Automatic ranking device for bearing production line

An automatic sorting and production line technology, applied in the field of bearing processing, can solve problems such as low sorting efficiency, achieve the effects of high sorting efficiency, avoid blockage, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

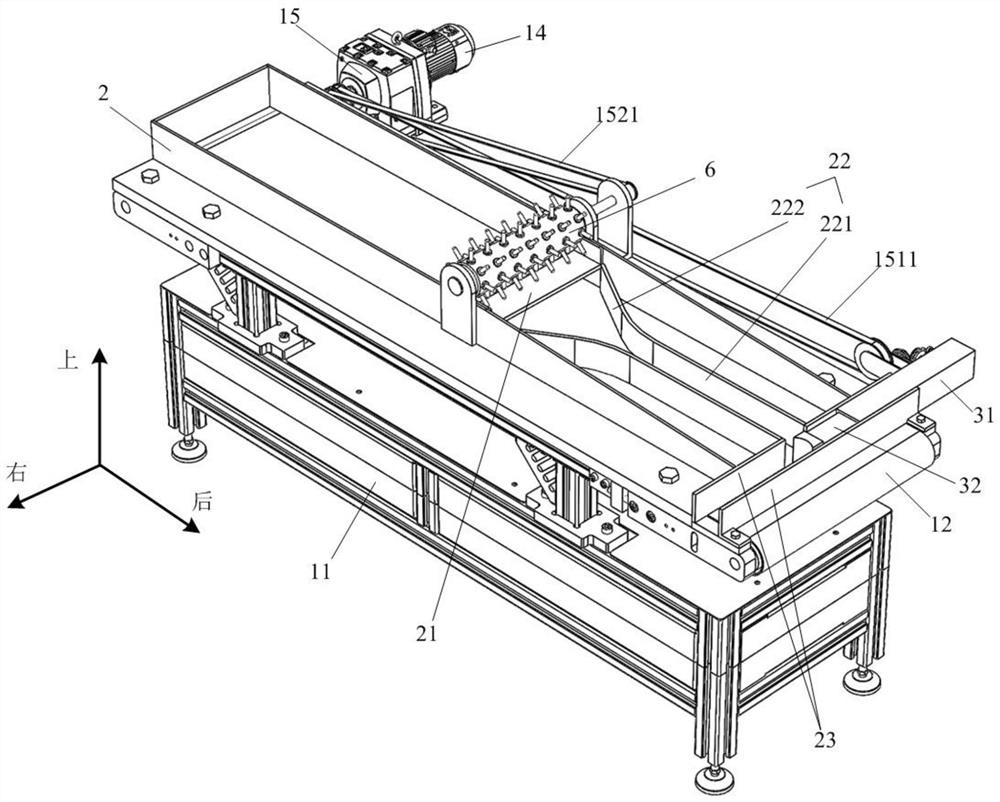

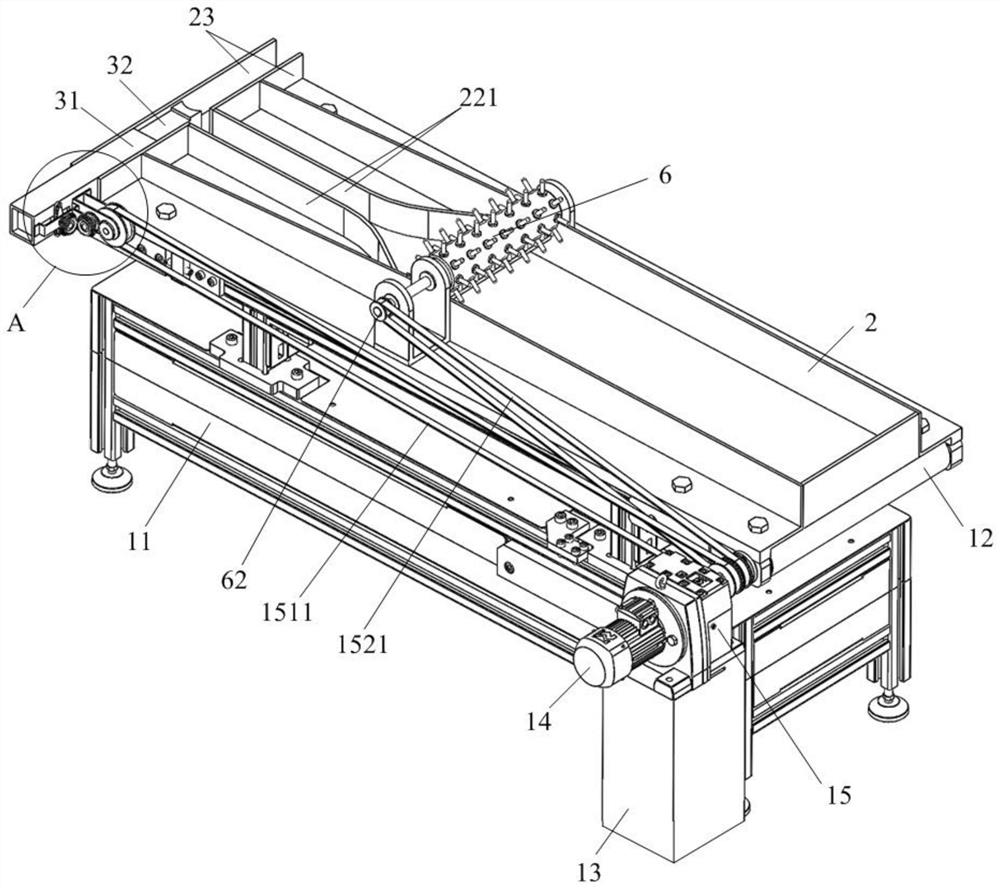

[0043] As a specific embodiment, the drive mechanism includes a drive motor 14 and a speed reducer 15 matched with the drive motor 14, the power output shaft of the speed reducer 15 is connected to the roller (not shown in the figure) match. In this way, the drive motor 14 drives the roller to rotate through the speed reducer 15, and the conveyor belt 12 is driven to rotate when the roller rotates.

Embodiment approach

[0044] As a specific implementation manner, the driving motor 14 is fixed on the outside ground through the motor base 13 .

