A kind of wear-resistant steel and its production process

A production process and wear-resistant steel technology, applied in the direction of improving process efficiency, etc., can solve the problems of poor wear resistance, low steel strength and hardness, etc., and achieve the effects of improving wear resistance, enhancing strength, and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

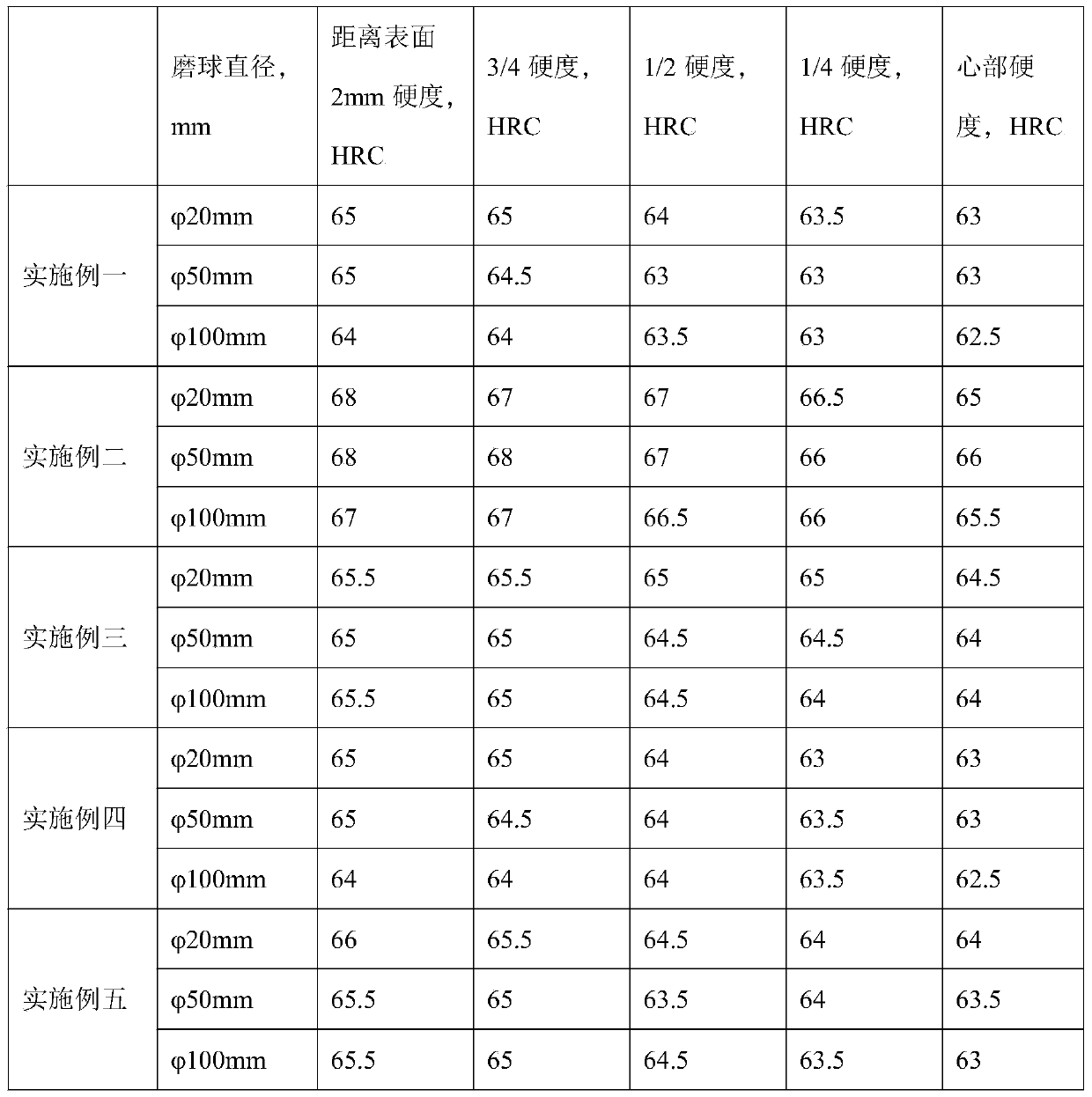

Examples

Embodiment Construction

[0046] The following is a further detailed description of the present invention.

