Patents

Literature

63results about How to "Accurate laying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Fast and Reliable New Technology for Underwater Laying

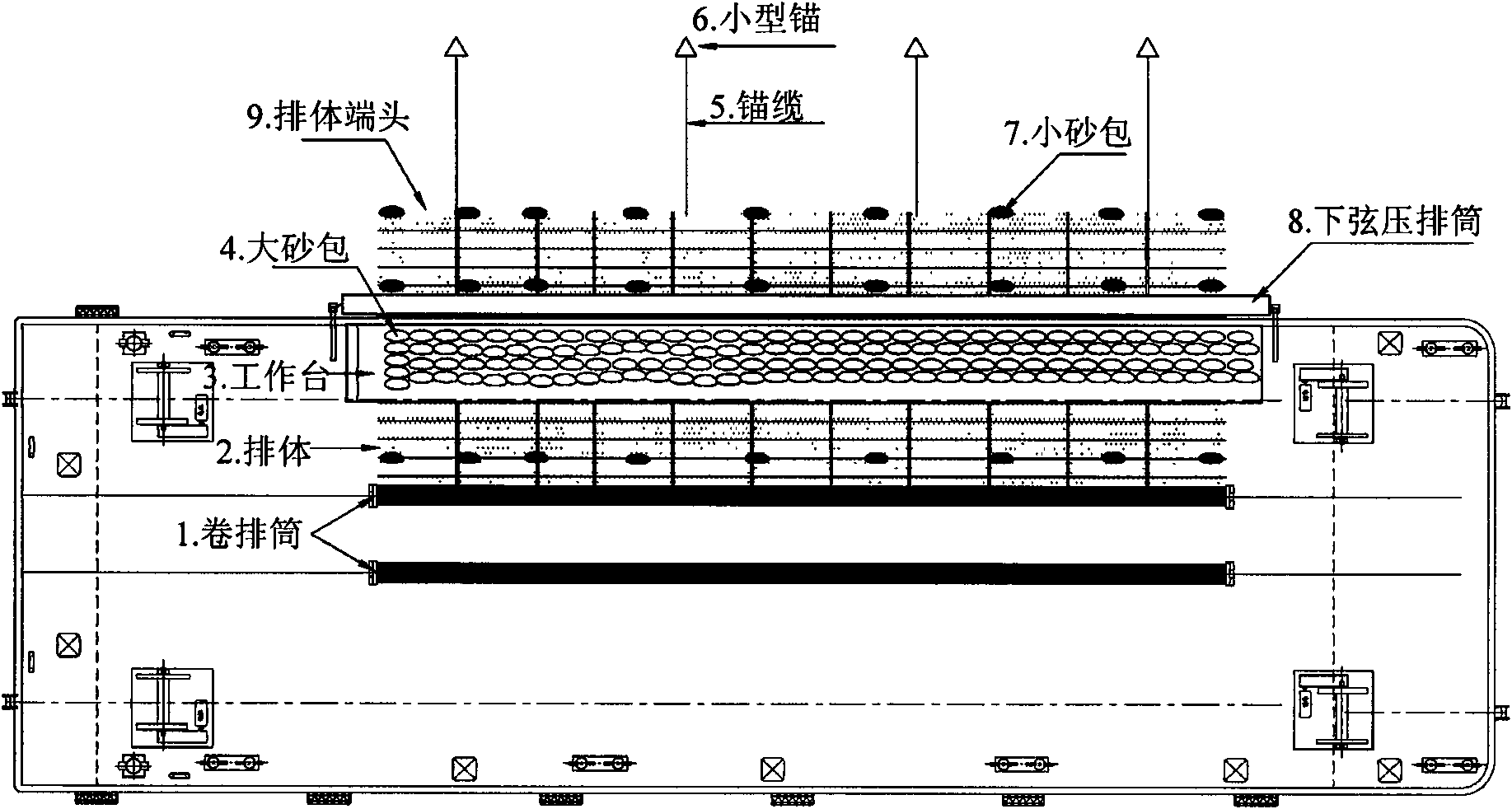

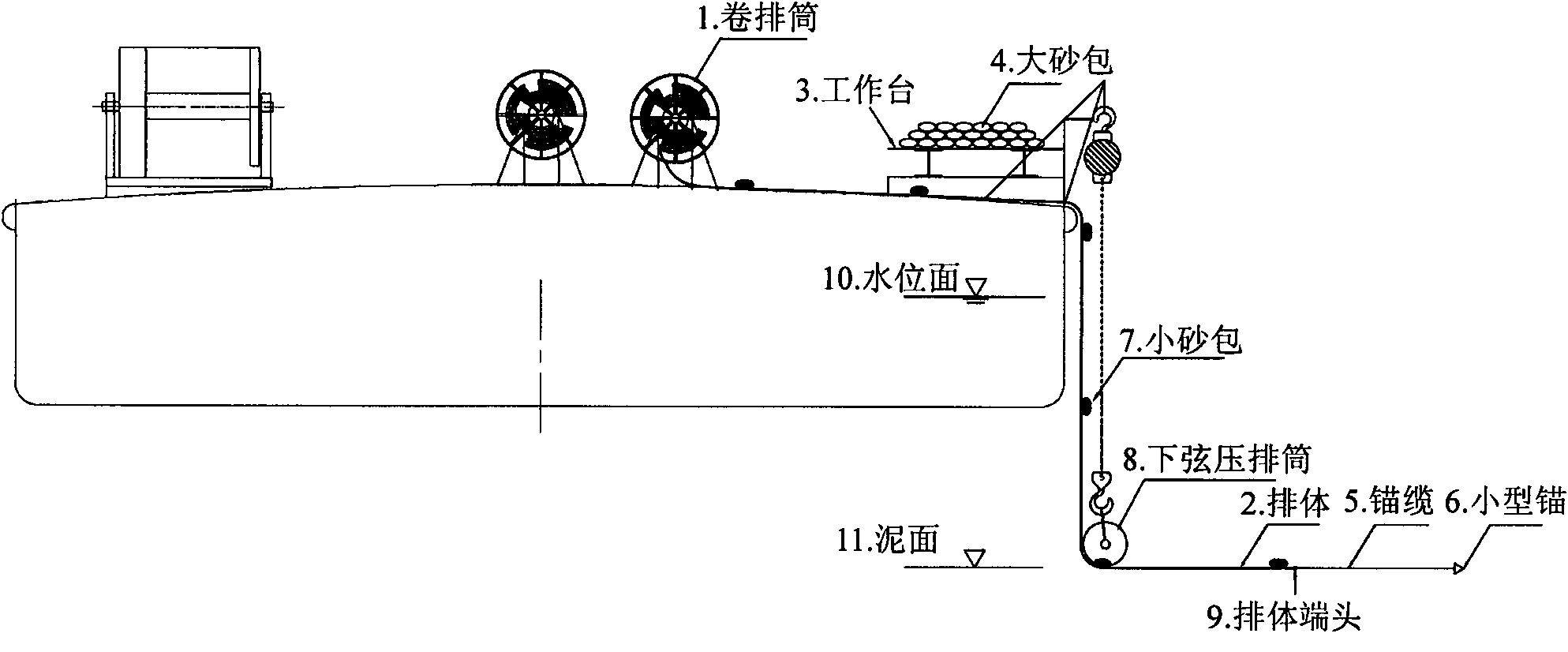

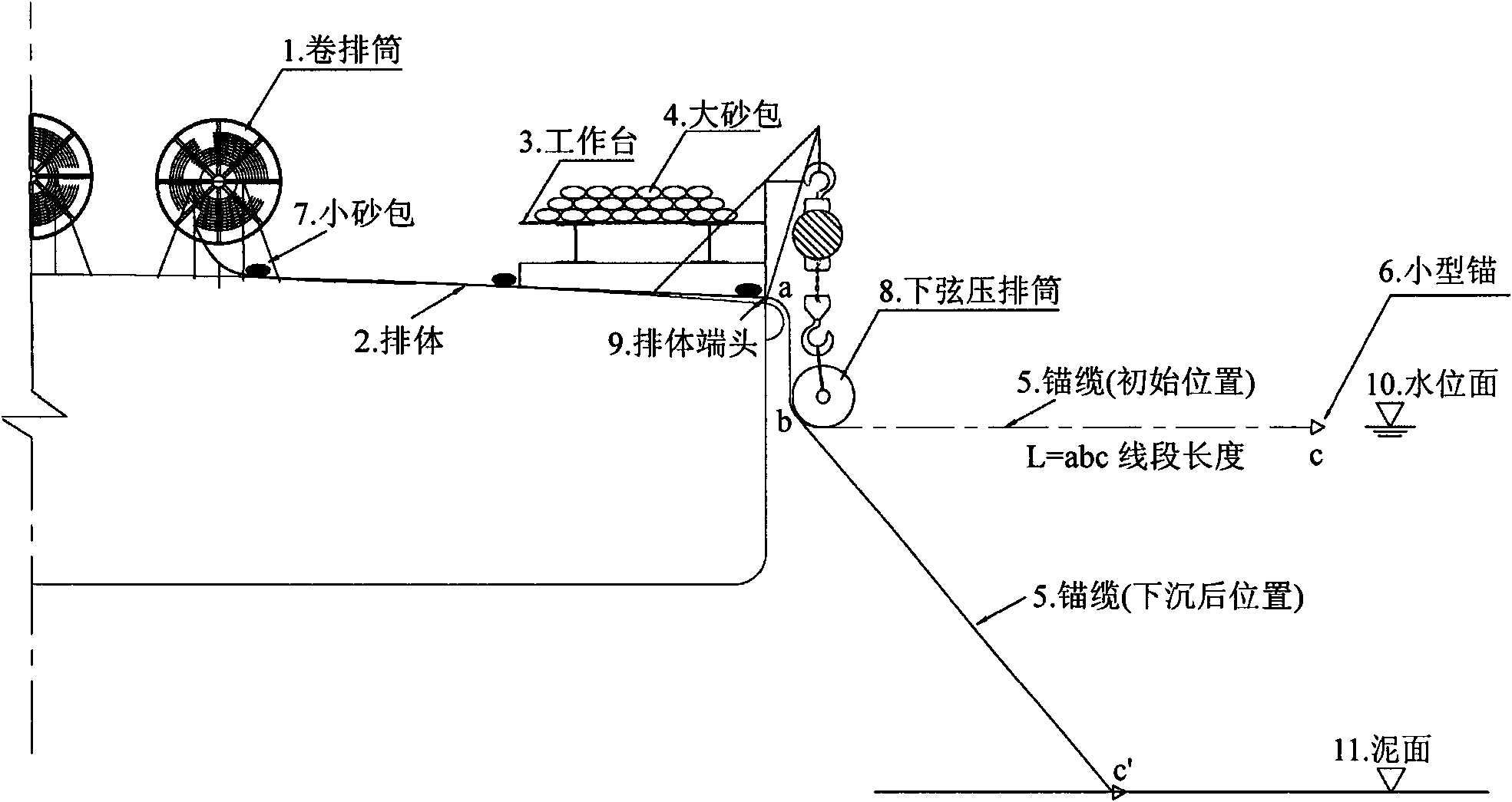

The invention relates to underwater arrangement, in particular to arrangement of a geotextile-geogrid complex which can play a role in isolating soil, reinforcing and reducing soil body deformation in soft foundation treatment projects such as reclamation projects and the like. In channel improvement projects, the novel technology is mainly used for protecting riverbed bottom matters in an arrangement range from being eroded by water to fulfill the aims of protecting the bottom and feet, preventing downcutting and protecting the engineering foundation. The conventional underwater arrangement lacks a key technology, so that the arrangement range and the axis deflection are difficult to control accurately, even phenomena of geo-mattress torsion, floating and the like occur, and the foundation stability and engineering quality cannot be ensured. The invention provides a novel quick and reliable underwater arrangement technology. In the technology, four important procedures, i.e., positioning, tiling, ironing and ballasting of the geo-mattress are combined organically by using the principles of tip anchoring, lower board arrangement barrel ironing and binding and throwing combination ballasting, so that the influences of load effects of wind, waves and the like and tide rise and fall on the construction during offshore operation are eliminated effectively, the geo-mattress can be quickly and accurately tiled on a coating surface, and the working efficiency is increased manifold.

Owner:CCCC FOURTH HARBOR ENG INST +3

Wind power blade main beam cloth laying device

PendingCN111497286AImprove laying qualityReduce manual labor intensityDomestic articlesStructural engineeringMechanical engineering

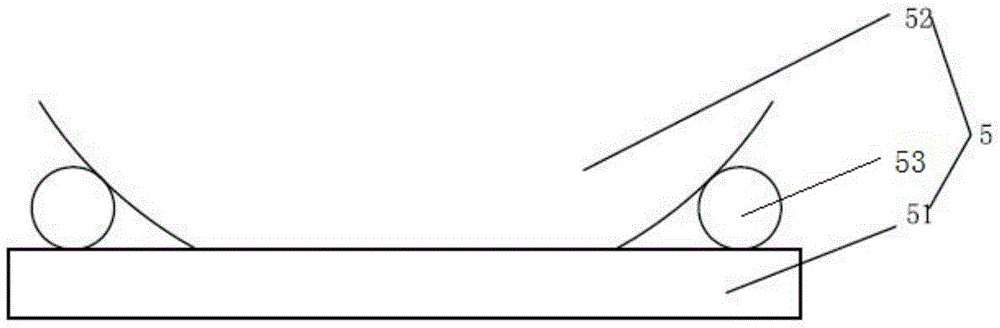

The invention discloses a wind power blade main beam cloth laying device. The wind power blade main beam cloth laying device comprises a cloth laying moving frame, a rotary transverse moving mechanismis arranged on the cloth laying moving frame, an unwinding frame is arranged on the rotary transverse moving mechanism, two cloth rolls which are parallel front and back are erected on the unwindingframe, the rotary transverse moving mechanism comprises a transverse moving assembly and a rotating assembly, the transverse moving assembly is used for controlling the unwinding frame to transverselymove in the chordwise direction of a blade main beam mold, and the rotating assembly is used for controlling the unwinding frame to rotate. The wind power blade main beam cloth laying device has theadvantages that the labor intensity of workers is reduced, the laying quality is improved, the blade forming period is shortened, and the laying efficiency is improved.

