Preparation method of heat-resistant oxygen-resistant polyester film

A technology of oxygen polyester and film, which is applied in the field of preparation of organic polymer compounds, and can solve the problem of affecting the heat and oxygen resistance of PET polyester film, affecting the uniformity of heat and oxygen resistance of the film, and the poor dispersion uniformity of antioxidants. and other problems, to achieve the effect of high temperature resistance, simple process and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

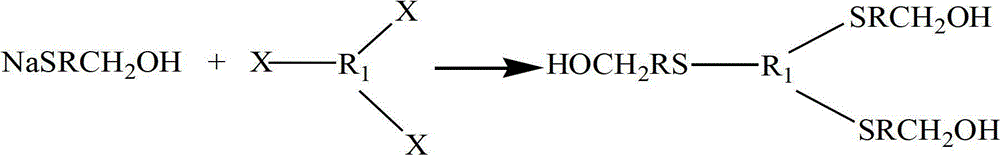

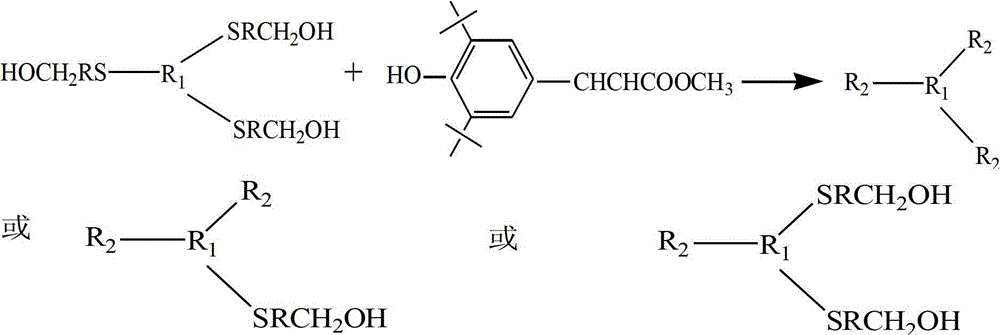

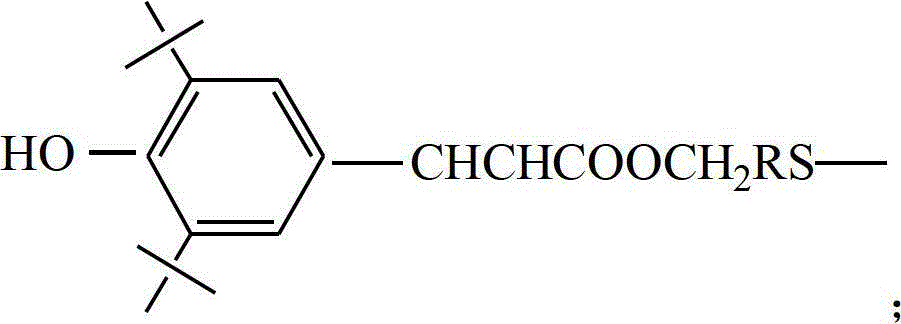

Method used

Image

Examples

Embodiment 1-1

[0056] Dissolve 22 parts by mass of sodium 4-hydroxybenzylthiophenate and 8 parts by mass of 1,3,5-trichlorobenzene in 80-100 parts by mass of N,N-dimethylformamide (DMF) solvent, and add a catalyst of 0.06 Parts by mass of palladium acetate, react at 90°C to 95°C for 1.5hr to 2hr, after the reaction is completed, distill off DMF under reduced pressure at 0.08 to 0.10MPa, and then use 50 parts by mass of isopropanol to extract the DMF once Then collect the extract, distill off isopropanol under reduced pressure at 0.08-0.10MPa to obtain 1,3,5-tris(4-hydroxybenzylthio)benzene liquid.

Embodiment 1-2

[0058] Dissolve 23 parts by mass of sodium 4-hydroxybenzylthiophenate and 8 to 10 parts by mass of 1,3,5-trichlorobenzene in 80 to 100 parts by mass of N,N-dimethylformamide (DMF) solvent, add Catalyst 0.10 parts by mass of iron acetate, react at 90°C to 95°C for 1.5hr to 2hr, after the reaction is completed, distill off DMF under reduced pressure at 0.08 to 0.10MPa, then extract with 60 parts by mass of isopropanol once to remove DMF The reactant; then collect the extract, and distill off isopropanol under reduced pressure at 0.08-0.10MPa to obtain 1,3,5-tris(4-hydroxybenzylthio)benzene liquid.

Embodiment 1-3

[0060] Dissolve 25 parts by mass of sodium 4-hydroxybenzylthiophenate and 8 parts by mass of 1,3,5-trichlorobenzene in 80-100 parts by mass of N,N-dimethylformamide (DMF) solvent, and add a catalyst of 0.08 Parts by mass of cobalt acetate, reacted at 90°C to 95°C for 1.5hr to 2hr, after the reaction was completed, distilled off DMF under reduced pressure at 0.08 to 0.10MPa, and then extracted twice with 80 parts by mass of isopropanol from which DMF had been removed Reactant; then collect the extract, distill off isopropanol under reduced pressure at 0.08-0.10MPa to obtain 1,3,5-tris(4-hydroxybenzylthio)benzene liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com