Al-Zn-Mg-SC series aluminum alloy powder for metal 3D printing and preparation method thereof

A 3D printing and aluminum alloy technology, applied in the direction of additive processing, etc., can solve the problems of unverified mechanical properties of printed parts, inability to know high-strength parts, small thermal conductivity, etc., to reduce insufficient metal dissolution and oxygen content Low, fast crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

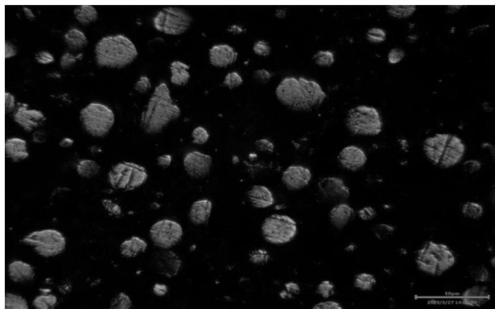

[0054] (1) Batching: batching according to the alloy ratio of 7% Zn, 2.75% Mg, 0.5% Mn, 0.15% Zr, 0.5% Cu, 0.3% Sc, 0.04% Ti, and the remainder is aluminum, which contains impurities Fe and Si , Fe≤0.2%, Si≤0.1%;

[0055] (2) Vacuum melting: using a vacuum melting furnace for melting, adding pure aluminum, aluminum copper alloy, aluminum scandium alloy, aluminum zirconium alloy, aluminum manganese alloy, magnesium ingot, aluminum titanium alloy, and aluminum zinc alloy in sequence. When the vacuum of the vacuum melting furnace reaches 3pa, the raw materials melt and the melting temperature is 750°C.

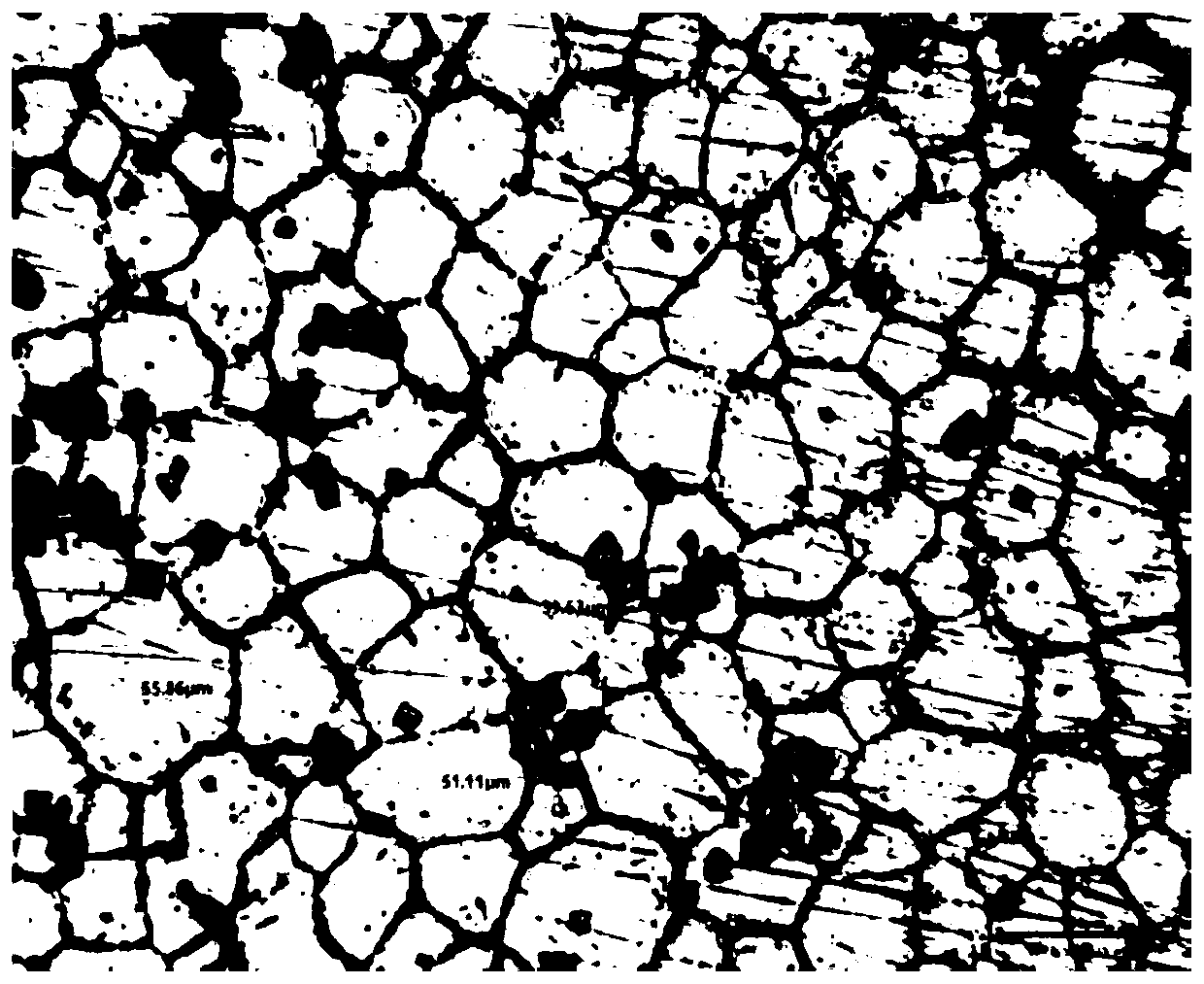

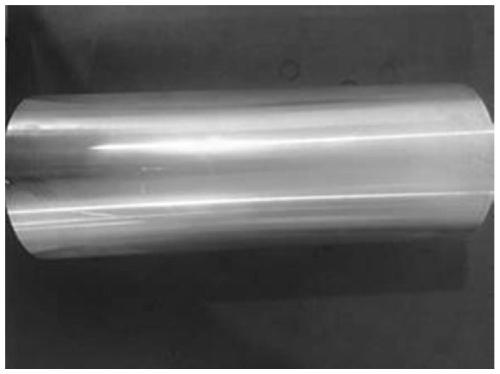

[0056] (3) Casting: After standing for 15 minutes, it is cast into a mold with a diameter of Ф120, and then taken out after cooling and forming. The mold is a water-cooled mold and is rapidly cooled for forming. The cooling rate is 100K / s and the casting temperature is 730°C.

[0057] (4) Homogenization treatment: Put the ingot into the annealing furnace for homogenization treatment, h...

Embodiment 2

[0068] (1) Batching: batching according to the alloy ratio of 7% Zn, 2.75% Mg, 0.5% Mn, 0.15% Zr, 0.5% Cu, 0.3% Sc, 0.04% Ti, and the remainder is aluminum, which contains impurities Fe and Si , Fe≤0.2%, Si≤0.1%;

[0069] (2) Vacuum melting: using a vacuum melting furnace for melting, adding pure aluminum, aluminum copper alloy, aluminum scandium alloy, aluminum zirconium alloy, aluminum manganese alloy, magnesium ingot, aluminum titanium alloy, and aluminum zinc alloy in sequence. When the vacuum of the vacuum melting furnace reaches 3pa, the raw materials melt and the melting temperature is 750°C.

[0070] (3) Casting: After standing for 15 minutes, it is cast into a mold with a diameter of Ф120, and then taken out after cooling and forming. The mold is a water-cooled mold and is rapidly cooled for forming. The cooling rate is 100K / s and the casting temperature is 730°C.

[0071] (4) Homogenization treatment: Put the ingot into the annealing furnace for homogenization treatment, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com