Owner:江阴市科诚技术有限公司

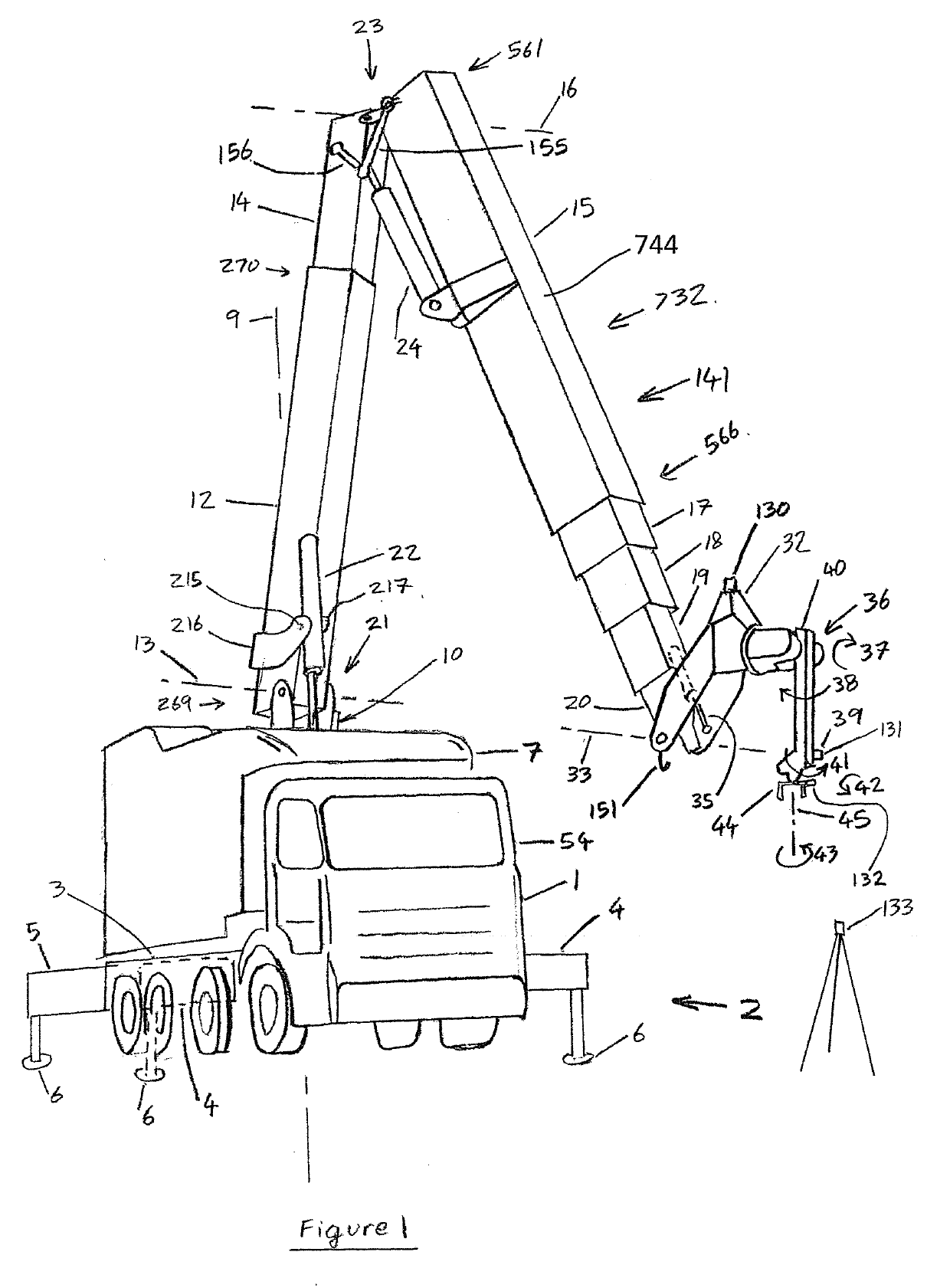

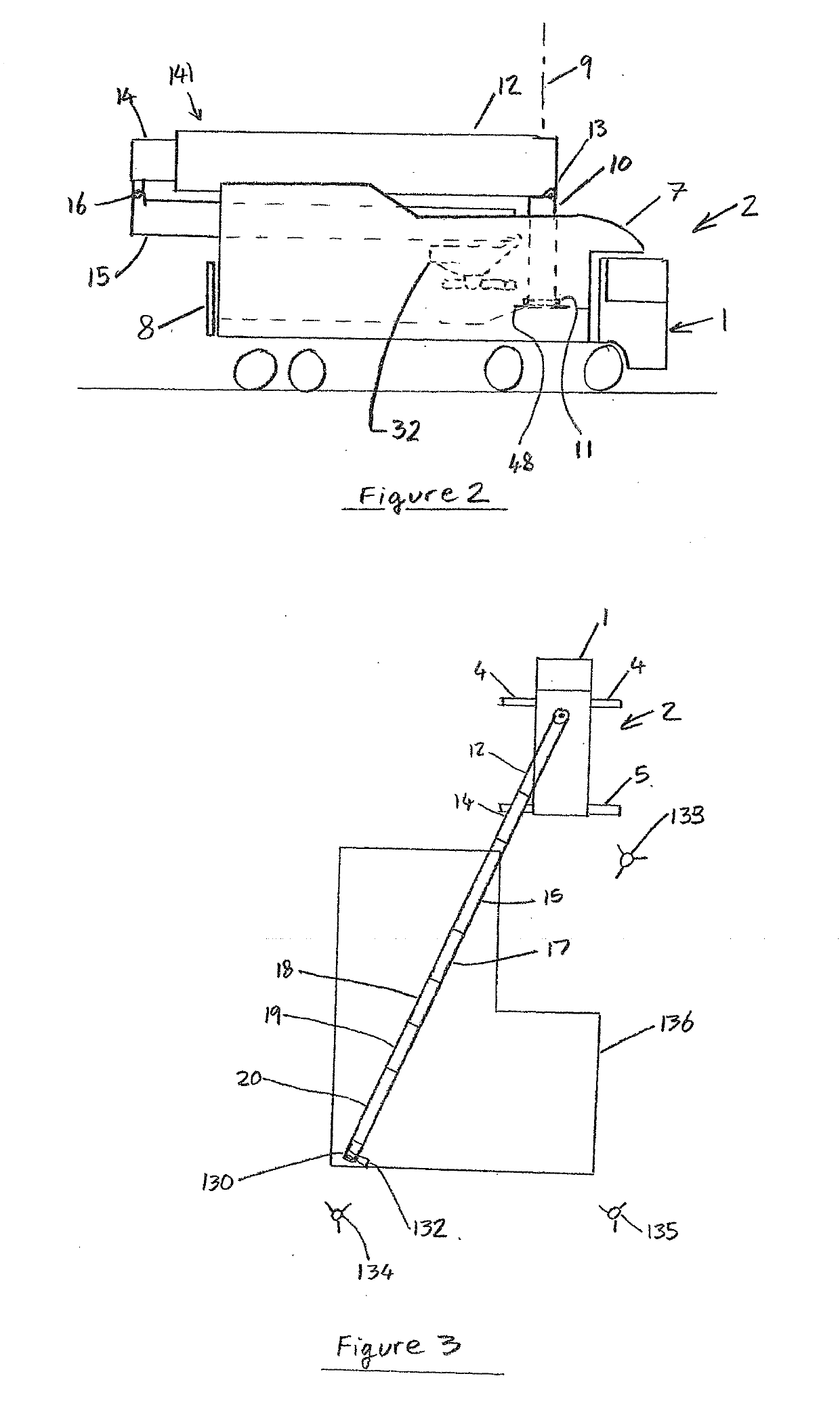

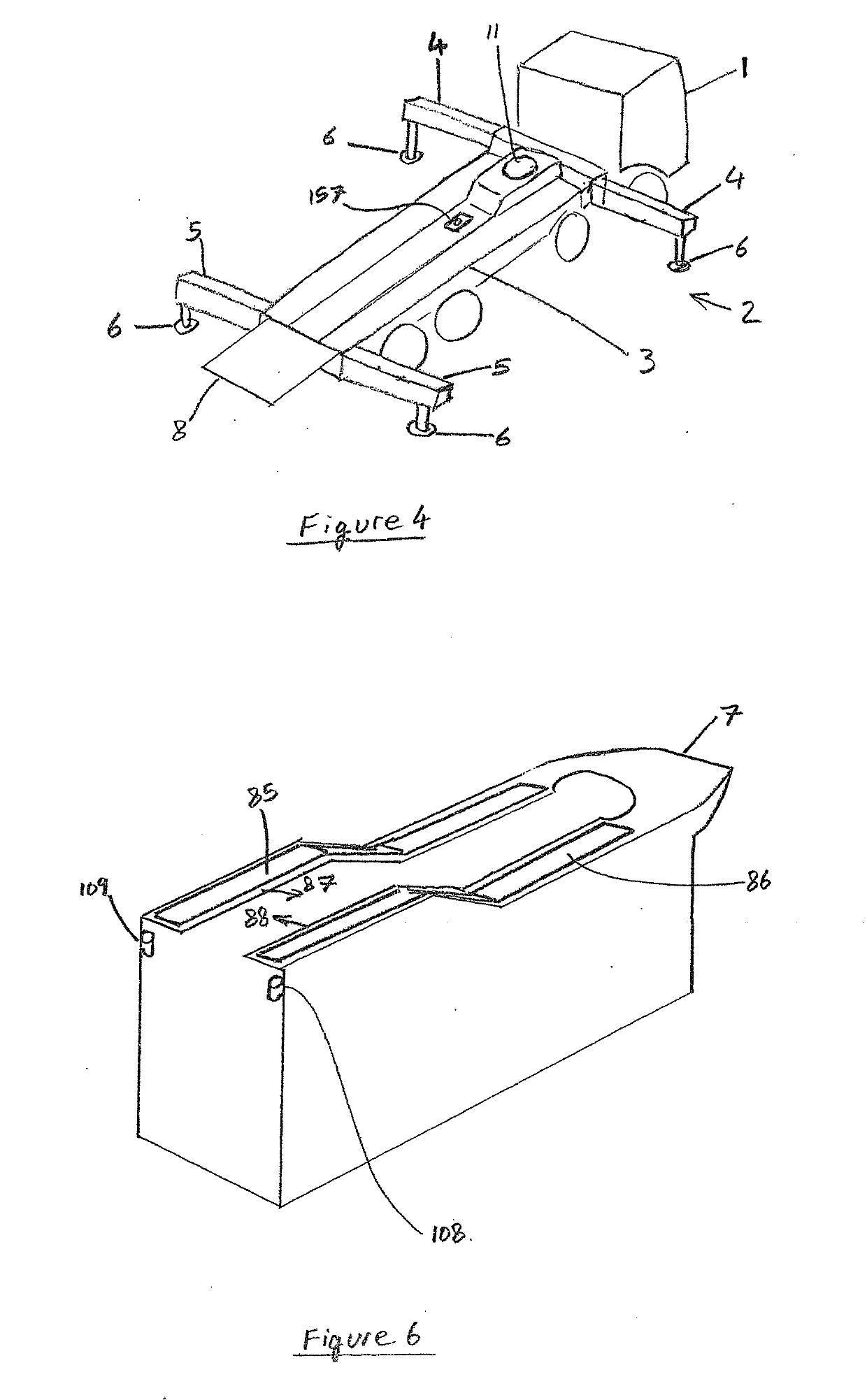

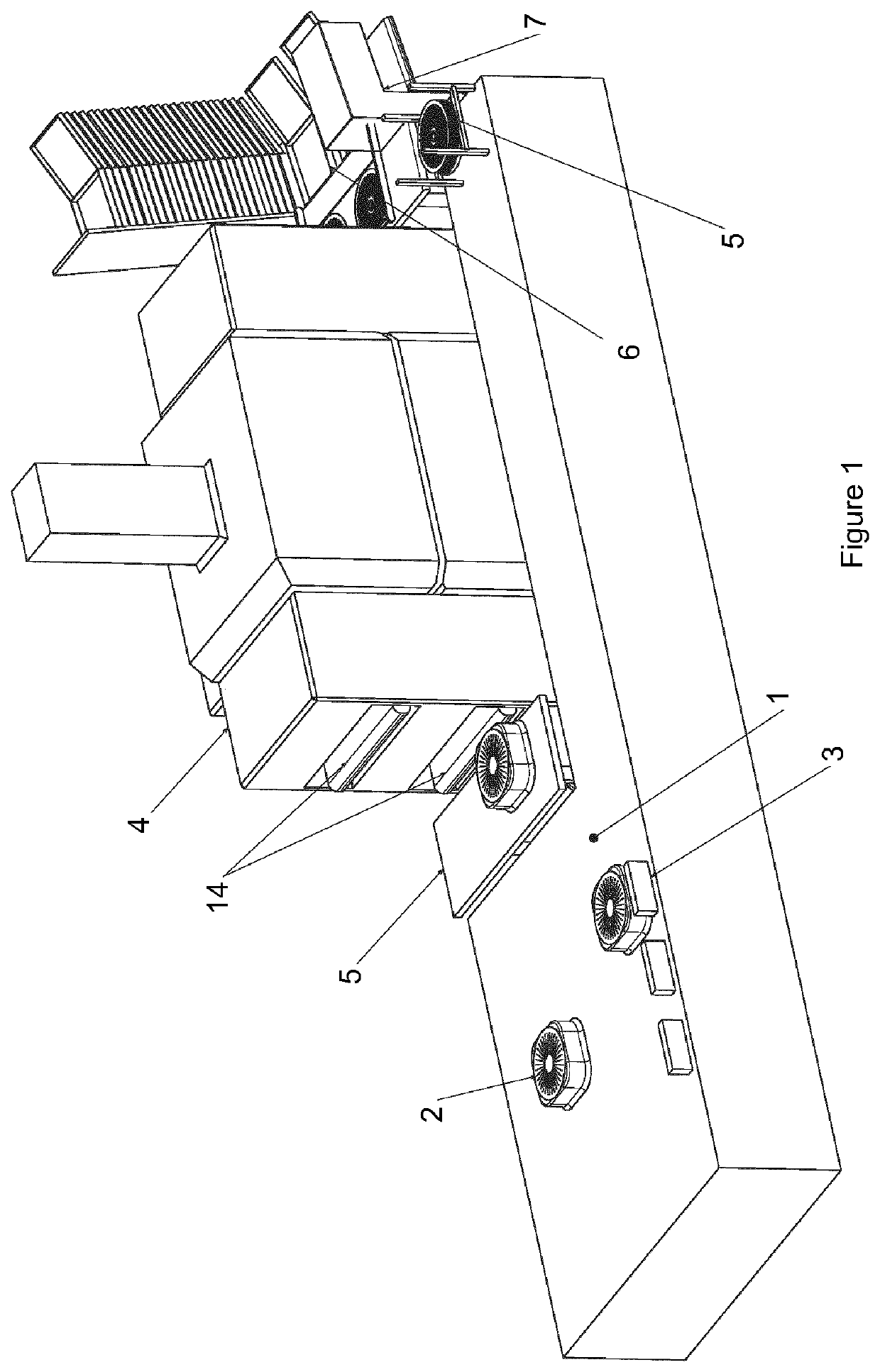

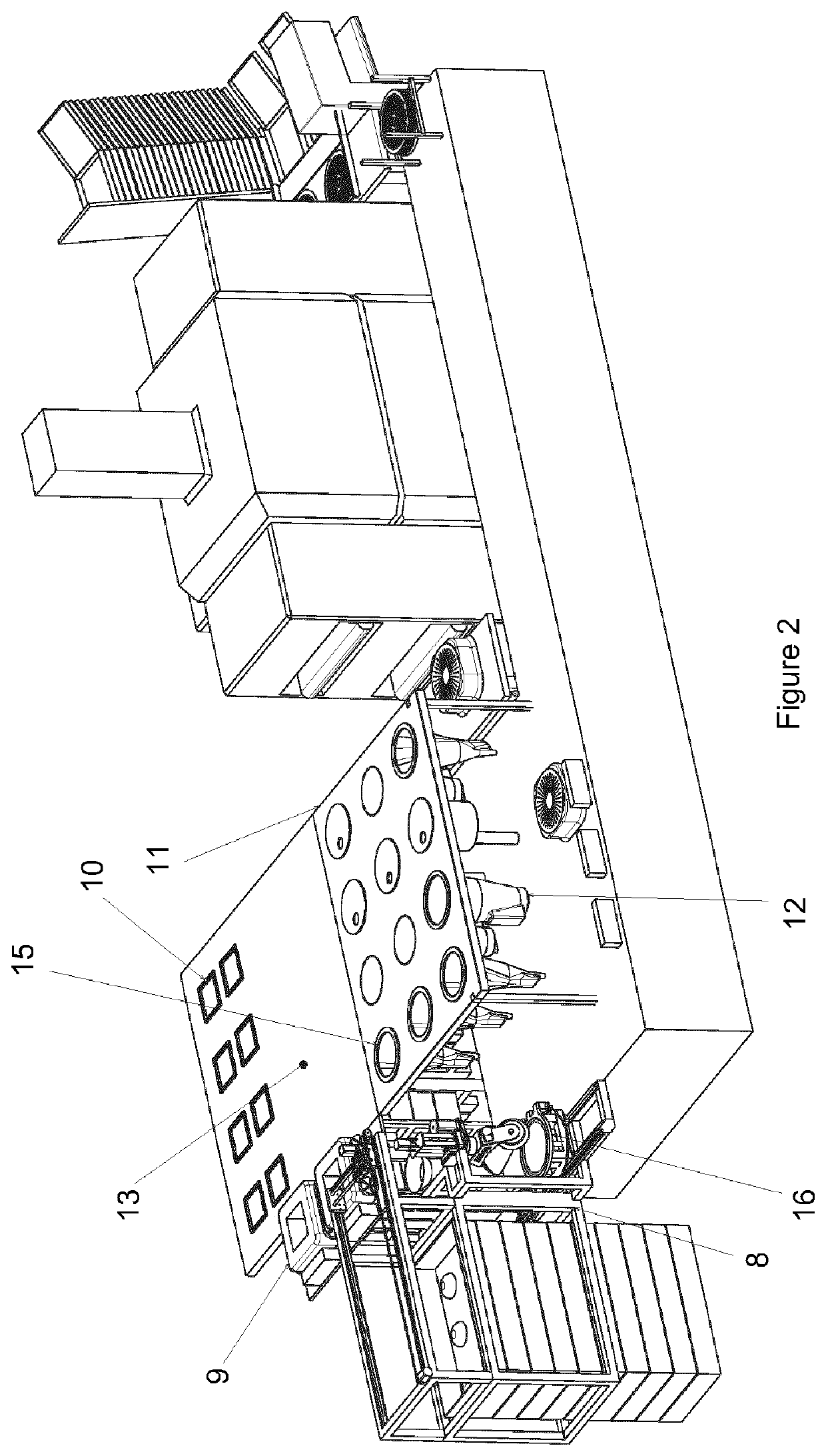

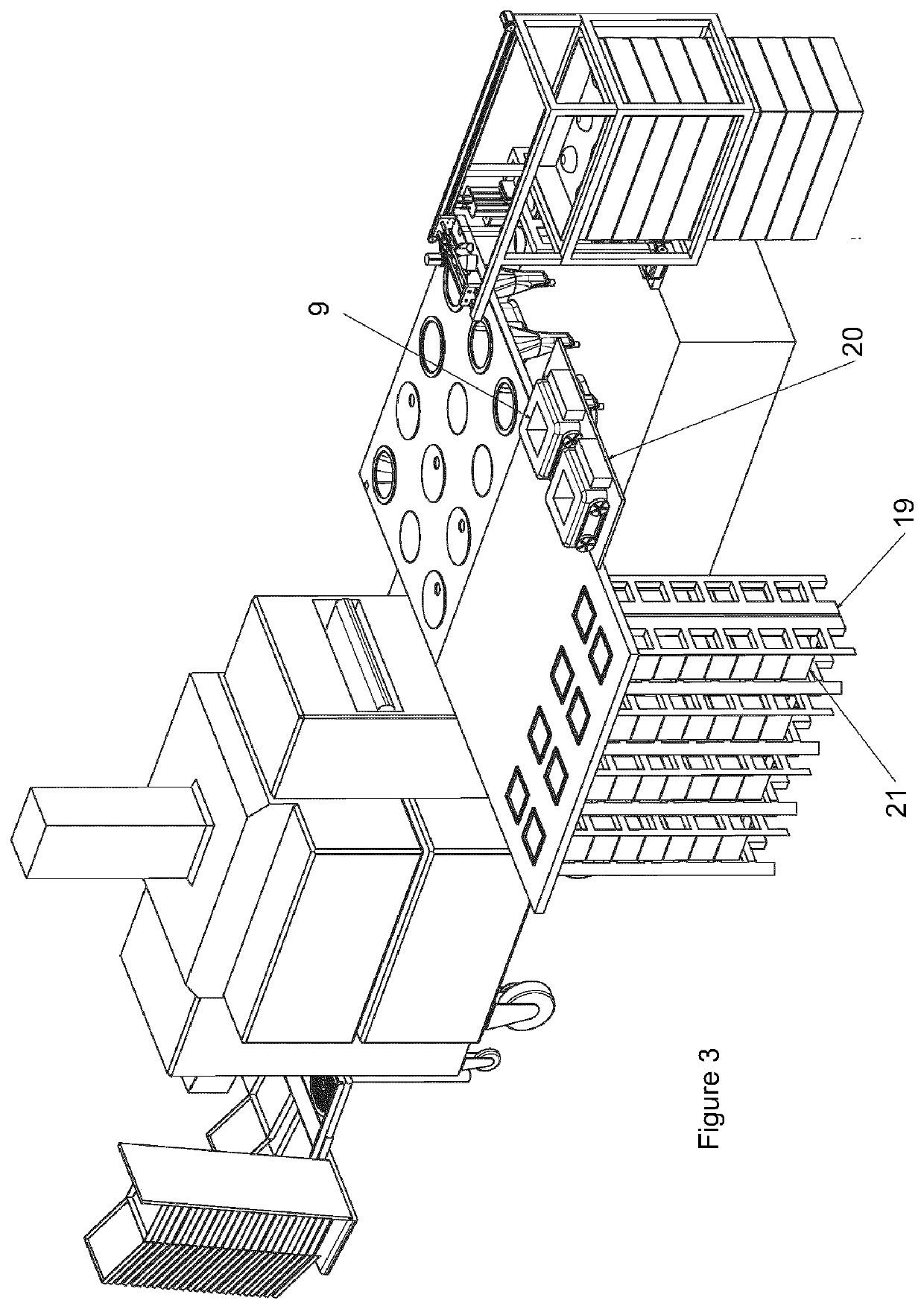

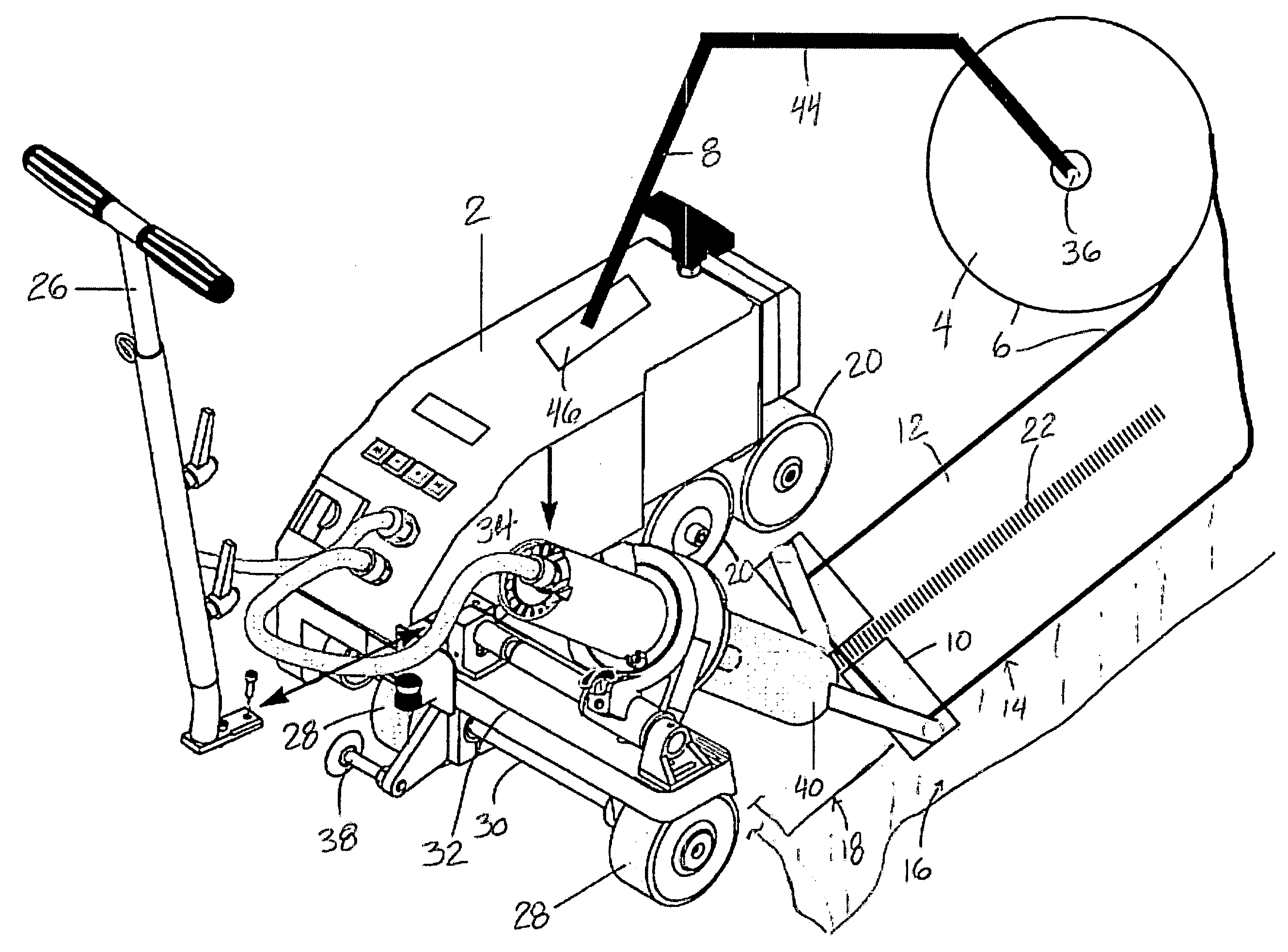

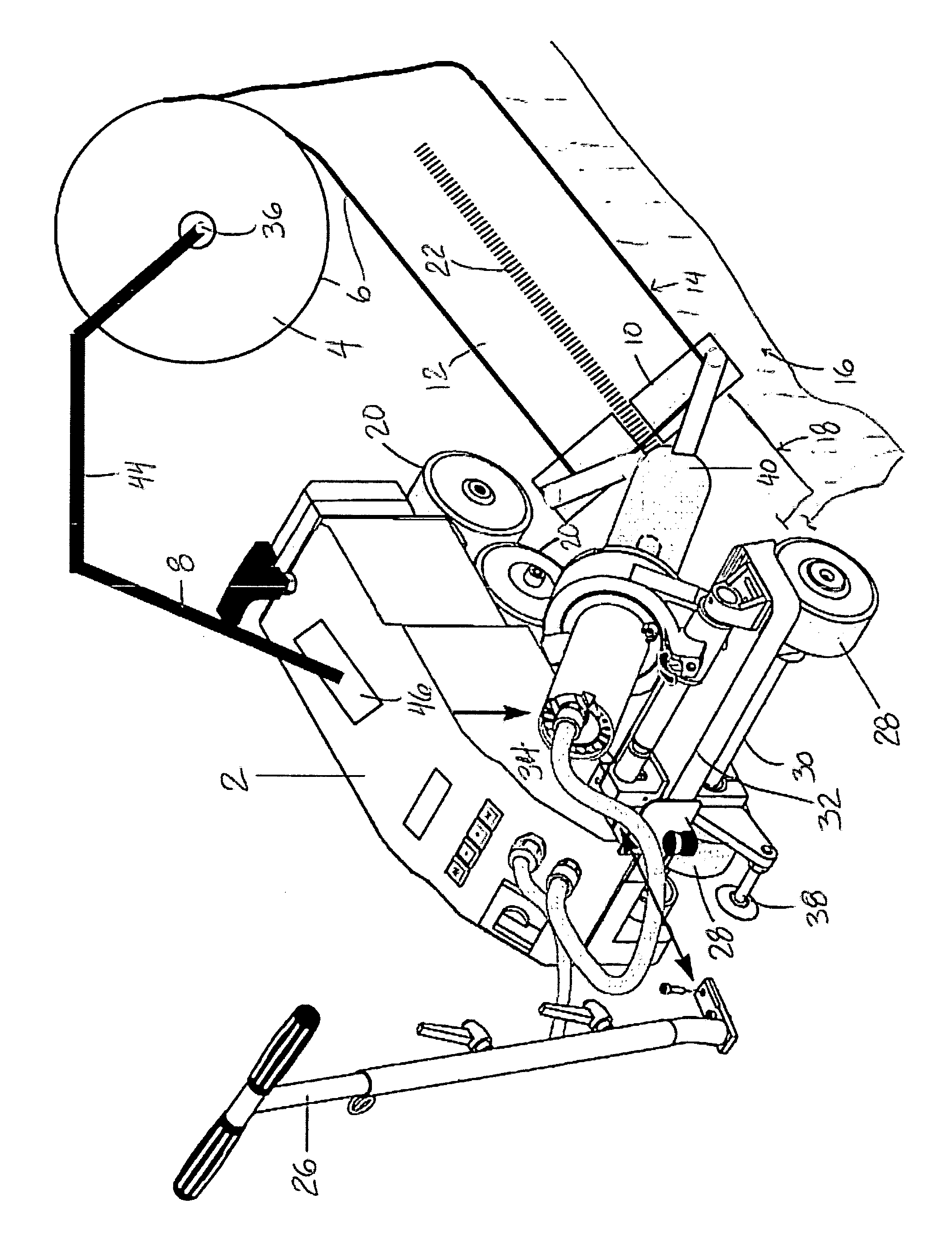

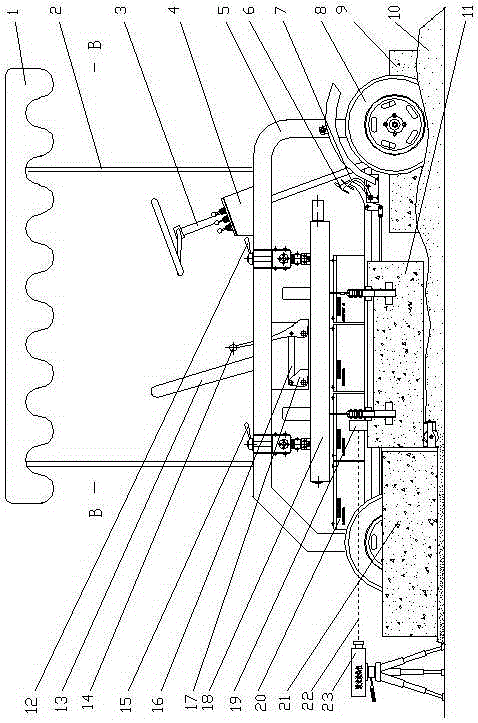

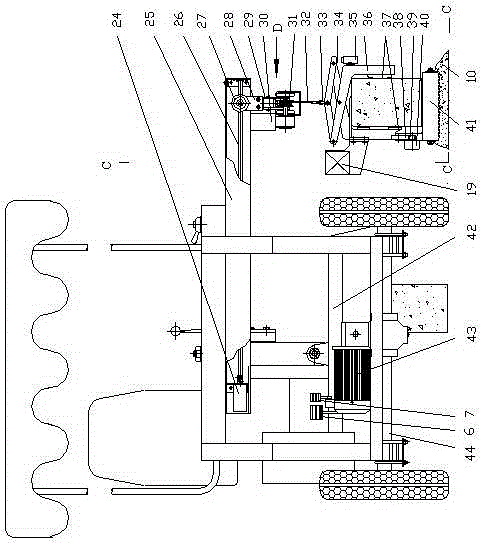

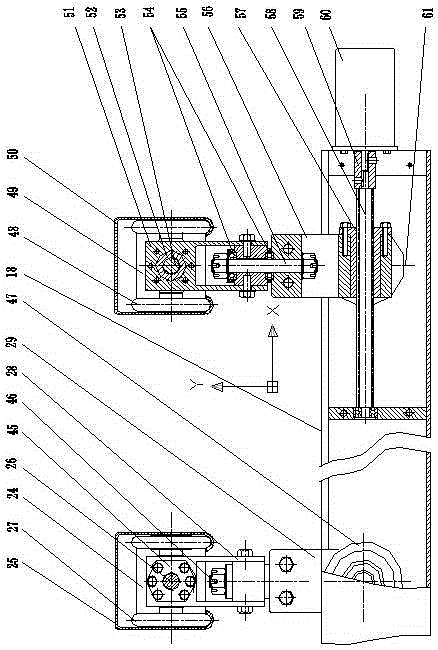

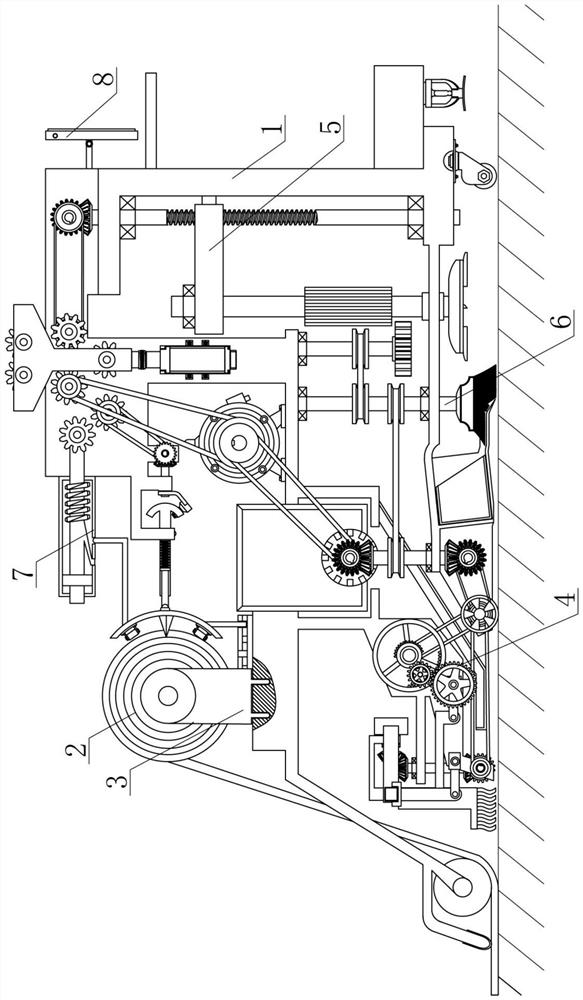

Brick/block laying machine incorporated in a vehicle

A self-contained truck-mounted brick laying machine (2) is described. A truck (1) supports the brick laying machine (2) which is mounted on a frame (3) on the truck chassis. The frame (3) supports packs or pallets of bricks (52, 53) placed on a platform (51). A transfer robot can then pick up an individual brick and move it to, or between either a saw (46) or a router (47) or a carousel (48). The carousel is located coaxially with a tower (10), at the base of the tower (10). The carousel (48) transfers the brick via the tower (10) to an articulated (folding about horizontal axis (16)) telescoping boom comprising first boom element in the form of telescopic boom (12, 14) and second boom element in the form of telescopic stick (15, 17, 18, 19, 20). The bricks are moved along the folding telescoping boom by linearly moving shuttles, to reach a brick laying and adhesive applying head (32). The brick laying and adhesive applying head (32) mounts to element (20) of the stick, about an axis (33) which is disposed horizontally. The poise of the brick laying and adhesive applying head (32) about the axis (33) is adjusted and is set in use so that the base (811) of a clevis (813) of the robotic arm (36) mounts about a horizontal axis, and the tracker component (130) is disposed uppermost on the brick laying and 110,111 adhesive applying head (32). The brick laying and adhesive applying head (32) applies adhesive to the brick and has a robot that lays the brick. Vision and laser scanning and tracking systems are provided to allow the measurement of as-built slabs, bricks, the monitoring and adjustment of the process and the monitoring of safety zones. The first, or any course of bricks can have the bricks pre machined by the router module (47) so that the top of the course is level once laid.

