Rare earth oxide modified copper-nickel-silicon alloy material and preparation method and application thereof

A rare earth oxide, copper-nickel-silicon technology, applied in the field of rare earth oxide modified copper-nickel-silicon alloy and its preparation, can solve the problems of rare earth application, low plasticity, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

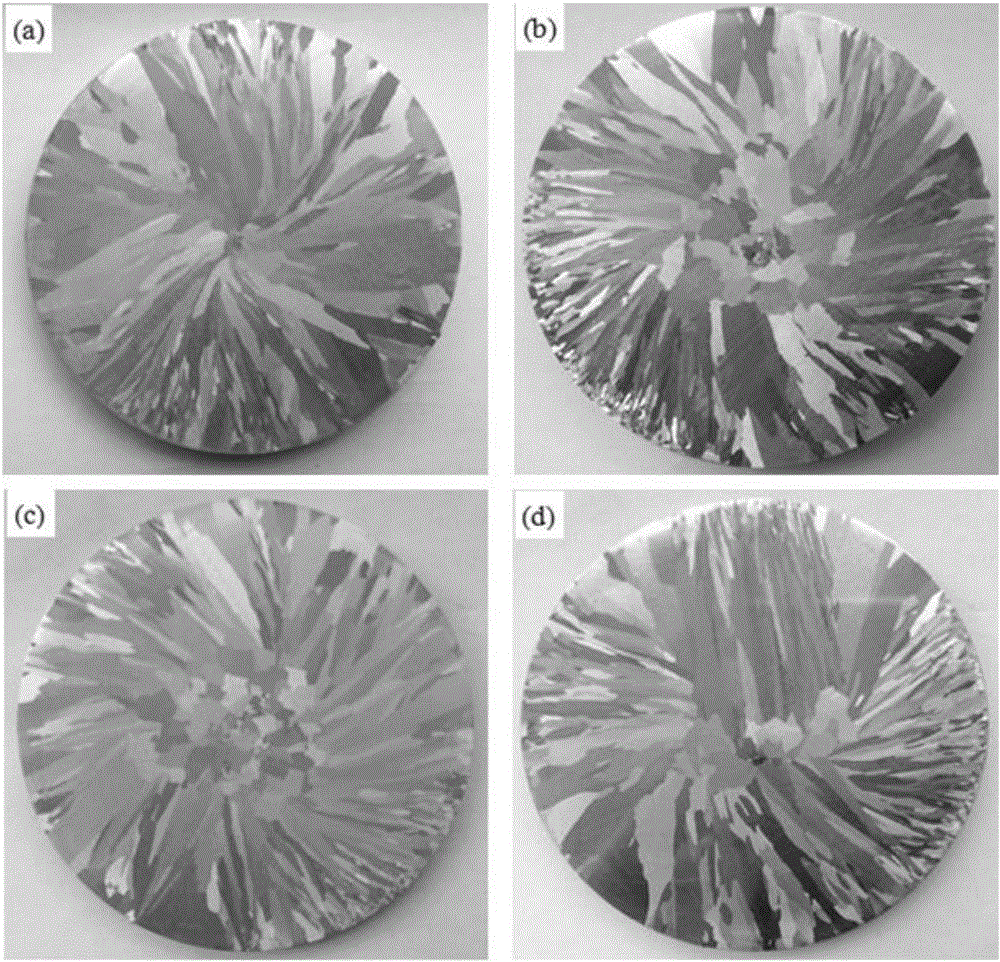

[0038] A rare earth oxide modified copper-nickel-silicon alloy, the raw material components are: copper 95.8%, nickel 3.8%, silicon 0.3%, strontium lanthanum manganate 0.03% (atomic percentage: strontium 0.28, lanthanum 0.58).

[0039] Melting method:

[0040] (1) Grind the oxide skin of raw materials such as copper, nickel and silicon with a grinder, and preheat the crucible and casting mold.

[0041] (2) Medium frequency induction melting is adopted. In order to prevent the oxidation of copper alloy, the melting process is carried out under the protection of argon gas.

[0042] (3) Continue to heat after the alloy is completely melted. When the temperature of the melt rises to about 1250°C, rare earth oxides are added, and the power is reduced for 15 minutes.

[0043] (4) When the molten metal temperature drops to about 1200°C, the molten metal is poured into the mold.

Embodiment 2

[0045] A copper-nickel-silicon alloy modified by rare earth oxides. The raw material components are: copper 95.6%, nickel 1.3%, silicon 1.9%, strontium lanthanum manganate 1.0% (atomic percentage: strontium 0.1, lanthanum 0.59)

[0046] Smelting method:

[0047] (1) Use a grinder to grind the scale of raw materials such as copper, nickel and silicon, and preheat the crucible and the casting mold.

[0048] (2) Medium frequency induction melting is adopted. In order to prevent the oxidation of copper alloy, the melting process is carried out under the protection of argon gas.

[0049] (3) Continue heating after the alloy is completely melted. When the temperature of the melt rises to about 1300°C, add rare earth oxides and reduce the power for 30 minutes.

[0050] (4) When the melt temperature drops to about 1250°C, pour the melt into the mold.

Embodiment 3

[0052] A rare earth oxide modified copper-nickel-silicon alloy, the raw material components are: 93.2% copper, 3.9% nickel, 2.0% silicon, 0.9% strontium lanthanum manganate (atomic percentage: strontium 0.29, lanthanum 0.1).

[0053] Smelting method:

[0054] (1) Use a grinder to grind the scale of raw materials such as copper, nickel and silicon, and preheat the crucible and the casting mold.

[0055] (2) Medium frequency induction melting is adopted. In order to prevent the oxidation of copper alloy, the melting process is carried out under the protection of argon gas.

[0056] (3) Continue heating after the alloy is completely melted. When the temperature of the melt rises to about 1300°C, add rare earth oxides and reduce the power for 30 minutes.

[0057] (4) When the melt temperature drops to about 1250°C, pour the melt into the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com