Heat-resisting silicone oil composite

A technology of silicone oil compound and compound, which is applied in the field of high-temperature resistant silicone oil, can solve the problems of inability to inhibit thermal degradation of silicone oil and thermal weight loss of silicone oil, and achieve the effects of reducing thermal degradation damage, reducing thermal weight loss, and reducing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

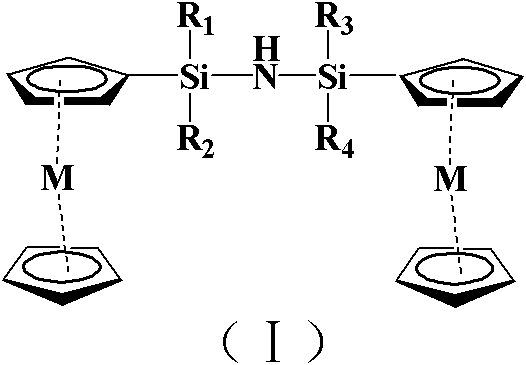

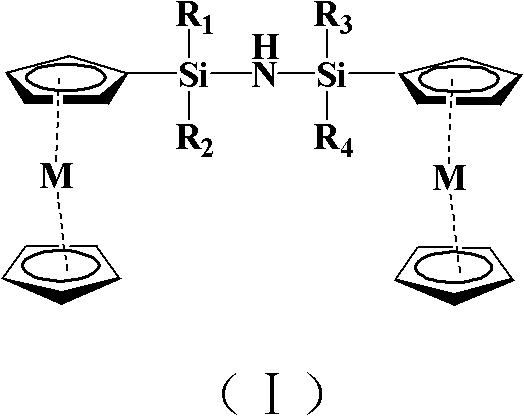

[0023] Embodiment 1, preparation and heat resistance test of silicone oil / ferrocenyl silazane compound

[0024] Take by weighing 100 parts (mass parts) of methyl silicone oil (η 25 1000mPa·S), 0.001 parts (parts by mass) of 1,1,3,3-tetramethyl-1,3-diferrocenylsilazane, mixed uniformly on a three-roll mill at room temperature to obtain Silicone oil / ferrocenylsilazane complex.

[0025] Take 50g of the compound prepared above and place it in a 150ml beaker, place it in an air circulation aging box, keep the temperature at 300°C, measure the weight loss when the aging time is 24h is 4.9%, and the gel time of methyl silicone oil is more than 1000 hours.

Embodiment 2

[0026] Example 2, Preparation and heat resistance test of silicone oil / ruthenocene-based silazane complex

[0027] Take by weighing 100 parts (mass parts) of methyl silicone oil (η 25 20mPa·S), 2.5 parts (parts by mass) of 1,1,3,3-tetraphenyl-1,3-diruthenocene-based silazane, stirred evenly at room temperature to obtain silicone oil / ruthenocene-based silicon Azane complex.

[0028] Take 50g of the compound prepared above and place it in a 150ml beaker, place it in an air circulation aging box, keep the temperature at 300°C, measure the weight loss when the aging time is 24h is 3.6%, and the gel time of methyl silicone oil is more than 1000 hours.

Embodiment 3

[0029] Embodiment 3, preparation and heat resistance test of silicone oil / ferrocenyl silazane compound

[0030] Take by weighing 100 parts (mass parts) of methyl silicone oil (η 25 5000mPa·S), 5 parts (parts by mass) of 1,3-dimethyl-1,3-diphenyl-1,3-diferrocenylsilazane, added to a vacuum kneader at 150°C / - Banbury mixing at 0.1Mpa, and silicone oil / ferrocenylsilazane compound can be obtained after cooling.

[0031] Take 50g of the above-prepared silicone oil / ferrocenylsilazane compound and place it in a 150ml beaker, place it in an air circulation aging box, keep the temperature at 300°C, and measure the weight loss when the aging time is 24h to be 3%. The gel time of silicone oil is more than 1000 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com