Owner:FASTBRICK IP PTY LTD

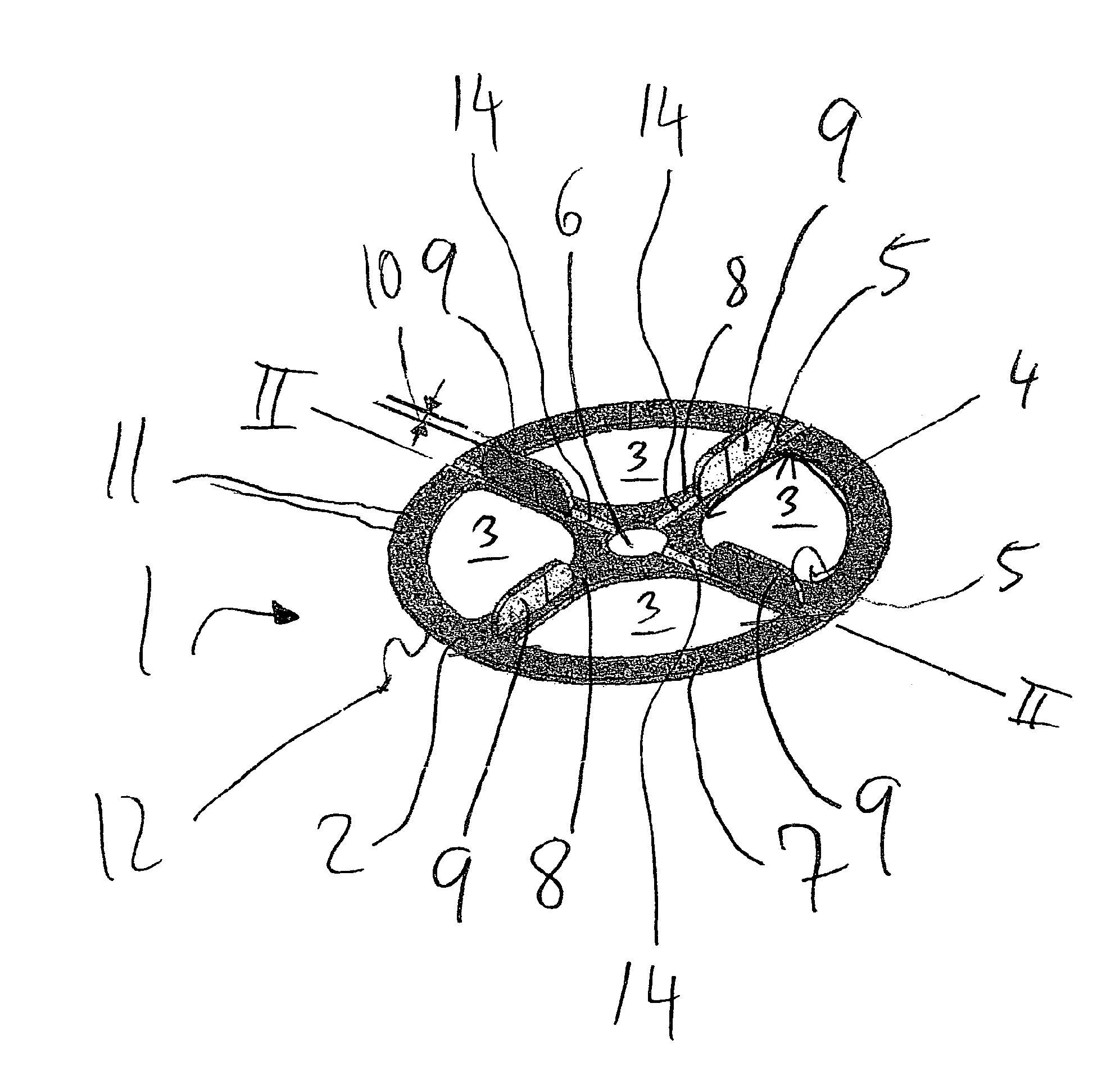

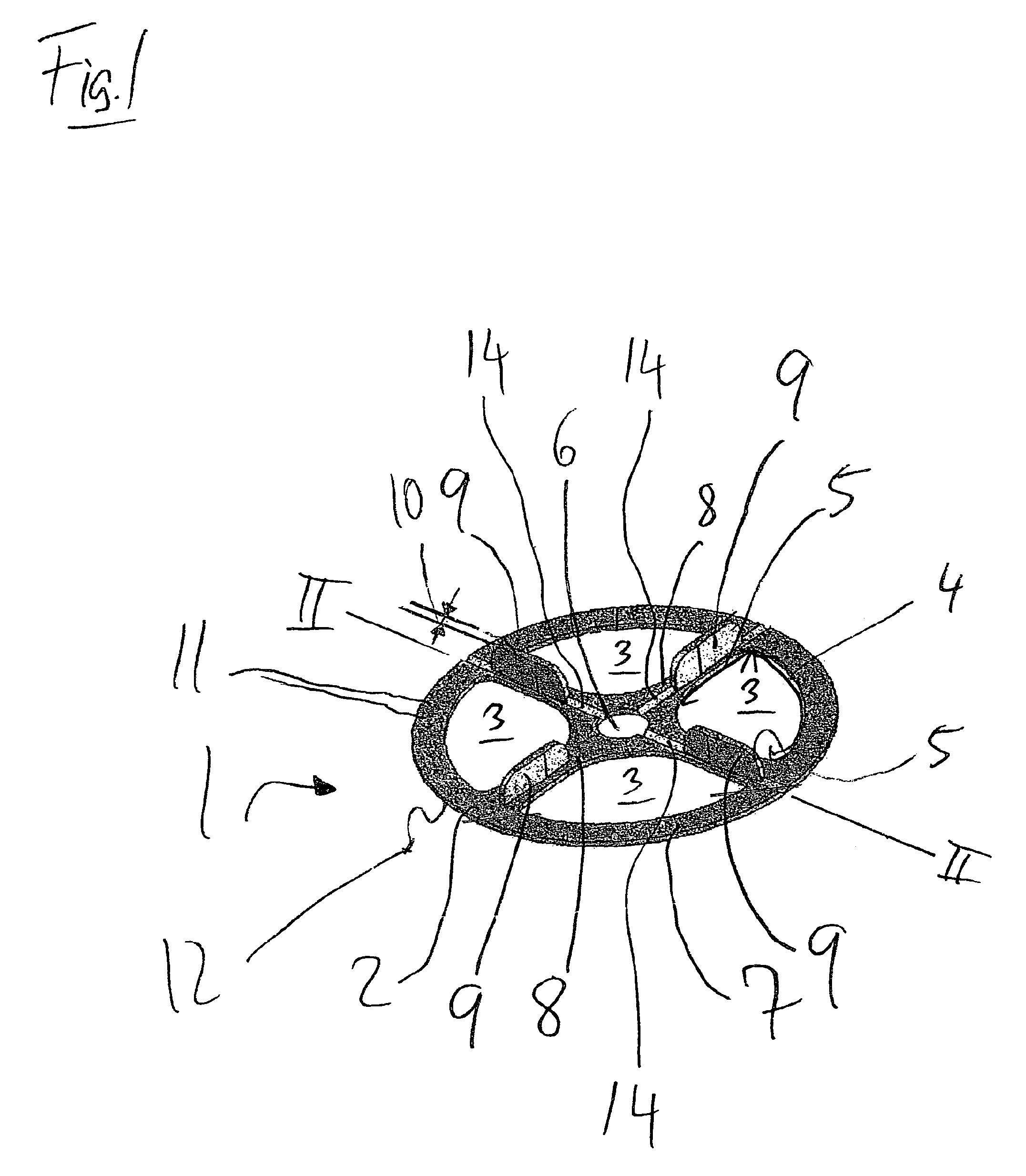

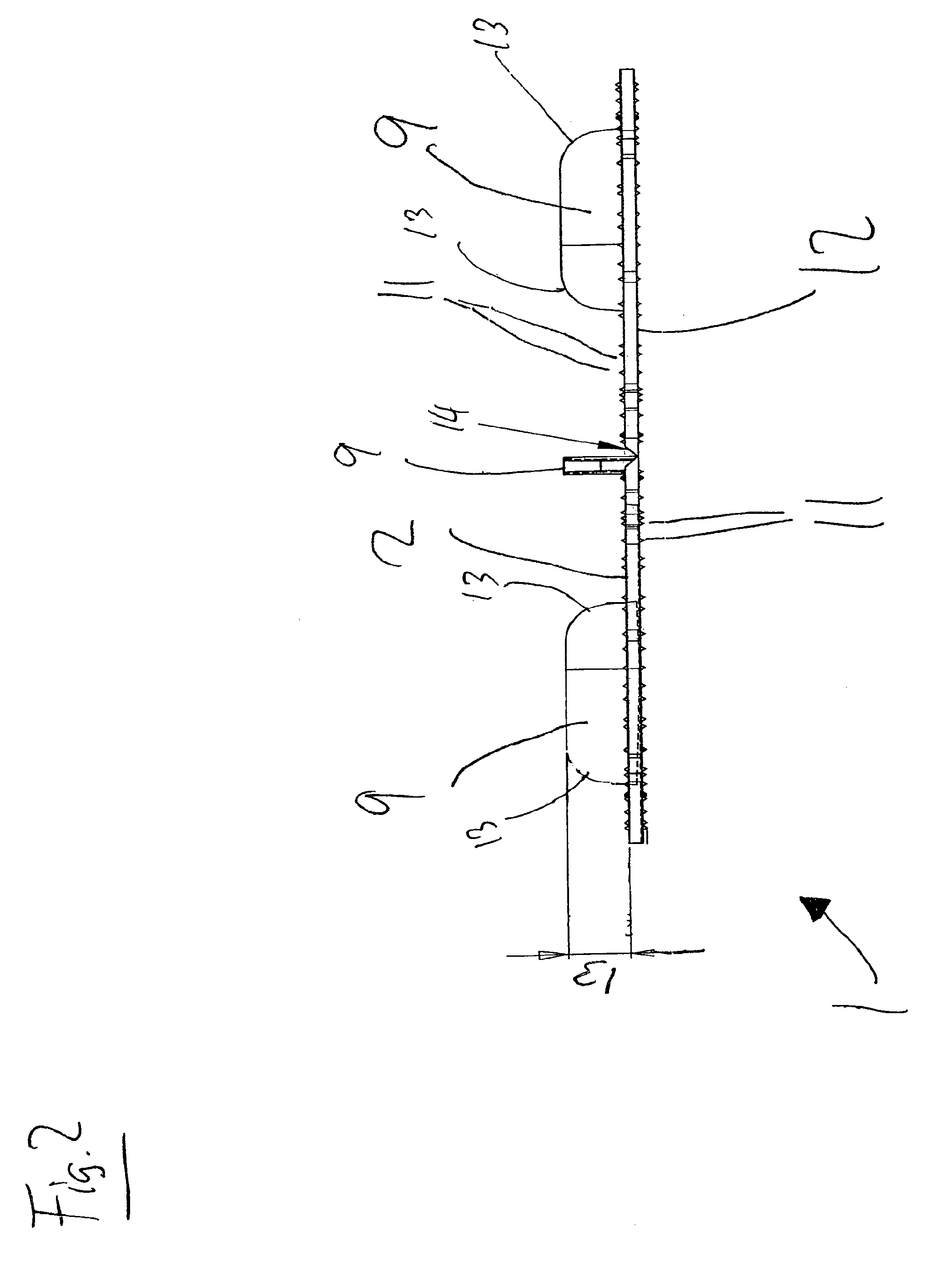

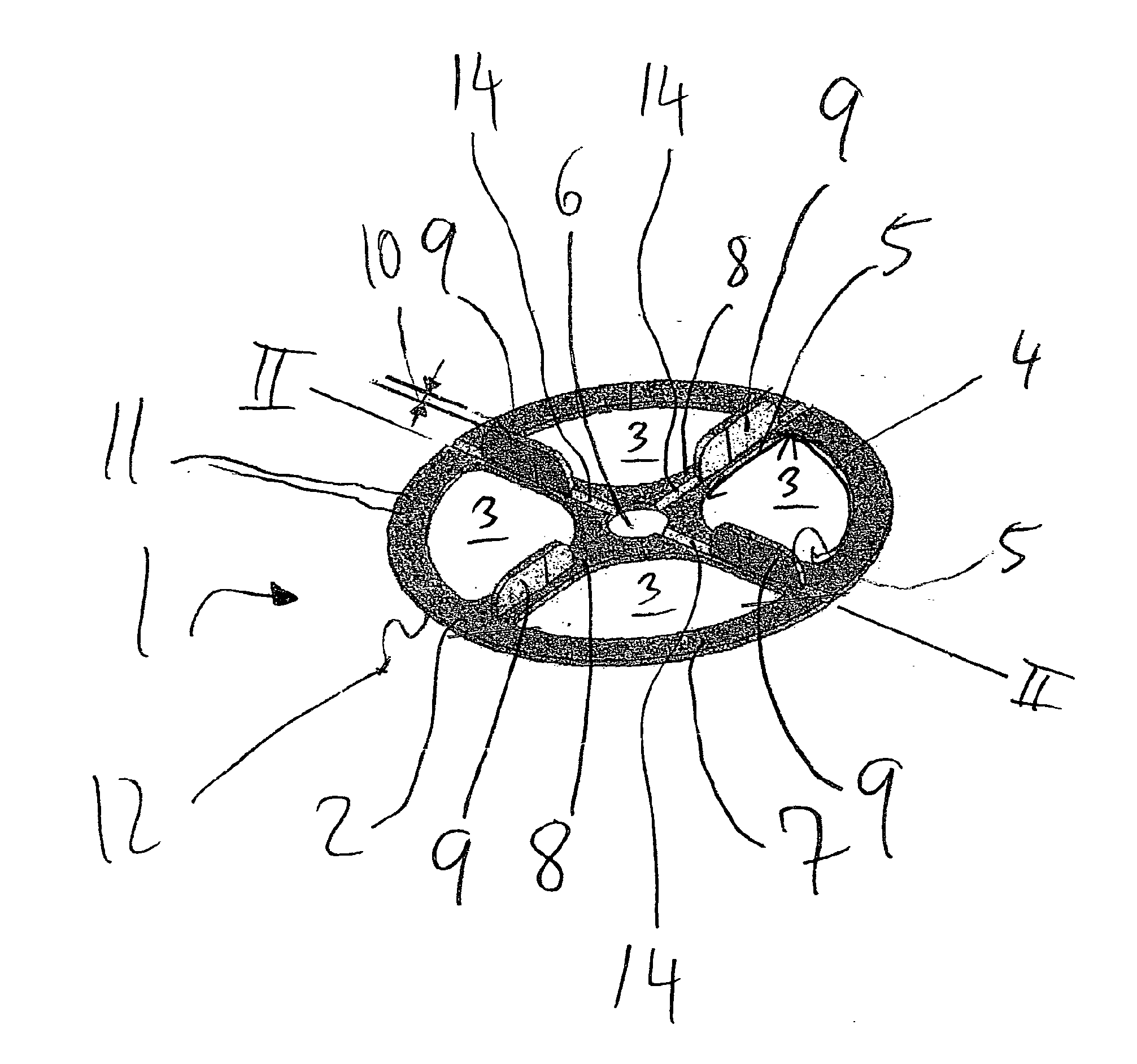

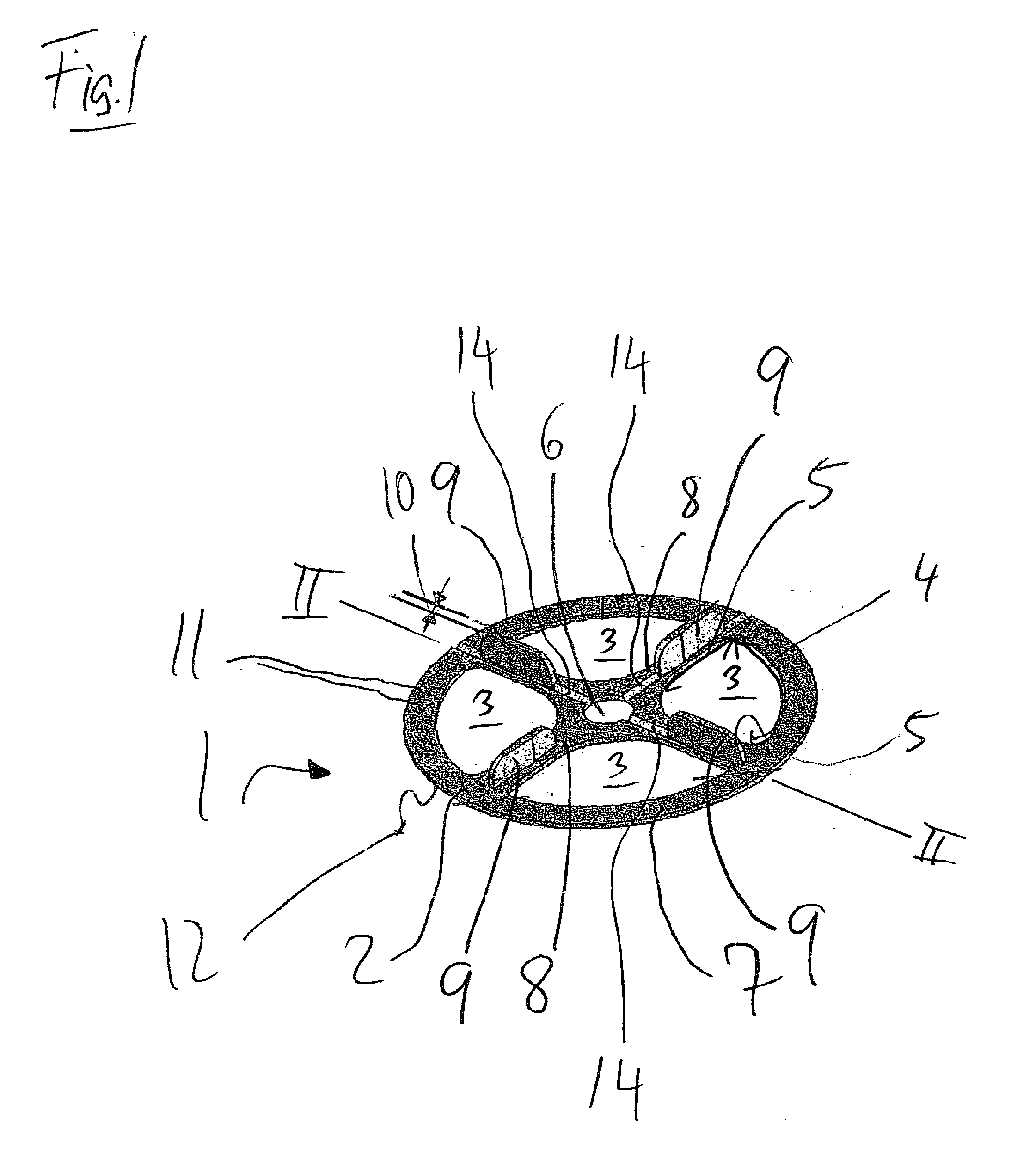

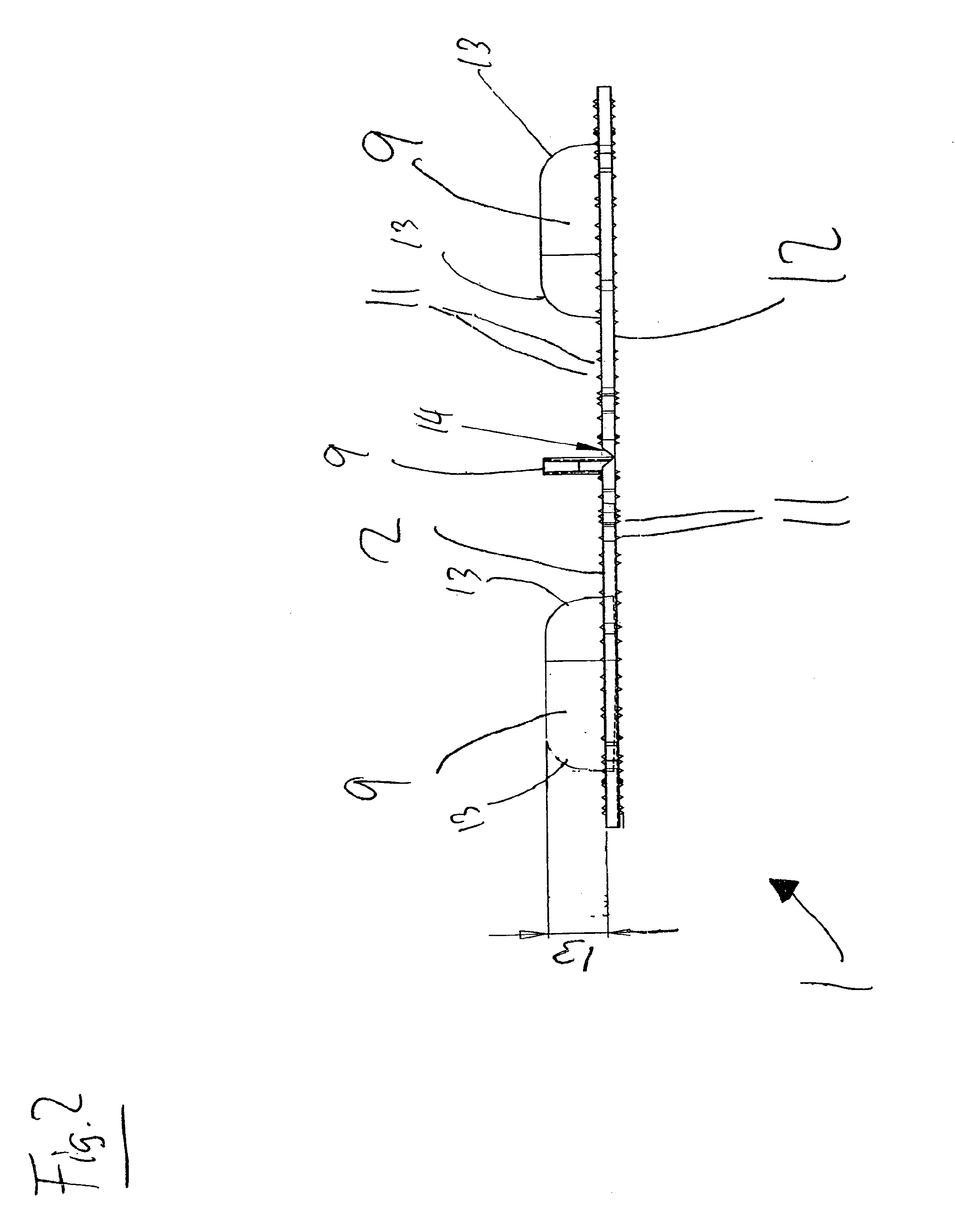

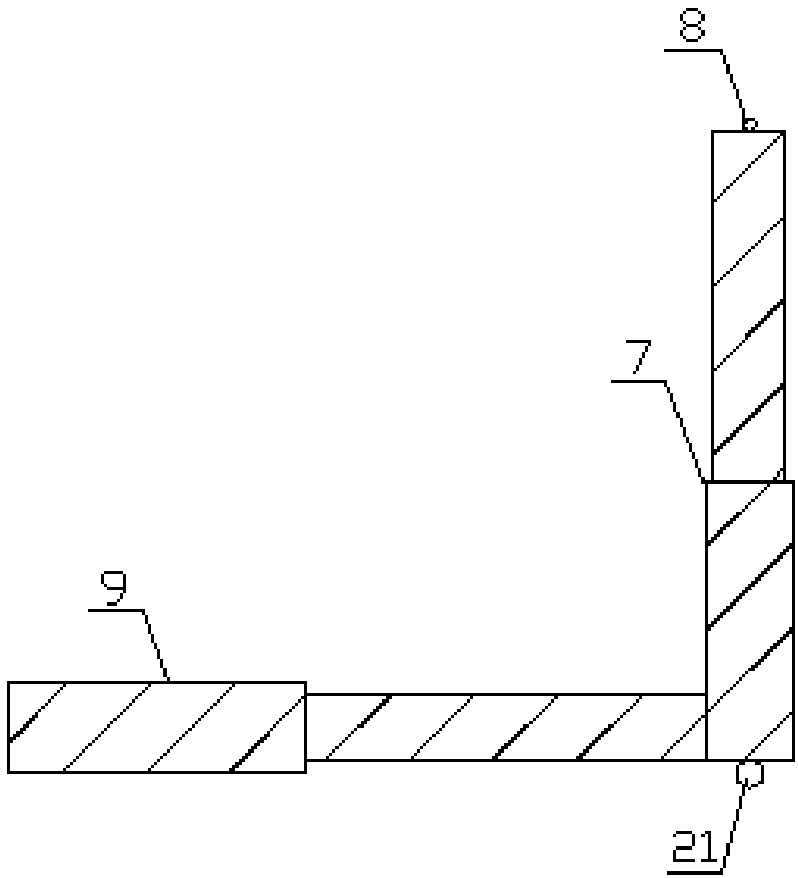

Laying aid for tiles

The invention relates to a device (1) used as a laying aid for tiling work, comprising a base element (7, 8) having a support region (12) for laying flat on a surface to be covered with tiles (16), and a tile-supporting region (2) on which tiles (16) are placed. The tile-supporting region (2) has at least two web-like spacer elements (9) which extend perpendicularly with respect to a plane defined by the tile-supporting region (2) and which are arranged at an angle of an integer multiple of 90° relative to one another in said plane, and which have a thickness (10) corresponding to a desired joint spacing. To avoid the disadvantages of the known laying aids and to achieve uniform joint spacing and an even surface, whereby the laying aid is intended to be especially easy to handle, the base element (7, 8) is designed as a disk-like element having a base area that is smaller than a base area of the tiles (16) to be laid.

Owner:BRINKMAN SILKE +1

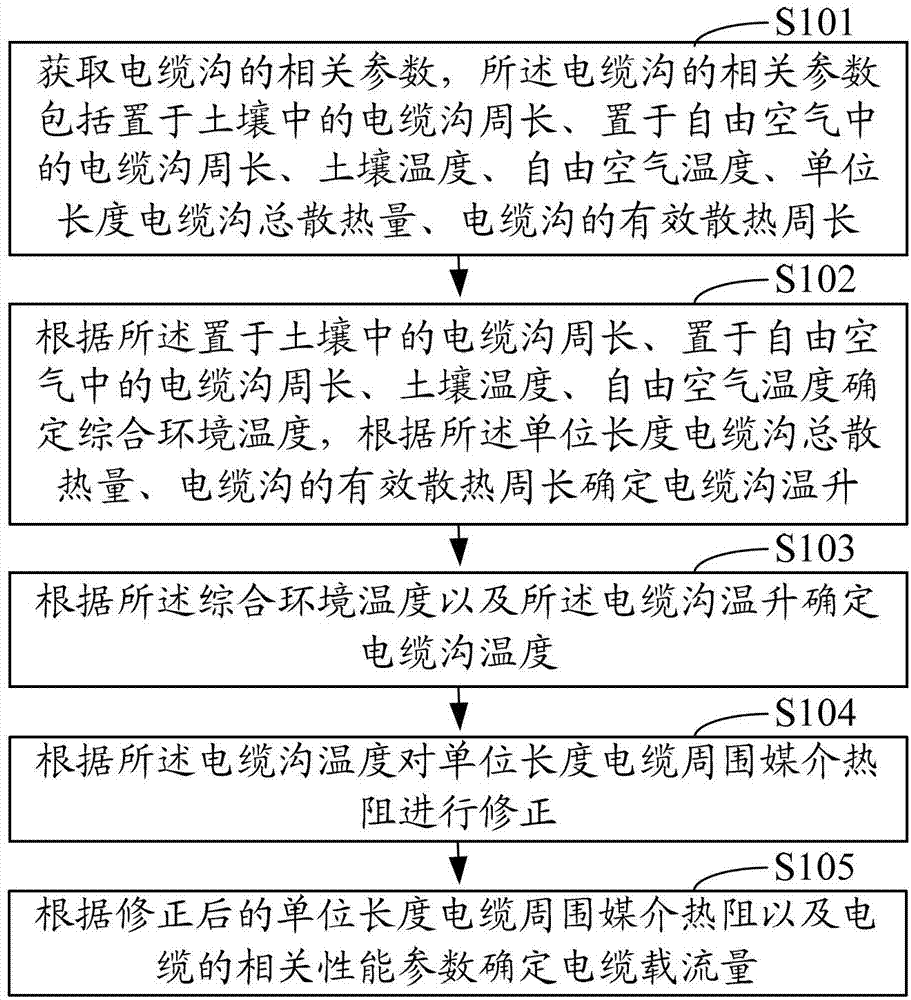

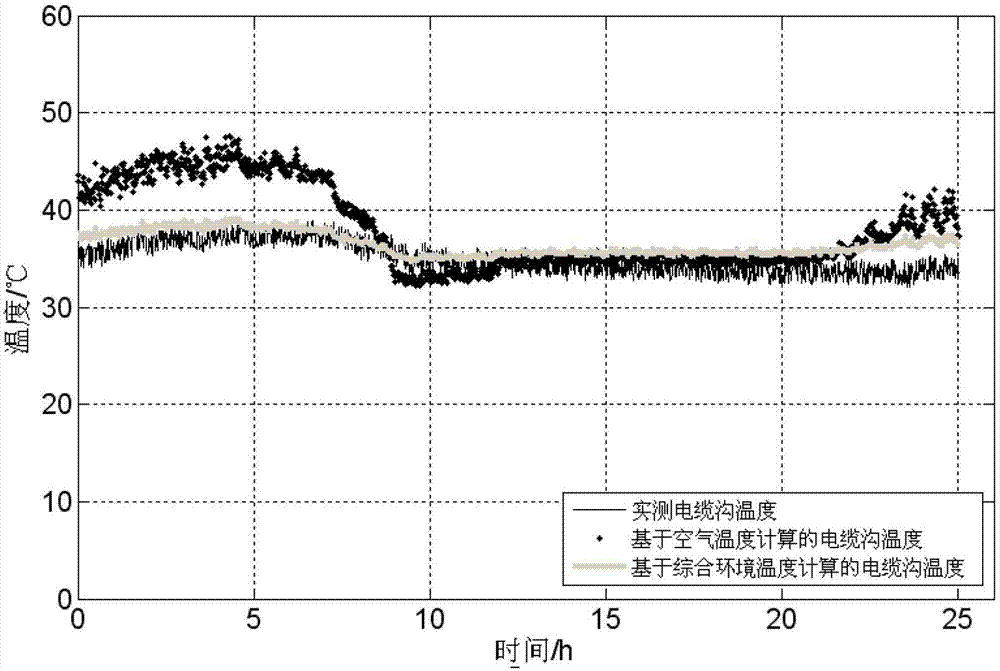

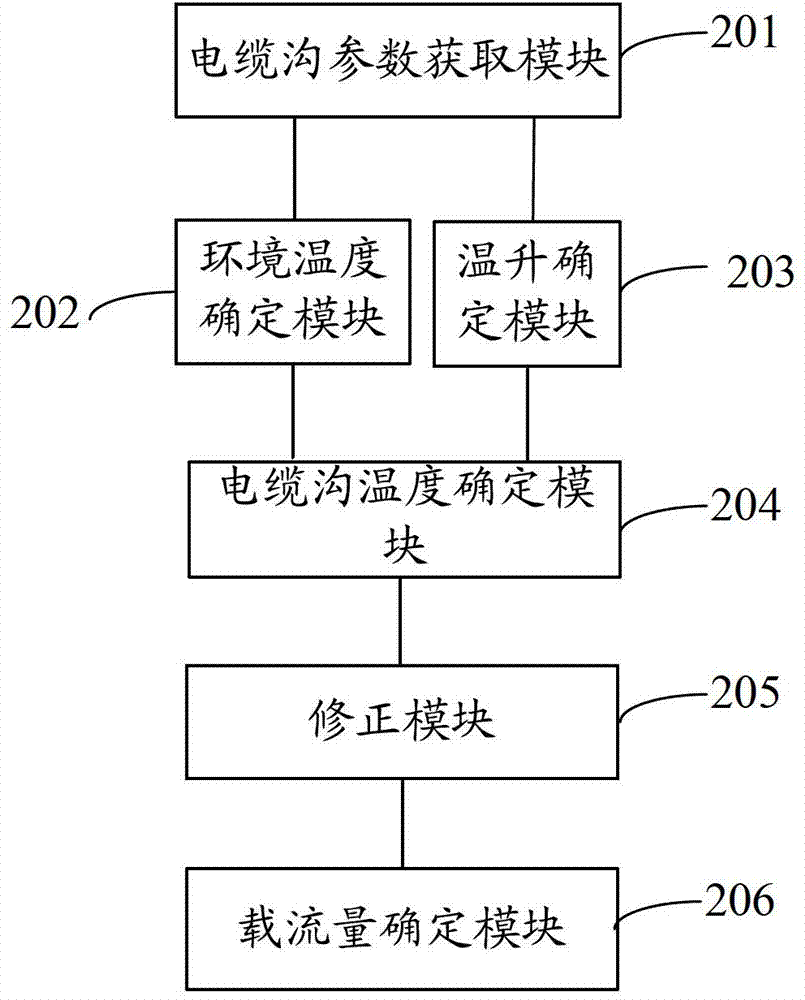

Method and system for determining current-carrying capacity of three-core cable laid in cable duct

The invention provides a method and a system for determining the current-carrying capacity of a three-core cable laid in a cable duct. The method comprises the following steps: acquiring related parameters of the cable duct; determining integrated environment temperature and cable duct temperature rise; determining cable duct temperature according to the integrated environment temperature and the cable duct temperature rise; correcting thermal resistance of media around the cable in unit length according to the cable duct temperature; and determining the current-carrying capacity of the cable according to the corrected thermal resistance of the media around the cable in the unit length and the related parameters of the cable. The method and the system effectively solve a problem that the current-carrying capacity of the cable in the cable duct is calculated to be obviously high in the prior art, and can accurately determine the current-carrying capacity of the cable laid in the cable duct.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

