High-damp-heat-aging-resistance pe film for solar cell panel and preparation method of pe film

A technology for solar panels, damp heat aging, applied in applications, circuits, electrical components, etc., can solve the problems of low pe film bonding strength, poor aging resistance and weather resistance, etc., to improve thermal oxygen resistance, good Anti-ultraviolet oxidation, the effect of expanding the absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

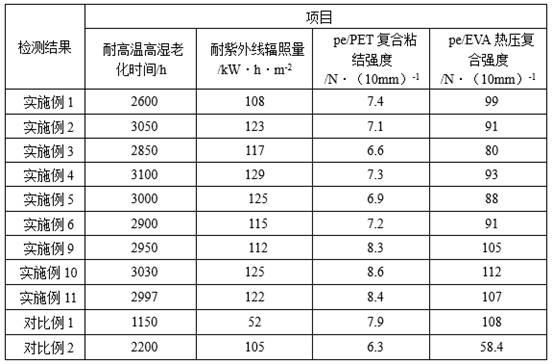

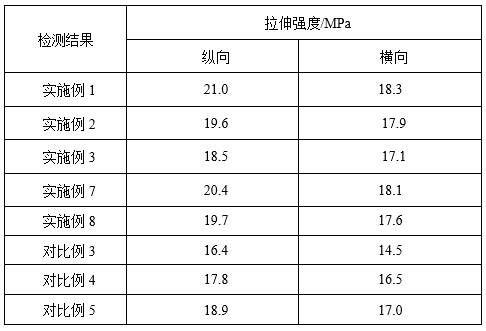

Examples

preparation example 1

[0053] Take 25kg of primary antioxidant 1010 and 25kg of secondary antioxidant 168, add them into a small high-speed mixer and stir to obtain antioxidant mixture 1.

preparation example 2

[0055] Take 25kg of primary antioxidant 300 and 25kg of secondary antioxidant TNP, add them into a small high-speed mixer and stir to obtain antioxidant mixture 2.

preparation example 3

[0057] Take 10kg of light stabilizer UV-326 and 10kg of light stabilizer UV-531, add them into a small high-speed mixer and stir to obtain light stabilizer mixture 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com