A low-alloyed Zn-Mn-Ag or Zn-Mn-Ca alloy and a preparing method thereof

A zn-mn-ag, low-alloy technology, applied in the field of non-ferrous metal alloy material composition design and preparation and processing, to achieve the effects of good mechanical properties, improved strength, and low total content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

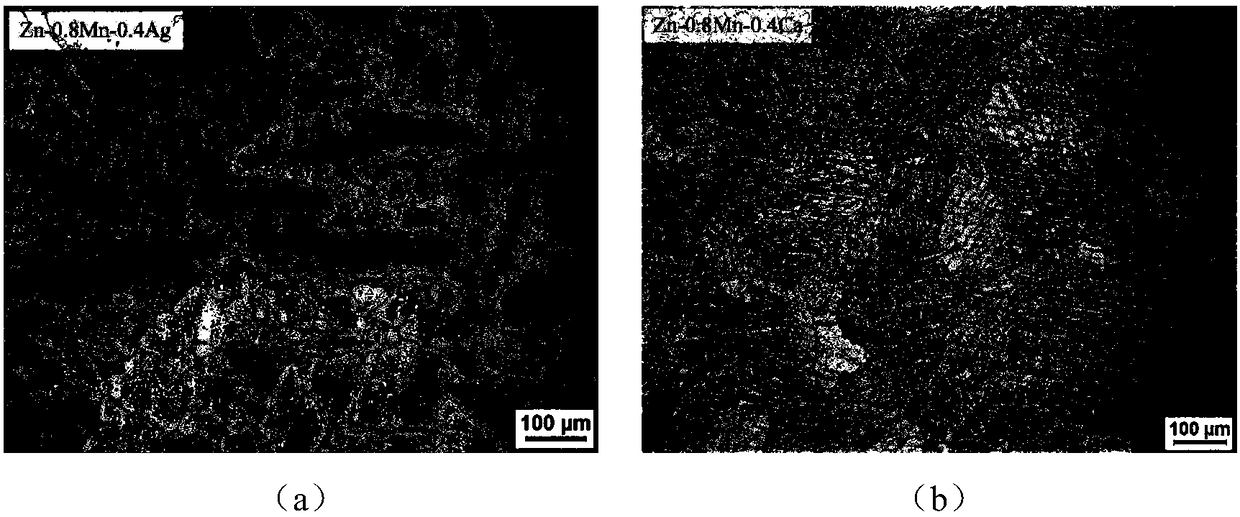

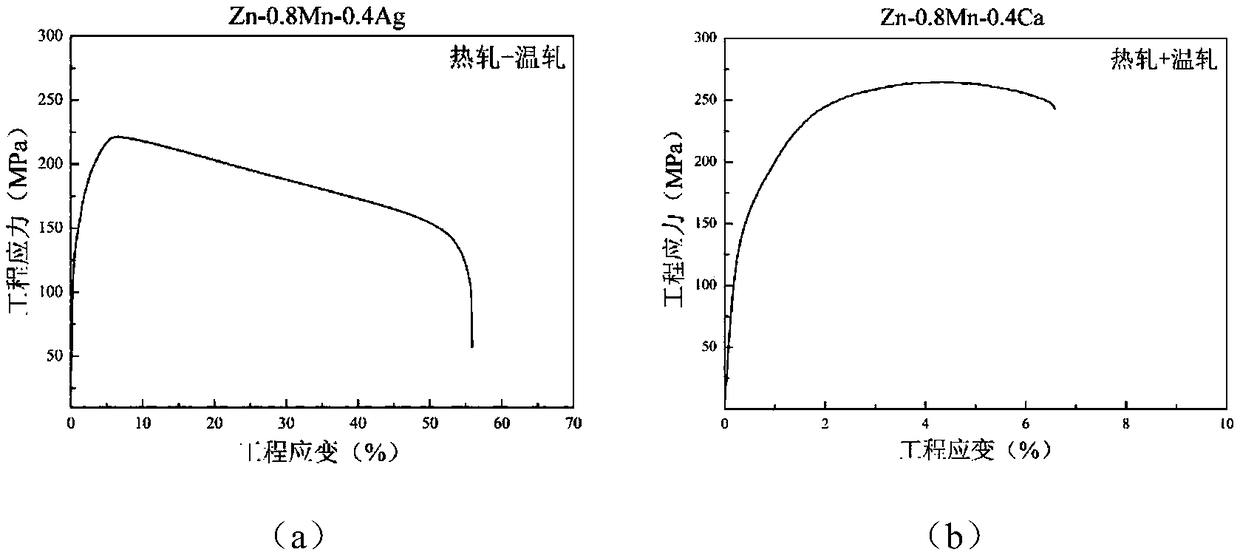

[0040] The warm-rolled Zn-0.8Mn-0.4Ag and Zn-0.8Mn-0.4Ca alloy sheets were prepared and the mechanical properties of the materials were measured.