Laying Aid for Tiles

The invention relates to a device (1) used as a laying aid for tiling work, comprising a base element (7, 8) having a support region (12) for laying flat on a surface to be covered with tiles (16), and a tile-supporting region (2) on which tiles (16) are placed. The tile-supporting region (2) has at least two web-like spacer elements (9) which extend perpendicularly with respect to a plane defined by the tile-supporting region (2) and which are arranged at an angle of an integer multiple of 90° relative to one another in said plane, and which have a thickness (10) corresponding to a desired joint spacing. To avoid the disadvantages of the known laying aids and to achieve uniform joint spacing and an even surface, whereby the laying aid is intended to be especially easy to handle, the base element (7, 8) is designed as a disk-like element having a base area that is smaller than a base area of the tiles (16) to be laid.

Owner:BRINKMAN SILKE +1

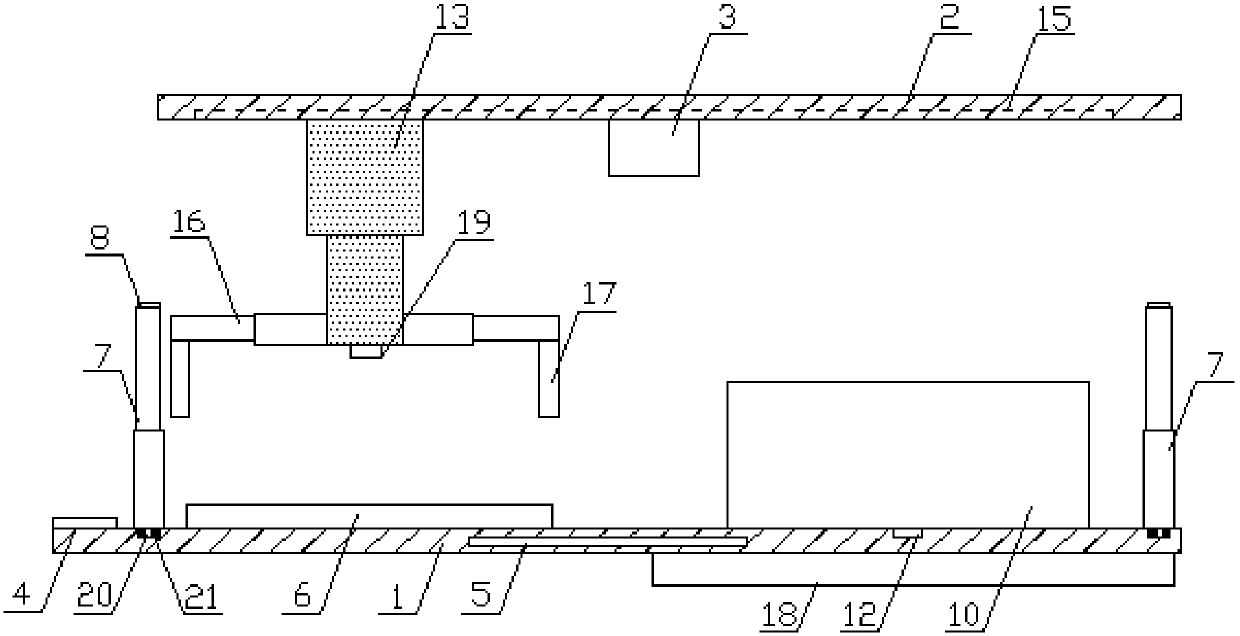

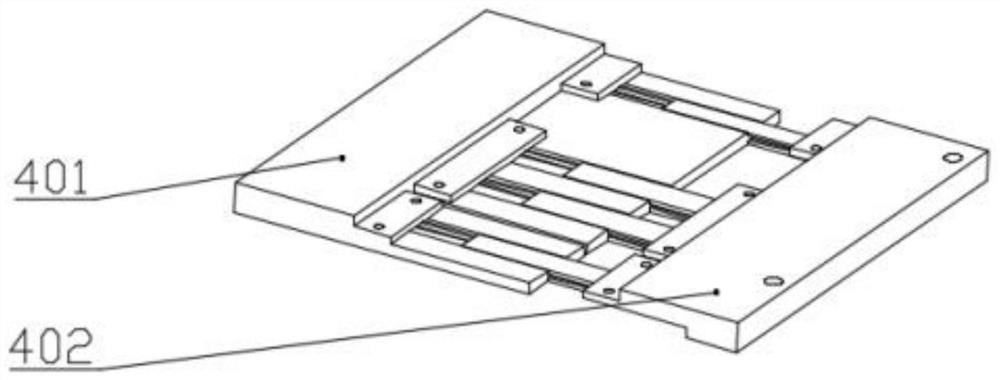

Reinforcing construction equipment for architectural design engineering

ActiveCN108560945AReduce labor intensityNo manual operationBuilding repairsBuilding designHuman health

The invention relates to reinforcing construction equipment for architectural design engineering, which comprises a bottom plate on which, a gluing device, a fixing device and a laying device are sequentially arranged from front to back. The gluing device comprises the gluing support frame which is installed on the bottom plate and is provided with a glue coating movement trough, a glue coating movement mechanism is installed on the gluing support frame and in the glue coating movement trough, a glue coating execution mechanism is provided at the lower end of the glue coating movement mechanism. The reinforcing construction equipment for architectural design engineering can solve the following problems existing in the prior bonded steel reinforcing building process: the prepared glue liquid is coated on the steel plate manually; the steel plate needs to be manually adhered to the designated working surface; the irritant odor from the adhesive liquid is harmful to human health; the manually applied coating glue liquid is not evenly smeared affecting the quality of the bonded steel reinforced building; the working face condition is complicated for the building to be reinforced; manual vibration compaction of the adhered steel plate is tedious, and the working range of the manual steel plate pasting is limited.

