A kind of polypropylene composite material and its preparation method and application

A composite material, polypropylene technology, applied in coatings and other directions, can solve the problems of poor bonding force between inorganic fillers and resins, lack of anti-oxidation properties, affecting mechanical properties, etc. , the effect of uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

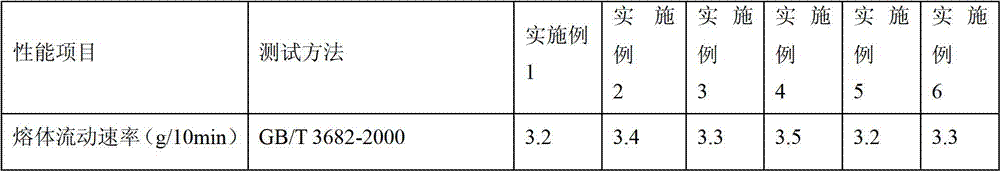

Examples

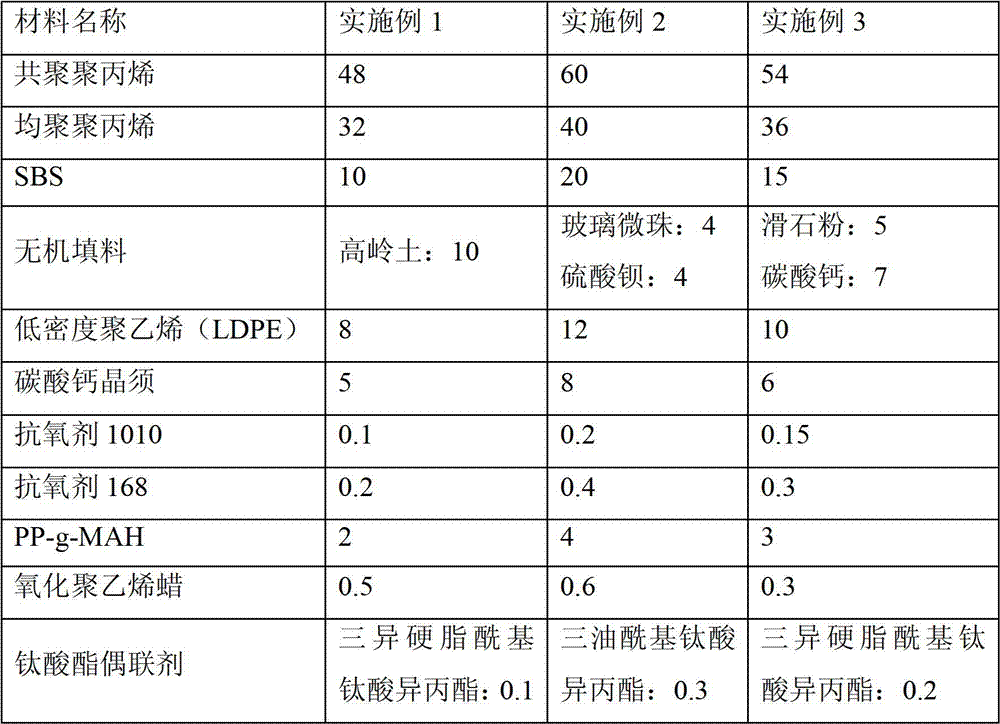

Embodiment 1~3

[0043] (1) Weigh the raw materials of each component according to the ratio in Table 1, add them to a high-speed mixer for low-speed mixing, the mixing time is 1min, and the mixing temperature is 40°C;

[0044] (2) Extrusion and granulation: put the mixed material into an extruder, heat and extrude, cool and cut into pellets to obtain the polypropylene composite material. Among them, the heating temperature of the extruder is as follows: 155°C, 175°C, 195°C, 215°C, 225°C, and the head is 220°C. The screw speed was 320r / min to obtain the polypropylene composite material.

[0045] The use of the polypropylene composite material prepared in step (2) as an automobile steering wheel material includes the following steps: adding the polypropylene composite material prepared in step (2) to an injection molding machine, and simultaneously putting the metal skeleton into the injection mold , injection encapsulation, the injection temperature is 225°C, 230°C, 235°C, 240°C; the injectio...

