Antibacterial polypropylene material and its preparation process

A technology of antibacterial polypropylene and polypropylene resin, applied in botany equipment and methods, biocides, plant growth regulators, etc., can solve the problems of poor antibacterial performance, unsustainable, high production cost, etc., and achieve improved weather resistance and reduced Production cost, fast effect of antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

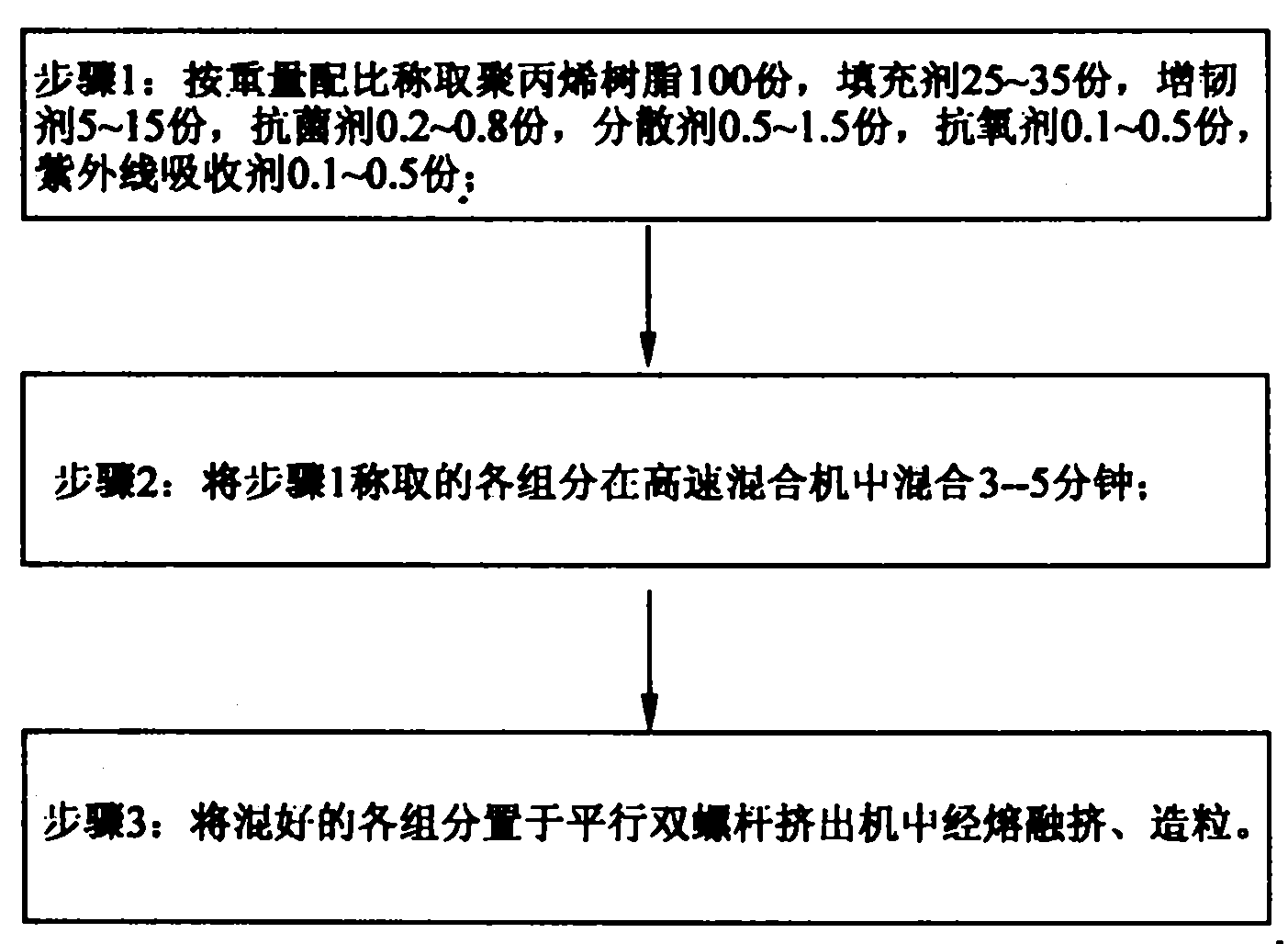

Method used

Image

Examples

specific Embodiment approach

[0014] The present invention proposes a kind of antibacterial polypropylene material, and its component and content are:

[0015] 100 parts of polypropylene (PP) resin;

[0016] Filling agent 25-35 parts;

[0017] Toughening agent 5-15 parts;

[0018] 0.2-0.8 parts of antibacterial agent;

[0019] Dispersant 0.5~1.5 parts;

[0020] Antioxidant 0.1~0.5 parts;

[0021] UV absorber 0.1~0.5 part;

[0022] The above contents are by weight.

[0023] The polypropylene resin is homopolypropylene.

[0024] The antibacterial agent is compounded by nano-silver and organic silicon antibacterial agent in a mass ratio of 5:1.

[0025] The filler is nanometer calcium carbonate.

[0026] The toughening agent is polyolefin elastomer ethylene-1-octene copolymer (POE), which is 8150 type POE produced by DuPont Company of the United States.

[0027] The dispersant is TAS-2A, an ethylene bis fatty acid amide high-gloss lubricating dispersant.

[0028] The antioxidant is phosphite antioxi...