Owner:山东滨地建筑设计院有限公司

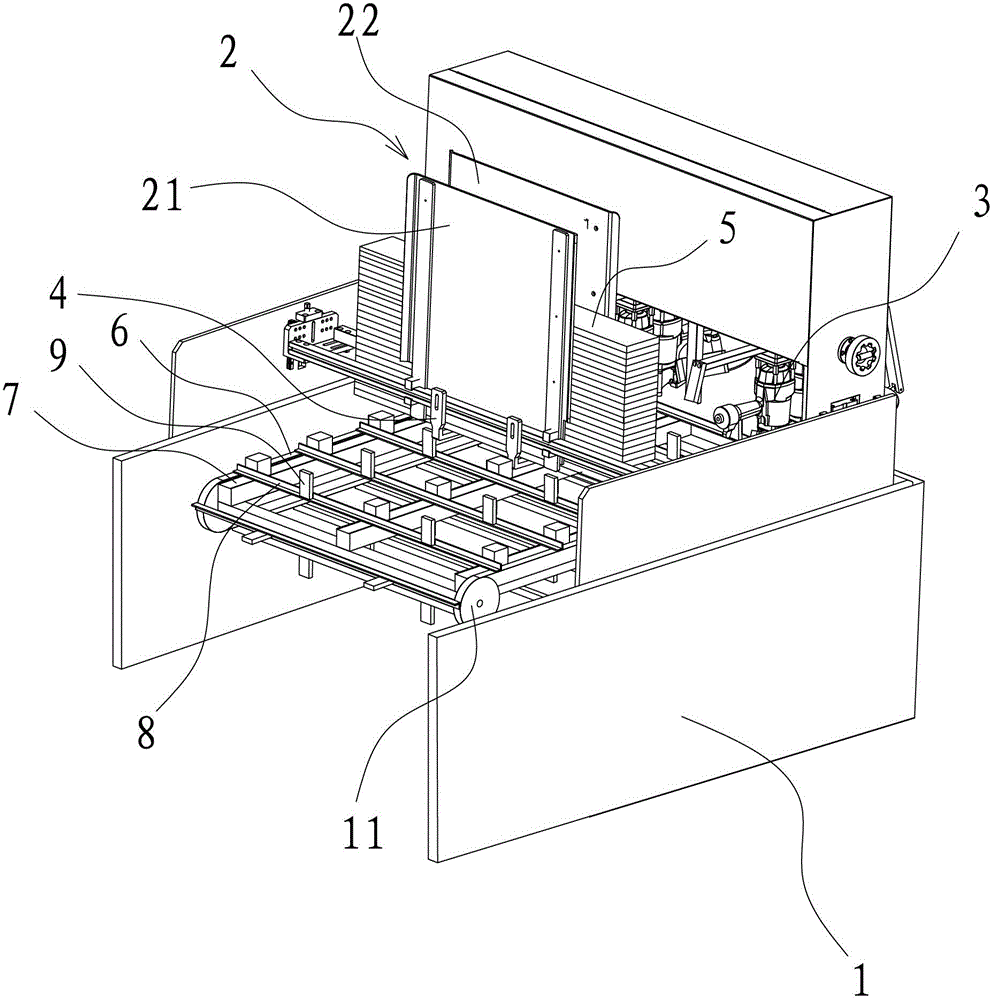

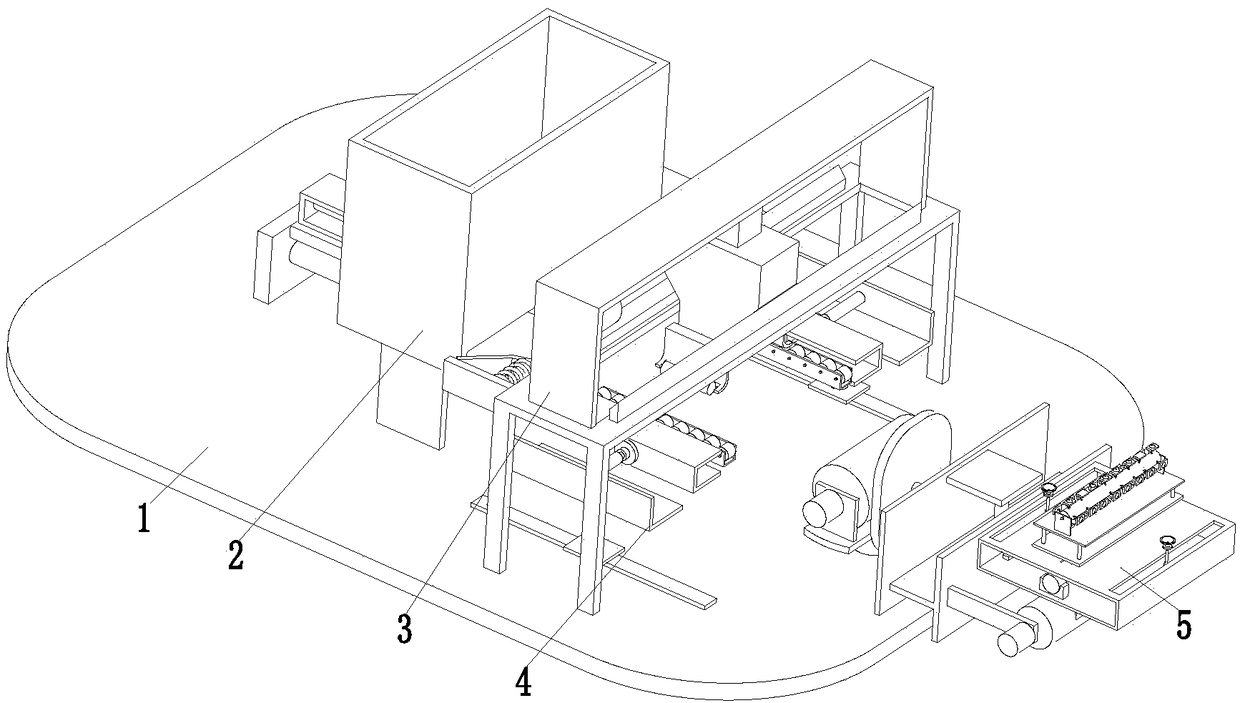

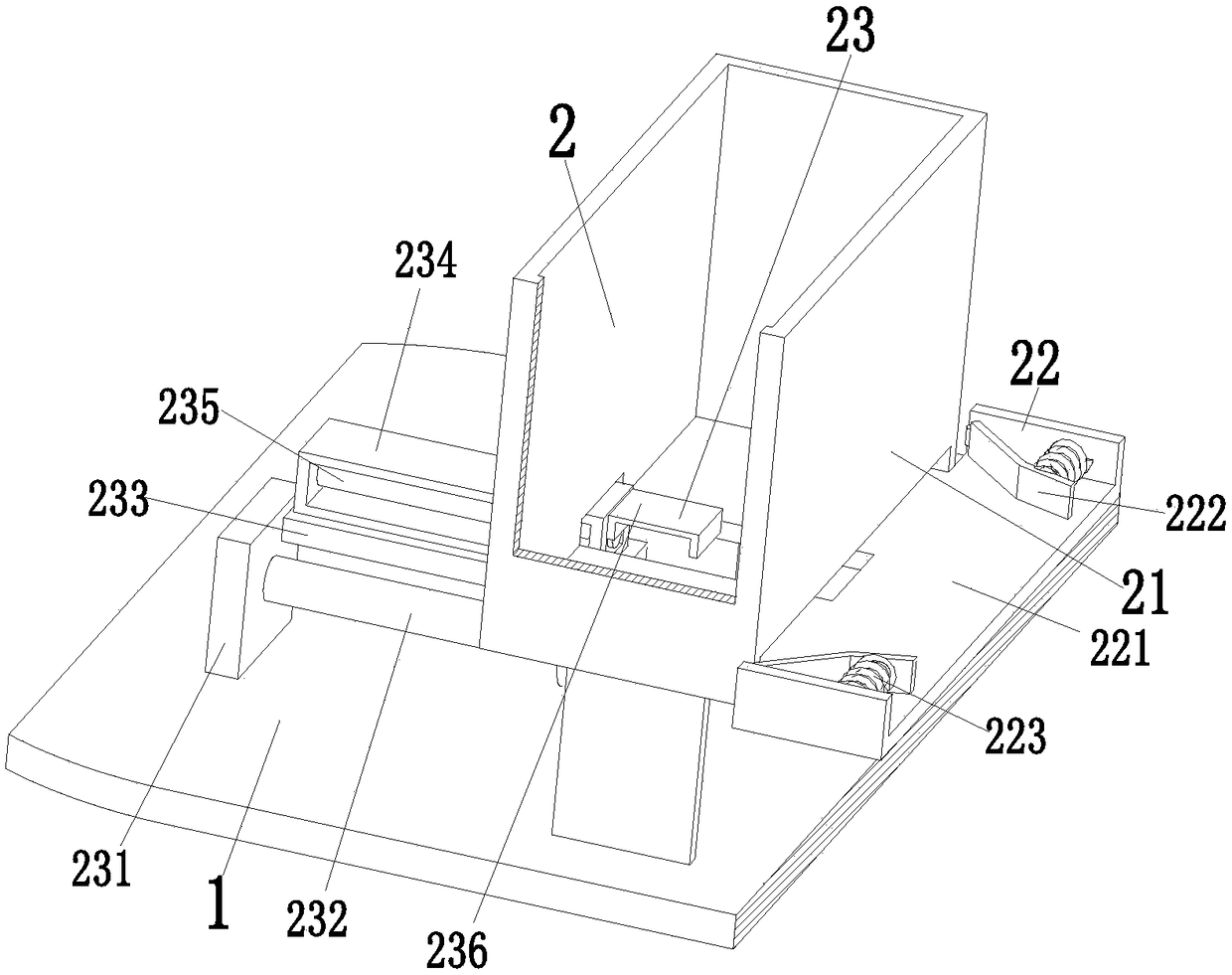

Base processing equipment for wooden pallet

The invention provides base processing equipment for a wooden pallet, belongs to the technical field of wooden pallets, and solves the problems that the traditional wooden pallet base has low processing efficiency. The base processing equipment for the wooden pallet comprises a rack and a conveying mechanism capable of conveying a plurality of foot piers side by side, wherein a bin and a nailing device are arranged above the conveying mechanism, and flitches are stacked in the bin; the bin and the nailing device are sequentially and fixedly arranged on the rack along the conveying direction of the foot piers, and a discharging mechanism is arranged between the conveying mechanism and the bin; and when each row of foot piers are conveyed to a position below the bin, the flitch rightly falling on the row of foot piers can be shifted from the bin by the discharging mechanism. According to the base processing equipment for the wooden pallet, the foot piers can be conveyed orderly, and supporting plates are accurately laid, so that the product quality is ensured, the degree of automation is high, and the production efficiency is greatly improved.

Owner:JINYUN XINYU METAL PROD

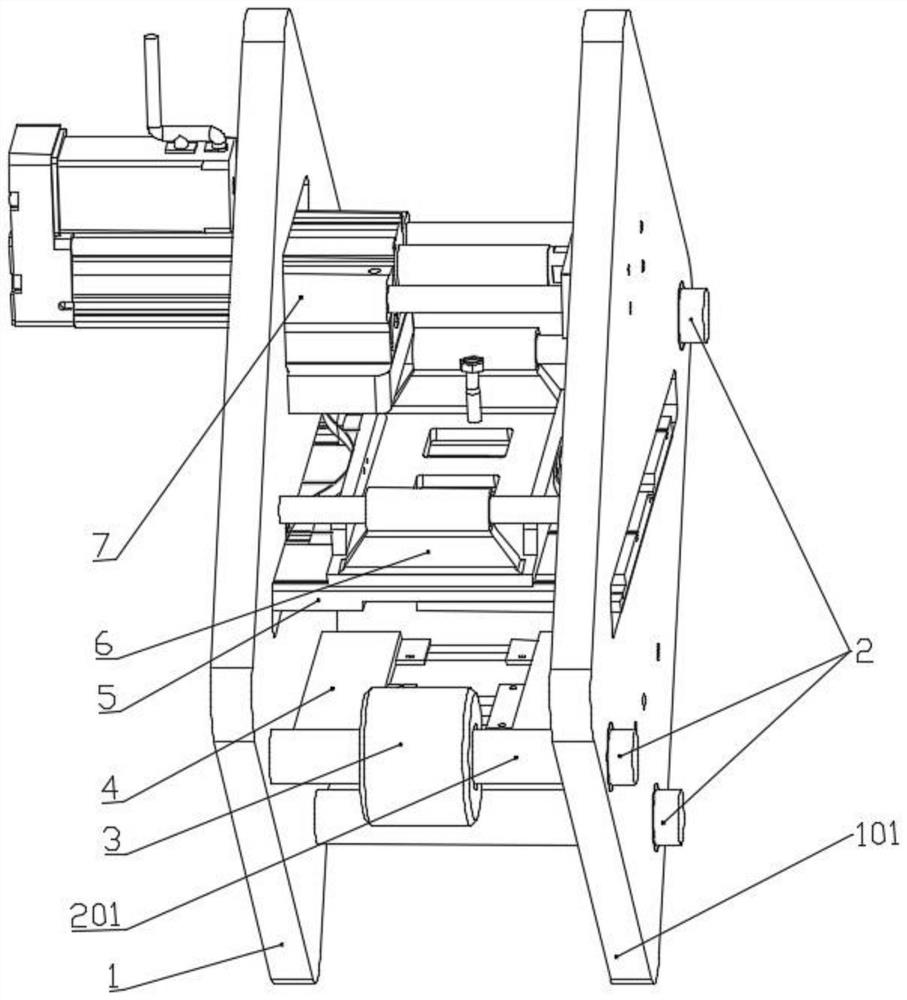

Construction equipment for building structure reinforcement

ActiveCN108571179ANo tiltReduce labor intensityBuilding repairsWorking environmentArchitectural engineering

The invention relates to construction equipment for building structure reinforcement. The construction equipment comprises a bottom plate, wherein a conveying device, a gluing device, two fixing devices and a laying device are sequentially installed on the bottom plate from front to back, and the two fixing devices are symmetrically located on the left side and the right side of the bottom plate.The problems that steel plates need to be transported manually, are coated with blended glue manually and are required to be bonded on designated working surfaces manually in the existing steel-bondedbuilding reinforcement process, manual transportation of the steel plates is time-consuming and strenuous, pungent odor in the glue is harmful to human health, the steel-bonded reinforcement effect on buildings is affected due to uneven manual application of the glue, potential safety hazards exist in the process of manual operation due to complex working environment of the to-be-reinforced building working surfaces, manual vibration compaction of the bonded steel plates is complicated, and frequent movement is required and stability is poor as a result of limited working range of manual bonding of the steel plates can be solved.

Owner:中铁建设集团中南建设有限公司

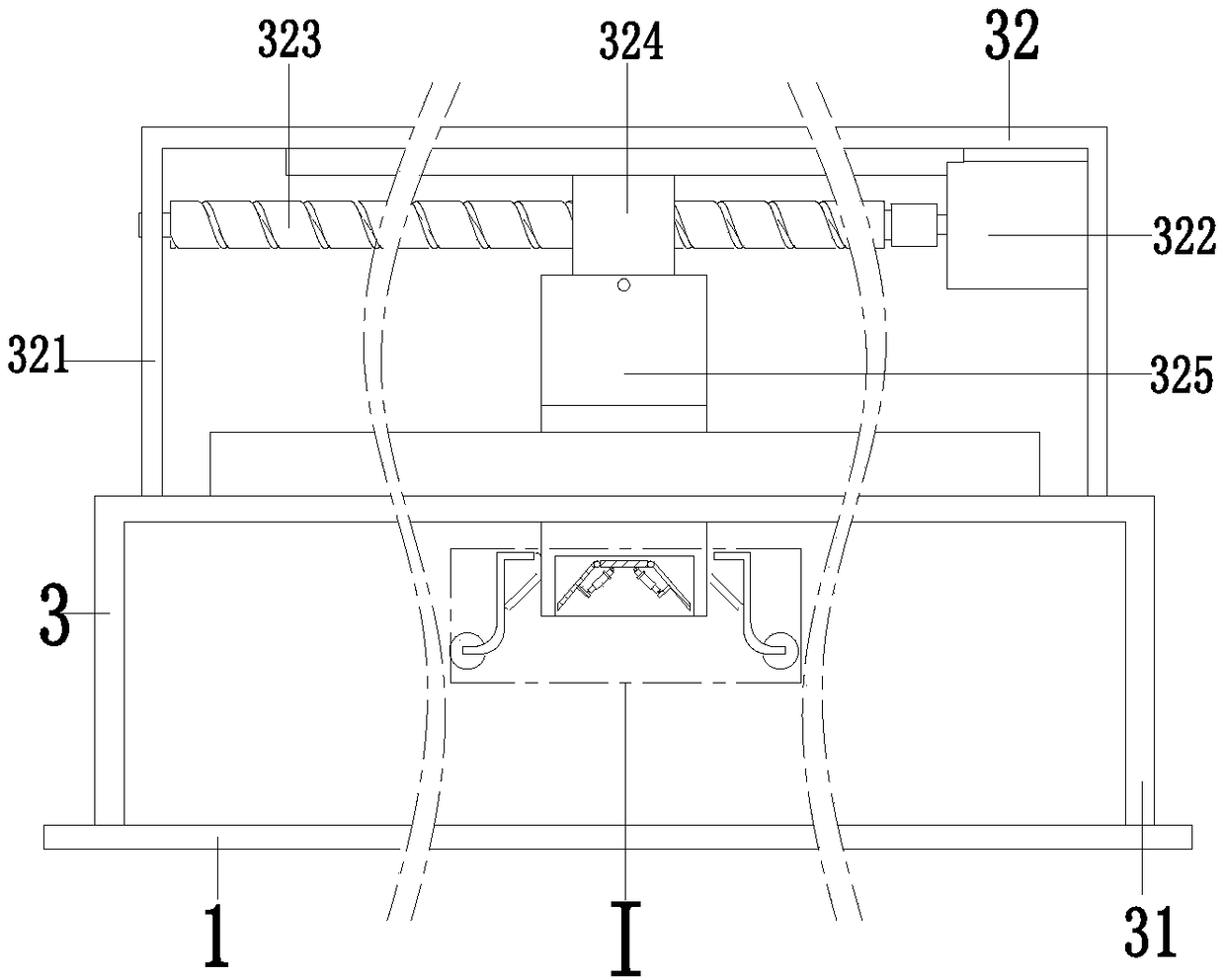

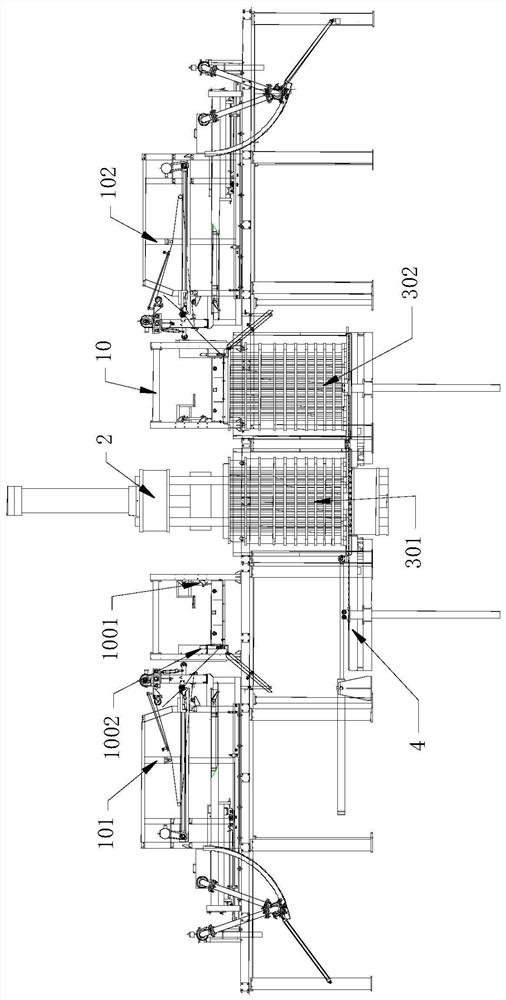

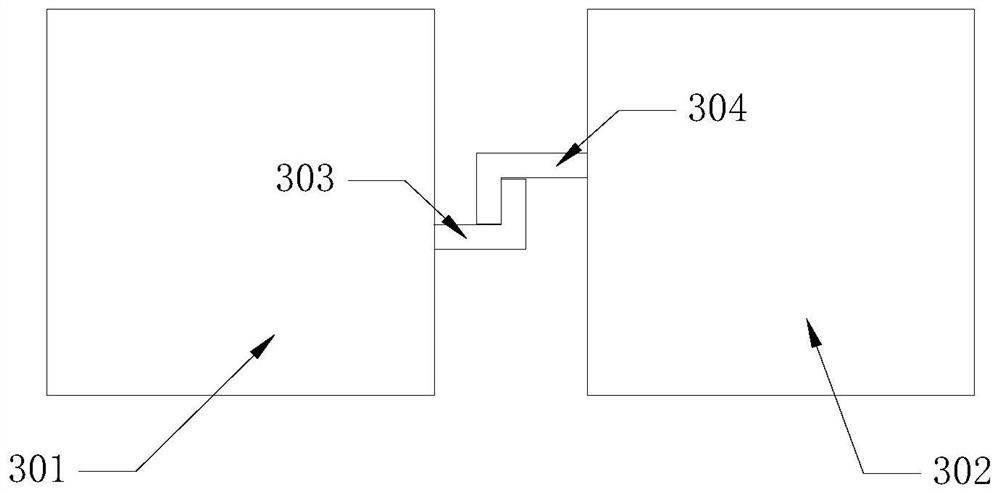

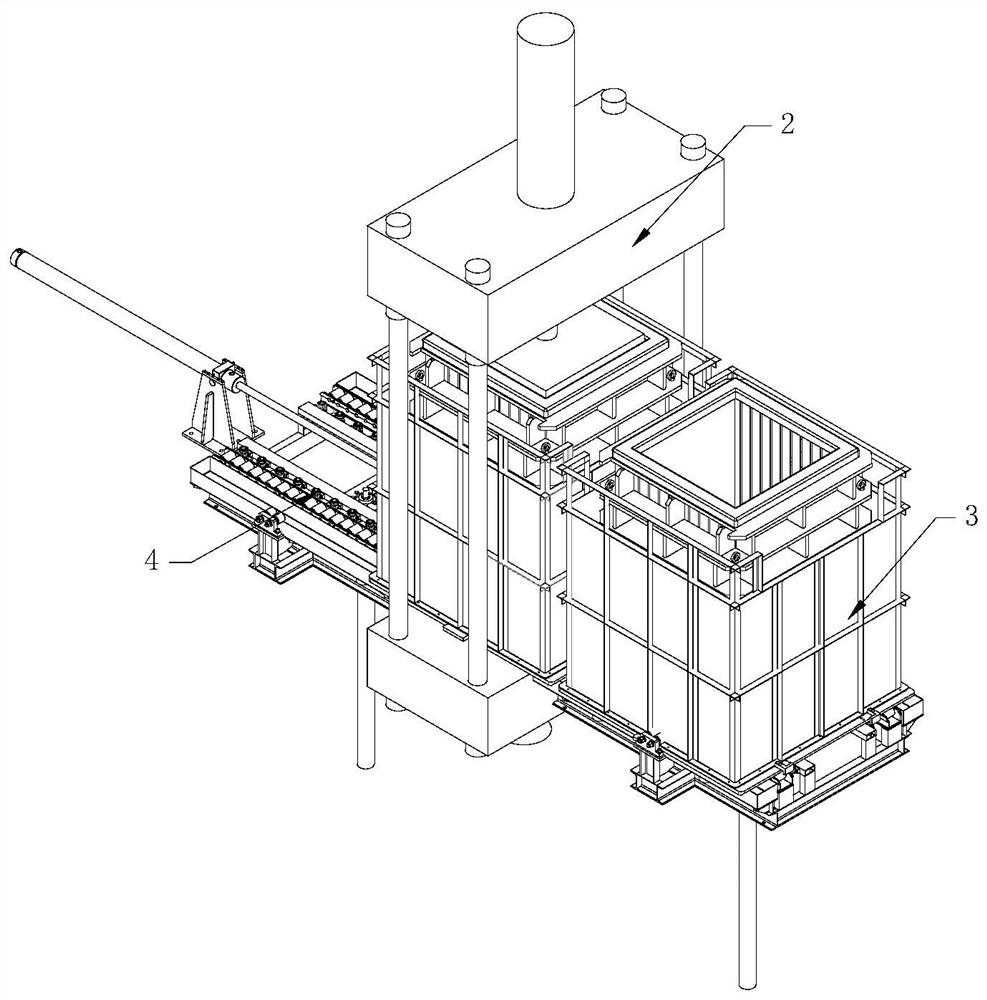

Reciprocating type ultrathin laminated filter press

PendingCN111760363AReduce areaGuaranteed work efficiencySludge treatmentMembrane filtersReciprocating motionWater filter

