Laser cladding method for improving abrasion resistance of mechanical seal sleeve for pump

A laser cladding and abrasion-resistant technology, which is applied in the coating, metal material coating process, etc., can solve the problems of non-wear resistance, acid and alkali corrosion resistance, and low hardness of the mechanical seal shaft sleeve, and achieve high temperature Oxidation and corrosion resistance, wear resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

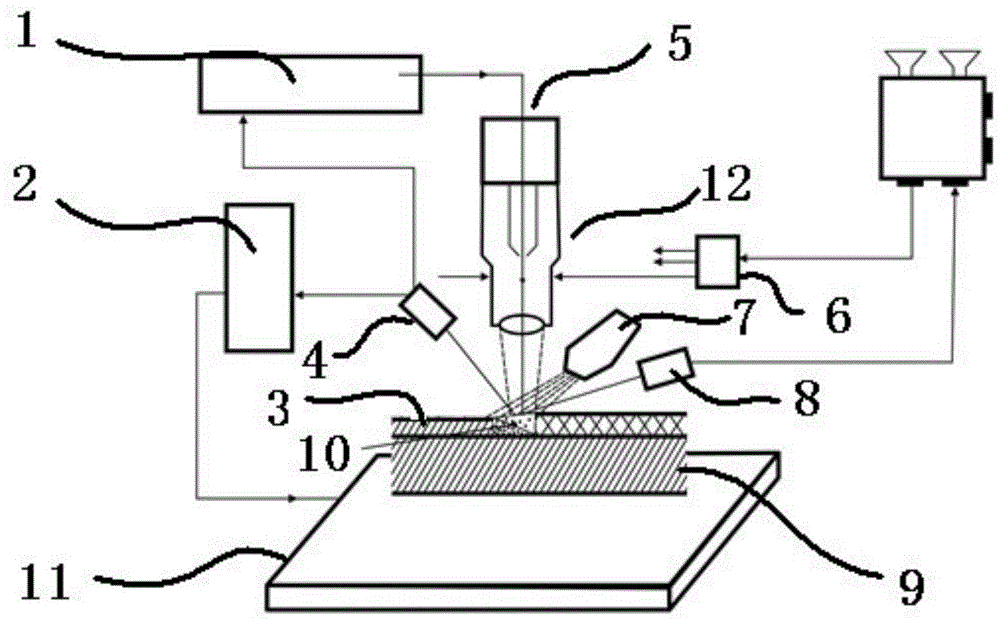

[0027] A kind of wear-resistant laser cladding method of mechanical seal shaft sleeve for pump (see figure 1 shown), including:

[0028] Step S1: surface treatment on the wear-resistant part of the shaft sleeve of the machine seal; specifically, unilateral cutting of the workpiece that needs to be modified by laser cladding to form grooves, the groove depth is 0.3-1.5mm; use acetone to clean the grooves , to remove oily impurities on the surface.

[0029] Step S2: Equipment 2000W high power semiconductor laser.

[0030] The wear-resistant parts after the surface treatment in step S1 are clad with nickel-based composite powder through a laser. The cladding adopts two layers of single-pass laser cladding layers, and helium is used to protect the molten pool during the cladding process; the output power The power is 1500W, the focal length is 160mm, the wavelength is 976nm, the powder feeding rate is 5g / min, the scanning speed is 12mm / s, and the melting temperature is 1080℃;

...

Embodiment 2

[0034] An abrasion-resistant laser cladding method for a shaft sleeve of a mechanical seal for a pump, comprising:

[0035] Step S1: Perform surface treatment on the wear-resistant part of the shaft sleeve of the machine seal; specifically, unilaterally cut the workpiece that needs to be modified by laser cladding to form a groove, the groove depth is 2-4mm; use acetone to clean the groove, Removes oily impurities from the surface.

[0036] Step S2: Equipment 2000W high power semiconductor laser.

[0037] The wear-resistant parts after the surface treatment in step S1 are clad with nickel-based composite powder through a laser. The cladding adopts 3 layers of single-pass laser cladding layers, and the thickness of the single-layer cladding layer is 0.1-1mm (the cladding thickness According to the scanning speed and powder feeding amount control), helium is used to protect the molten pool during the cladding process; the output power is 1800W, the focal length is 260mm, the wa...

Embodiment 3

[0041] The process of embodiment 3 is the same as embodiment 1, and its difference is as follows:

[0042] Process parameters in the cladding process: output power is 1600W, focal length is 200mm, wavelength is 976nm, powder feeding rate is 15g / min, scanning speed is 5mm / s, and melting temperature is 1060°C.

[0043] The chemical composition and mass percentage of the components of the nickel-based composite powder are as follows (the particle size of the nickel-based composite powder is: -150 / +280): C: 0.8%, Cr: 16%, Si: 4%, B: 4 %, Cu: 3%, Mo: 4%, Fe: 9%, CeO: 0.4%, Ti: 0.8%, W: 3%, and Ni: the balance;

[0044] Step S3: performing wet grinding on the shaft sleeve of the mechanical seal after cladding in step S2. Quality inspection: Carry out quality inspection on the mechanical seal shaft sleeve after cladding to confirm that the quality of the cladding parts meets the requirements for use.

[0045] The mechanical seal shaft sleeve for pumps in the present invention has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com