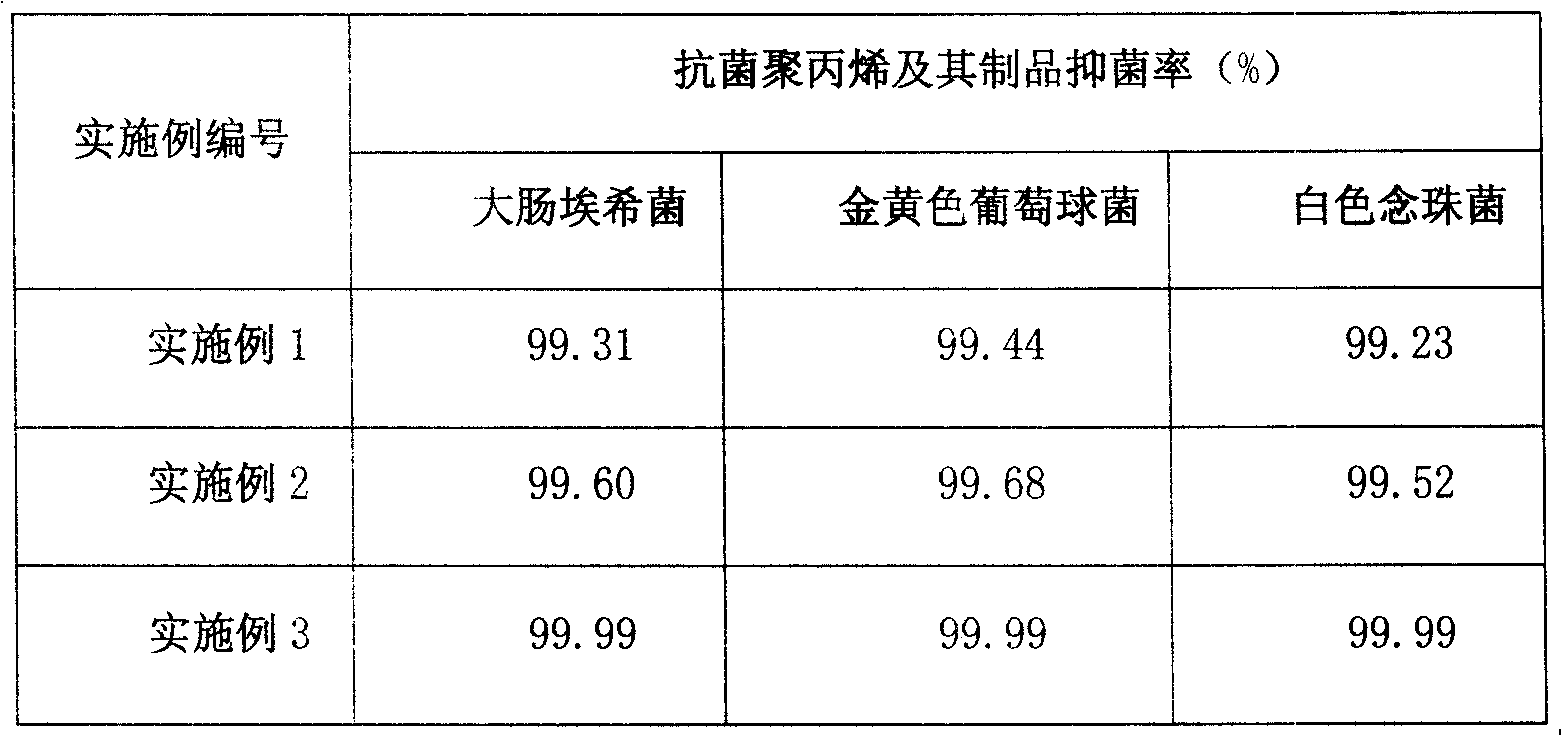

Embodiment 1

[0038] In parts by weight, mix 100 parts of PP resin, 25 parts of filler, 5 parts of toughening agent, 0.2 part of antibacterial agent, 0.5 part of dispersant, 0.1 part of antioxidant, and 0.1 part of ultraviolet absorber in a high-speed mixer 3 to 5 minutes, the speed of the high-speed mixer is 800 rpm; then the mixed raw materials are placed in a parallel twin-screw extruder for melt extrusion and granulation. The extrusion process is: 1 zone 170--180 ℃ , Zone 2 180--190°C, Zone 3 180--190°C, Zone 4 175--185°C, screw speed 300-350r / min, feeding frequency 15-20Hz, melt pressure 3.0-4.0MPa, vacuum degree -0.03---0.06MPa.

Embodiment 2

[0040] In parts by weight, 100 parts of PP resin, 30 parts of filler, 10 parts of toughening agent, 0.5 part of antibacterial agent, 1 part of dispersant, 0.3 part of antioxidant, 0.3 part of ultraviolet absorber, mixed in a high-speed mixer 3 to 5 minutes, the speed of the high-speed mixer is 800 rpm; then the mixed raw materials are placed in a parallel twin-screw extruder for melt extrusion and granulation. The extrusion process is: 1 zone 170--180 ℃ , Zone 2 180--190°C, Zone 3 180--190°C, Zone 4 175--185°C, screw speed 300-350r / min, feeding frequency 15-20Hz, melt pressure 3.0-4.0MPa, vacuum degree -0.03---0.06MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com