Nickel-based high-temperature alloy powder suitable for powder metallurgy and preparation method thereof

A technology of nickel-based superalloy and powder metallurgy, applied in the field of powder metallurgy nickel-based superalloy powder and its preparation, to achieve the effects of low inclusions, low production cost, and low sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

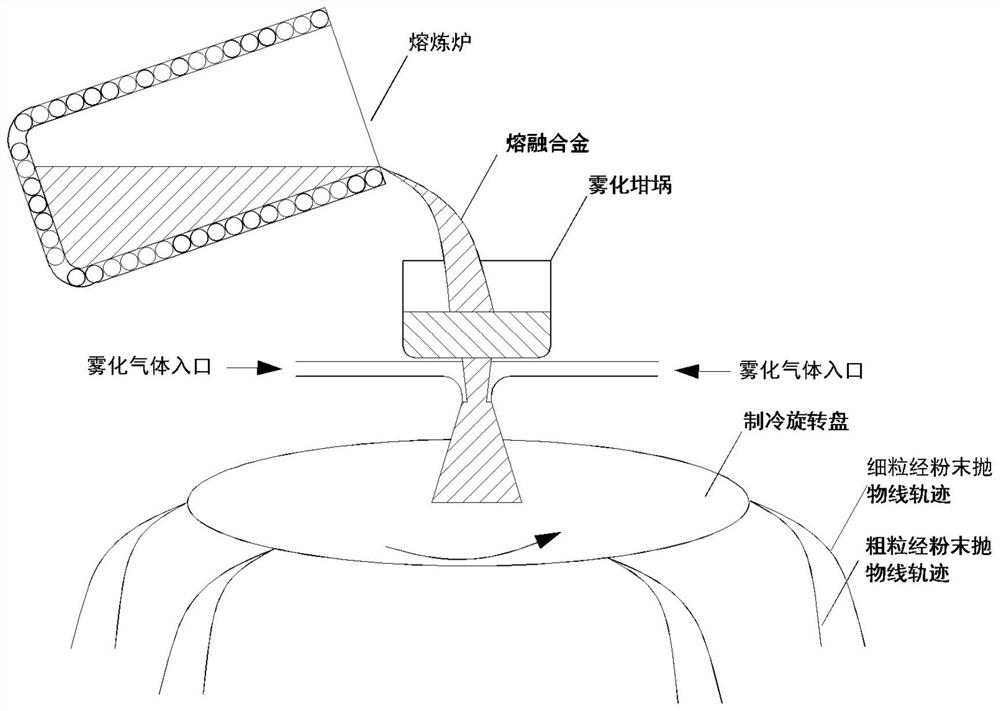

Method used

Image

Examples

Embodiment 1

[0082] A nickel-based superalloy powder, the composition of which is calculated by mass percentage: Cr: 12.5%, Co: 19%, Mo: 3.1%, Ta: 1.3%, Ti: 2.1%, Al: 2.6%, Nb: 1.5 %, Hf: 0.15%, B: 0.01%, C: 0.022%, and the balance consists of Ni and unavoidable impurities. The nickel-based superalloy powder is prepared by the following steps:

[0083]Step 1, according to the chemical composition of the nickel-based superalloy such as the proportion of alloy elements such as Ni, Cr, W and the amount of burning loss, the ingredients are selected, and Ni-Co, Ni-Cr, Ni-Mo master alloy and other configurations of nickel are selected. Base superalloy raw materials, spare.

[0084] Step 2, charging, the feeding mechanism feeds the material into the melting furnace and clamps it. Vacuumize, vacuumize the vacuum induction furnace and atomization furnace, and the vacuum degree reaches 10 -3 Pa. Fill the smelting chamber and atomizing furnace with high-purity Ar gas as a protective gas to avoid ...

Embodiment 2

[0095] A nickel-based superalloy powder, the composition of which is calculated by mass percentage: Cr: 9.6%, Co: 19.8%, Mo: 3.7%, Ti: 2.2%, Al: 3.4%, W: 5.1%, Hf: 0.1 %, B: 0.003%, C: 0.03%, and the balance consists of Ni and unavoidable impurities. The nickel-based superalloy powder is prepared by the following steps:

[0096] Step 1, according to the chemical composition of the nickel-based superalloy such as the proportion of alloy elements such as Ni, Cr, W and the amount of burning loss, the ingredients are selected, and Ni-Co, Ni-Cr, Ni-Mo master alloy and other configurations of nickel are selected. Base superalloy raw materials, spare.

[0097] Step 2, charging, the feeding mechanism feeds the material into the melting furnace and clamps it. Vacuumize, vacuumize the vacuum induction furnace and atomization furnace, and the vacuum degree reaches 10 -3 Pa. Fill the smelting chamber and atomizing furnace with high-purity Ar gas as a protective gas to avoid oxidation ...

Embodiment 3

[0108] A nickel-based superalloy powder, the composition of which is calculated by mass percentage: Cr: 12.8%, Co: 15.1%, Mo: 5.2%, Ti: 2.1%, Al: 4.7%, W: 5.8%, Hf: 0.4 %, B: 0.008%, C: 0.04%, and the balance consists of Ni and unavoidable impurities. The nickel-based superalloy powder is prepared by the following steps:

[0109] Step 1, according to the chemical composition of the nickel-based superalloy such as the proportion of alloy elements such as Ni, Cr, W and the amount of burning loss, the ingredients are selected, and Ni-Co, Ni-Cr, Ni-Mo master alloy and other configurations of nickel are selected. Base superalloy raw materials, spare.

[0110] Step 2, charging, the feeding mechanism feeds the material into the melting furnace and clamps it. Vacuumize, vacuumize the vacuum induction furnace and atomization furnace, and the vacuum degree reaches 10 -4 Pa~10 -3 Pa. Fill the smelting chamber and atomizing furnace with high-purity Ar gas as a protective gas to avoid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com