Ceramic reinforced Ni-based composite coating applying to steel surface through laser cladding and preparation method thereof

A laser cladding, steel surface technology, applied in the direction of coating, metal material coating process, etc., can solve the problems of strong corrosion, alloy coating can not meet the requirements of use, etc., to achieve the effect of improving hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Ni60A+ZrN series

[0064] The composition of the cladding material used in this embodiment is shown in the following table 1:

[0065] Table 1

[0066] serial number Ni60A(wt.%) ZrN(wt.%) 1 90% 10% 2 85% 15% 3 80% 20% 4 70% 30% 5 60% 40%

[0067] A method for preparing a cladding layer, comprising the steps of:

[0068] Preparation of steel specimens:

[0069] 1) The base material is processed into a sample of a certain size by using a wire electric discharge machine tool;

[0070] 2) Grind the surface of the sample to be clad with sandpaper, remove the scale, until it is smooth and polished.

[0071] 3) Place the sample in absolute ethanol and ultrasonically clean it for 30 minutes to remove surface oil. After washing, take out the samples and let them dry naturally in the air.

[0072] Laser cladding steps:

[0073] 1) According to the ratio designed in Table 1, use an electronic balance to weigh and mix various p...

Embodiment 2

[0101] Ni60A+ZrB 2 series:

[0102] The composition of the cladding material used in this embodiment is shown in Table 5:

[0103] table 5

[0104] serial number Ni60A(wt.%) ZrB 2 (wt.%)

1 90% 10% 2 85% 15% 3 80% 20% 4 70% 30% 5 60% 40%

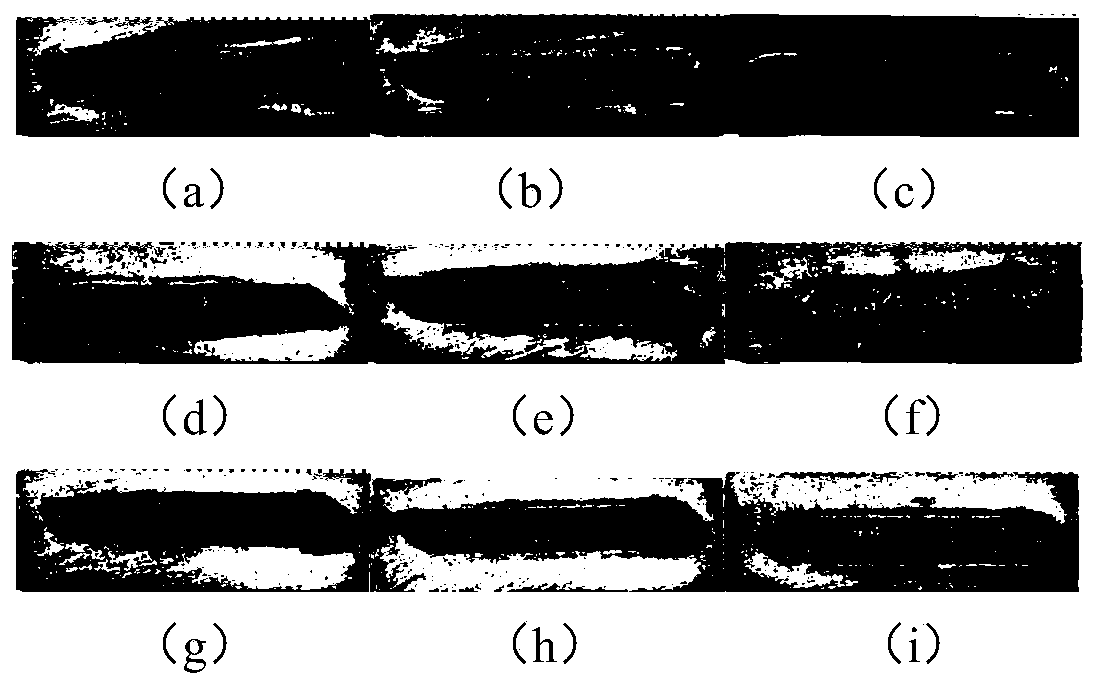

[0105] Ni60A+15wt.%ZrB under different process conditions 2 The cladding quality of the coating, as shown in Table 6, corresponds to image 3 .

[0106] Table 6

[0107] 3kW 4kW 5kW 150mm / min (a) (b) (c) 250mm / min (d) (e) (f) 350mm / min (g) (h) (i)

[0108] image 3 It is laser cladding Ni60A+15wt.%ZrB under different process conditions 2 The appearance of the coating, it can be seen that within a certain process range, Ni60A+15wt.%ZrB 2 The coating is continuous and uniform, the surface is flat, and the number of slag particles is small. This shows that Ni60A+15wt.%ZrB 2 The powder has good cladding formability. Under the conditions of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com