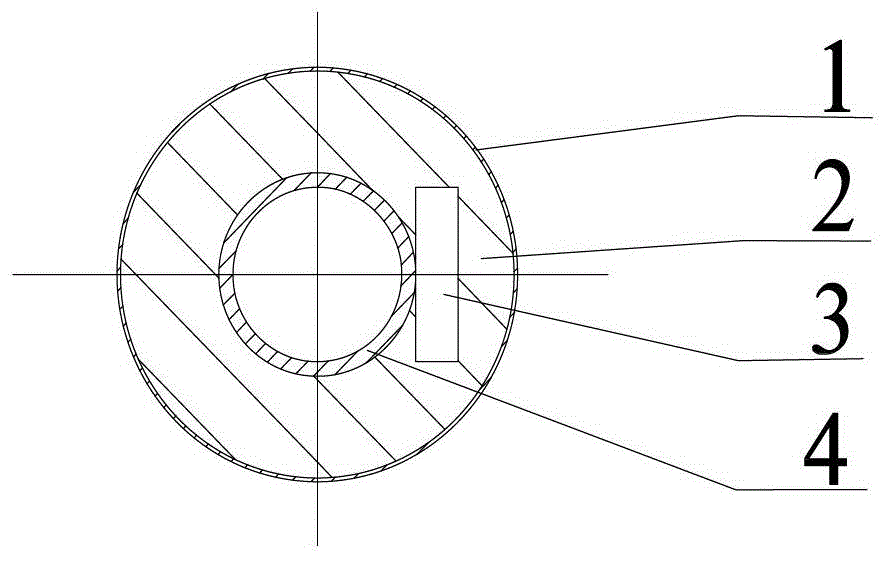

Thermal insulating pipe and manufacturing method of thermal insulating pipe

InactiveCN102913689AImprove aging resistanceImprove thermal oxidation resistanceThermal insulationPipe heating/coolingUltraviolet radiationUltraviolet

The invention provides a thermal insulating pipe and a manufacturing method of the thermal insulating pipe. The thermal insulating pipe is composed of a crosslinked polyethylene layer, a polyethylene thermal insulating layer and an ultraviolet radiation resisting polyethylene layer which are arranged from inside to outside in sequence, wherein an electric heating device is arranged between the crosslinked polyethylene layer and the polyethylene thermal insulating layer. Compared with the existing split-type single piece water conveying thermal insulating pipe, the thermal insulating pipe is an integer composed of the crosslinked polyethylene layer, the polyethylene thermal insulating layer, the ultraviolet radiation resisting polyethylene layer and the electric heating device; firstly, the aging resistance performance of the thermal insulating pipe is improved by the ultraviolet radiation resisting polyethylene layer; secondly, as the thermal insulating pipe is an integer, no thermal insulating materials need to be wrapped, so that the use is convenient, and the working quantity during the installation process is reduced; thirdly, as the electric heating device is added, the electric heating can be carried out, so that the liquid is prevented from being refrozen in a low temperature environment; and moreover the crosslinked polyethylene layer is used as the inner layer of a water conveying pipe, and crosslinking can be carried out slowing by using the heat of the liquid, thus the heat-resisting oxidation susceptibility of the water conveying pipe is improved.