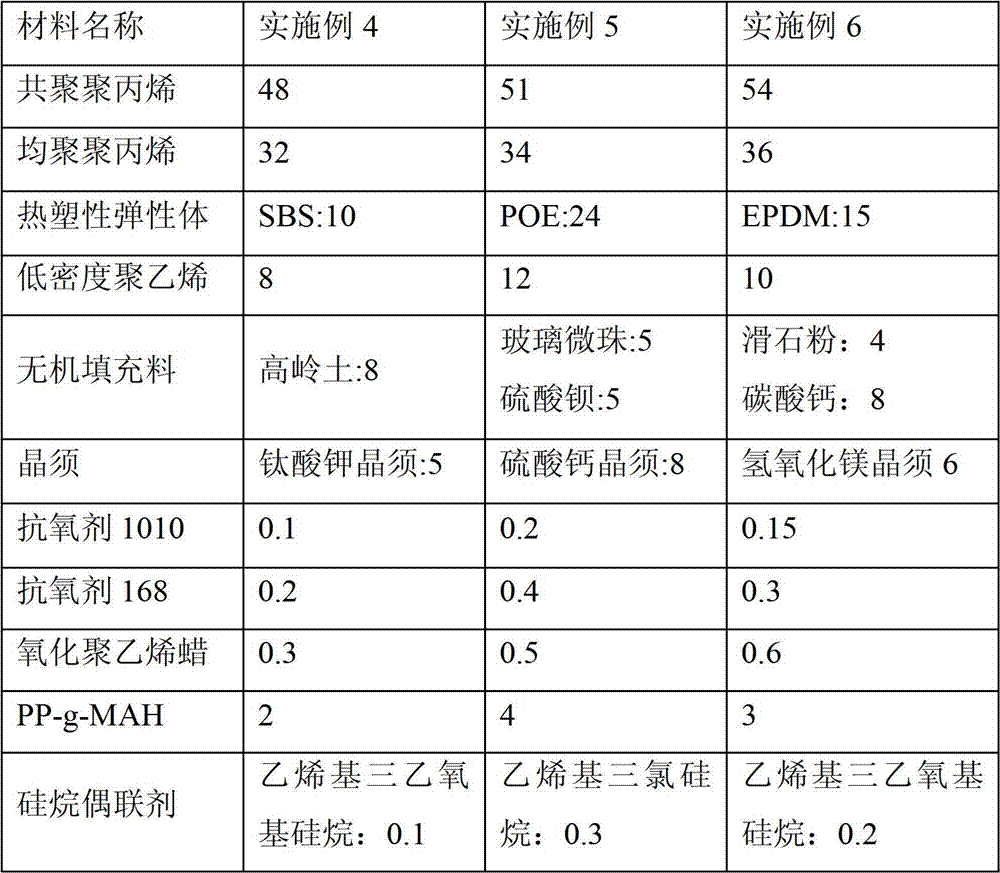

Embodiment 4~6

[0050] (1) Weigh the raw materials of each component according to the ratio in Table 2, add them to a high-speed mixer for low-speed mixing, the mixing time is 3 minutes, and the mixing temperature is 30°C;

[0051] (2) Extrusion and granulation: put the mixed material into an extruder, heat and extrude, cool and cut into pellets to obtain the polypropylene composite material.

[0052] The use of the polypropylene composite material prepared in step (2) as an automobile steering wheel material comprises the following steps:

[0053]Add the polypropylene composite material prepared in step (2) into the injection molding machine, and at the same time put the titanium alloy metal skeleton into the injection mold, inject and encapsulate, and the injection temperature is 235°C, 240°C, 245°C, 250°C; The pressure is 45Mpa, the holding pressure is 40Mpa, the injection time is 3s, the holding time is 4s, the cooling time is 30s, the mold temperature is 60°C, and the finished automobile...

Embodiment 4

[0055] In the step (2) of Example 4, the heating temperature of the extruder is as follows: 150°C, 170°C, 190°C, 210°C, 220°C, and 215°C at the head. The screw speed is 200r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com