A crack-free nickel-based superalloy and its composition design method and preparation method

A nickel-based superalloy and composition design technology, applied in the field of metal additive manufacturing, can solve the problems of prolonging the process flow, limited improvement effect, increasing production cost, etc., to reduce stacking fault energy, improve thermal oxidation resistance, The effect of increasing the operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Modified GH3536M alloy composition, by mass percentage: Mo: 10.94%, Cr: 24.96%, W: 1.18%, Co: 4.27%, Fe: 10.55%, C: 0.073%, Mn: 0.61%, Si: 0.3% , and the balance is Ni. The preparation method comprises the following steps:

[0056] S1. Alloy powder preparation:

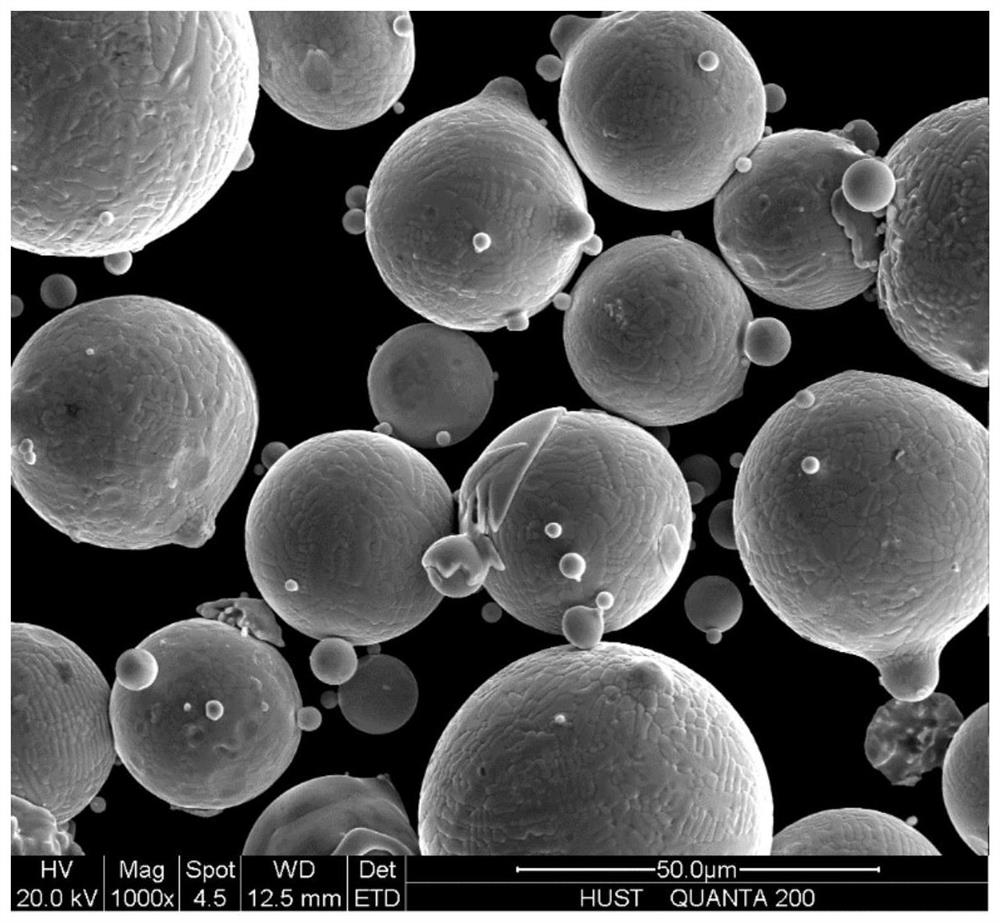

[0057] 1) Raw material smelting: Weigh the raw material of the intermediate compound metal block according to the proportion of alloy elements and place it in a vacuum induction furnace for heating and melting. The above-mentioned pre-alloyed metal after smelting is transferred into an atomizing tank, and argon gas is used to make powder, and the atomization pressure is about 2.0MPa; 3) Powder screening: the above-mentioned pre-alloyed powder is subjected to a visual screening process to obtain an average particle size of 31.8μm metal powder, the particle size range is 15μm~53μm, the appearance of the modified GH3536 alloy powder is as follows figure 1 4) heat preservation and drying: put the above-mentioned...

