Ultralow-expansion-coefficient high-transparency microcrystalline glass and preparation method thereof

A technology of glass-ceramic and expansion coefficient, which is applied in the field of ultra-low expansion coefficient and high-transparency glass-ceramic and its preparation, can solve the problems of difficult-to-heat dishes, inability to solve environmental and glass pollution, difficult glass-ceramic products, etc. The effect of solving molding difficulties, improving heat resistance, and reducing high temperature viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

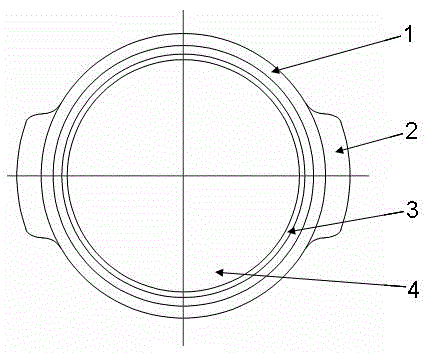

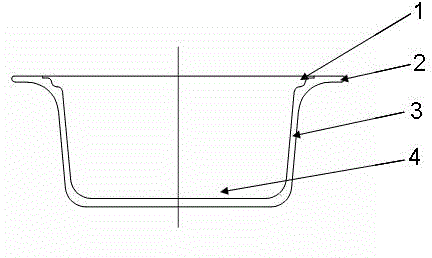

Image

Examples

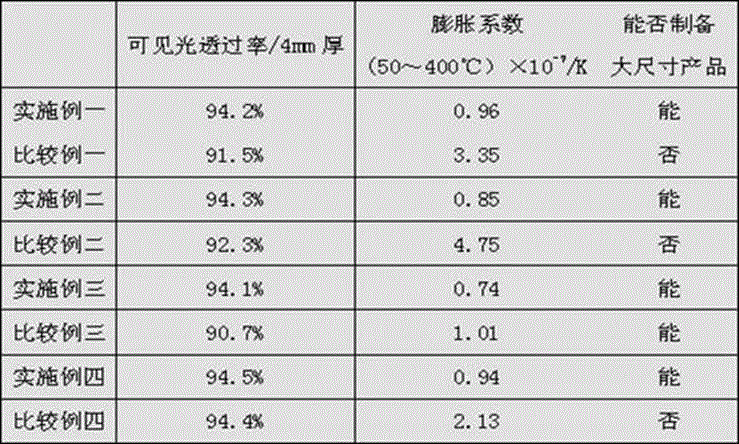

Embodiment 1

[0029] An ultra-low expansion coefficient high-transparency glass-ceramic, comprising a base glass, a crystal nucleating agent and a clarifying agent, and the components of the glass-ceramic by weight percentage: including 68.0% SiO 2 , 19.4% Al 2 O 3 , 3.30% Li 2 O, 3.77% of B 2 O 3 , 0.40% Na 2 O, 0.11% K 2 Base glass consisting of O, 0.30% MgO, 0.69% BaO, and 0.61% ZnO; 1.30% TiO 2 , 1.10% ZrO 2 , 0.40% of P 2 O 5 and 0.60% F of crystal nucleating agent; and 0.02% CeO 2 As a clarifying agent, where CeO 2 with SiO 2 The content ratio of CeO 2 / SiO 2 =0.0003, CeO 2 with Al 2 O 3 The content ratio of CeO 2 / Al 2 O 3 =0.0010 and CeO 2 , SiO 2 , Al 2 O 3 The sum of the weight percentages of the three CeO 2 +SiO 2 +Al 2 O 3 =87.42%. A method for preparing a glass-ceramic with ultra-low expansion coefficient and high transparency, the preparation method is carried out according to the following steps: (1) according to the formula of the above-mentioned ...

Embodiment 2

[0033] A glass-ceramic with ultra-low expansion coefficient and high transparency, including base glass, crystal nucleating agent and clarifying agent, the composition of the glass-ceramic is calculated by weight percentage: including 65.0% SiO 2 , 20.0% Al 2 o 3 , 3.60% Li 2 O, 4.50% B 2 o 3 , 0.20% Na 2 O, 0.28% K 2 Base glass composed of O, 0.50% MgO, 1.40% BaO and 0.76% ZnO; 1.66% TiO 2 , 1.20% ZrO 2 , 0.50% P 2 o 5 and 0.30% of the F composition of the nucleating agent; and 0.10% of CeO 2 As a clarifying agent, where CeO 2 with SiO 2 The content ratio of CeO 2 / SiO 2 =0.0015, CeO 2 with Al 2 o 3 The content ratio of CeO 2 / Al 2 o 3 =0.0050 and CeO 2 , SiO 2 、Al 2 o 3 The sum of the weight percentages of the three CeO 2 +SiO2 2 +Al 2 o 3 =85.10%. A method for preparing glass-ceramic with ultra-low expansion coefficient and high transparency. The preparation method is carried out according to the following steps: (1) ingredients according to the ...

Embodiment 3

[0037]A glass-ceramic with ultra-low expansion coefficient and high transparency, including base glass, crystal nucleating agent and clarifying agent, the components of the glass-ceramic are calculated by weight percentage: including 66.0% SiO 2 , 19.5% Al 2 o 3 , 4.20% Li 2 O, 3.40% B 2 o 3 , 0.10% Na 2 O, 0.40% K 2 Base glass composed of O, 0.32% MgO, 0.60% BaO and 0.73% ZnO; 1.70% TiO 2 , 1.30% ZrO 2 , 0.80% P 2 o 5 and 0.80% of the F composition of the nucleating agent; and 0.15% of CeO 2 As a clarifying agent, where CeO 2 with SiO 2 The content ratio of CeO 2 / SiO 2 =0.0023, CeO 2 with Al 2 o 3 The content ratio of CeO 2 / Al 2 o 3 =0.0077 and CeO 2 , SiO 2 、Al 2 o 3 The sum of the weight percentages of the three CeO 2 +SiO2 2 +Al 2 o 3 =85.65%. A method for preparing glass-ceramic with ultra-low expansion coefficient and high transparency. The preparation method is carried out according to the following steps: (1) ingredients according to the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com