Colored glass-ceramic with ultra-low expansion coefficient and high transparency and preparation method thereof

A technology for glass-ceramic and expansion coefficient, which is applied in the field of ultra-low expansion coefficient and high-transparency colored glass-ceramic and its preparation, which can solve the problem that it is difficult to meet the dual requirements of use function and appearance art, cannot solve the environment and glass pollution, and is difficult to microscopic. Crystal glass products and other problems, to achieve the effect of high coordination number, large radius and solving difficult forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

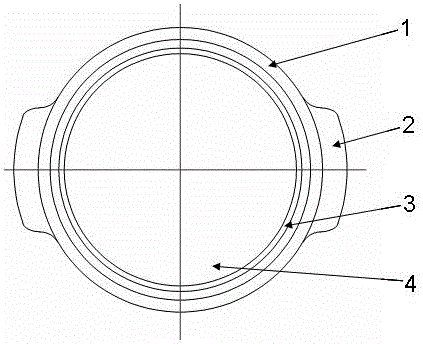

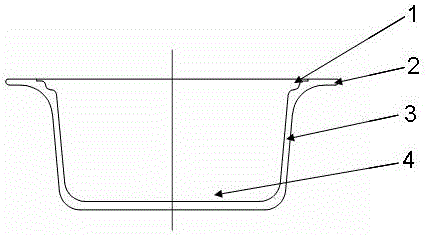

Image

Examples

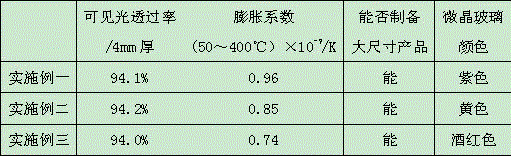

Embodiment 1

[0031] A purple glass-ceramic with ultra-low expansion coefficient and high transparency, including base glass, crystal nucleating agent, clarifying agent and coloring agent, the basic components of glass-ceramic in weight percentage are: including 68.0% SiO 2 , 19.4% Al 2 o 3 , 3.30% Li 2 O, 3.77% B 2 o 3 , 0.40% Na 2 O, 0.11% K 2 Base glass composed of O, 0.30% MgO, 0.69% BaO and 0.61% ZnO, 1.30% TiO 2 , 1.10% ZrO 2 , 0.40% P 2 o 5 and 0.60% of F as a nucleating agent, and 0.02% of CeO 2 As a clarifying agent, where CeO 2 with SiO 2 The content ratio of CeO 2 / SiO 2 =0.0003, CeO 2 with Al 2 o 3 The content ratio of CeO 2 / Al 2 o 3 =0.0010 and CeO 2 , SiO 2 、Al 2 o 3 The sum of the weight percentages of the three CeO 2 +SiO2 2 +Al 2 o 3 =87.42%; when the weight of the above basic components is 100%, the purple glass-ceramic is additionally added with 0.5% of the total weight of the basic components of Co 2 o 3 as a coloring agent.

[0032] A meth...

Embodiment 2

[0035] A yellow glass-ceramic with ultra-low expansion coefficient and high transparency, including base glass, crystal nucleating agent, clarifying agent and coloring agent, the basic components of glass-ceramic by weight percentage are: including 65.0% SiO 2 , 20.0% Al 2 o 3 , 3.60% Li 2 O, 4.50% B 2 o 3 , 0.20% Na 2 O, 0.28% K 2 Base glass composed of O, 0.50% MgO, 1.40% BaO and 0.76% ZnO, 1.66% TiO 2 , 1.20% ZrO 2 , 0.50% P 2 o 5 and 0.30% of F as a nucleating agent, and 0.10% of CeO 2 As a clarifying agent, where CeO 2 with SiO 2 The content ratio of CeO 2 / SiO 2 =0.0015, CeO 2 with Al 2 o 3 The content ratio of CeO 2 / Al 2 o 3 =0.0050 and CeO 2 , SiO 2 、Al 2 o 3 The sum of the weight percentages of the three CeO 2 +SiO2 2 +Al 2 o 3 =85.10%; when the weight of the above-mentioned basic components is 100%, the yellow glass-ceramics is additionally added with 1.6% Ni as the total weight of the basic components 2 o 3 as a coloring agent.

[0036...

Embodiment 3

[0039] A wine red glass-ceramic with ultra-low expansion coefficient and high transparency, including base glass, crystal nucleating agent, clarifying agent and coloring agent, the basic components of glass-ceramic by weight percentage are: including 66.0% SiO 2 , 19.5% Al 2 o 3 , 4.20% Li 2 O, 3.40% B 2 o 3 , 0.10% Na 2 O, 0.40% K 2 Base glass composed of O, 0.32% MgO, 0.60% BaO and 0.73% ZnO, 1.70% TiO 2 , 1.30% ZrO 2 , 0.80% P 2 o 5 and 0.80% of F as a nucleating agent, and 0.15% of CeO 2 As a clarifying agent, where CeO 2 with SiO 2 The content ratio of CeO 2 / SiO 2 =0.0023, CeO 2 with Al 2 o 3 The content ratio of CeO 2 / Al 2 o 3 =0.0077 and CeO 2 , SiO 2 、Al 2 o 3 The sum of the weight percentages of the three CeO 2+SiO2 2 +Al 2 o 3 =85.65%; when the weight of the above basic components is 100%, the wine red glass-ceramic is additionally added with 4.0% of the total weight of the basic components of Nd 2 o 3 as a coloring agent.

[0040] A m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com