Owner:青岛鑫三鸿塑胶制品有限公司

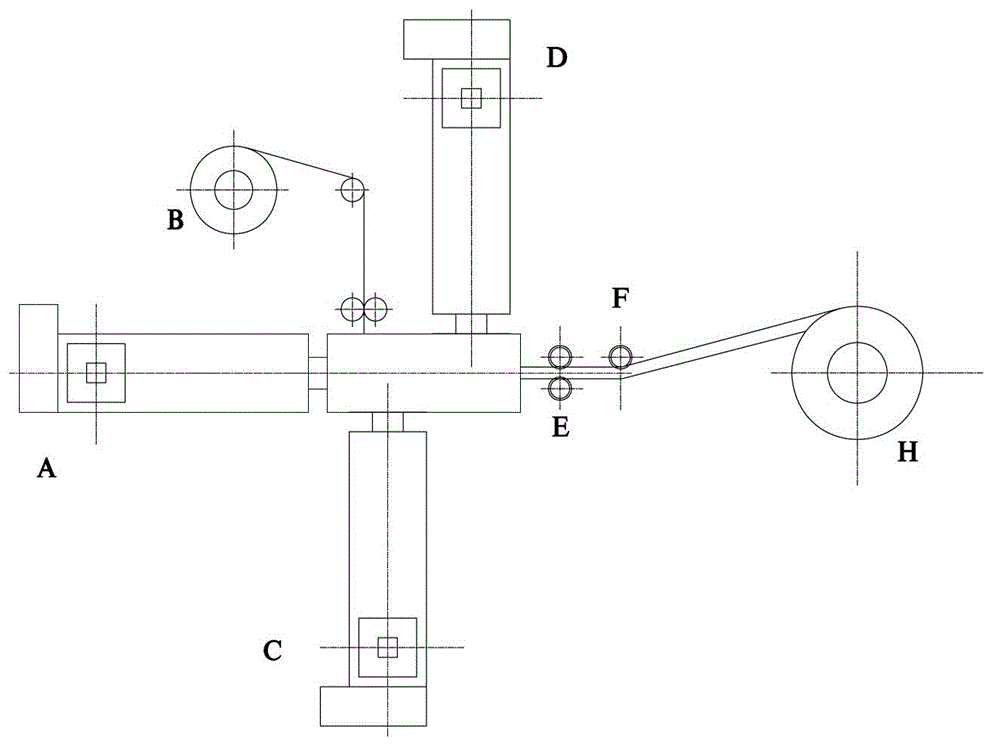

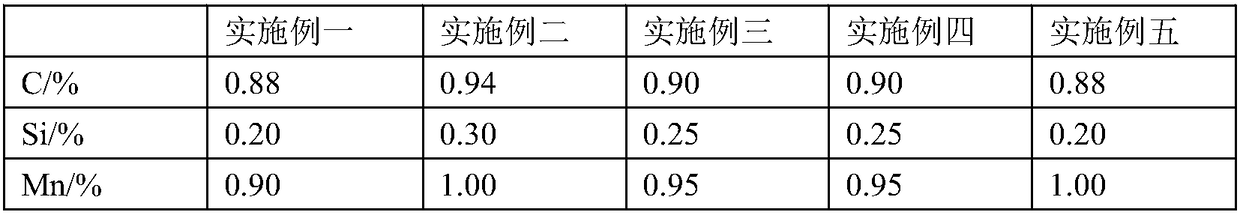

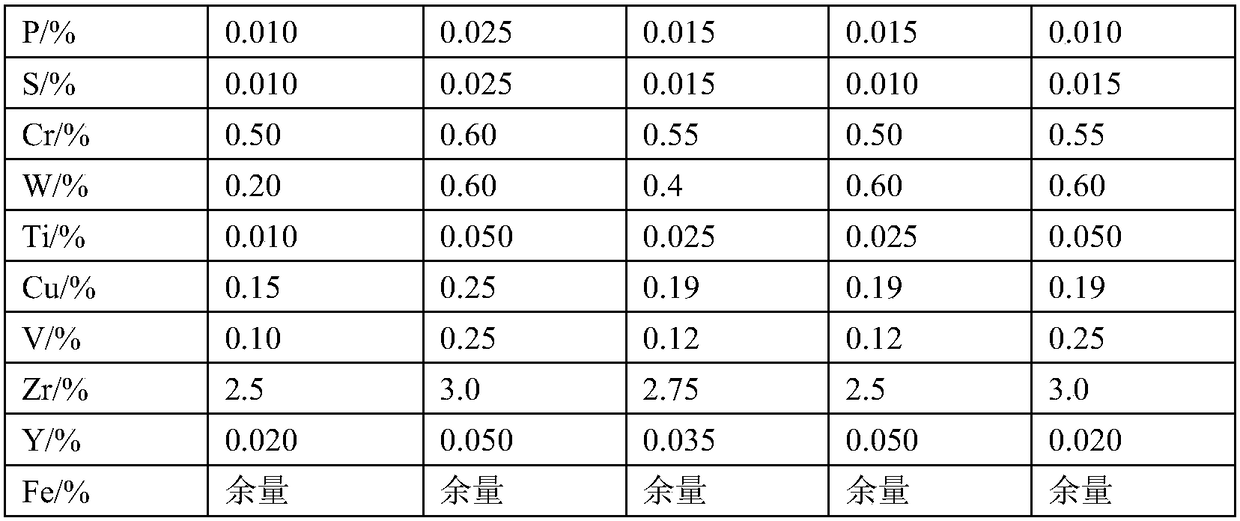

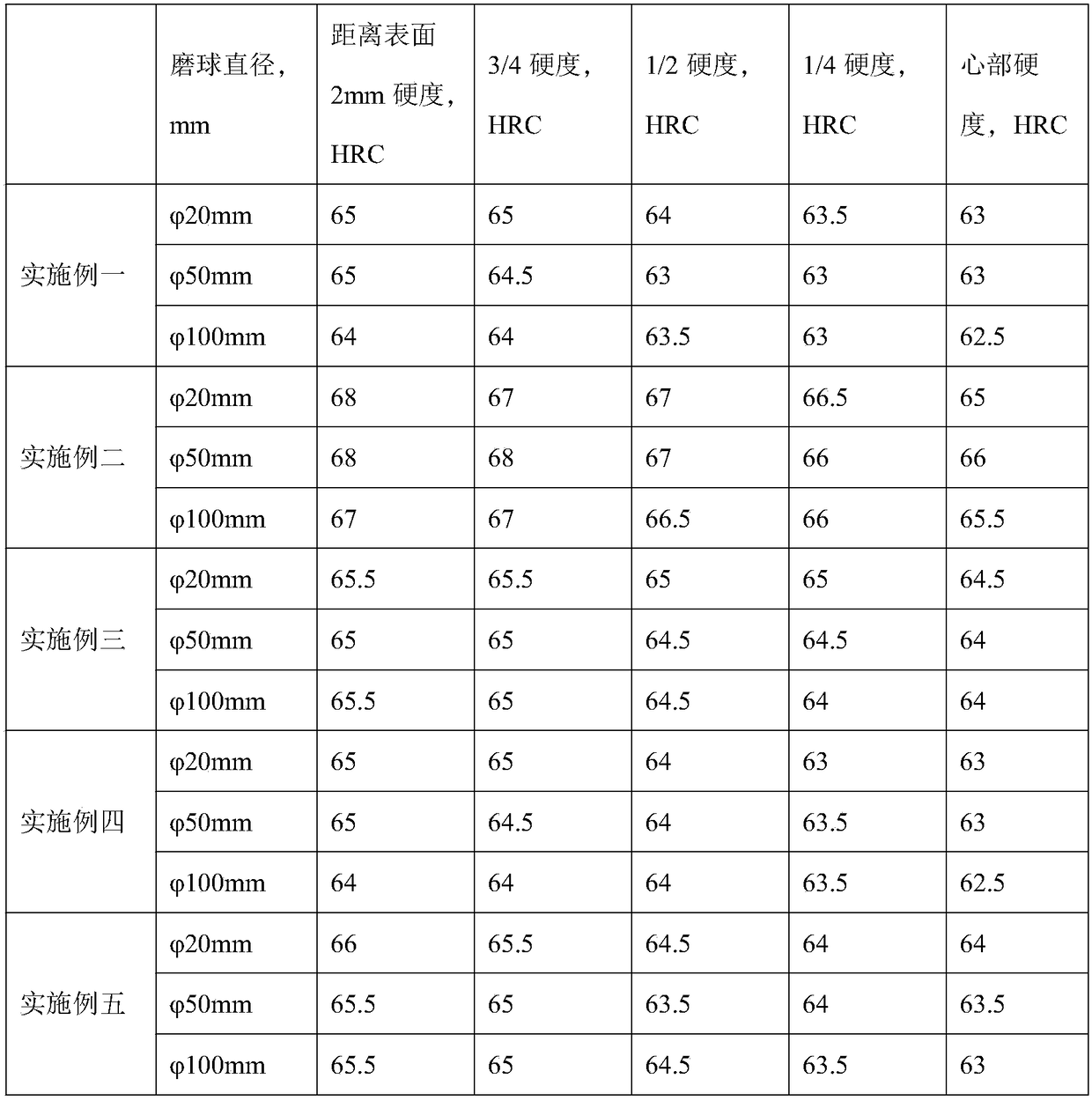

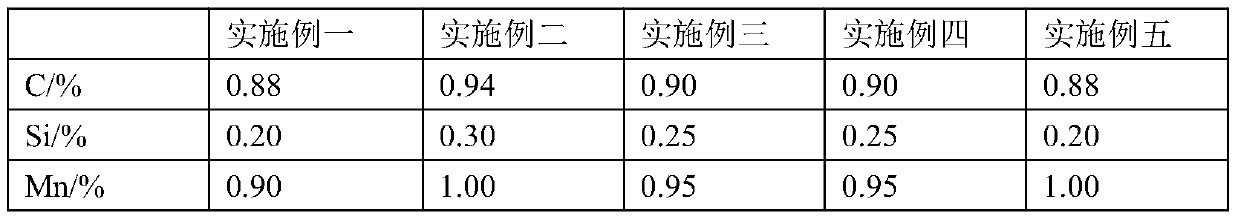

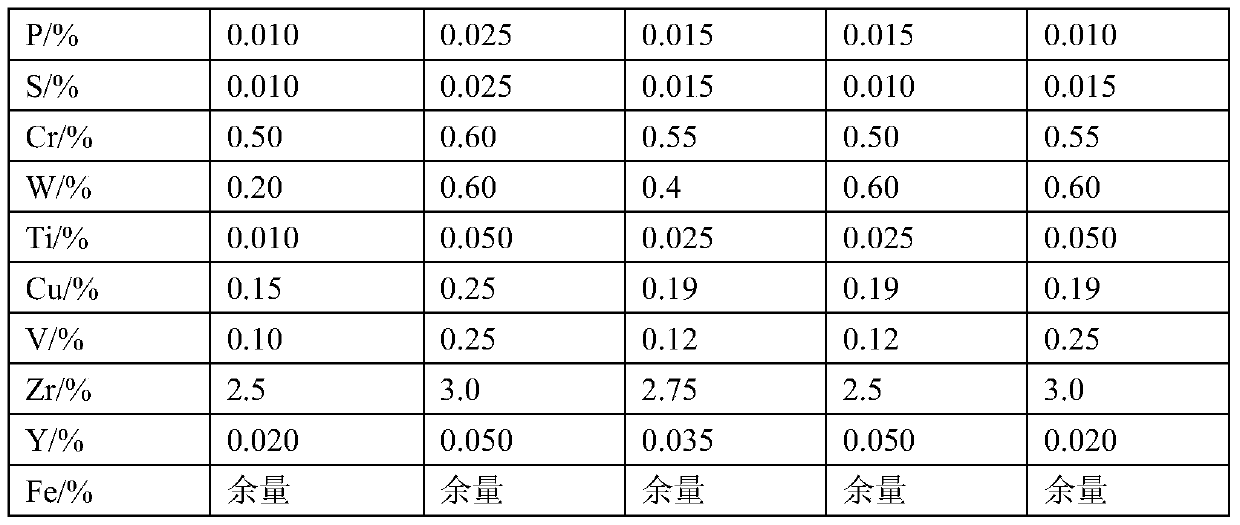

Wear-resistant steel and production process thereof

ActiveCN108315645AImprove wear resistanceHigh strengthProcess efficiency improvementWear resistantUltimate tensile strength

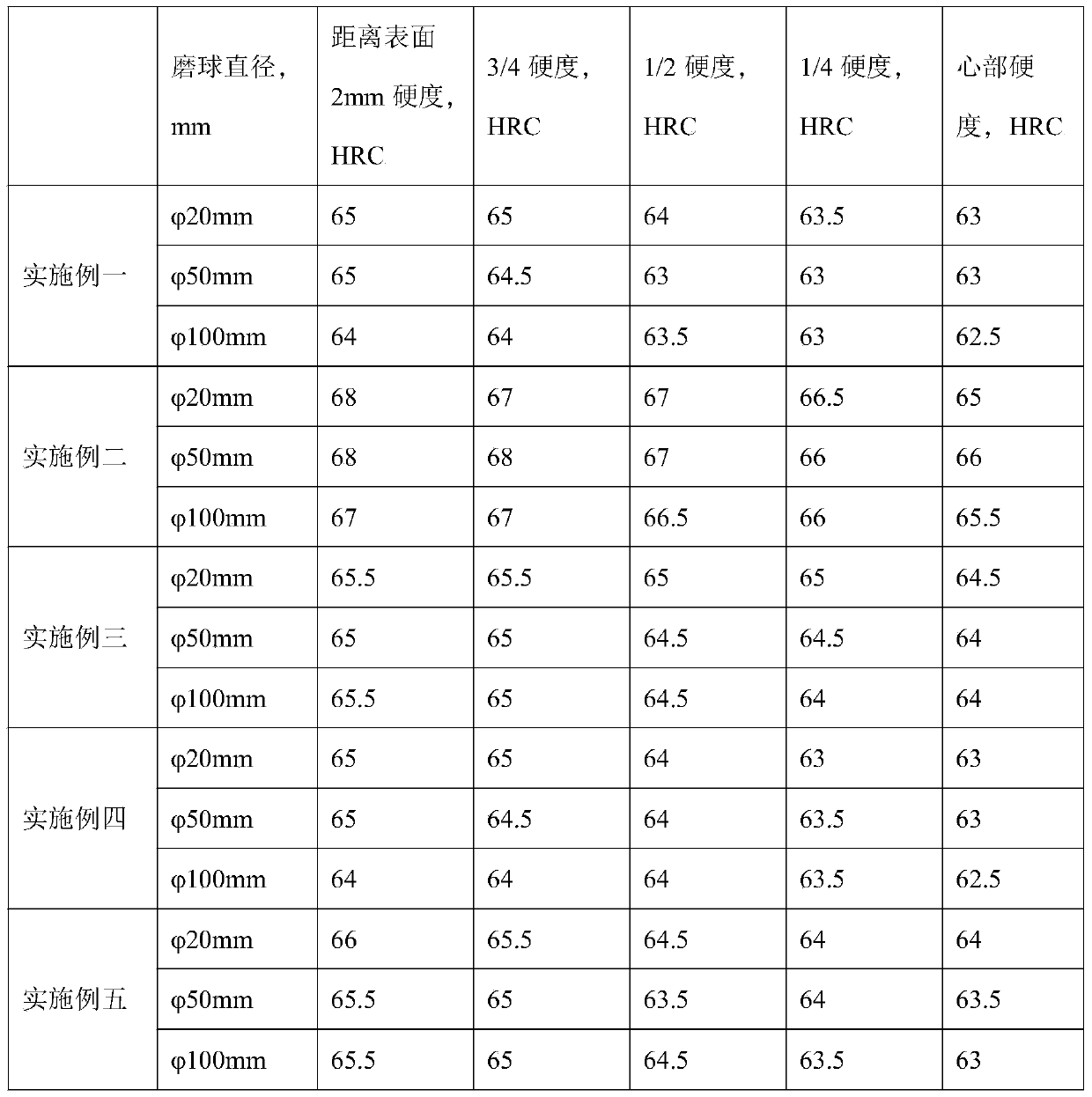

The invention relates to wear-resistant steel and belongs to the technical field of metal smelting. The wear-resistant steel is prepared from the following components in percent by mass: 0.88-0.94% ofC, 0.20-0.30% of Si, 0.90-1.00% of Mn, 0.50-0.60% of Cr, 0.20-0.60% of W, 0.10-0.25% of V, 2.50-3.00% of Zr, 0.010-0.050% of Ti, 0.020-0.050% of Y, less than or equal to 0.025% of P, less than or equal to 0.025% of S, less than or equal to 0.25% of Cu and the balance of Fe and inevitable impurities. The wear-resistant steel has the beneficial effects that the problems of low strength and poor wear resistance of the existing low-carbon wear-resistant steel is solved; the wear-resistant steel is finer in crystal and fuller in internal density, and a grinding ball prepared by the wear-resistantsteel is larger in hardness and good in wear resistance.

