Method for preparing SiC coating on surface of graphite crucible by using in-situ reaction method

A graphite crucible and in-situ reaction technology, which is applied in the field of SiC coating, can solve the problems of long coating cycle and complex method, and achieve the effects of improving service life, simple process and preventing reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 in-situ reaction method prepares the SiC coating on graphite crucible surface

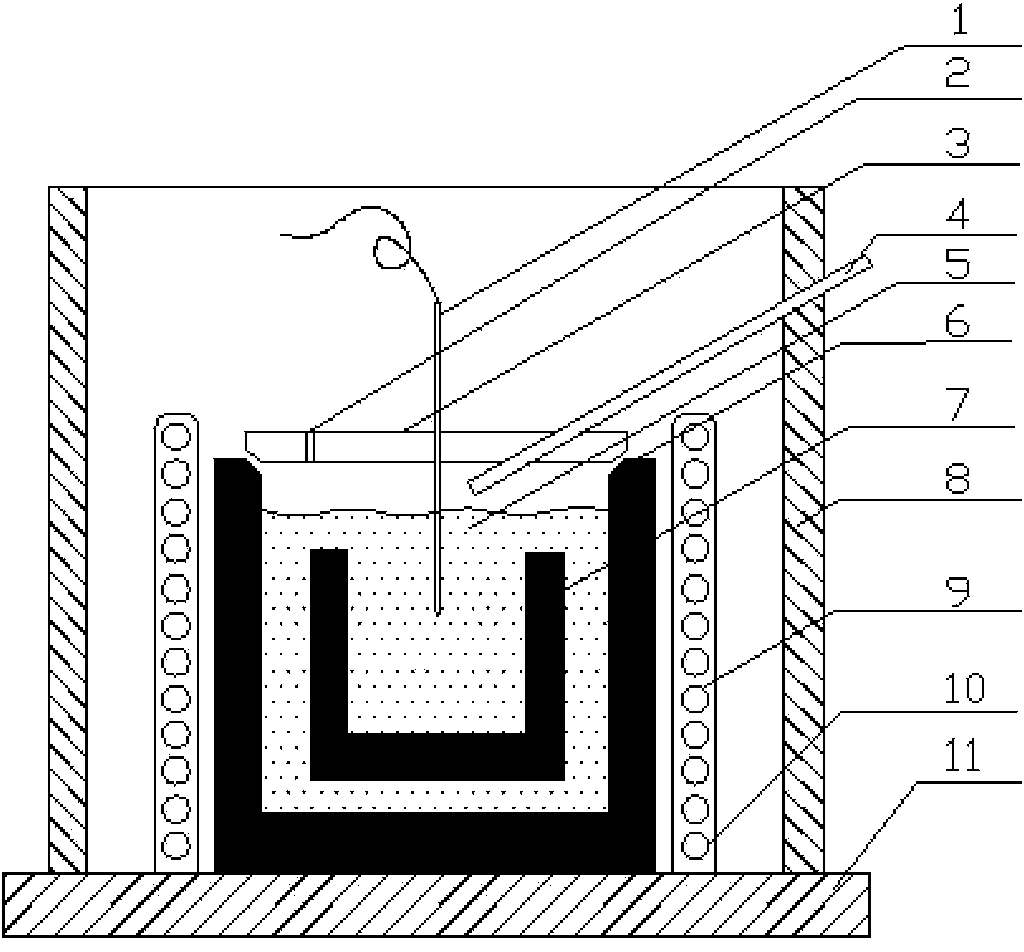

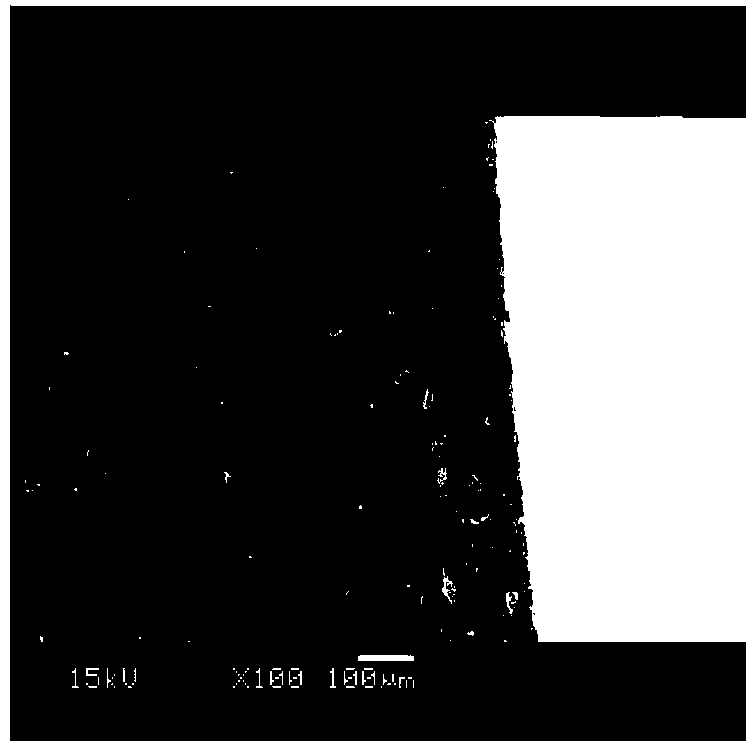

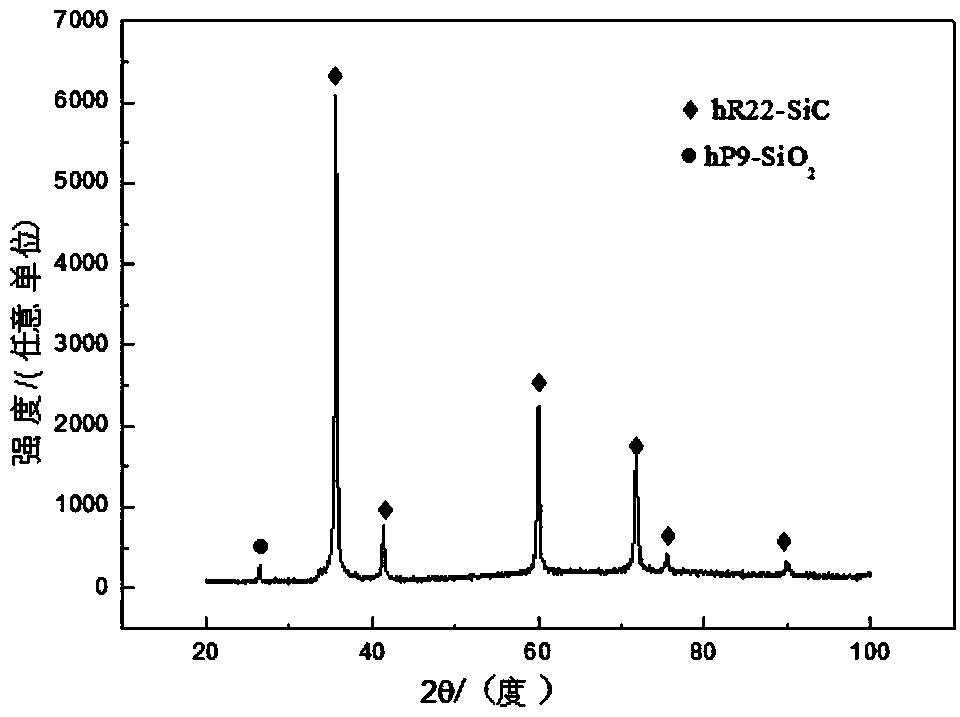

[0034] The graphite crucible for coating is buried in the silicon powder in the graphite crucible for heat generation, and placed in a supersonic frequency induction furnace. After being heated by supersonic frequency, the graphite crucible for coating and the silicon powder react in situ. A SiC coating with uniform thickness is formed on the surface, such as figure 1 , the specific method includes the following steps:

[0035] ① Grind the crucible for coating with sandpaper until the surface is smooth, and the sequence of using sandpaper is 200#, 600#, 1000#, 2000#;

[0036] ②The polished coating is buried in the silicon powder in the graphite crucible for heating with a graphite crucible to obtain the pre-reaction material;

[0037] ③ place the pre-reaction material in step ② in the supersonic frequency induction heating furnace, cover the graphite crucible for heating tight...

Embodiment 2

[0042] The mensuration of the thermal oxidation resistance of embodiment 2 SiC coating graphite crucible

