Abrasion-resistant laser cladding method for mechanical seal shaft sleeve of pump

A laser cladding and wear-resistant technology, applied in the field of laser cladding, can solve the problems of non-wear resistance, acid and alkali corrosion resistance, and low hardness of the shaft sleeve of the machine seal, so as to improve wear resistance and temperature resistance Oxidizing and corrosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

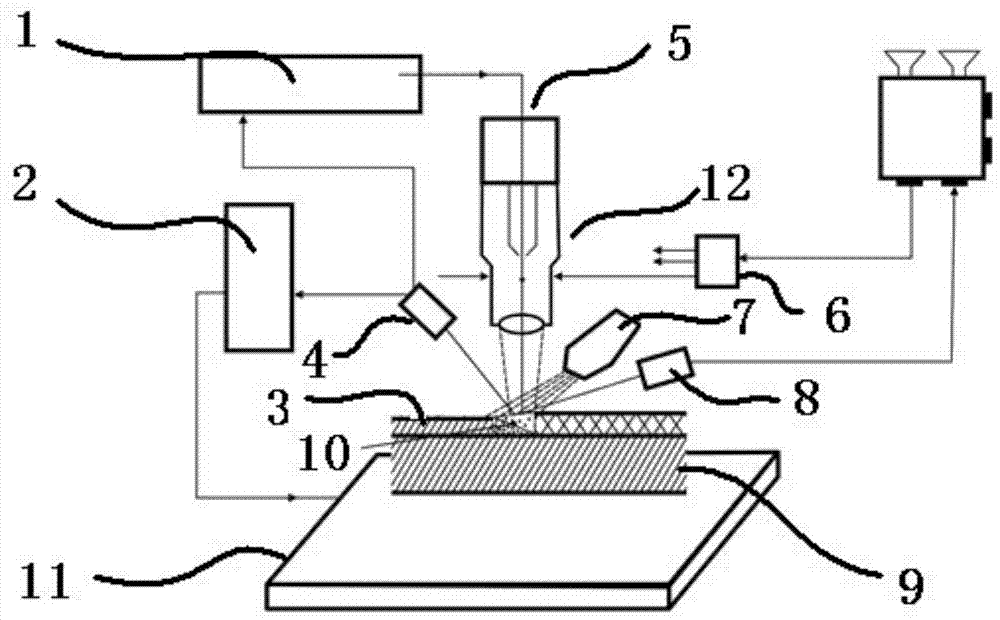

[0027] A kind of wear-resistant laser cladding method of mechanical seal shaft sleeve for pump (see figure 1 shown), including:

[0028] Step S1: surface treatment on the wear-resistant part of the shaft sleeve of the machine seal; specifically, unilateral cutting of the workpiece that needs to be modified by laser cladding to form grooves, the groove depth is 0.3-1.5mm; use acetone to clean the grooves , to remove oily impurities on the surface.

[0029] Step S2: Equipment 2000W high power semiconductor laser.

[0030] The wear-resistant parts after the surface treatment in step S1 are clad with nickel-based composite powder through a laser. The cladding adopts two layers of single-pass laser cladding layers, and helium is used to protect the molten pool during the cladding process; the output power The power is 1500W, the focal length is 160mm, the wavelength is 976nm, the powder feeding rate is 5g / min, the scanning speed is 12mm / s, and the melting temperature is 1080℃;

...

Embodiment 2

[0034] An abrasion-resistant laser cladding method for a shaft sleeve of a mechanical seal for a pump, comprising:

[0035] Step S1: Perform surface treatment on the wear-resistant part of the shaft sleeve of the machine seal; specifically, unilaterally cut the workpiece that needs to be modified by laser cladding to form a groove, the groove depth is 2-4mm; use acetone to clean the groove, Removes oily impurities from the surface.

[0036] Step S2: Equipment 2000W high power semiconductor laser.

[0037] The wear-resistant parts after the surface treatment in step S1 are clad with nickel-based composite powder through a laser. The cladding adopts 3 layers of single-pass laser cladding layers, and the thickness of the single-layer cladding layer is 0.1-1mm (the cladding thickness According to the scanning speed and powder feeding amount control), helium is used to protect the molten pool during the cladding process; the output power is 1800W, the focal length is 260mm, the wa...

Embodiment 3

[0041] The process of embodiment 3 is the same as embodiment 1, and its difference is as follows:

[0042] Process parameters in the cladding process: output power is 1600W, focal length is 200mm, wavelength is 976nm, powder feeding rate is 15g / min, scanning speed is 5mm / s, and melting temperature is 1060°C.

[0043] The chemical composition and mass percentage of the components of the nickel-based composite powder are as follows (the particle size of the nickel-based composite powder is: -150 / +280): C: 0.8%, Cr: 16%, Si: 4%, B: 4 %, Cu: 3%, Mo: 4%, Fe: 9%, CeO: 0.4%, Ti: 0.8%, W: 3%, and Ni: the balance;

[0044] Step S3: performing wet grinding on the shaft sleeve of the mechanical seal after cladding in step S2. Quality inspection: Carry out quality inspection on the mechanical seal shaft sleeve after cladding to confirm that the quality of the cladding parts meets the requirements for use.

[0045] The mechanical seal shaft sleeve for pumps in the present invention has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com