[0041] Process route: casting→homogenizing heat treatment→hot rolling→warm rolling→finished product.

[0042] The raw material that smelting uses is pure Zn (99.99%), pure Mn (99.9%), pure Ag (99.5%) and pure Ca (99.99%), carry out batching according to following mass percentage: (1) Mn is 0.8%, Ag 0.4%, the rest is Zn; (2) Mn is 0.8%, Ca is 0.4%, and the rest is Zn. Put the batched raw materials into the Al of the vacuum induction melting furnace 2 o 3 in the crucible. After that, the vacuum is drawn, and argon gas is introduced when the pressure in the furnace drops to about 30Pa, and heating is started when the pressure reaches 0.035MPa. When the temperature rises to 780°C, heating is stopped and refining is carried out. The refining time is 5 minutes. During the whole melting process Perform electromagnetic stirring. Then ...

Embodiment 2

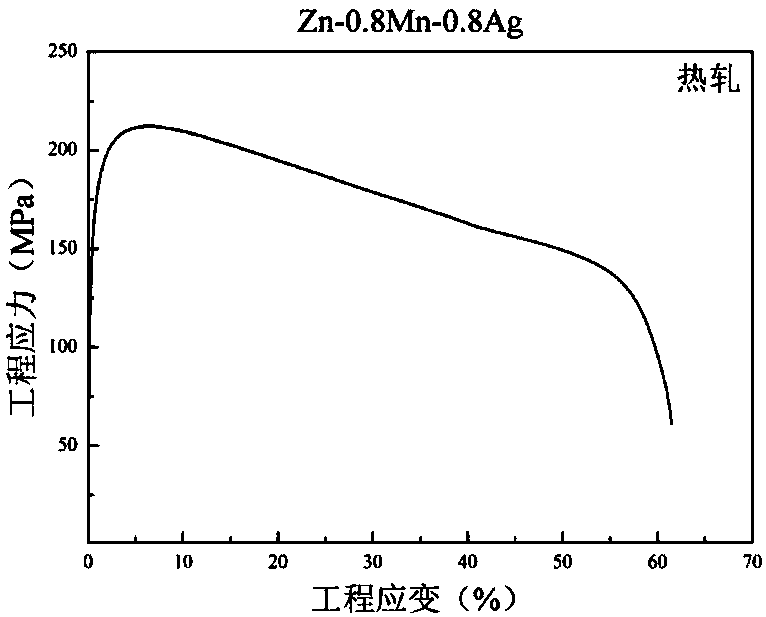

[0047] The hot-rolled Zn-0.8Mn-0.8Ag alloy sheet was prepared and the mechanical properties of the material were measured.

[0048] Process route: casting→homogenizing heat treatment→hot rolling→finished product.

[0049] The composition of the alloy is as follows: Mn is 0.8%, Ag is 0.8%, and the rest is Zn. A Zn-0.8Mn-0.8Ag alloy ingot was prepared according to the smelting method provided in Example 1, and a plate with a thickness of 20 mm was cut from the ingot. Homogenized heat treatment is first performed on the plate at a temperature of 360°C for 6 hours, and then water quenched. Afterwards, the plate is hot-rolled, and the plate is kept at 320° C. for 1 hour, and then the thickness is reduced to 2 mm through 5 rolling passes, and the total deformation is 90%.

[0050] According to the method provided in Example 1, the mechanical properties of the hot-rolled Zn-0.8Mn-0.8Ag alloy sheet were tested. The tensile engineering stress-strain curve of hot-rolled Zn-0.8Mn-0.8A...

Embodiment 3

[0052] Cold-rolled Zn-0.8Mn-0.4Ag and Zn-0.8Mn-0.4Ca alloy sheets were prepared and the mechanical properties of the materials were measured.

[0053] Process route: casting→homogenizing heat treatment→hot rolling→warm rolling→solution→cold rolling→finished product.

[0054] The composition of the alloy is as follows: (1) Mn is 0.8%, Ag is 0.4%, and the rest is Zn; (2) Mn is 0.8%, Ca is 0.4%, and the rest is Zn. Perform alloy casting→homogenizing heat treatment→hot rolling→warm rolling according to the method provided in Example 1 to obtain warm-rolled Zn-0.8Mn-0.4Ag and Zn-0.8Mn-0.4Ca alloy sheets with a thickness of 5mm. Firstly, the warm-rolled Zn-0.8Mn-0.4Ag and Zn-0.8Mn-0.4Ca alloy sheets are subjected to solution treatment, and the specific process is to keep the temperature at 380° C. for 1 hour, and then water quench. Then the warm-rolled Zn-0.8Mn-0.4Ag and Zn-0.8Mn-0.4Ca alloy plates are fed into the cold rolling mill, and the thickness is reduced to 1mm after 4 pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com