[0047] A production process of wear-resistant steel includes the following steps:

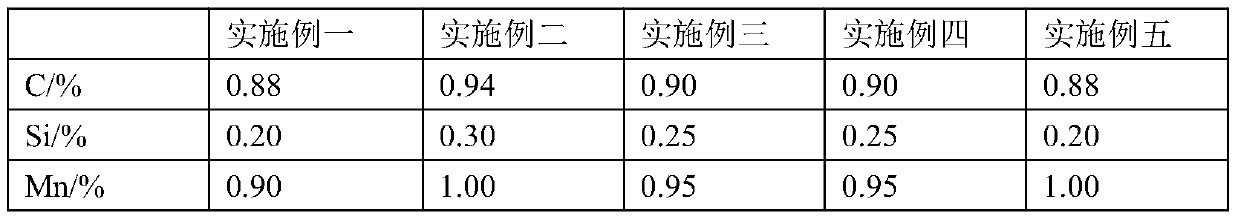

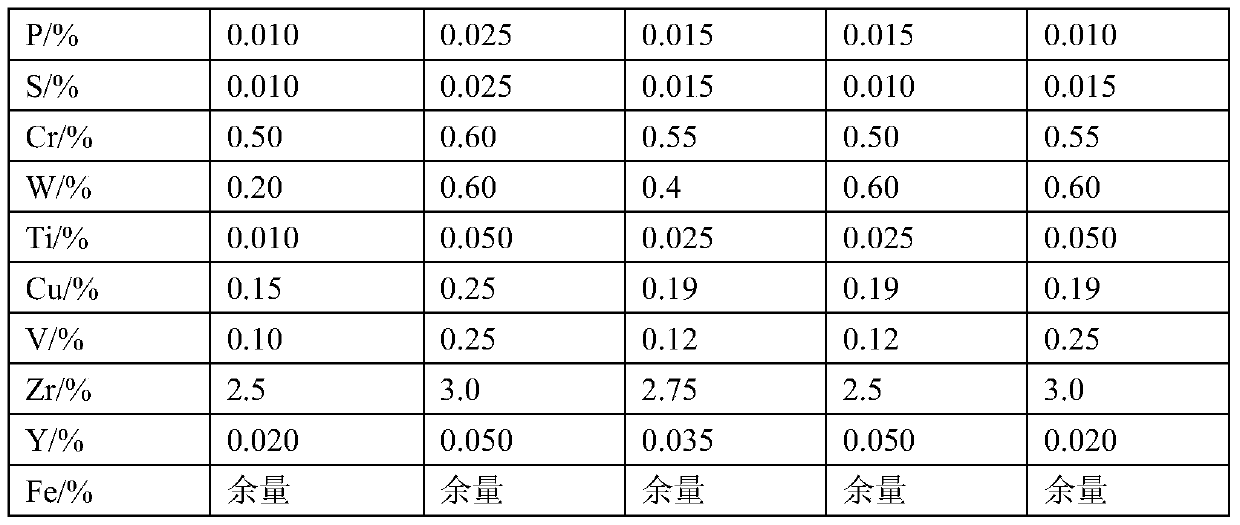

[0048] Step 1: According to the mass percentage, the 115t steel containing C0.73~0.83%, Si0.15~0.20%, Mn0.75~0.85%, Cr0.40~0.50%, P≤0.020%, S≤0.025% It is added to the converter for smelting, and then low-nitrogen carbon powder, deoxidizer, silicomanganese, ferrosilicon, high-carbon ferrochrome, titanium, copper, tungsten, vanadium, and yttrium are sequentially added to the converter. Aluminum strips and aluminum strips are used as deoxidizers. The amount of steel is 0.8~1.0kg / t, and Ar is injected from the bottom of the converter in the whole process, the oxygen pressure is controlled to be ≥0.8Mpa, and the end point of smelting is C≥0.15%, P≤0.015%, and the temperature of molten iron reaches 1615~1635℃. After that, the steel is tapped, and white ash is added to the ladle. The amount of white ash added is 0.25 to 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com