Embodiment 2

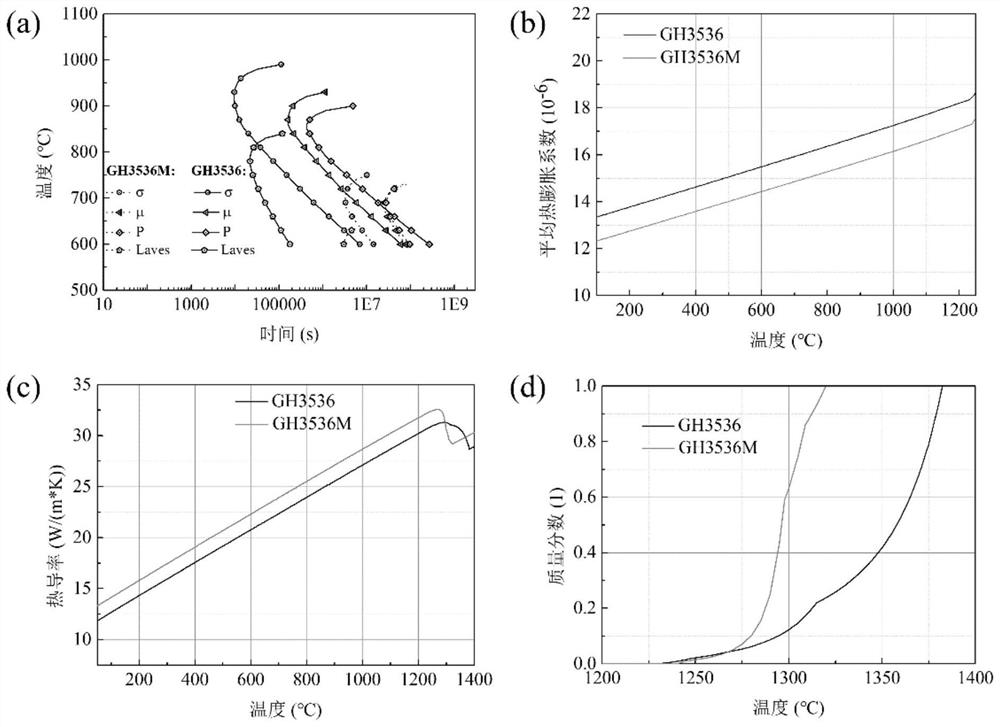

[0061] Modified GH3536M alloy composition, by mass percentage: Mo: 10.94%, Cr: 24.96%, W: 1.18%, Co: 4.27%, Fe: 10.55%, C: 0.073%, Mn: 0.61%, Si: 0.3% , the balance is Ni; the Md and B of the GH3536M 0 The values are 0.9275 and 0.8598.

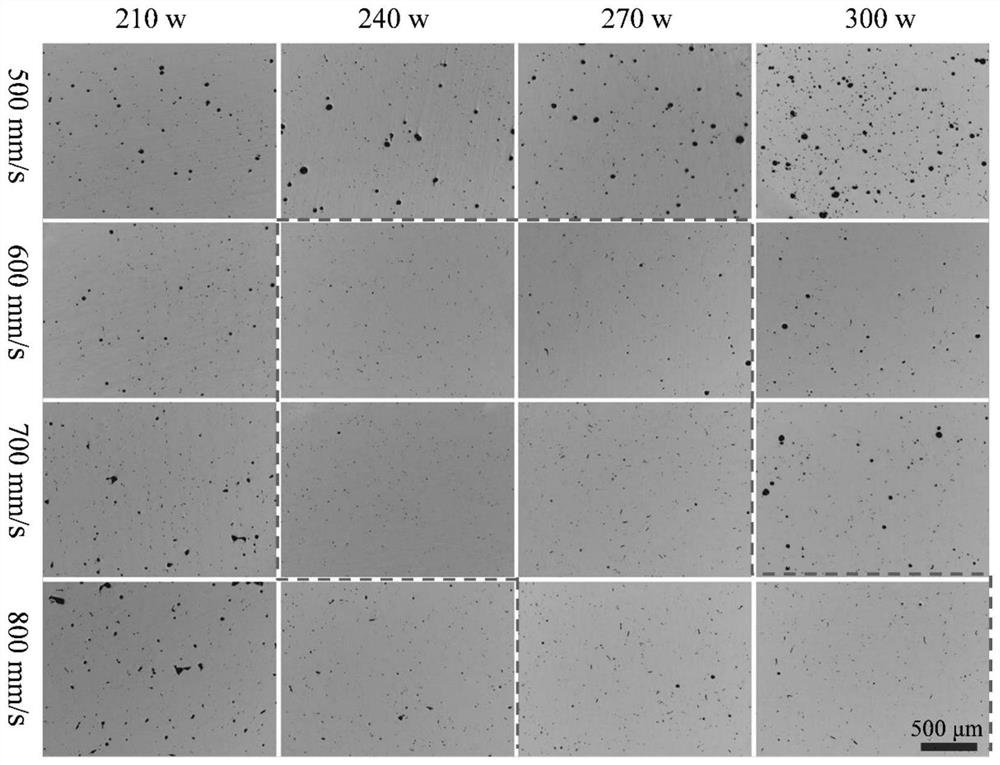

[0062] The traditional GH3536 and the modified GH3536M are subjected to laser selective melting and forming. The specific parameters are: substrate preheating temperature 100°C, laser scanning power 240w, laser scanning speed 600mm / s, powder coating thickness 0.04mm, scanning distance 0.1mm, progressive scanning 67° rotation between layers.

[0063] The GH3536 alloy and GH3536M alloy were formed by selective laser melting, and after electrochemical polishing, the microstructures were compared and analyzed, as follows: Figure 4 As shown in (a) and (b), the comparison found that the microcracks of the GH3536M alloy were almost eliminated.

[0064] For the modified GH3536M alloy formed by selective laser melting and the traditional brand GH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com