The invention provides a reciprocating type ultrathin laminated filter press. The filter press comprises a material spreading and discharging part, a material pressing part and a water filtering framebasket, wherein the water filtering frame basket has a first position and a second position; the water filtering frame basket does linear reciprocating motion between the first position and the second position; when the water filtering frame basket is located between the material spreading and discharging part and the material pressing part at the first position, the water filtering frame basketis arranged at the end close to the material spreading and discharging part; and at the second position, the water filtering frame basket is located under the material pressing part. When the water filtering frame basket is located at the first position, the water filtering frame basket has two working states, namely a spreading working state and a discharging working state; and when the water filtering frame basket is located at the second position, the filter press is in a filter pressing state. The filter press is arranged to be reciprocating, and the work of material spreading, filter pressing, discharging and batching is completed through reciprocating motion of the water filtering frame basket; and thus, working efficiency is guaranteed, the area of an installation site is saved, andequipment movement precision and rhythm are better controlled.

Owner:中合清源(济南)生态科技有限公司

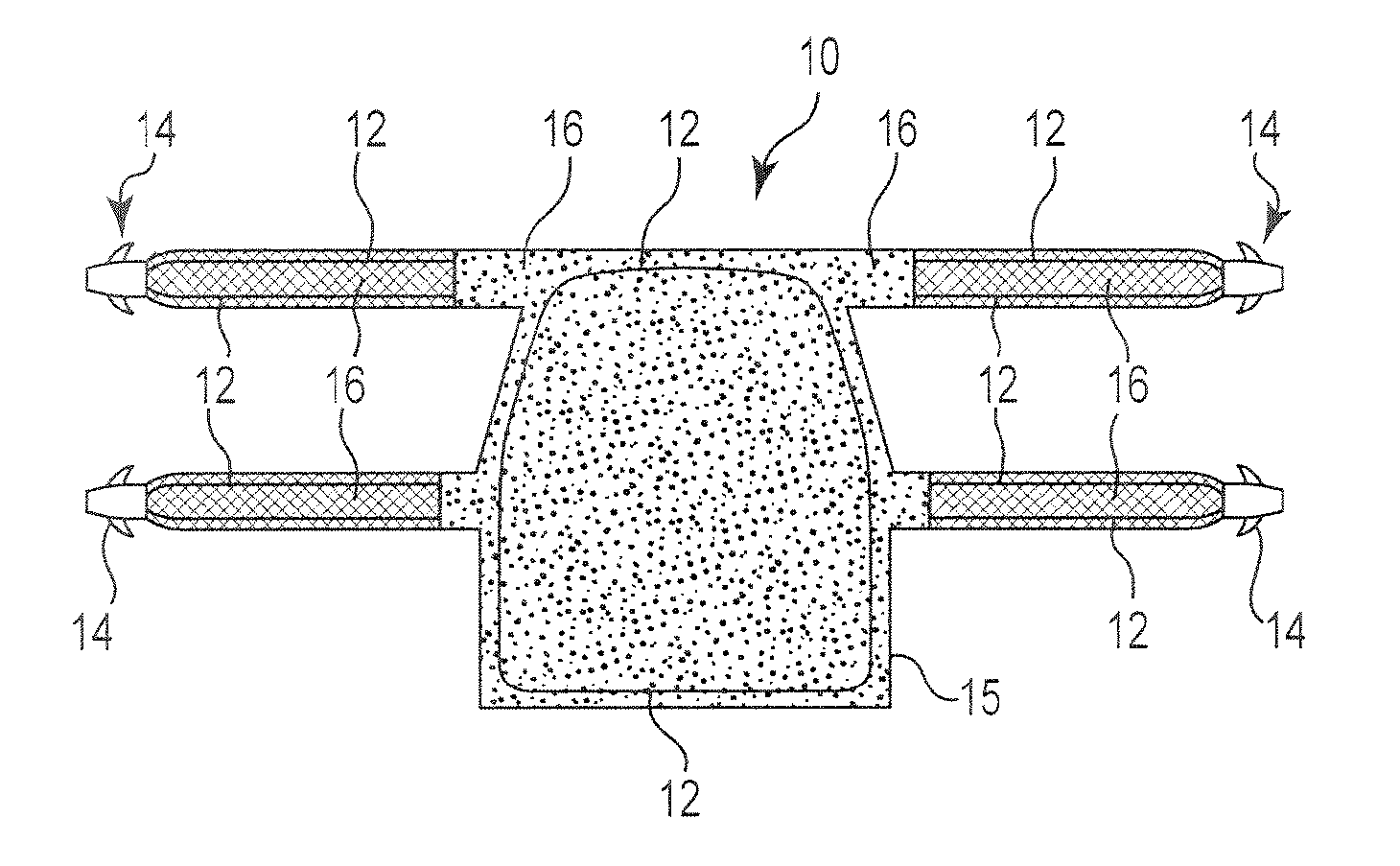

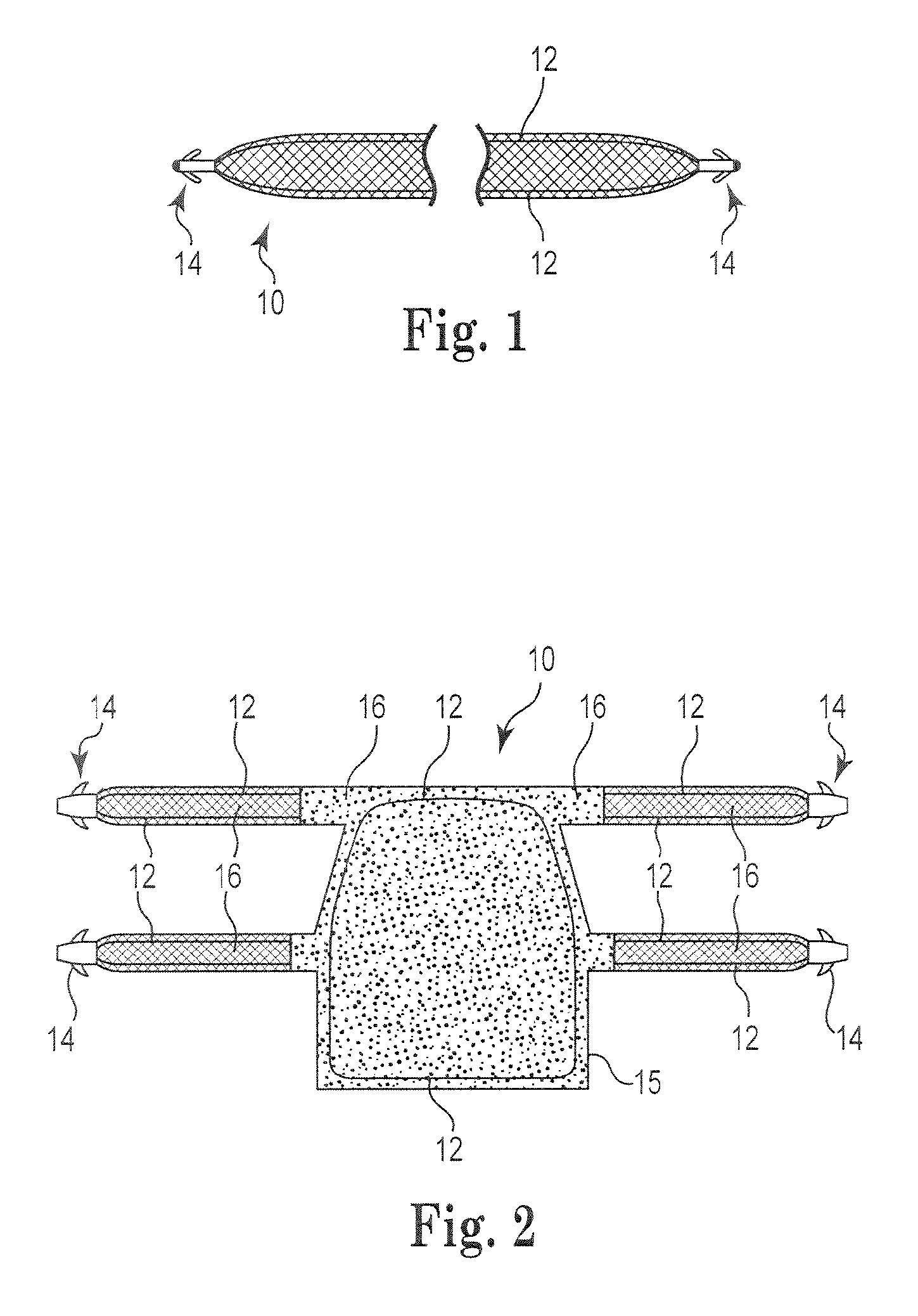

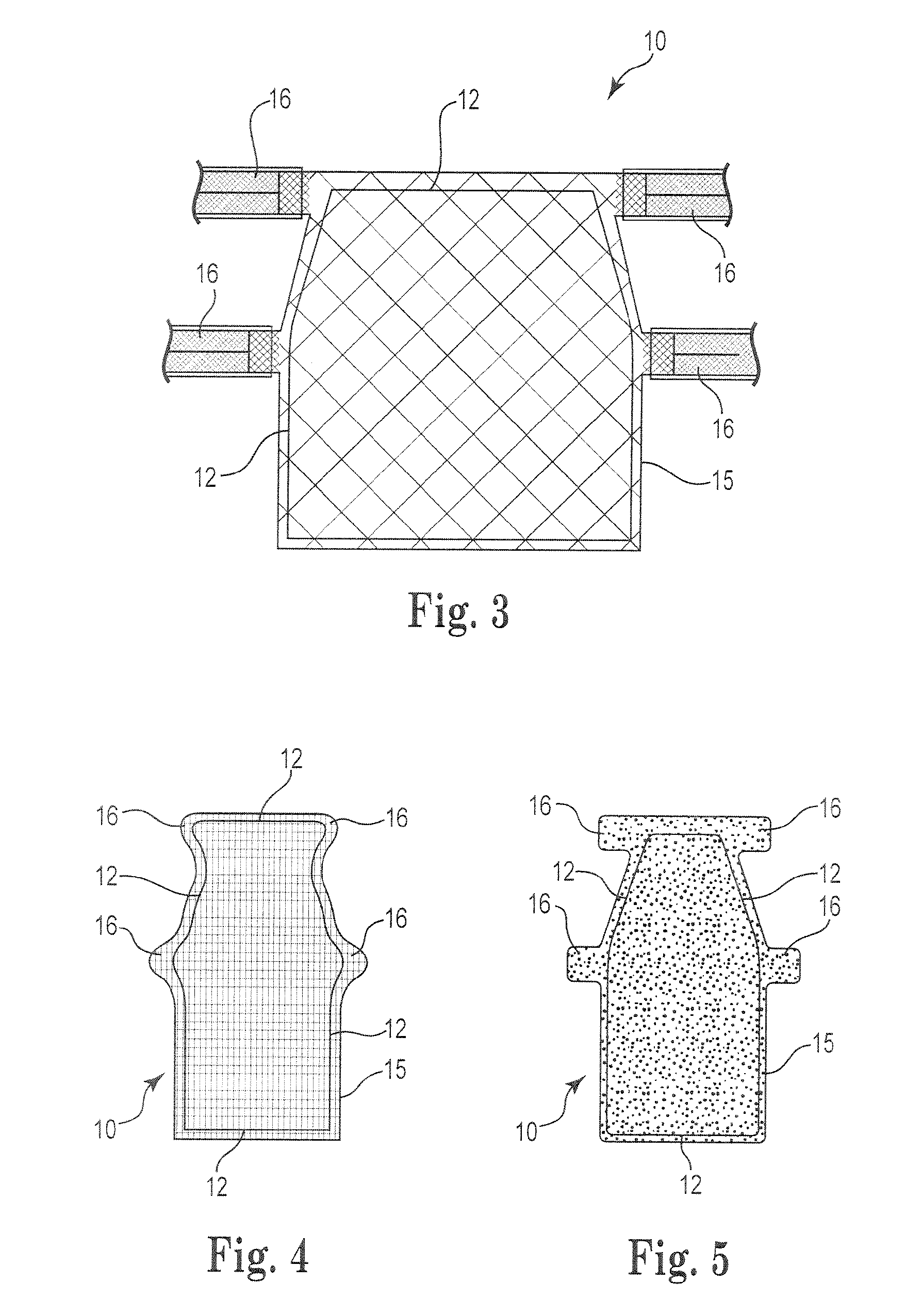

Pelvic Implants having Perimeter Imaging Features

InactiveUS20120283510A1Eliminating opportunityReduced effectivenessAnti-incontinence devicesLigamentsX-rayImaging Feature

An implant adapted to treat various pelvic disorders can include one or more imaging features constructed of a material adapted to provide visualization on an imaging machine (e.g., X-Ray, fluoroscopy, etc.). The imaging feature generally follows along the perimeter shape of at least a portion of the implant to visually confirm how the implant is lying in a patient's body during implantation. The imaging feature can be constructed of a wire (e.g., platinum-iridium), a radio-opaque material or substance, or like materials or constructs adapted to provide the desired visualization.

Owner:BOSTON SCI SCIMED INC

Flexible automatic food processing and client orders execution machine

PendingUS20210094188A1Easy and efficient to manufactureLower sales priceProgramme-controlled manipulatorBakery productsLogistics managementProcess engineering

The present technology is to be used in used in pizzerias and other food restaurants to fully substitute manual labor in food processing. The present technology utilizes a modular principle for flexibility. It allows tuning the machine to (1) different dishes like pizza, chicken wings or hamburgers (2) different sizes and shapes of the room and (3) different orders capacity. The machine utilizes autonomous driving robots with autopilot for food logistics between ingredient stations and for the refilling of the stations with ingredients. Autonomous autopilot robot allows to precisely position the food to cook, e.g. pizza, with the ingredient station for precisely topping or other food processing. Precise interposition allows deep food customization by a client with the possibility of making drawings on food using ingredients. The matrix modular structure of the machine allows parallel orders execution. It is extremely beneficial in peak hours.

Owner:RODIONOV DENIS +2

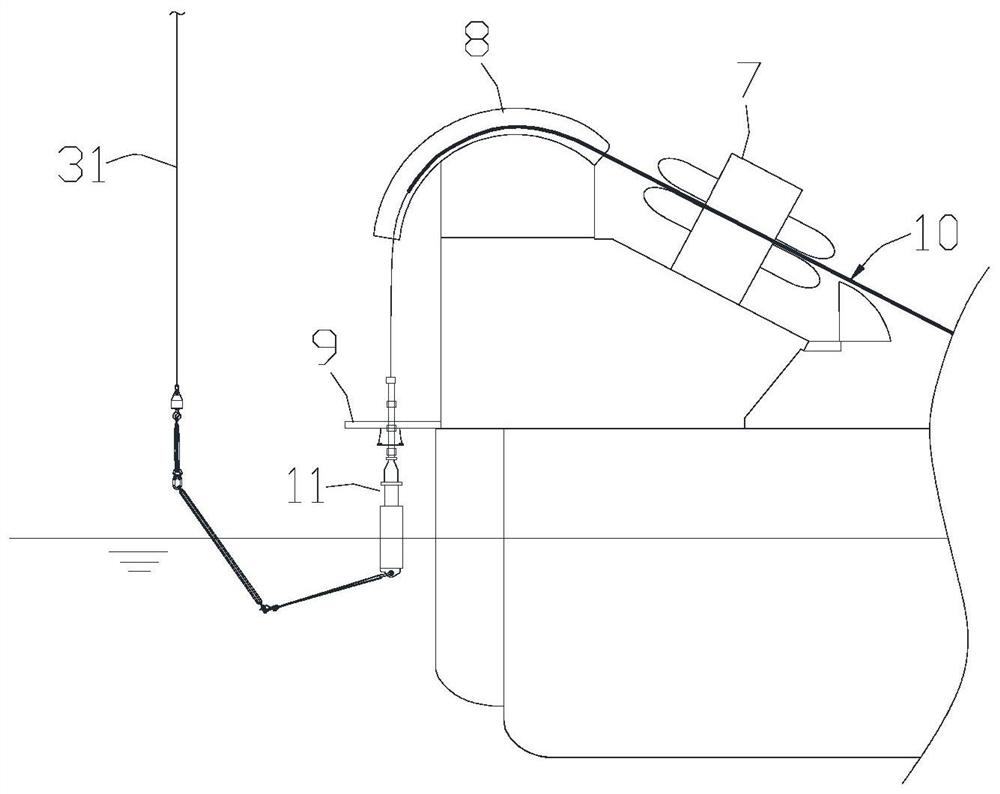

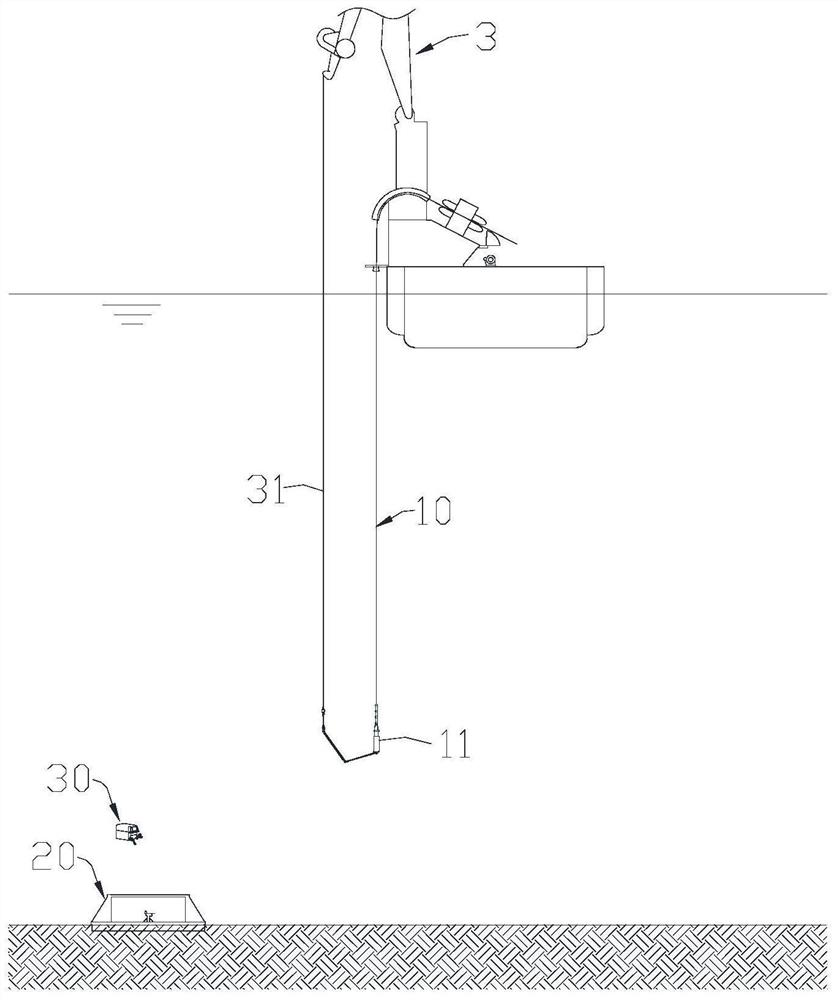

Laying and mounting method for deepwater submarine cable broadside launching

ActiveCN113148030AAccurate placementAccurate layingCargo handling apparatusPassenger handling apparatusWinchElectric cables

The invention discloses a laying and mounting method for deepwater submarine cable broadside launching. The laying and mounting method comprises the steps: S1, enabling a submarine cable mounting workboat to transport submarine cables stored by a cable reel to a mounting site; S2, hoisting the underwater power distribution unit at the head end of the submarine cable and then placing the underwater power distribution unit above the outboard working platform; S3, putting the underwater power distribution unit into water, and putting the underwater power distribution unit into an underwater power distribution system base plate on a seabed; S4, horizontally laying submarine cables at the rear end of the underwater power distribution unit on the seabed; S5, hoisting and hanging the tail end of the submarine cable on an outboard working platform; S6, enabling the floating production storage and offloading oil tanker to lower a steel wire rope; S7, enabling the steel wire rope to be connected with the hoisting rigging of the main crane, and connecting the steel wire rope with the tail end of the submarine cable after the hoisting rigging is recycled to the outboard working platform; S8, hoisting and putting the tail end of the submarine cable and the steel wire rope into water, lifting the winch to recycle the steel wire rope, and lifting the tail end of the submarine cable to the floating type production storage and offloading oil tanker. According to the invention, the submarine cable can be accurately positioned and laid underwater.