[0043] First, the temperature of the tube furnace (a furnace capable of long-term heating and heat preservation) is raised to 700°C. The SiC-coated graphite crucible and the uncoated graphite crucible of the present invention are placed in a tube furnace, and the two ends of the tube furnace heating quartz tube are not sealed so that they are in direct contact with the air. The graphite crucible with SiC coating and the graphite crucible without coating were kept in a tube furnace for 2 hours. After the heat preservation was completed, they were taken out and weighed with an electronic balance, and the mass loss rate was calculated. The main reason for the mass loss of the graphite crucible is the oxidation reaction with the oxygen in the air, and the less the mass loss rate, the stronger the oxidation resistance at high temperature, and vice versa, the weaker the oxidati...

Embodiment 3

[0044] The mensuration of the thermal shock resistance performance of embodiment 3 SiC coating graphite crucible

[0045] First, the temperature of the tube furnace (a furnace capable of long-term heating and heat preservation) is raised to 700°C. The SiC-coated graphite crucible and the uncoated graphite crucible of the present invention are placed in a tube furnace, and the two ends of the tube furnace heating quartz tube are not sealed so that they are in direct contact with the air. The graphite crucible with SiC coating and the graphite crucible without coating of the present invention are kept in a tube furnace for 2 hours, and taken out after the heat preservation is completed. After it was cooled to room temperature, the SiC-coated graphite crucible and the uncoated graphite crucible were placed in the tube furnace again, kept at 700°C for 2 hours in the tube furnace, and taken out after the heat preservation was completed. Repeat this six times. After six cycles of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com