Owner:天津荣程联合钢铁集团有限公司

Laser cladding method for improving abrasion resistance of mechanical seal sleeve for pump

ActiveCN103981518AAchieving grain boundary strengtheningImprove wear resistanceMetallic material coating processesHardnessMaterials science

The invention provides a laser cladding method for improving the abrasion resistance of a mechanical seal sleeve for a pump. The laser cladding method comprises the following steps: carrying out surface treatment on an abrasion resistance part of the mechanical seal sleeve; carrying out fusion covering on the abrasion resistance part subjected to surface treatment by using nickel-based composite powder through a laser, wherein the nickel-based composite powder comprises the following chemical components in percentage by mass: 0.5-1% of C, 14-19% of Cr, 3.5-5% of Si, 3-4.5% of B, 2-4% of Cu, 2-4% of Mo, 8-9% of Fe, 0.3-0.5% of CeO, 0.5-1% of Ti, 2.5-3.5% of W and the balance of Ni; and carrying out wet-type grinding on the mechanical seal sleeve subjected to fusion covering, detecting and processing. After the mechanical seal sleeve for the pump is modified by laser cladding, the hardness of the mechanical seal sleeve for the pump can reach HRC (Rockwell hardness) 72-76, and the mechanical seal sleeve for the pump is anti-abrasive and meanwhile resists various chemical media.

Owner:HANGZHOU DAYE LASER TECH

Preparation method of polyphenyl thioether-organic montmorillonite composite material

InactiveCN106751832AImprove chroma variationImprove thermal oxidation resistanceMontmorilloniteOxidation resistant

The invention relates to the technical fields of synthetic resin and plastic, and particularly relates to a preparation method of a polyphenyl thioether-organic montmorillonite composite material. The preparation method of the polyphenyl thioether-organic montmorillonite composite material comprises the following steps of (1), the preparation of organic montmorillonite; (2), the preparation of the polyphenyl thioether-organic montmorillonite composite material; (3), the heat treatment of the polyphenyl thioether-organic montmorillonite composite material. According to the polyphenyl thioether-organic montmorillonite composite material made by the preparation method, the chrominance change of polyphenyl thioether which is subjected to the heat treatment is ameliorated; the thermal oxidation resistance effect of the polyphenyl thioether is improved; the oxidation resistance effect of the composite material is better.

Owner:SHAANXI HI-TECH IND CO LTD

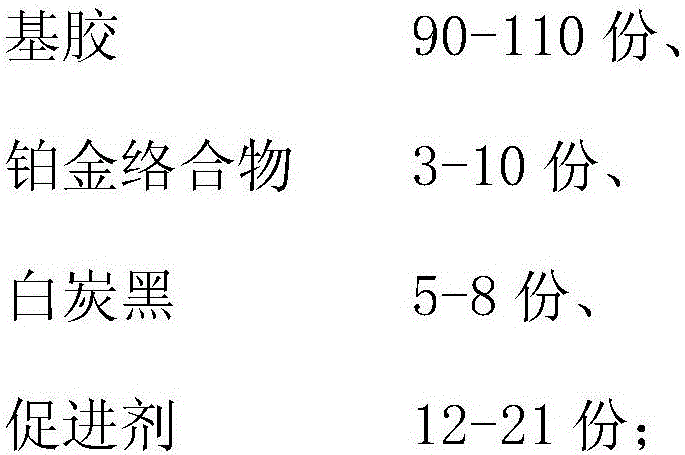

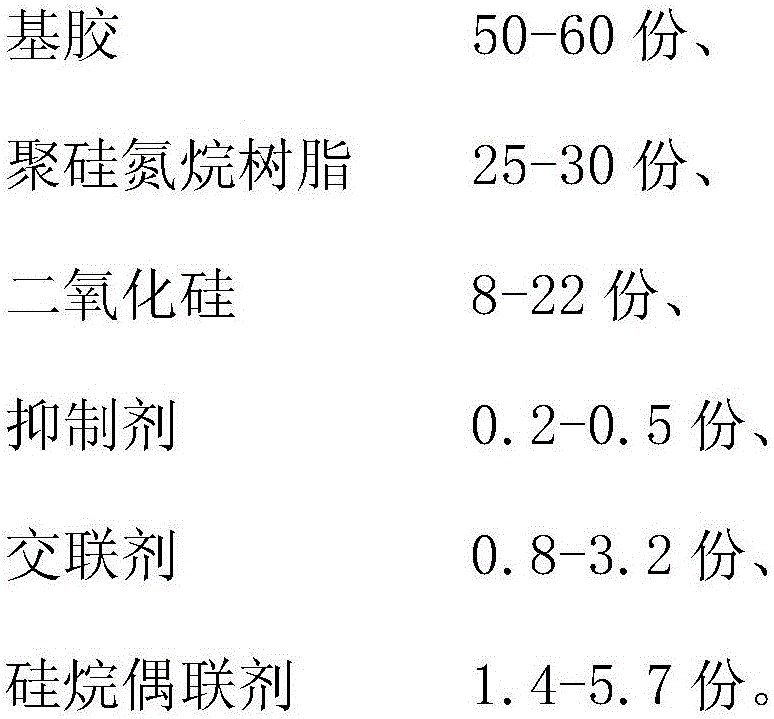

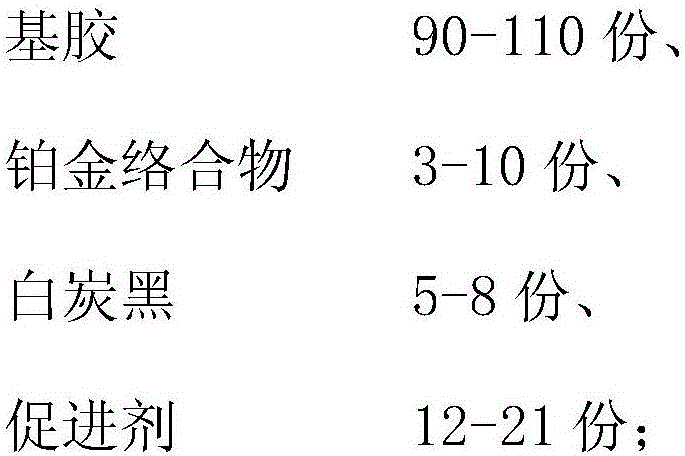

Antioxidant and high-temperature-resistant liquid silicone rubber and preparation method thereof

The invention relates to an antioxidant and high-temperature-resistant liquid silicone rubber which is prepared by mixing a component A with a component B at a weight ratio of 3: 40-18: 7; the component A comprises the following components in parts by weight: 90-110 parts of base rubber, 3-10 parts of a platinum complex, 5-8 parts of white carbon black and 12-21 parts of an accelerator; the components B comprises the following components in parts by weight: 50-60 parts of base rubber, 25-30 parts of polysiloxane resin, 8-22 parts of silica, 0.2-0.5 part of an inhibitor, 0.8 to 3.2 parts of a crosslinking agent and 1.4-5.7 parts of a silane coupling agent. The antioxidant and high-temperature-resistant liquid silicone rubber is relatively high in heat resistance and relatively good in oxidation resistance. The invention provides a preparation method of the liquid silicone rubber.

Owner:镇江高美新材料有限公司

Heat-resisting silicone oil composite

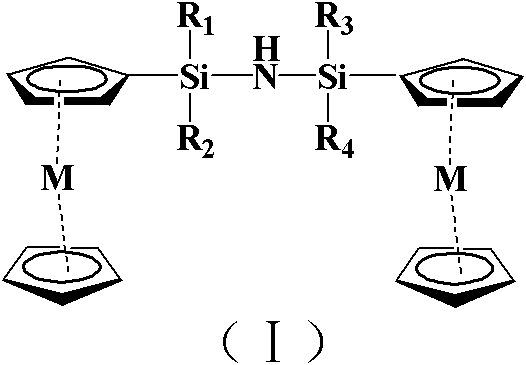

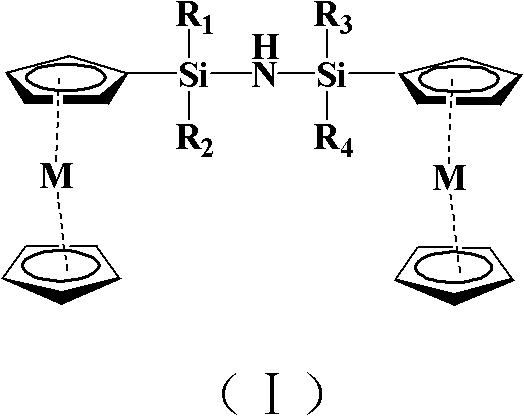

ActiveCN102220004AImprove thermal oxidation resistanceSmall heat lossHeat-exchange elementsSilazaneWeightlessness

