Flavor compound health wine and preparation method thereof

A health care wine and flavor technology, applied in the field of food processing, can solve the problems of difficult to guarantee wine quality, lack of aroma, single taste, etc., and achieve the effect of pure taste, good flavor, and not easy to separate out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

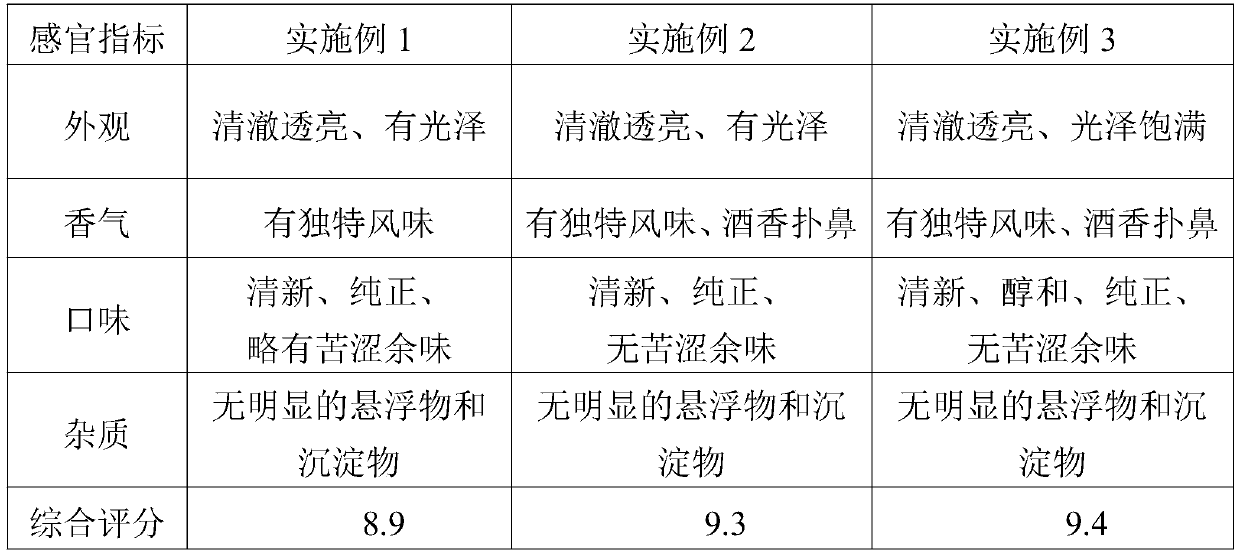

Examples

Embodiment 1

[0023] Step 1: Take Luo Han Guo juice, stevia extract, sweet tea extract in a weight ratio of: 1: 1 and mix, add pure water to dissolve into a 5% solution by mass, add wine active dry yeast BV818 (purchased from Angel yeast) (Chongzuo Co., Ltd.), the amount of yeast added was 1‰ of the weight of the solution, and the fermentation was carried out at room temperature of 30°C for 48 hours. Pectinase was added for enzymatic hydrolysis, enzymatic hydrolysis was carried out in a water bath at 45 °C for 1 hour, and after the enzymatic hydrolysis was completed, it was heated to 80 °C for 10 minutes. Allow to cool to room temperature and centrifuge to obtain supernatant solution A.

[0024] Step 2: Take Luo Han Guo juice, stevia extract, sweet tea extract in a weight ratio of 1:1:1 and mix, add pure water to dissolve into a 10% mass fraction solution, add cyclodextrin glucosyltransferase (1mL / L) and maltodextrin (addition amount of 10 g / L) was stirred at 45° C. for 10 hours, and the s...

Embodiment 2

[0029] Step 1: Take Luo Han Guo juice, stevia extract, sweet tea extract in a weight ratio of 2: 3: 5 and mix, add pure water to dissolve into a 5% mass fraction solution, add wine active dry yeast BV818 (purchased from Angel Yeast (Chongzuo) Co., Ltd.), the amount of yeast added is 2‰ of the weight of the solution, and it was fermented at room temperature at 32°C for 50 hours. Pectinase was added for enzymatic hydrolysis, enzymatic hydrolysis was carried out in a water bath at 48 °C for 1.5 hours, and after the enzymatic hydrolysis was completed, it was heated to 83 °C for 12 minutes. Allow to cool to room temperature and centrifuge to obtain supernatant solution A.

[0030] Step 2: Take Luo Han Guo juice, stevia extract, sweet tea extract in a weight ratio of 2:3:5 and mix, add pure water to dissolve into a 10% mass fraction solution, add cyclodextrin glucosyltransferase (2mL / L) and maltodextrin (addition amount 15g / L) was stirred and reacted at 48°C for 12 hours, and the s...

Embodiment 3

[0035] Step 1: Take Luo Han Guo juice, stevia extract, sweet tea extract in a weight ratio of 5: 6: 8 and mix, add pure water to dissolve into a 5% mass fraction solution, add wine active dry yeast BV818 (purchased from Angel Yeast (Chongzuo) Co., Ltd.), the amount of yeast added is 3‰ of the weight of the solution, and it was fermented at 35°C at room temperature for 72 hours. Pectinase was added for enzymatic hydrolysis, enzymatic hydrolysis was carried out in a water bath at 50 °C for 2 hours, and after the enzymatic hydrolysis was completed, it was heated to 85 °C for 15 minutes. Allow to cool to room temperature and centrifuge to obtain supernatant solution A.

[0036] Step 2: Take Luo Han Guo juice, stevia extract, sweet tea extract in a weight ratio of 5:6:8 and mix, add pure water to dissolve into a 10% mass fraction solution, add cyclodextrin glucosyltransferase (3mL / L) and maltodextrin (addition amount of 20 g / L) were stirred and reacted at 50° C. for 15 hours, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com