Heat-resistant anti-aging high-strength artificial transparent stone and preparation method thereof

An anti-aging, high-strength technology, applied in the field of translucent stone, heat-resistant, aging-resistant, high-strength artificial translucent stone and its preparation, can solve the problems of easy scratch and wear, and achieve improved mechanics and mechanical properties , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

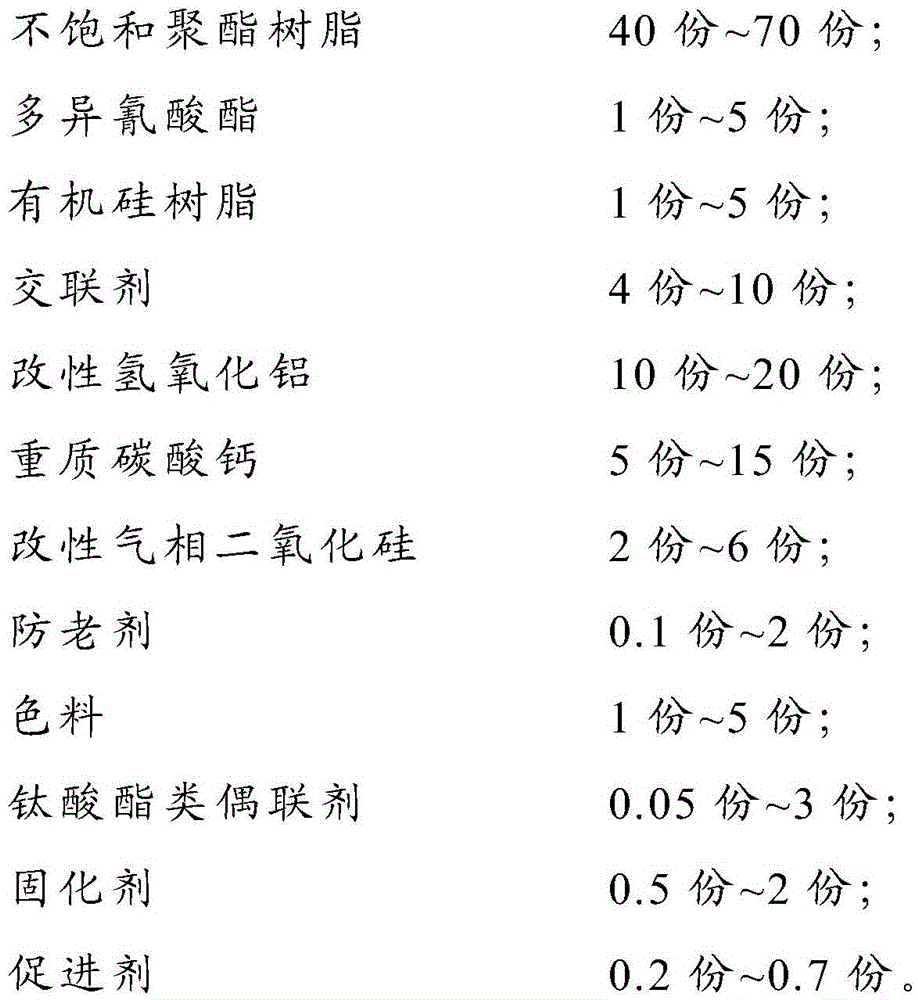

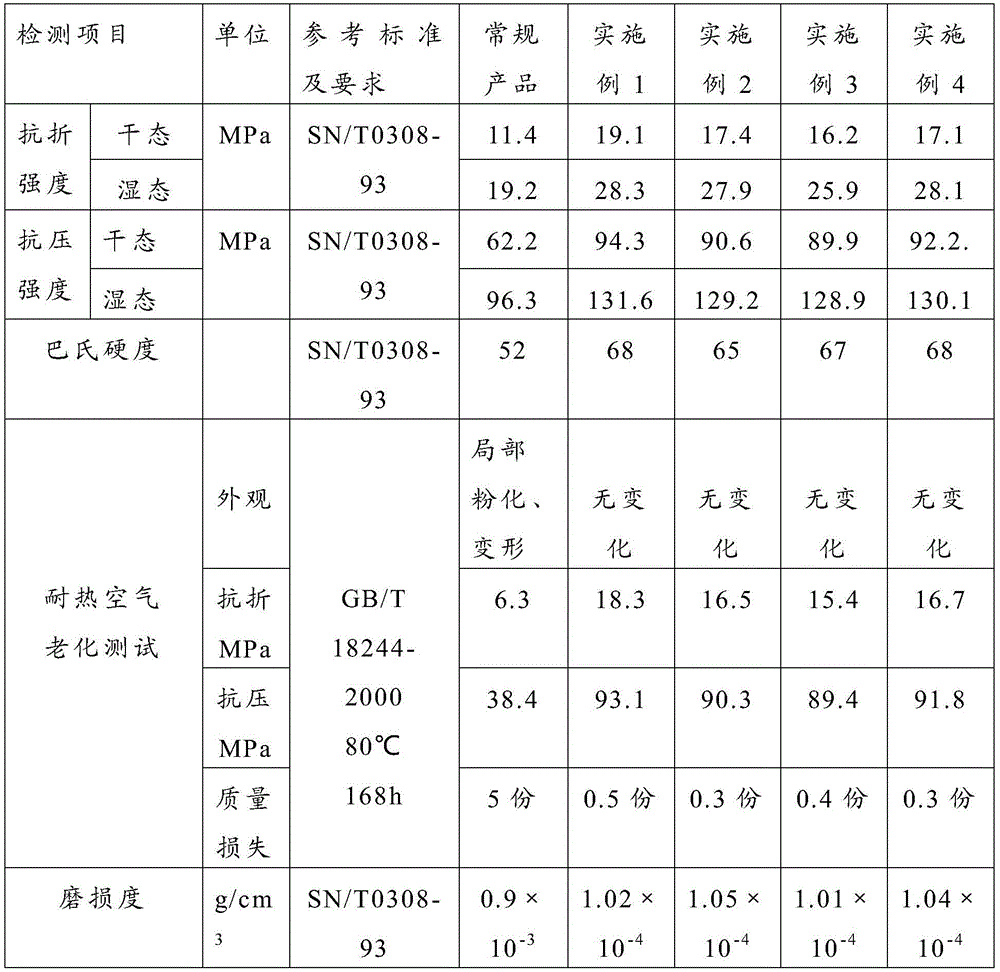

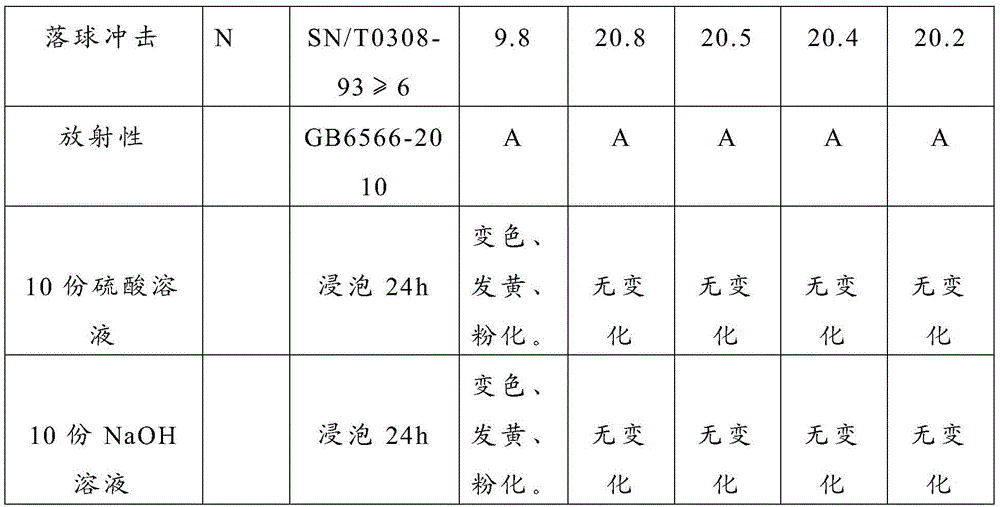

[0030] Embodiment 1, this embodiment provides a heat-resistant, aging-resistant, high-strength artificial translucent stone

[0031] First weigh 40 parts of unsaturated polyester resin, 1 part of polyisocyanate, 1 part of silicone resin, 6 parts of crosslinking agent, 12.5 parts of modified aluminum hydroxide, 7.7 parts of heavy calcium carbonate, and 3.5 parts of modified fumed silica. 1.2 parts of anti-aging agent, 1.6 parts of colorant, 1.4 parts of titanate coupling agent, 1.1 parts of curing agent, and 0.3 parts of accelerator.

[0032] Among them, the unsaturated polyester resin is composed of the following components (by weight percentage): bisphenol A type unsaturated polyester resin 47%, isophthalic acid type unsaturated polyester resin 26%, neopentyl glycol type unsaturated poly Ester resin 27%; Polyisocyanate is made up of following composition (by weight percentage): TDI-TMP adduct 49%, has the triisocyanate 51% of diurea structure; Silicone resin is made up of fol...

Embodiment 2

[0035] Embodiment 2, this embodiment provides a heat-resistant, high-strength artificial translucent stone:

[0036] First weigh 56.5 parts of unsaturated polyester resin, 1 part of polyisocyanate, 1 part of silicone resin, 4 parts of crosslinking agent, 10 parts of modified aluminum hydroxide, 5 parts of heavy calcium carbonate, and 2 parts of modified fumed silica. 0.1 part of anti-aging agent, 1 part of colorant, 0.05 part of titanate coupling agent, 0.5 part of curing agent, and 0.2 part of accelerator.

[0037] Wherein, the unsaturated polyester resin is composed of the following components by weight percentage: bisphenol A type unsaturated polyester resin 26%, isophthalic acid type unsaturated polyester resin 47%, neopentyl glycol type unsaturated polyester resin 27%; the polyisocyanate is a TDI-TMP adduct, the silicone resin is a silanol-modified hydroxyl silicone resin, and the cross-linking agent is composed of the following components by weight percentage: diallyl ph...

Embodiment 3

[0040] Embodiment 3, this embodiment provides a heat-resistant, high-strength artificial translucent stone:

[0041] First weigh 70 parts of unsaturated polyester resin, 5 parts of polyisocyanate, 5 parts of silicone resin, 10 parts of crosslinking agent, 20 parts of modified aluminum hydroxide, 15 parts of heavy calcium carbonate, and 6 parts of modified fumed silica. 2 parts, anti-aging agent 2 parts, colorant 5 parts, titanate coupling agent 3 parts, curing agent 2 parts, accelerator 0.7 parts.

[0042] Wherein, the unsaturated polyester resin is composed of the following components by weight percentage: isophthalic acid type unsaturated polyester resin 46%, neopentyl glycol type unsaturated polyester resin 54%; polyisocyanate is composed of the following components by weight percentage : TDI-TMP adduct 32%, triisocyanate with diurea structure 68%, silicone resin consists of the following components by weight percentage silanol 33%, silanol modified hydroxyl silicone resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com