The invention discloses a heat-resisting silicone oil composite comprising silicone oil and metallocene base silazane which is shown as a formula (1); the mass fraction ratio of the silicone oil and the metallocene base silazane shown as the formula (1) is 100:(0.001 to 5); in the formula (1), M is selected from Fe and Ru; and R1, R2, R3 and R4 are all selected from methyl, ethyl, propyl, butyl, octyl, methoxyl, ethyoxyl, ethylene, phenyl, tolyl, chlorphenyl and naphthyl. In the heat-resisting silicone oil composite, the heat-resisting oxidizability of the silicone oil is improved, thermal degradation damage of a molecular chain is reduced, heat weightlessness of the silicone oil is reduced, and the silicone oil has better heat-resisting comprehensive performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A kind of wear-resistant steel and its production process

ActiveCN108315645BRefining as-cast structureHigh hardnessProcess efficiency improvementWear resistantUltimate tensile strength

The invention relates to wear-resistant steel and belongs to the technical field of metal smelting. The wear-resistant steel is prepared from the following components in percent by mass: 0.88-0.94% ofC, 0.20-0.30% of Si, 0.90-1.00% of Mn, 0.50-0.60% of Cr, 0.20-0.60% of W, 0.10-0.25% of V, 2.50-3.00% of Zr, 0.010-0.050% of Ti, 0.020-0.050% of Y, less than or equal to 0.025% of P, less than or equal to 0.025% of S, less than or equal to 0.25% of Cu and the balance of Fe and inevitable impurities. The wear-resistant steel has the beneficial effects that the problems of low strength and poor wear resistance of the existing low-carbon wear-resistant steel is solved; the wear-resistant steel is finer in crystal and fuller in internal density, and a grinding ball prepared by the wear-resistantsteel is larger in hardness and good in wear resistance.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

Low smoke zero halogen flame retardant crosslinking polyolefin jacket material and preparation method thereof

InactiveCN109054164AImprove thermal oxidation resistanceImprove flame retardant performancePolymer sciencePolyolefin

The invention provides a low smoke zero halogen flame retardant crosslinking polyolefin jacket material. The low smoke zero halogen flame retardant crosslinking polyolefin jacket material comprises the following components in parts by weight: 55-65 parts of ethylene-vinyl acetate polymer, 35-50 parts of polyethylene, 5-8 parts of carbon black, 6-8 parts of melamine polyphosphates, 55-65 parts of modified aluminum hydroxide, 0.1-0.2 part of dicumyl peroxide, 1.5-2.0 parts of a silane coupling agent, 1-2 parts of barium stearate, 1-2 parts of polyethylene wax, 2-3 parts of talcum powder, 0.5-0.6part of a light stabilizer and 2-5 parts of an antioxidant, wherein the modified aluminum hydroxide is titanate modified aluminum hydroxide. The low smoke zero halogen flame retardant crosslinking polyolefin jacket material makes the thermal oxidation resistance and flame retardant capability of the material be greatly improved, and meanwhile has the good mechanical performance. The invention further provides a preparation method of the low smoke zero halogen flame retardant crosslinking polyolefin jacket material, and the preparation method is reasonable in design, easy and convenient to operate, high in raw material utilization rate and can easily achieve industrialized production.

