Fluorescent ageing resistant coating for electronic equipment

A technology of anti-aging coatings and electronic equipment, applied in the field of coatings, can solve the problems of poor aging fastness, poor weather resistance, non-abrasion resistance, etc., and achieve the effects of good water resistance, strong UV shielding, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

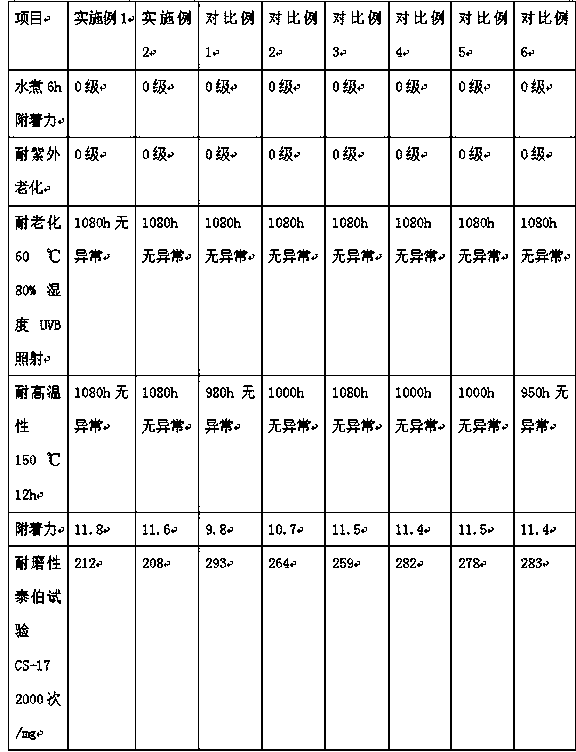

Examples

Embodiment 1

[0021] A fluorescent aging-resistant coating for electronic equipment, made of the following raw materials in parts by weight:

[0022] Vinyl acetate (mass concentration 20%) 45 parts, ethanol 60 parts, comonomer 35 parts, polyvinylpyrrolidone 30 parts, acetone 29 parts, butyl acetate 8 parts, trimethylolpropane 47 parts, (fluorene-2 -yl)-5-(N-ethylcarbazol 3-yl)ketene 4 parts, polyethylene adipate 17 parts, thickener 0.3 parts, phenol 5 parts, bamboo trim 7 parts, filler 33 parts, 0.2 parts of azobisisobutyronitrile, 13 parts of ethylene glycol, 2.3 parts of phenylhydrazine, 3.5 parts of concentrated hydrochloric acid, 24 parts of glacial acetic acid, 0.8 parts of potassium dichromate, 0.8 parts of acetic anhydride, 33 parts of toluene diisocyanate .

[0023] A fluorescent aging-resistant coating for electronic equipment, characterized in that the preparation method comprises the following steps: (1) Weighing each raw material, pulverizing moso bamboo corners into 100-200 me...

Embodiment 2

[0028] A fluorescent aging-resistant coating for electronic equipment, made of the following raw materials in parts by weight:

[0029] Vinyl acetate (mass concentration 20%) 15 parts, ethanol 40 parts, comonomer 30 parts, polyvinylpyrrolidone 20 parts, acetone 16 parts, butyl acetate 5 parts, trimethylolpropane 28 parts, (fluorene-2 -yl)-5-(N-ethylcarbazol 3-yl)ketene 2 parts, polyethylene adipate 10 parts, thickener 0.1 parts, phenol 3 parts, bamboo trim 5 parts, filler 10 parts, 0.1 parts of azobisisobutyronitrile, 6 parts of ethylene glycol, 1.4 parts of phenylhydrazine, 2.4 parts of concentrated hydrochloric acid, 13~24 parts of glacial acetic acid, 0.3 parts of potassium dichromate, 0.4 parts of acetic anhydride, toluene diisocyanate 21 servings.

[0030] A fluorescent aging-resistant coating for electronic equipment, characterized in that the preparation method comprises the following steps: (1) Weighing each raw material, pulverizing moso bamboo corners into 100-200 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com