Owner:SHENZHEN OFFSHORE OIL ENG UNDERWATER TECH

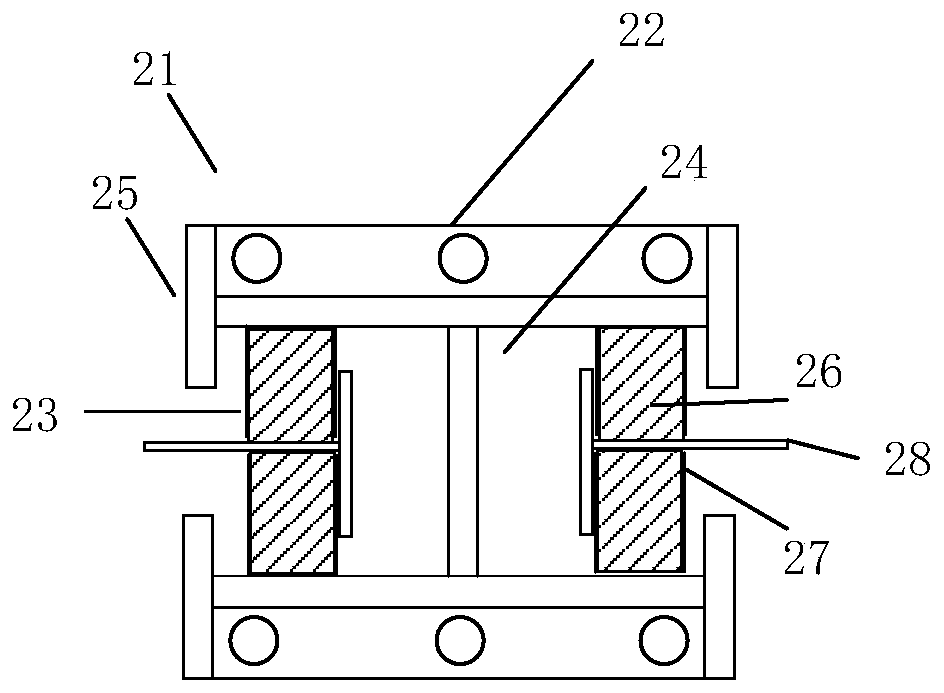

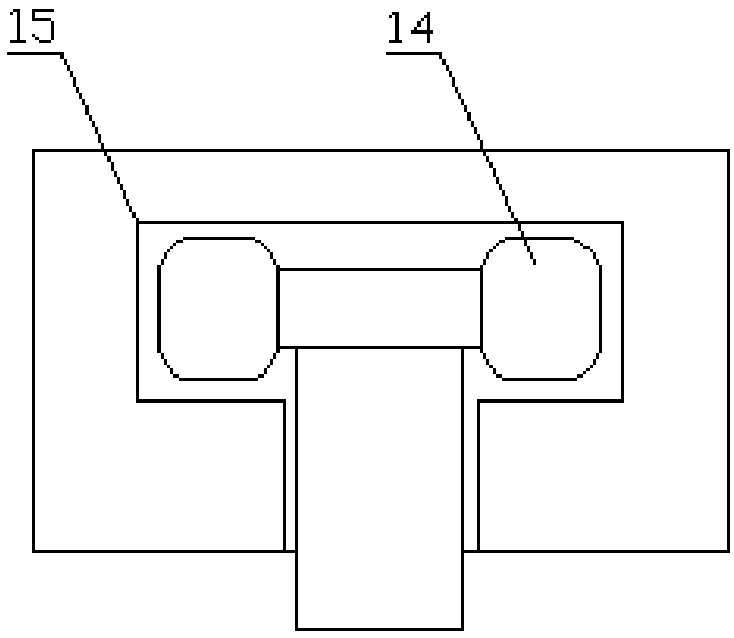

Laying device and method for impermeable films

ActiveCN110042871AImprove water resistance and impermeabilityLaying speed is fastProtective foundationSoil preservationEngineeringMechanical engineering

The invention discloses a laying device and method for impermeable films. The laying device for the impermeable films comprises a plurality of connecting assemblies and a film supplying device, the multiple connecting assemblies are arranged at intervals, the film supplying device is used for conveying the impermeable films, the two opposite ends of the impermeable films are connected to the two adjacent connecting assemblies correspondingly, each connecting assembly comprises a mounting part, two or more sets of waterproofing fixing assemblies and two or more connecting parts, each mounting part comprises a first mounting groove and a second mounting groove, the waterproofing fixing assemblies are arranged in the first mounting grooves and the second mounting grooves correspondingly, eachwaterproofing fixing assembly comprises two fixing parts, wherein a gap is formed between the two fixing parts, each connecting part is connected with the corresponding waterproofing fixing assemblyand comprises a first end and a second end, the first ends are connected to the waterproofing fixing assemblies, the second ends penetrate through the gaps, each connecting part is clamped by the twocorresponding fixing parts, and the second ends extend to the outer sides of the mounting parts and are used for being connected with the impermeable films. The laying device and method for the impermeable films, the impermeability and the waterproofing property of the junction of the adjacent impermeable films can be effectively achieved.

Owner:DAYAN MINE IND NEIMENGGU +1

Apparatus for creating an encased cable seam

InactiveUS8794290B2Improve efficiencyQuick installationLaminationLamination apparatusBraced frameEngineering

An apparatus for creating an encased cable seam includes a transportable support frame with a roll of encased cable material supported by a support bar, boom and spindle. Heating units supported by the frame heat the bottom surface of the membrane portion of the encased cable material. The encased cable material released from the roll toward the substrate to create an overlapping seam of the encased cable material on the membrane substrate of a roof deck. The apparatus includes a handle and a roller, whereby the roller presses the encased cable material causing a welded bond as the handle moves the apparatus forward.

Owner:HAMLIN III HENRY L

Pouring system paving method

ActiveCN107745080AEfficient processImprove work efficiencyFoundry mouldsFoundry coresEngineeringSoftware

The invention discloses a pouring system paving method, which comprises: (1) drawing: drawing a two-dimensional picture by using CAD software, wherein the drawing contents comprise a mold placement position border, a gate positioning border, a mold inner gate position size border, a horizontal runner position border and a straight runner position border. According to the present invention, the two-dimensional picture is drawn through the CAD software, the two-dimensional picture is projected onto a working table through a projector, a horizontal runner porcelain tube, a mold, an inner gate porcelain tube and a straight runner porcelain tube are paved, a first pneumatic rod drives an ultrasonic wave sensor to detect the paving of the horizontal runner porcelain tube and the inner gate porcelain tube, the influence of the leakage caused by the non-flat paving on the pouring is avoided, a second pneumatic rod stably inserts the bundled horizontal runner porcelain tube into the inner gateporcelain tube, the whole process is rapid, efficient and stable, different two-dimensional pictures can be replaced according to different molds, the operation can be performed without professionals,the working efficiency is high, and the pouring error cannot be easily generated.

Owner:TONGLING ANDONG CAST STEEL

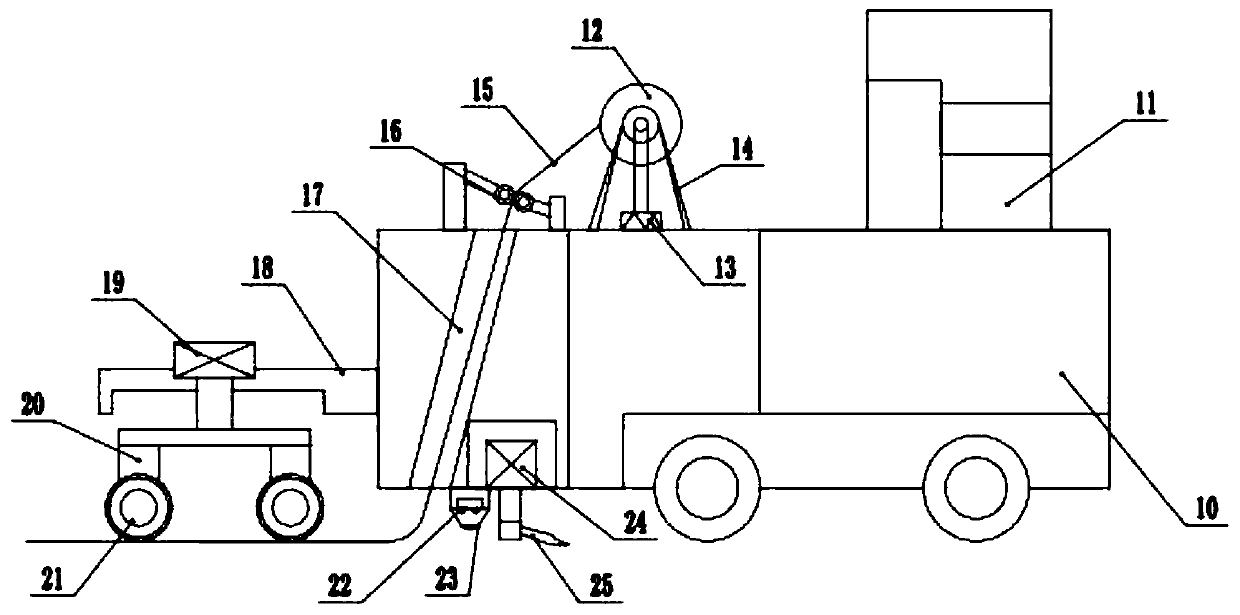

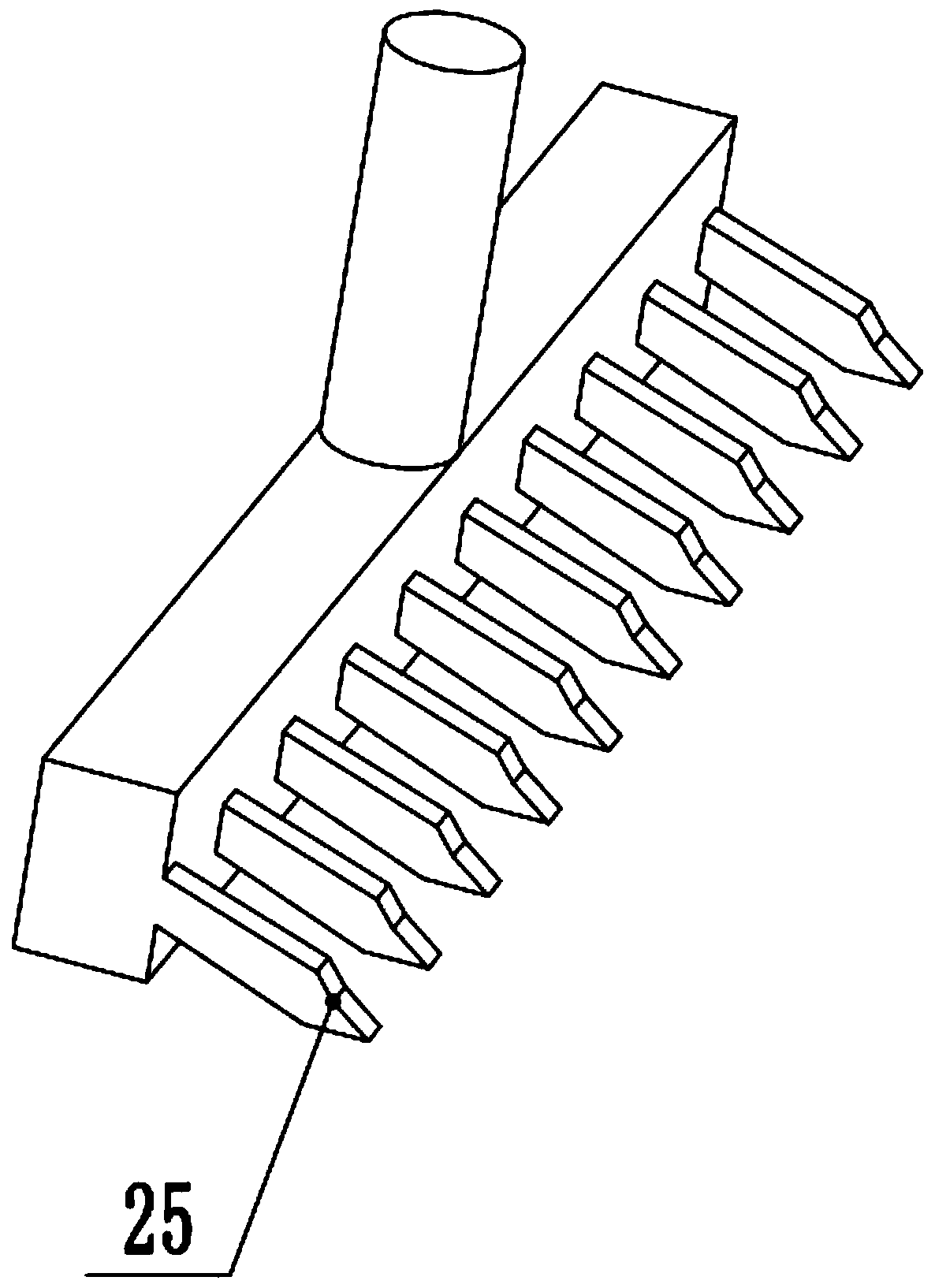

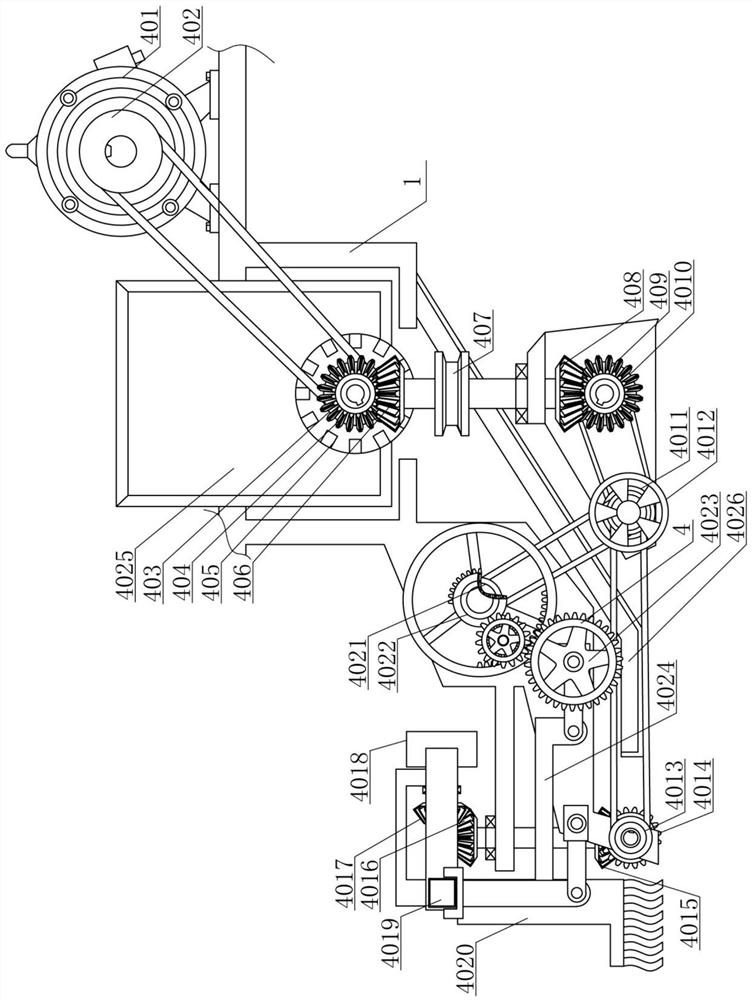

Flattening and winding device of waterproof waterstop for bridge expansion joint

InactiveCN111395177AFast and efficient filling and laying operationsHigh filling accuracyBridge structural detailsBridge erection/assemblyClassical mechanicsExpansion joint

The invention relates to the technical field of bridge construction and discloses a flattening and winding device of a waterproof waterstop for a bridge expansion joint. The device comprises a locomotive, a driving device, waterstop rollers, a waterstop and compression rollers. A set of waterstop rollers is supported in the middle of the top of the locomotive through a support in a transition mode. A set of inclined discharging grooves are formed in the position, located on the left sides of the waterstop rollers, of the interior of the locomotive. A transverse extension plate is fixedly mounted outwards on the left side wall of the locomotive; a first lifter is fixedly mounted in the middle of the extension plate; the lower side of the first lifter is connected with a mounting frame having a U-shaped structure through a lifting rod; two sets of compression rollers are connected to the two sides of the bottom of the mounting frame in a rolling mode, a set of second lifters are fixedlyarranged in the bottom of the locomotive located on the right sides of dust suction holes, a set of transverse rods are fixedly mounted on the lower sides of the second lifters through lifting rods, and a plurality of sets of ash shovels are fixedly mounted on the right side faces of the transverse rods at equal intervals. The flattening and winding device has the advantages of uniform and orderedfeeding, automatic operation process and high working efficiency.

Owner:上安实业江苏有限公司

Method for maintaining airplane composite material part by adopting coordinate transformation method

ActiveCN110524918AAccurate layingAccurate laying and repairingAircraft maintainanceDomestic articlesAirplaneRectangular coordinates

The invention discloses a maintenance method of an airplane composite material part, which comprises the following steps: (1) determining a damage area of the airplane composite material part, and removing the damage area; (2) establishing a first rectangular coordinate system outside the damage area; (3) selecting a first separation membrane to cover the whole damage area, establishing the same second rectangular coordinate system on the first separation membrane, and labeling the laying information of the damage area on the first separation membrane; (4) selecting a second separation membrane, and copying the layering information to the second separation membrane; (5) according to the paving layer information of the second separation membrane, cutting the second separation membrane layerby layer according to a ratio of 1:1 to obtain a repair layer; (6) paving repair layers on the surface of the first separation membrane layer by layer, and sticking the repair layers back to the damage area; and (7) removing the first separation membrane, and curing the repair layers. According to the method, a coordinate system conversion method is adopted to determine the positioning and reference of a repaired paving layer after a damaged area is removed, the repaired paving layer for maintenance is prepared, and the repaired paving layer is adopted to maintain the damaged area.

