Antioxidant and high-temperature-resistant liquid silicone rubber and preparation method thereof

A technology of liquid silicone rubber and high temperature resistance is applied in the field of liquid silicone rubber to achieve the effects of simple and easy preparation method, good mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

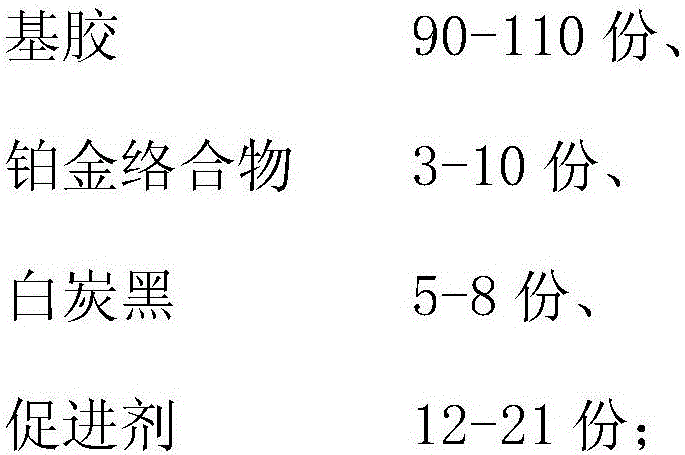

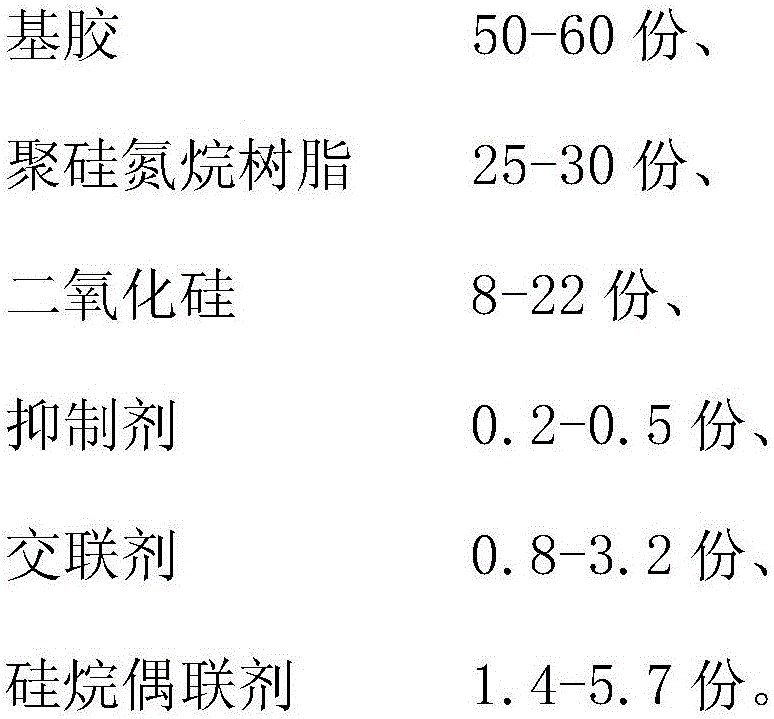

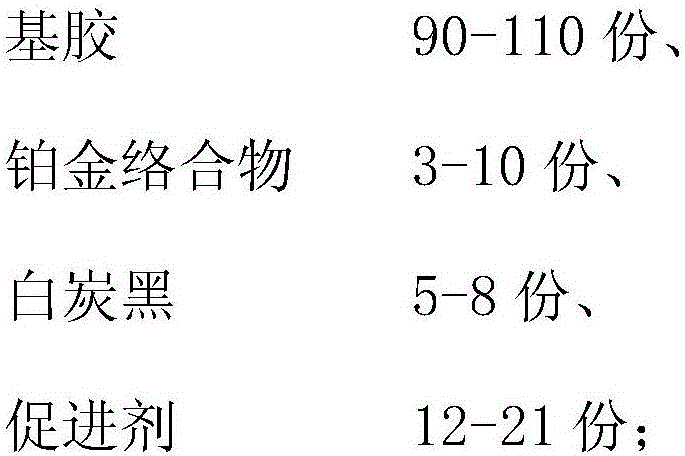

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of anti-oxidation and high temperature resistant liquid silicone rubber, the steps are as follows:

[0036] (1) Prepare base glue:

[0037] ① In parts by weight, 15 parts of vinylpolysiloxane, 28 parts of glycerol, 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid n- Add 5 parts of stearyl ester into the kneader, and knead for 3.5 hours at a temperature of 35°C;

[0038] ② After raising the kneader to 75°C within 40 minutes, add 38 parts of vinyl polysiloxane with a viscosity of 7500 cp measured at 25°C in parts by weight and continue kneading for 2.5 hours;

[0039] ③ Continue to add 22 parts of vinyl polysiloxane, 5 parts of dicyclohexane, and 15 parts of tetramethyltetravinylcyclotetrasiloxane with a viscosity of 20,000 cp measured at 25°C in parts by weight, and increase the kneading while kneading The temperature inside the machine is to increase the temperature at a rate of 5°C / 15min until the temperature rises to 175°C, and then continue...

Embodiment 2

[0050] A preparation method of anti-oxidation and high temperature resistant liquid silicone rubber, the steps are as follows:

[0051] (1) Prepare base glue:

[0052] ① In parts by weight, 18 parts of vinyl polysiloxane, 23 parts of glycerol, 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid n- Add 3 parts of stearyl ester into the kneader, and knead for 3.5 hours at a temperature of 35°C;

[0053] ② After raising the kneader to 75°C within 45 minutes, add 32 parts of vinyl polysiloxane with a viscosity of 7200cp measured at 25°C in parts by weight and continue kneading for 2.5 hours;

[0054]③ Continue to add 27 parts of vinylpolysiloxane, 7 parts of dicyclohexane, and 16 parts of tetramethyltetravinylcyclotetrasiloxane with a viscosity of 18000cp measured at 25°C in parts by weight, and knead while kneading The temperature inside the machine is to increase the temperature at a rate of 5°C / 15min until the temperature rises to 175°C, and then continue kneading for 2.5 hou...

Embodiment 3

[0065] A preparation method of anti-oxidation and high temperature resistant liquid silicone rubber, the steps are as follows:

[0066] (1) Prepare base glue:

[0067] ① In parts by weight, 10 parts of vinyl polysiloxane, 20 parts of glycerol, 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid n- Add 1 part of stearyl ester into the kneader, and knead for 3 hours at a temperature of 30°C;

[0068] ②After raising the temperature in the kneader to 70°C within 30 minutes, add 30 parts of vinyl polysiloxane with a viscosity of 8000 cp measured at 25°C in parts by weight and continue kneading for 2 hours;

[0069] ③ Continue to add 18 parts of vinyl polysiloxane, 2 parts of dicyclohexane, and 12 parts of tetramethyltetravinylcyclotetrasiloxane with a viscosity of 25,000 cp measured at 25°C in parts by weight, and knead while kneading The temperature inside the machine is to increase the temperature at a rate of 5°C / 15min until the temperature rises to 170°C, and then continue kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com