Owner:ANHUI TELI SCI & TECH

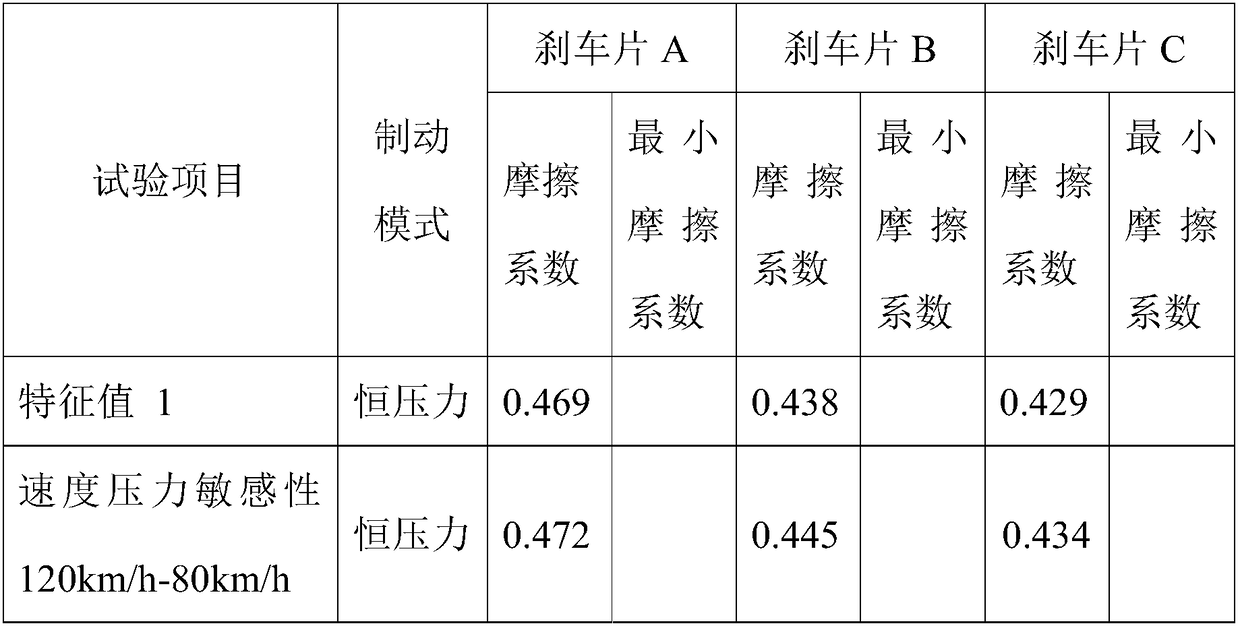

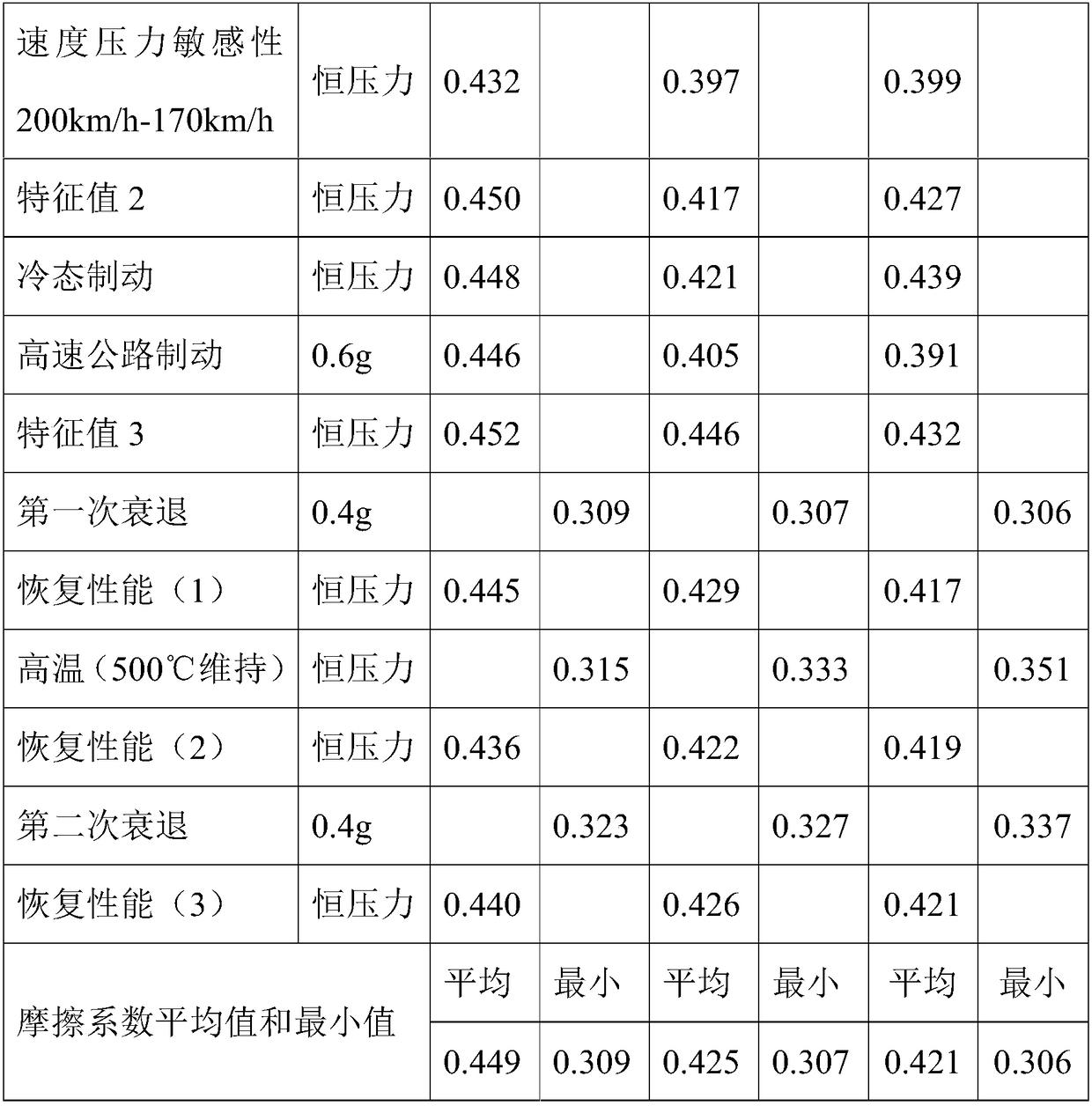

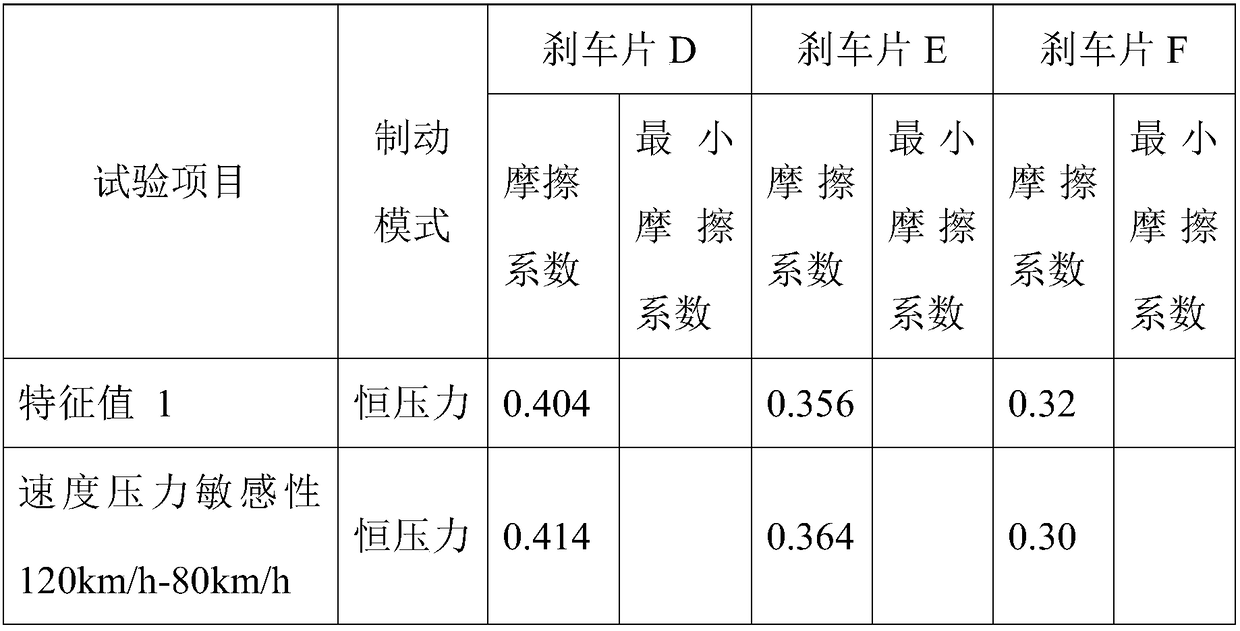

Friction material, organic carbon-ceramic brake pad for light-weight carbon-ceramic plate prepared from friction material, as well as preparation method and application thereof

InactiveCN109404450AImprove strengthHigh strengthOther chemical processesFriction liningTotal organic carbonBasalt fiber

The invention relates to the technical field of brake materials, in particular to a friction material, an organic carbon-ceramic brake pad for a light-weight carbon-ceramic plate prepared from the friction material, as well as a preparation method and application thereof. The organic carbon-ceramic brake pad for the light-weight carbon-ceramic plate is prepared from the following raw materials including, by weight, 2 to 4 parts of basalt fiber, 10 to 15 parts of steel fiber, 5 to 10 parts of mineral fiber, 8 to 12 parts of phenolic resin, 5 to 10 parts of elastic particles, 6 to 10 parts of cashew nut oil friction powder, 10 to 20 parts of precipitated barium sulphate, 1 to 3 parts of acrylic fiber, 2 to 4 parts of silicon carbide, 6 to 11 parts of kieselguhr and 9 to 12 parts of glass beads. The preparation method is pressing and thermosetting forming. The organic carbon-ceramic brake pad for the light-weight carbon-ceramic plate provided by the invention is stable in structure, goodin heat resistance and friction performance, simple in preparation process, and short in preparation period, and has good compatibility with the light-weight carbon-ceramic plate and good practicability so as to form a light-weight friction pair, so that the light weight of a vehicle can be effectively realized.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

High-gloss and high-impact resistance PS / PP composite for manufacturing telephone case and preparation method thereof

The invention discloses a high-gloss and high-impact resistance PS / PP composite for manufacturing a telephone case and a preparation method thereof. The composite is mainly prepared by the following raw materials by weight portion: 100 portions of PS resin, 20-60 portions of PP resin, 5-15 portions of compatilizer, 3-30 portions of flexibilizer, 0.1-0.9 portion of nucleator and 0.1-0.9 portion of antioxidant. The PS raw material and the PP raw material are fused together by the special compatilizer. The prepared composite has the high-gloss and high-impact resistance features and excellent physical and mechanical properties, and can be used for replacing ABS to manufacture the telephone case. The composite has the characteristics of simple preparation technology, stable size, high gloss, high impact resistance, low cost, and the like.

Owner:ANHUI KEJU NEW MATERIALS

Fluorescent ageing resistant coating for electronic equipment

InactiveCN109321022AImprove mechanical propertiesImprove hydrolysis resistanceFireproof paintsLuminescent paintsFluorescencePolyethylene glycol

The invention discloses a fluorescent ageing resistant coating for electronic equipment. The fluorescent ageing resistant coating for the electronic equipment is prepared from the following componentsincluding vinyl acetate, ethyl alcohol, a comonomer, polyvinylpyrrolidone, acetone, n-butyl acetate, trimethylolpropane, (fluorene-2-yl)-5-(N-ethylcarbazole-3-yl) ketene, polyethylene glycol adipate,a thickener, phenol, filler, azodiisobutyronitrile, ethylene glycol, phenylhydrazine, concentrated hydrochloric acid, glacial acetic acid, potassium dichromate, acetic anhydride and toluene diisocynate. Through blending modification, the fluorescent ageing resistant coating provided by the invention has excellent mechanical performance, ageing resistance and better wear resistance, is uniform andstable, can keep properties stable on the surface of the electronic equipment, is good in heat resistance, excellent in ageing resistance and relatively low in cost and can prolong the service life of the electronic equipment.

Owner:蚌埠心里程教育科技有限公司

Oxidation-resistant high-heat-conductivity maleic-anhydride-grafted polyphenyl ether modified epoxy resin composite material for LED packaging and preparation method thereof

The invention discloses an oxidation-resistant high-heat-conductivity maleic-anhydride-grafted polyphenyl ether modified epoxy resin composite material for LED packaging. According to the composite material, epoxy resin is modified through grafted polyphenyl ether; the polyphenyl ether obtained after maleic anhydride, nano titania and other raw materials are grafted maintains the excellent properties of low dielectric, low loss and high heat resistance, compatibility between the polyphenyl ether and the epoxy resin is improved, and the defects of traditional epoxy resin serving as a packaging material are effectively overcome; added nano copper and aquadag powder are good in adhesiveness, improve the heat conducting capacity, heat dissipating capacity and heat oxidation resisting capacity of the composite material, delay heat ageing of the material and also can shield certain electromagnetic radiation and delay ageing of the material. Serving as an LED packaging material, the prepared modified composite epoxy resin is excellent in overall performance, long in service life, more economical and more durable.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

A kind of lignin-based antioxidant for polyolefin and its preparation method and application

The invention relates to the technical field of antioxidants, in particular to a lignin based antioxidant for polyolefin, a preparation method and an application. The lignin based antioxidant is prepared from the following raw materials in parts by weight: 100 parts of industrial lignin, 50-200 parts of a modified monomer, 3-10 parts of an organic basic catalyst and 500 parts of a solvent, wherein the modified monomer is 3,5-di-tert-butyl-4-hydroxyphenylpropionyl chloride. The preparation method comprises the following steps: (1) stirring and mixing the industrial lignin and the solvent uniformly; (2) then, adding the modified monomer and the organic basic catalyst in sequence for a reaction for 12-72 h at 40-80 DEG C, precipitating the product with a precipitant, and performing suction filtration, washing and drying to obtain the lignin based antioxidant for polyolefin. The industrial lignin is from recycled pulping and papermaking waste liquor and the bioethanol industry, is low in price and renewable; the preparation method is simple, the cost is low, the prepared lignin based antioxidant has outstanding performance and is of great significance in promoting application and development of polyolefin and high value-added utilization of the industrial lignin.