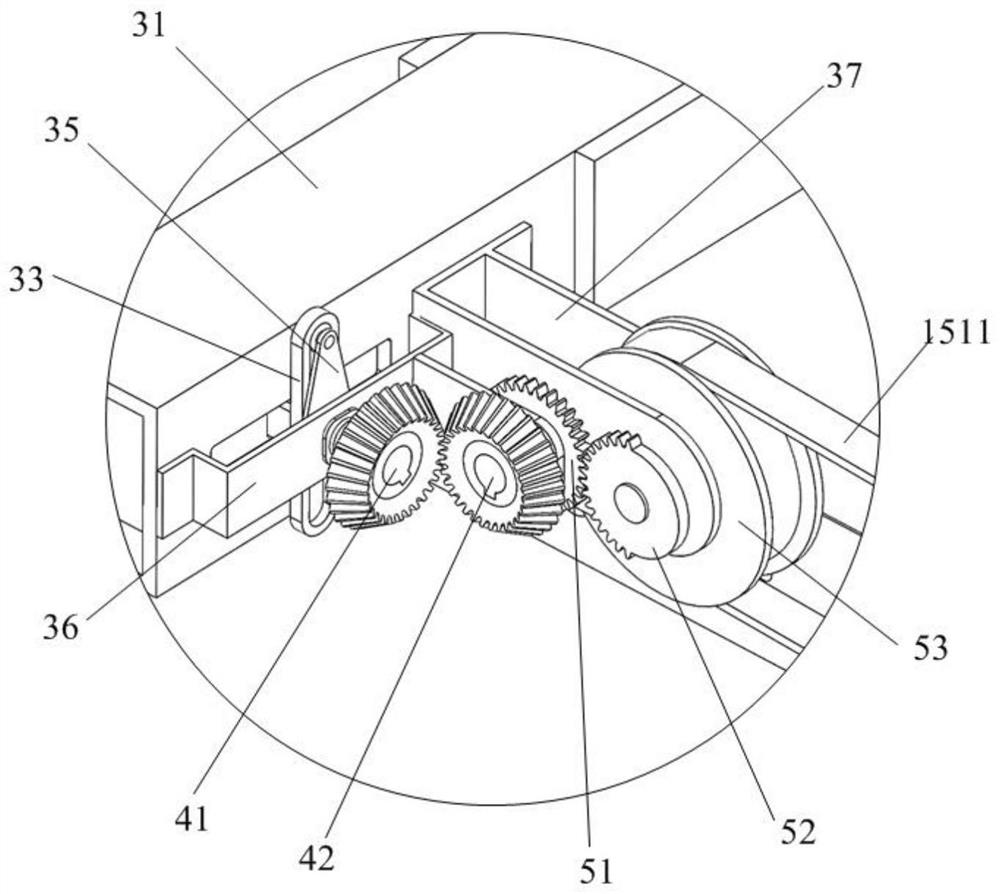

[0045] As a specific implementation, a guide cylinder 31 is provided in the second guide channel, and the push arm 32 is slidably disposed in the guide cylinder 31. One side of the guide cylinder 31 is penetrated with a horizontally extending The first guide groove 311, the push arm 32 is provided with a first slider 322 passing through the first guide groove 311 and extending to the outside of the guide cylinder 31, and the transmission mechanism includes a The connecting piece 33 at the free end of the slider 322 is provided with a second guide groove 331 extending vertically on the connecting piece 33; one side of the guiding cylinder 31 is also rotatably provided with a driving arm 35 and is used to drive the driving arm 33. The arm 35 rotates the first transmission assembly, and the dangling end of the driving arm 35 is provided with a second slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com