Thermal insulating pipe and manufacturing method of thermal insulating pipe

A technology of thermal insulation pipe and thermal insulation layer, applied in the field of pipeline, can solve the problems of shortening the service life of thermal insulation pipe, leakage of energy, low quality, etc., and achieve the effects of improving thermal oxidation resistance, improving aging resistance and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

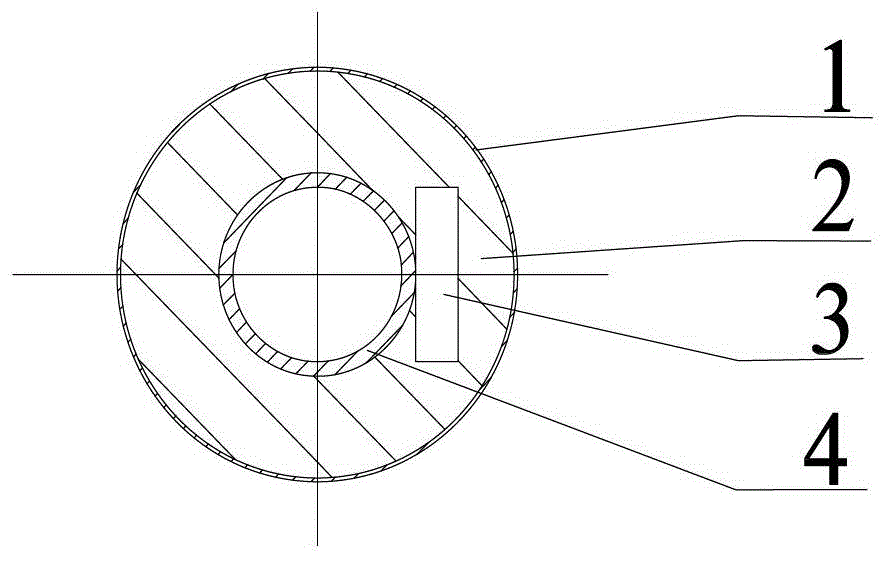

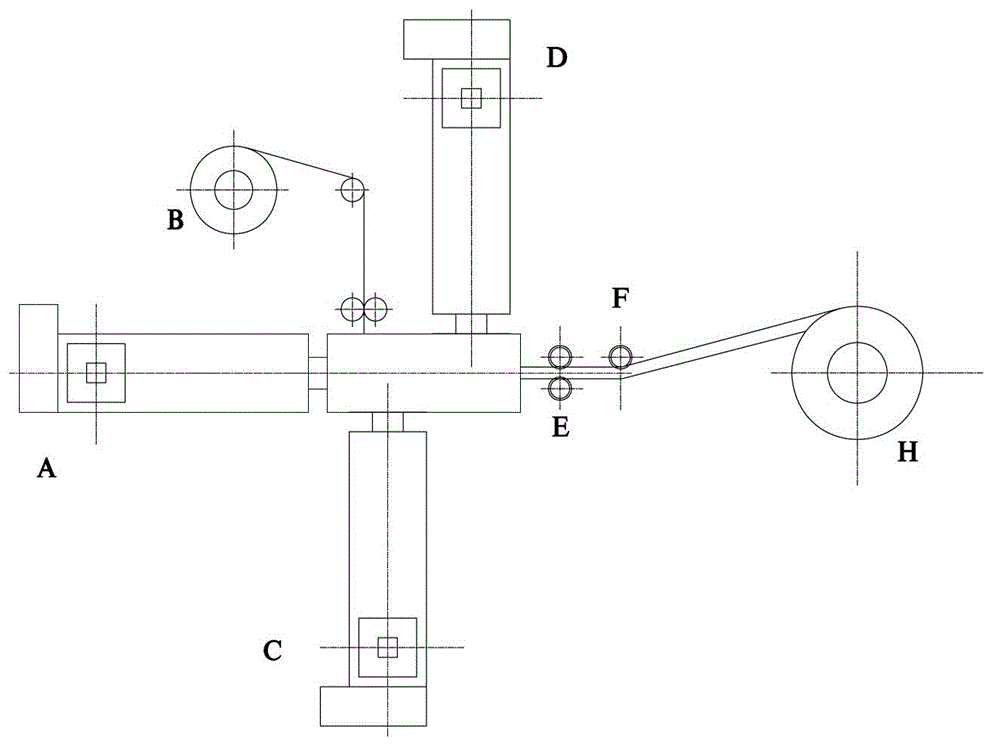

[0040]The present invention also provides a method for preparing a thermal insulation pipe, which includes the following steps: extruding and preliminarily molding the cross-linked polyethylene pellets through No. 1 extruder to obtain a hollow cross-linked polyethylene layer; The device is drawn out from the machine head and laid on the cross-linked polyethylene layer, and then the polyethylene insulation pellets are extruded through the No. 2 extruder, and spread on the cross-linked polyethylene layer containing the electric heating device to obtain the polyethylene insulation layer; the ultraviolet radiation resistant polyethylene pellets are extruded through the No. 3 extruder, spread on the polyethylene insulation layer, and then cooled and shaped to obtain the insulation pipe. The cross-linked polyethylene layer, the polyethylene insulation layer, the ultraviolet radiation-resistant polyethylene layer and the electric heating device are the same as those described above, a...

Embodiment 1

[0053] 1.1 60 parts by weight of high-density polyethylene, 40 parts by weight of low-density polyethylene, 2 parts by weight of silane, 0.8 parts by weight of antioxidant 1010, 0.2 parts by weight of dicumyl peroxide and 0.15 parts by weight of di-n-butyltin dilaurate Add granulation equipment to obtain cross-linked polyethylene pellets, put them into No. 1 extruder, extrude at a temperature of 120°C, and obtain an empty tube with an inner diameter of 12mm after preliminary molding, and a cross-linked polyethylene layer with a thickness of 2mm The inner tube of the heating wire is laid on the cross-linked polyethylene layer through the machine head.

[0054] 1.2 Add 100 parts by weight of low-density polyethylene, 8 parts by weight of butane foaming agent and 2 parts by weight of monoglyceride lubricating and homogenizing agent to the granulation equipment to obtain polyethylene insulation layer pellets, which are added to No. 2 extruder , extruded at a temperature of 175°C, ...

Embodiment 2

[0057] 2.1 62 parts by weight of high-density polyethylene, 42 parts by weight of low-density polyethylene, 1 part by weight of silane, 0.5 parts by weight of antioxidant 1010, 0.2 parts by weight of dicumyl peroxide and 0.15 parts by weight of di-n-butyltin dilaurate Add granulation equipment to obtain cross-linked polyethylene pellets, put them into No. 1 extruder, extrude at a temperature of 120°C, and obtain an empty tube with an inner diameter of 12mm after preliminary molding, and a cross-linked polyethylene layer with a thickness of 2mm The inner tube of the heating wire is laid on the cross-linked polyethylene layer through the machine head.

[0058] 2.2 Add 100 parts by weight of low-density polyethylene, 9 parts by weight of butane foaming agent and 2.5 parts by weight of monoglyceride lubricating homogenizer to the granulation equipment to obtain polyethylene insulation layer pellets, which are added to No. 2 extruder , extruded at a temperature of 175°C, and spread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com