Owner:WUHAN TEXTILE UNIV

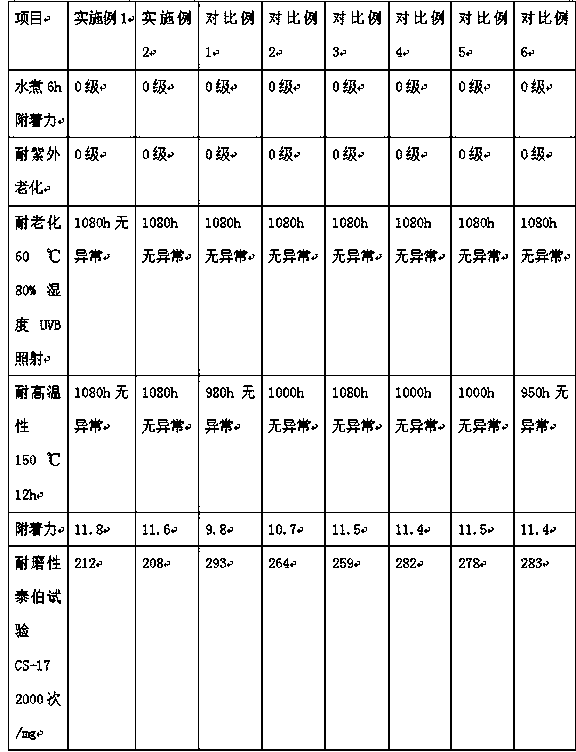

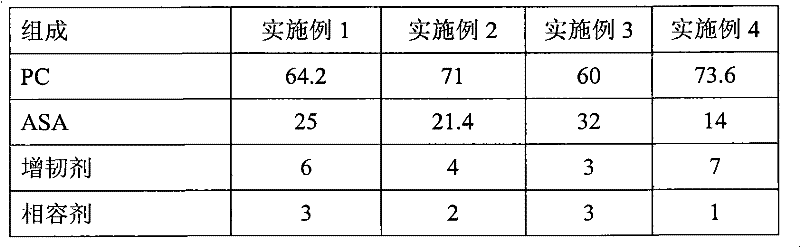

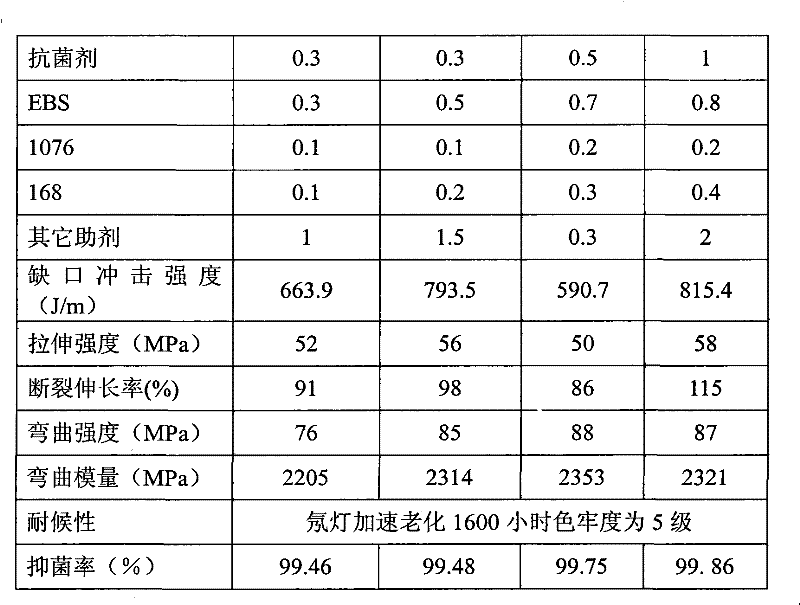

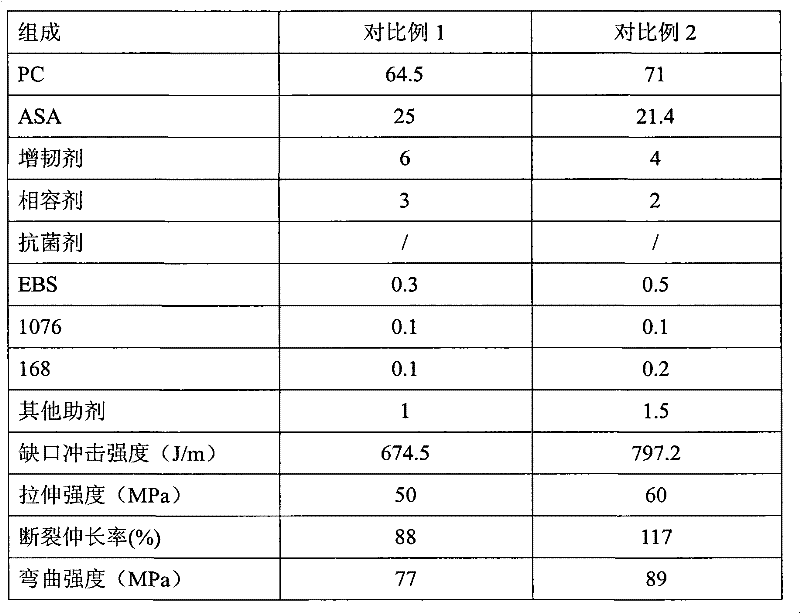

Weatherproof and antibacterial polycarbonate engineering plastic and preparation method thereof

The invention discloses a weatherproof and antibacterial polycarbonate engineering plastic and a preparation method thereof. The engineering plastic is prepared from the following raw materials in part by weight: polycarbonate, weatherproof resin ASA, an antibacterialagent, a flexibilizer, a compatilizer, a dispersing agent, an antioxygen and other aids. The preparation method comprises the following steps: a, respectively performing force air drying on the polycarbonate and the weatherproof resin ASA; b, weighing the antibacterialagent and the dispersing agent, and mixing the two uniformly; c, weighing the flexibilizer, the compatilizer, the antioxygen and other aids, and putting into a super mixer for dry mixing, together with raw materials in step a and step b; and d, putting the mixedmaterials in the step c into a twin-screw extruder, and performing melt extrusion for granulation. The weatherproof and antibacterial polycarbonate engineering plastic has the advantages of ageing resistance, yellowing resistance, good weatherability, and durable antibacterial function.

Owner:SHENZHEN KEJU NEW MATERIAL

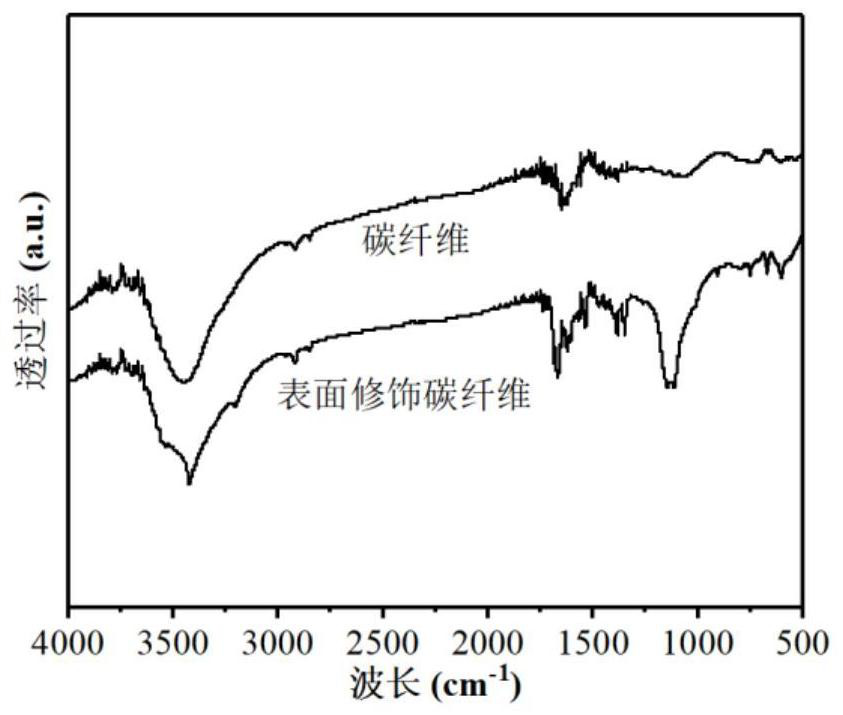

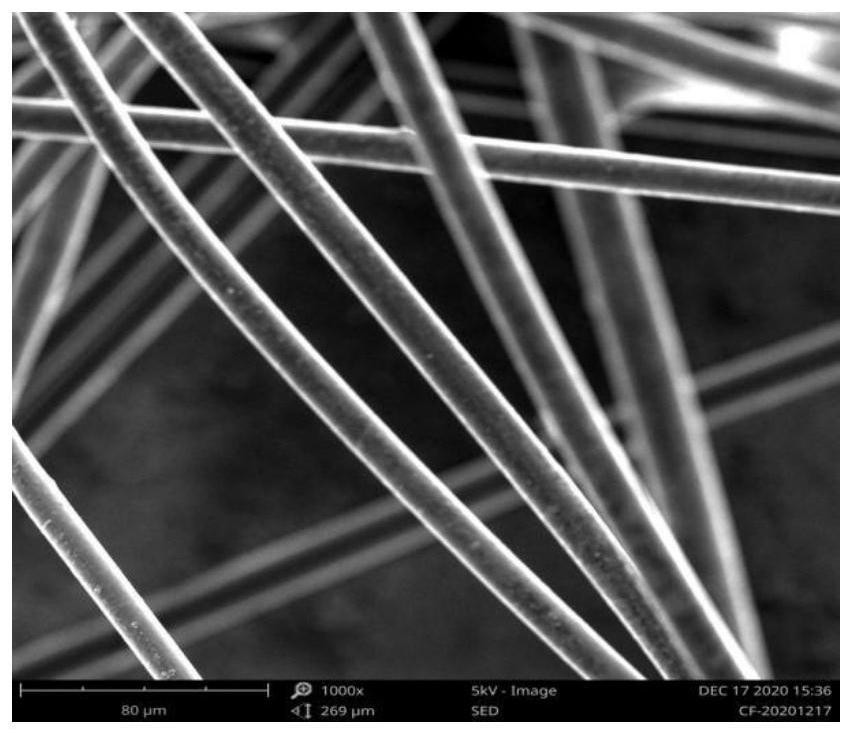

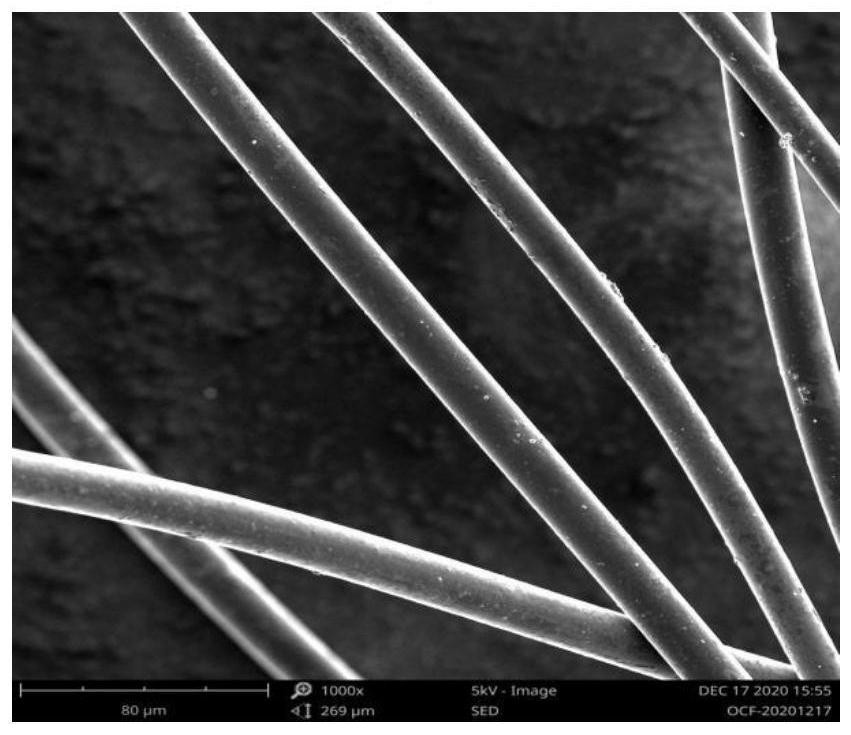

Magnesium oxide ceramic composite carbon fiber and preparation method thereof

ActiveCN114736028AThe preparation process is stableImprove product qualityCarbon fibresOxide ceramicCarbon fibers

The invention relates to a magnesium oxide ceramic composite carbon fiber and a preparation method thereof. The composite carbon fiber is a ceramic surface modified carbon fiber coated by magnesium oxide sol. The highest heat-resistant oxidation temperature of the composite carbon fiber in air reaches 1540 DEG C. The monofilament tensile strength of the composite carbon fiber is 0.5 to 1.1 GPa. Compared with the prior art, the magnesium oxide ceramic composite carbon fiber has the beneficial effects that the magnesium oxide ceramic composite carbon fiber has excellent thermal oxidation resistance and monofilament tensile property. The magnesium oxide ceramic composite carbon fiber can be potentially applied to the fields of advanced aero-engines, advanced nuclear energy and the like, and is simple in preparation method, low in cost and suitable for large-scale production, and raw materials are easy to obtain.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

A crack-free nickel-based superalloy and its composition design method and preparation method

The invention belongs to the field of metal additive manufacturing, and specifically discloses a non-crack nickel-based superalloy and its composition design method and preparation method. In terms of mass percentage, the composition of the non-crack nickel-based superalloy is: Mo: 10.50%~ 11.00%, Cr: 24.50% to 25.30%, W: 1.00% to 1.50%, Co: 4.00% to 4.50%, Fe: 10.00% to 11.00%, C: 0.05% to 0.08%, Mn: 0.60% to 0.80% , Si: 0-0.30%, the balance being Ni. The nickel-based superalloy can make full use of the rapid solidification effect of the laser selective melting forming technology, which can significantly improve the strength of the GH3536 alloy, and at the same time significantly reduce the micro-crack defects and mechanical properties of the traditional nickel-based superalloy in the laser selective melting forming process. superior.

Owner:HUAZHONG UNIV OF SCI & TECH

Maleic anhydride-grafted polyphenyl ether modified epoxy resin composite used for LED packaging and preparation method thereof

The invention discloses a maleic anhydride-grafted polyphenyl ether modified epoxy resin composite used for LED packaging. A polyphenyl ether material obtained after grafting by raw materials like maleic anhydride and nanometer titanium dioxide maintains excellent low dielectric performance, low loss and high heat resistance and has improved compatibility with epoxy resin, so the defects of the epoxy resin as a packaging material are effectively improved; blended talcum powder having undergone surface roughening by hydrofluoric acid has a greater contact surface with the resin and better adsorptivity and can improve ultraviolet resistance and toughness of the composite; and added nanometer zirconia further improves the thermal conduction speed of the composite, enhances thermal oxidation resistance of the resin and alleviates thermal ageing. The composite prepared in the invention has excellent mechanical properties and dielectric properties, long service life, economic performance and durability when used as an LED packaging material.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

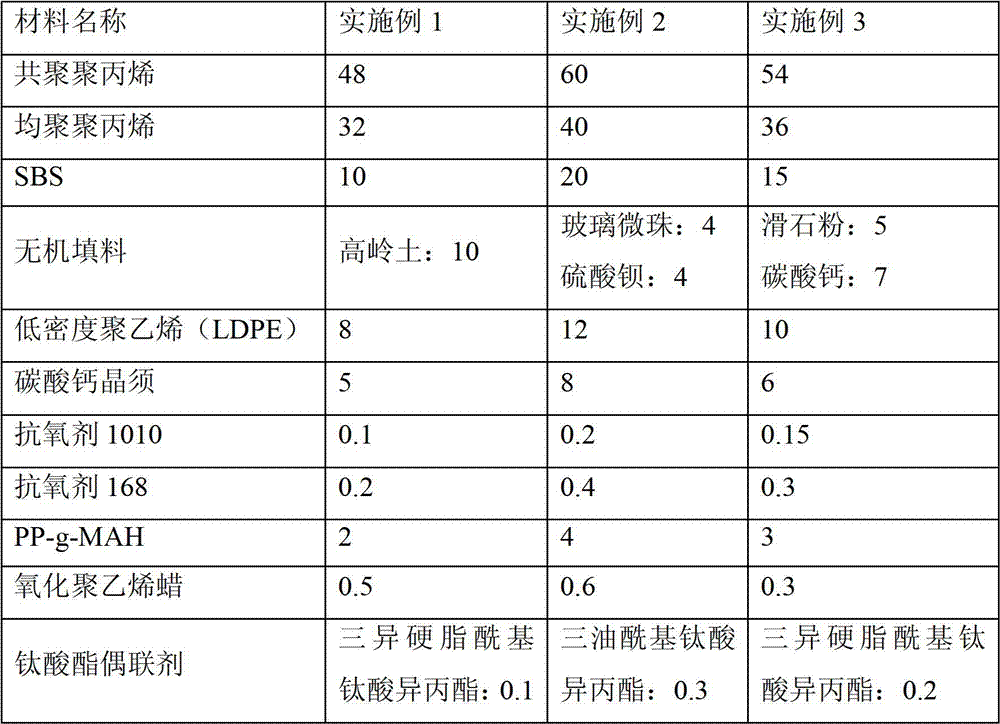

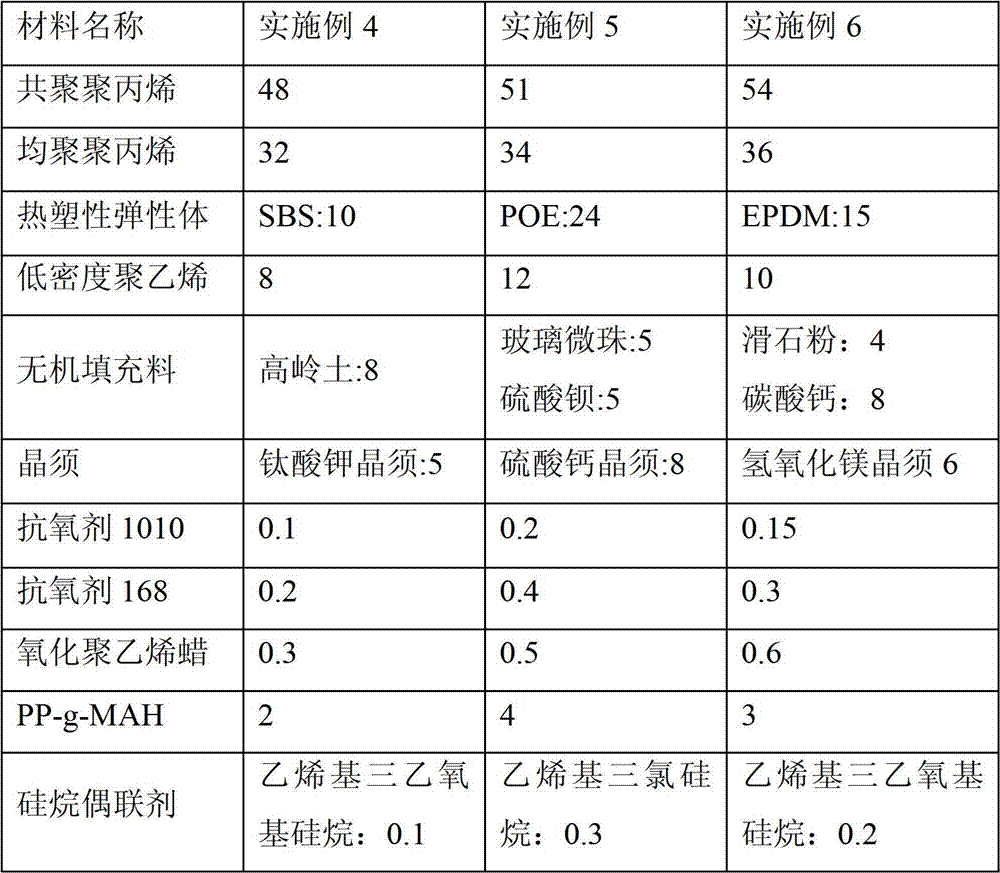

A kind of polypropylene composite material and its preparation method and application

ActiveCN103571059BSurface gloss is equal toUniform colorCoatingsLow-density polyethyleneCrack resistance

The invention belongs to the field of organic high molecular compounds, and relates to a polypropylene composite material as well as a preparation method and use thereof. The polypropylene composite material is prepared from the following components in parts by weight: 80-100 parts of polypropylene, 10-20 parts of thermoplastic elastomers, 8-12 parts of low density polyethylene, 8-12 parts of inorganic filler, 5-8 parts of crystal whiskers, 0.3-0.6 part of an antioxidant, 0.3-0.6 part of oxidized polyethylene wax, 2-4 parts of polypropylene-grafted maleic anhydride and 0.1-0.3 part of a coupling agent. The polypropylene composite material disclosed by the invention can be used for preparing steering wheels. The product produced by using the composite material has the advantages of uniform surface gloss, uniform color, comfortable feel, good stress cracking resistance, good comprehensive mechanical property and the like.

Owner:LIAONING LIAOJIE SCI & TECH

A kind of insulation pipe and its preparation method

InactiveCN102913689BImprove aging resistanceImprove thermal oxidation resistanceThermal insulationPipe heating/coolingAging resistanceEngineering

Owner:青岛鑫三鸿塑胶制品有限公司

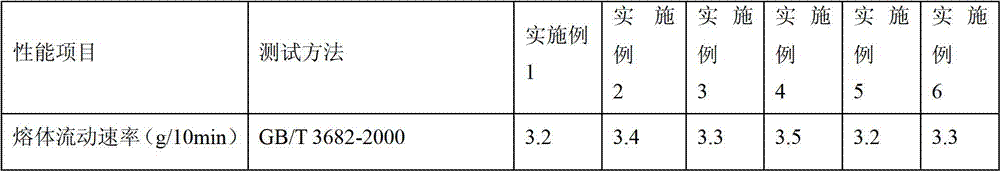

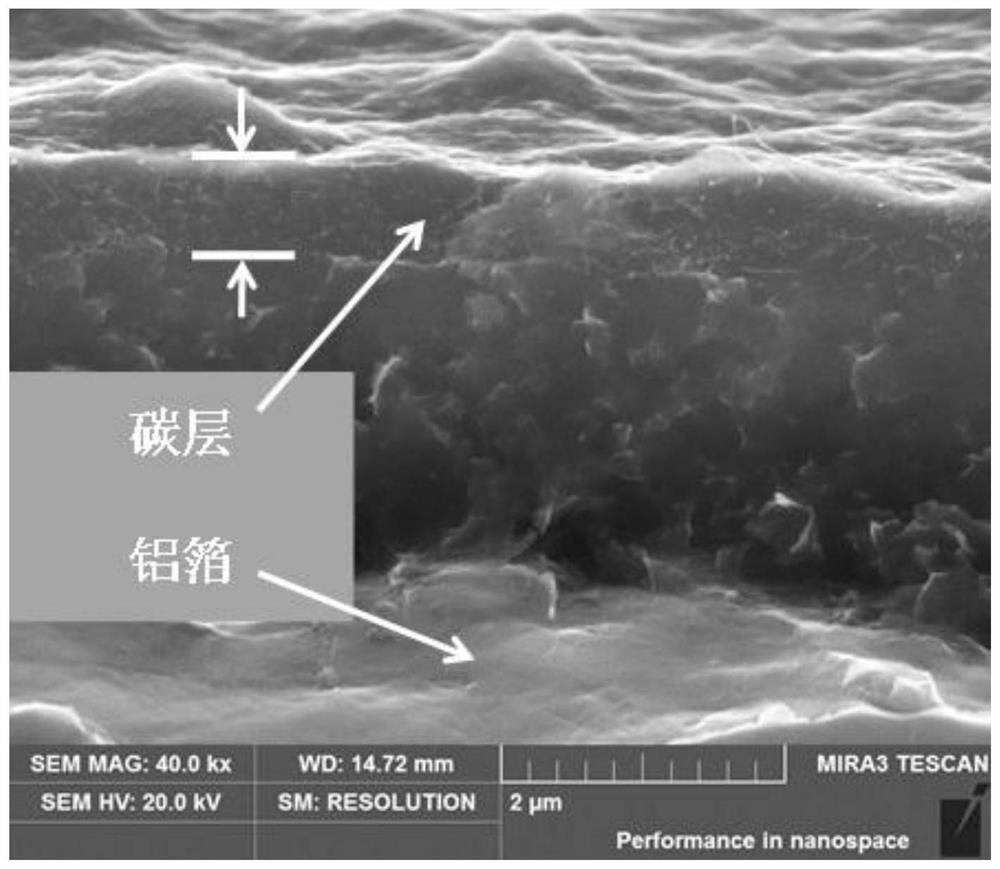

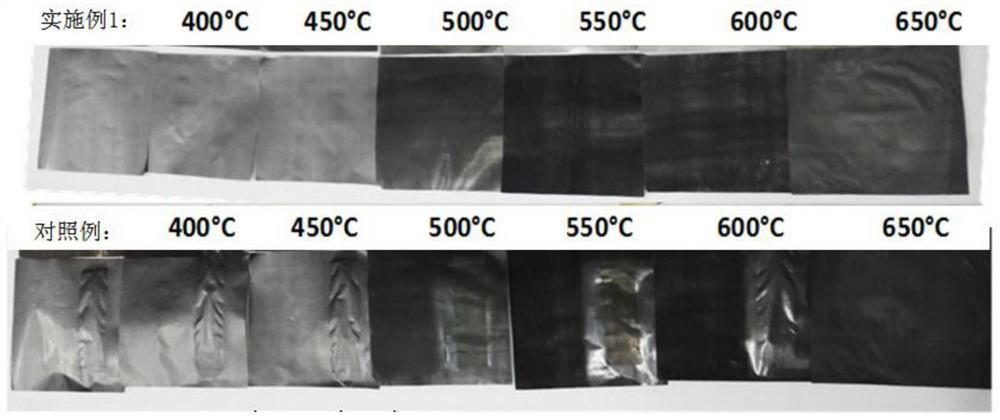

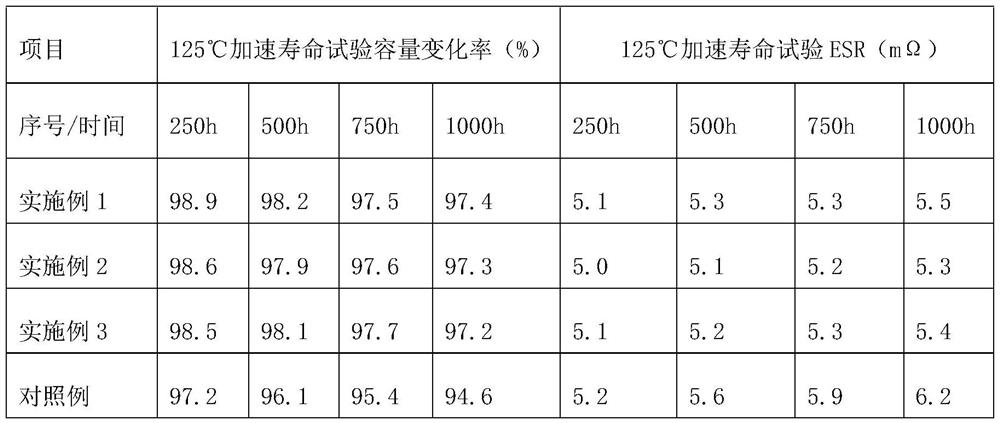

A high-density, acid-resistant and oxidation-resistant solid capacitor carbon foil production process

ActiveCN111105933BModerate surface tensionImprove densification performanceSolid electrolytic capacitorsFiberAluminium electrolysis

The invention relates to a high-density, acid-resistant and oxidation-resistant solid capacitor carbon foil production process. The process steps are as follows: add half of the binder to the polymer solvent, and add acidified acidified carbon nanotubes mixed with carbon nanotubes. Nano conductive carbon fiber system, and then mixed with the other half of the binder and processing aids to obtain a slurry, which is double-sided coated on both sides of the corroded aluminum foil with a gravure coater, and the coating thickness is 20-42 μm. Cutting, inspection and packaging of solid capacitor carbon foil; using unique nano-conductive paste, coating on both sides of corroded aluminum foil by coating process, after interface treatment, it can be tightly combined and completely covered, which is beneficial to reduce process difficulty and improve carbon foil compactness , carbon foil products have excellent thermal oxidation resistance, and have wider adaptability to heating and patch reflow temperatures in the production process of solid aluminum electrolysis.

Owner:南通宇华新材料科技有限公司

Thermal oxidation stable polyformaldehyde preparation method

InactiveCN109082069AImprove impact toughnessHigh elongation at breakChemical industryCellulose acetate

The invention discloses a thermal oxidation stable polyformaldehyde preparation method, and belongs to the technical field of chemical industry. According to the method, an aluminum alloy and cellulose acetate are compounded to prepare composite metal resin, cutting grains are extruded and grinded into compound aluminum resin powder, and the compound aluminum resin powder and the cellulose acetateare dissolved by diethyl ether in the polymerization process to form a porous aluminum base material. According to the method, rice hulls can be activated through reaction by zinc powder and iron powder at high temperature, lignocellulose components are swelled and gradually transformed into a gummy matter under the action of organic metal solution, the recrystallization temperature of aluminum alloy can be increased by manganese, recrystallization grains are thinned, growth of the thinned recrystallization grains is hindered by compound dispersoid particles, so that the aluminum alloy acquires more force bearing points when external acting force is applied on the aluminum alloy, the aluminum alloy is dispersed, ferromanganese iron metal elements are added into the aluminum alloy, montmorillonoid is adsorbed on gaps of the aluminum alloy, the aging effect of ultraviolet light on polyformaldehyde is reduced, and the mechanical property of the polyformaldehyde is improved.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of graphene-based thermal-oxidation-resistant V-belt coated composite rubber

The invention relates to the technical field of transmission triangular belts, in particular to a preparation method of graphene-based thermal-oxidation-resistant V-belt coated composite rubber. The preparation method comprises the steps that graphene is dispersed in slurry formed by chloroprene rubber and gradually forms microchip zinc hydroxide in zinc salt, so that the graphene slurry adheres to the surface of the microchip zinc hydroxide in situ; the temperature is increased, inorganic fiber is added, and the microchip zinc hydroxide is gradually decomposed and converted into microporous zinc oxide, so that the graphene closely stays and is compounded in micropores of the microporous zinc oxide and is wrapped with an inorganic fiber macroscopic interface; the obtained compound micro powder of zinc oxide and graphene adheres to the inorganic fiber and can be effectively dispersed in the rubber to serve as V-belt coating glue through carrying of the inorganic fiber. The thermal oxidation resistance is greatly improved, and the strength of a V-belt is improved, so that the V-belt is suitable for being used in high-load and high-temperature environments.

Owner:TAIZHOU BAIHUA RUBBER BELT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com