Owner:中国南方航空股份有限公司

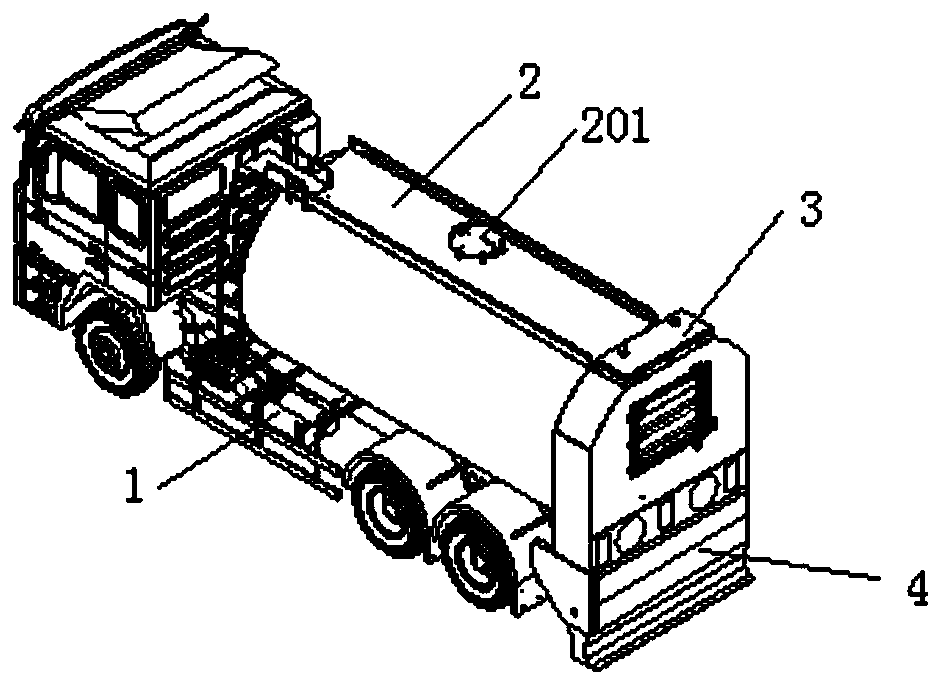

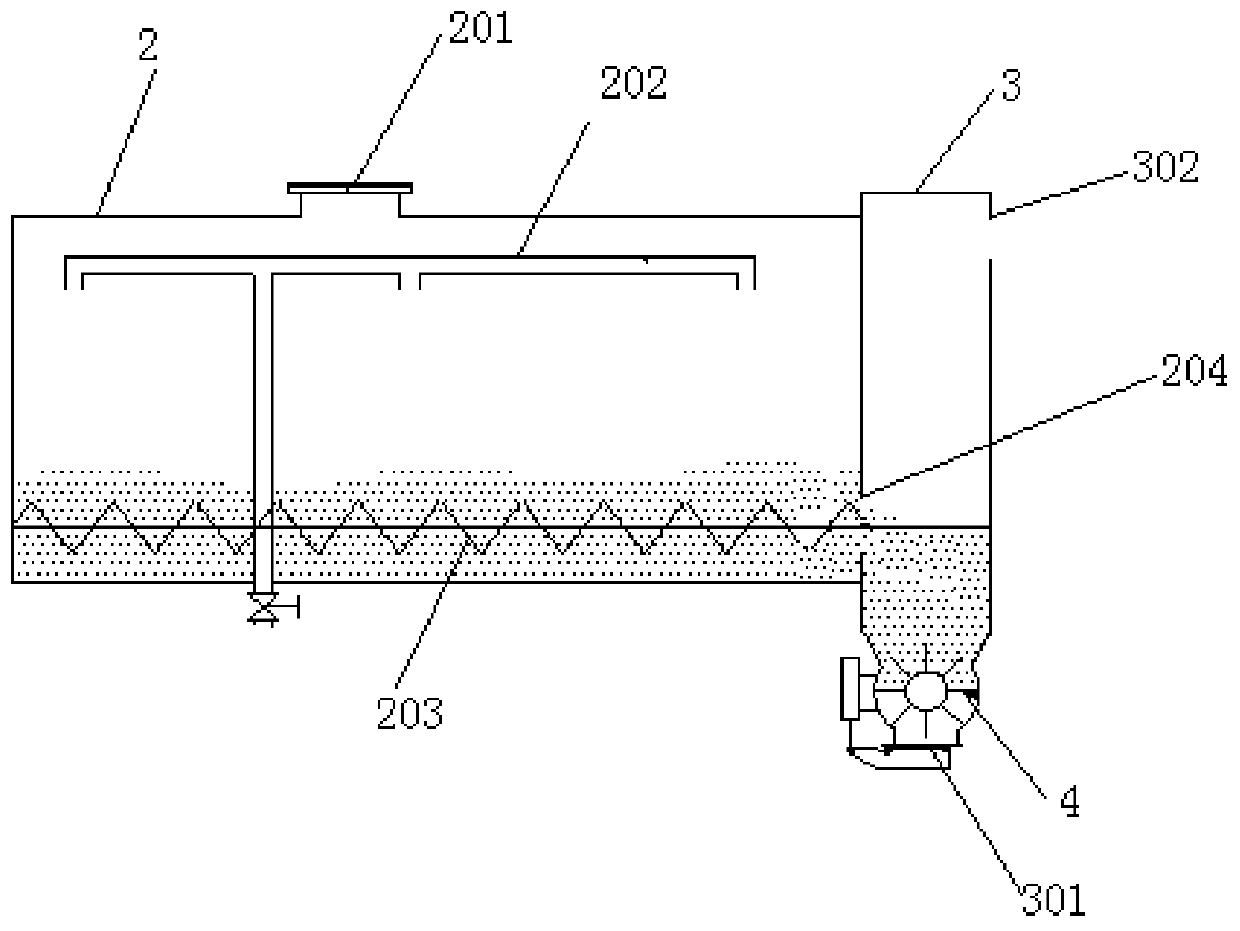

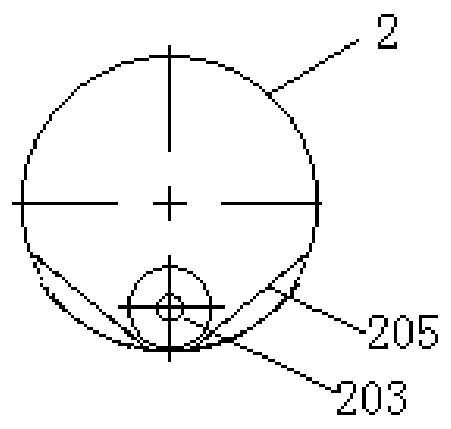

Powder spreading car

The invention belongs to road building equipment, and provides a powder spreading car. The powder spreading car solves the problem that in the prior art, a square powder tank is prone to disturbing powder spiral conveying, a large amount of powder is prone to remaining and stacking on the bottom of the powder tank, and ramming of the powder tank is not uniform. The powder spreading car comprises acontrol system, a car body, a powder tank and a rear box body, wherein the powder tank and the rear box body are fixedly mounted on the car body, a spiral conveying opening is formed in the rear endof the powder tank, the powder tank communicates with the rear box body through the spiral conveying opening, the section of the powder tank is a round or polygon including at least six sides, a manhole is formed in the powder tank, a charging mechanism is arranged on the upper portion of the powder tank, at least one feeding spiral rod is arranged on the bottom of the powder tank, the tail end ofthe feeding spiral rod is located on the spiral conveying opening, a material door is arranged on the bottom of the rear box body, and an exhaust opening is formed in the upper portion of the rear box body; the power part of the car body provides a power source for the powder tank and the rear box body; and the control system controls a charging mechanism of the powder spreading car to carry outcharging, a feeding spiral rod to rotate and the material door to be opened and closed.

Owner:DAGANG HLDG GRP CO LTD

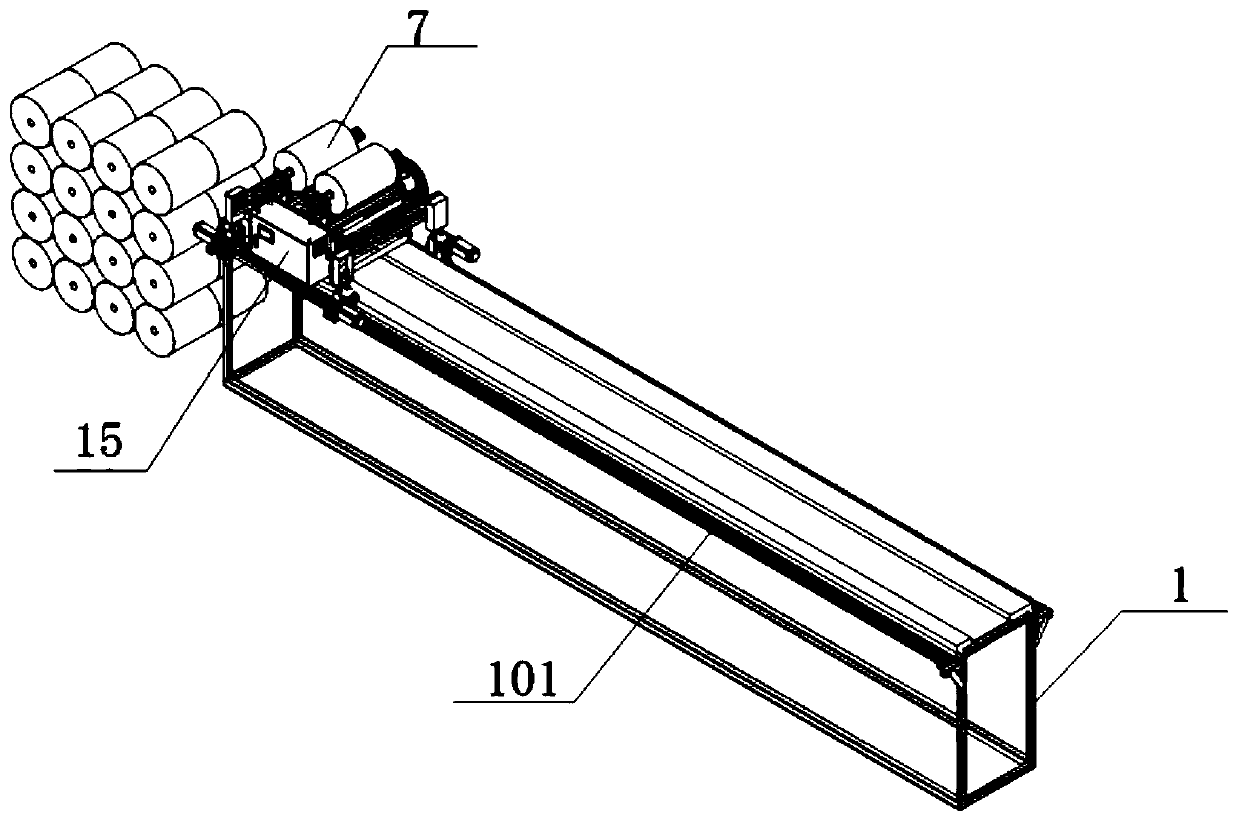

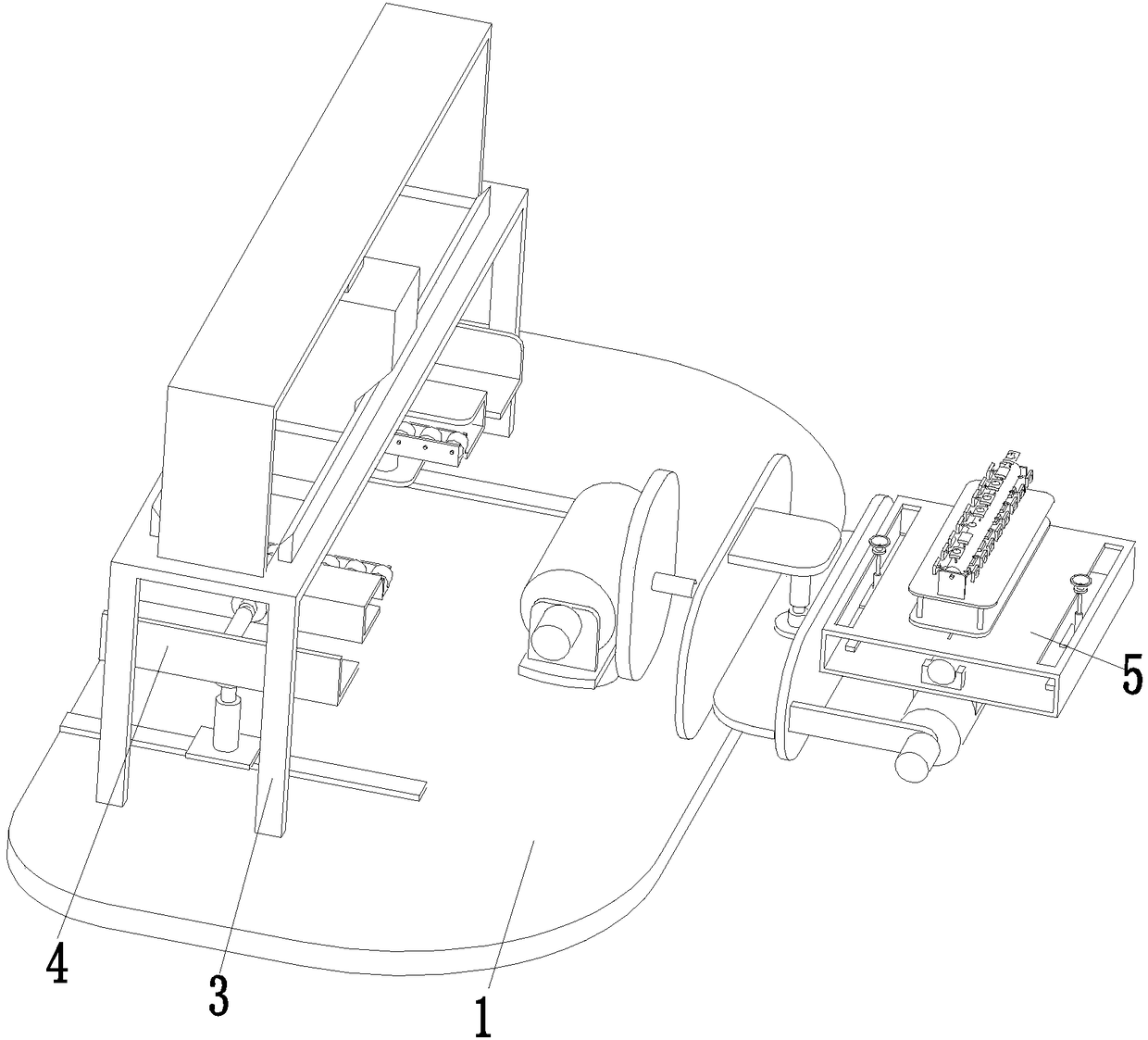

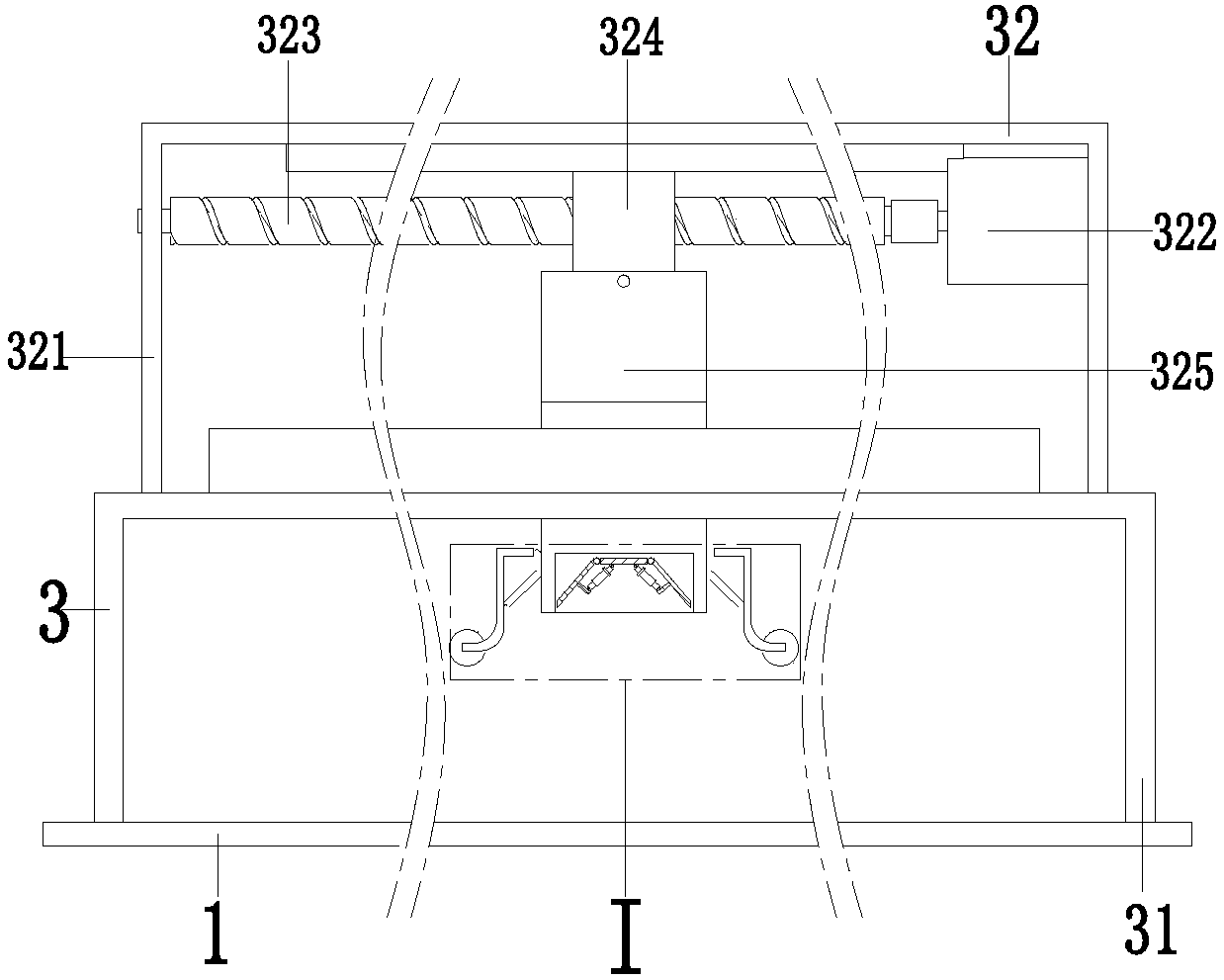

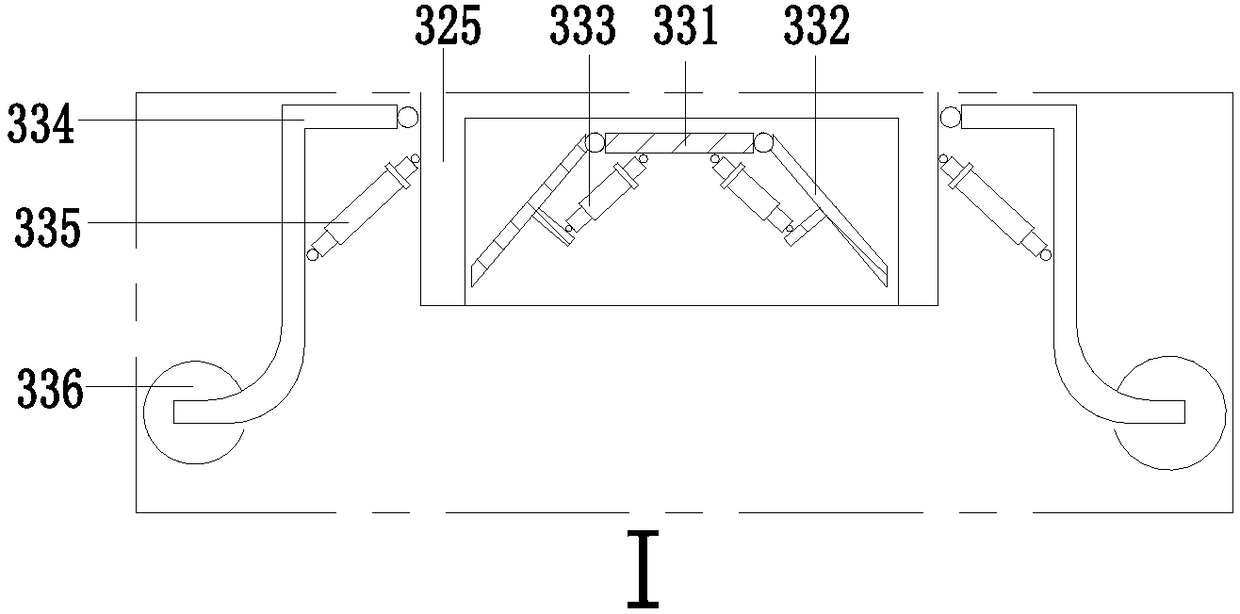

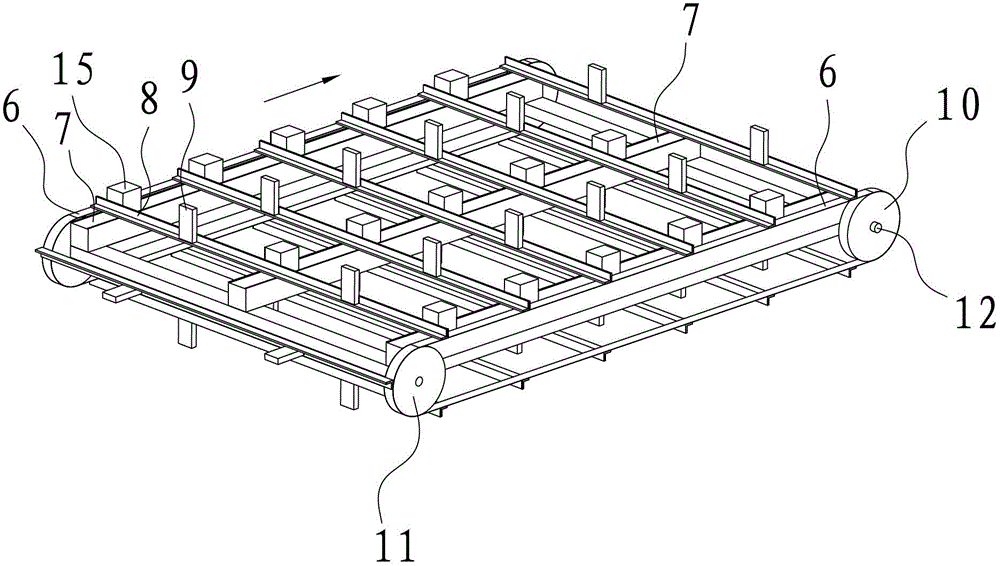

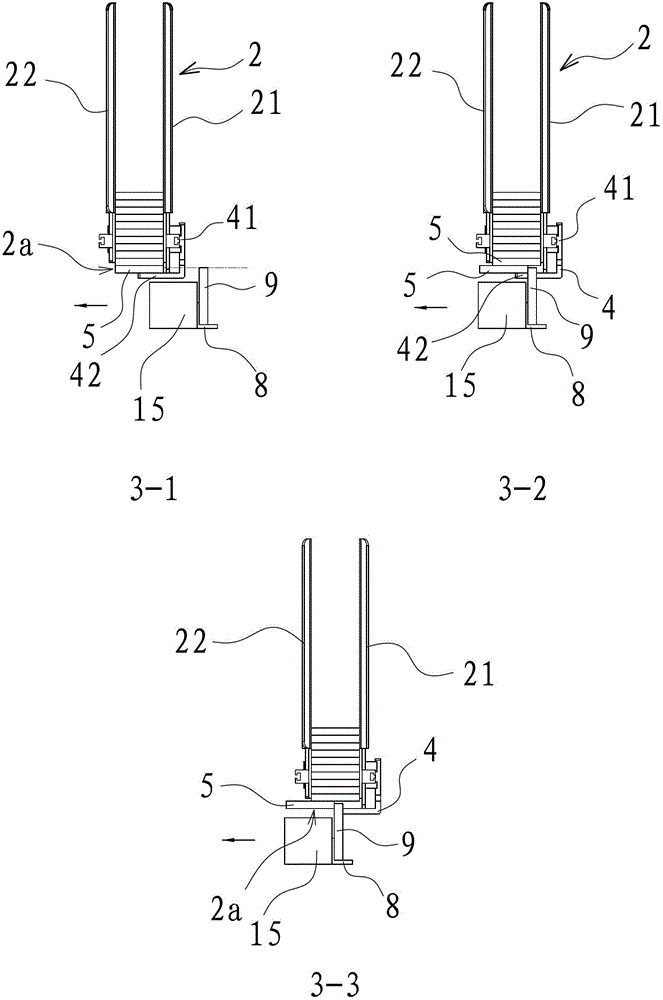

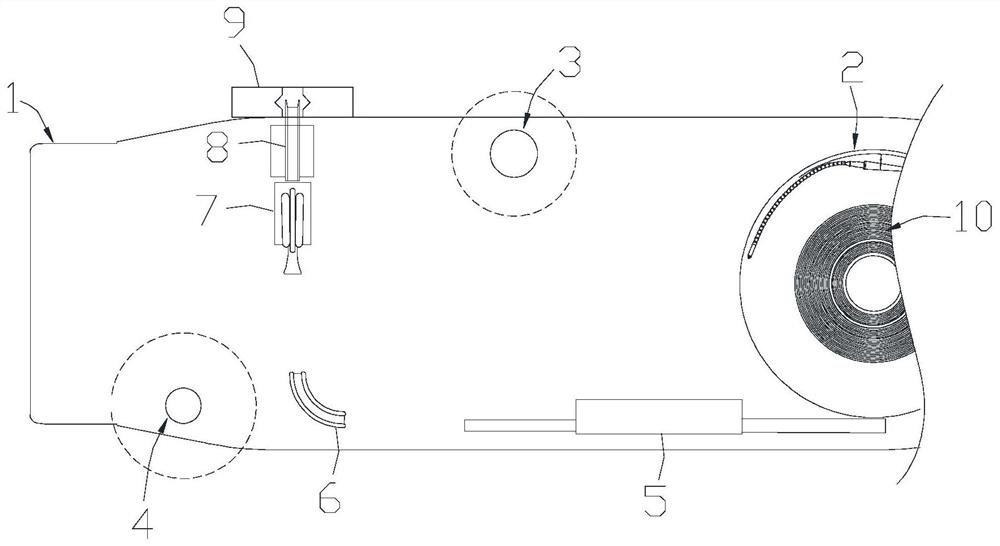

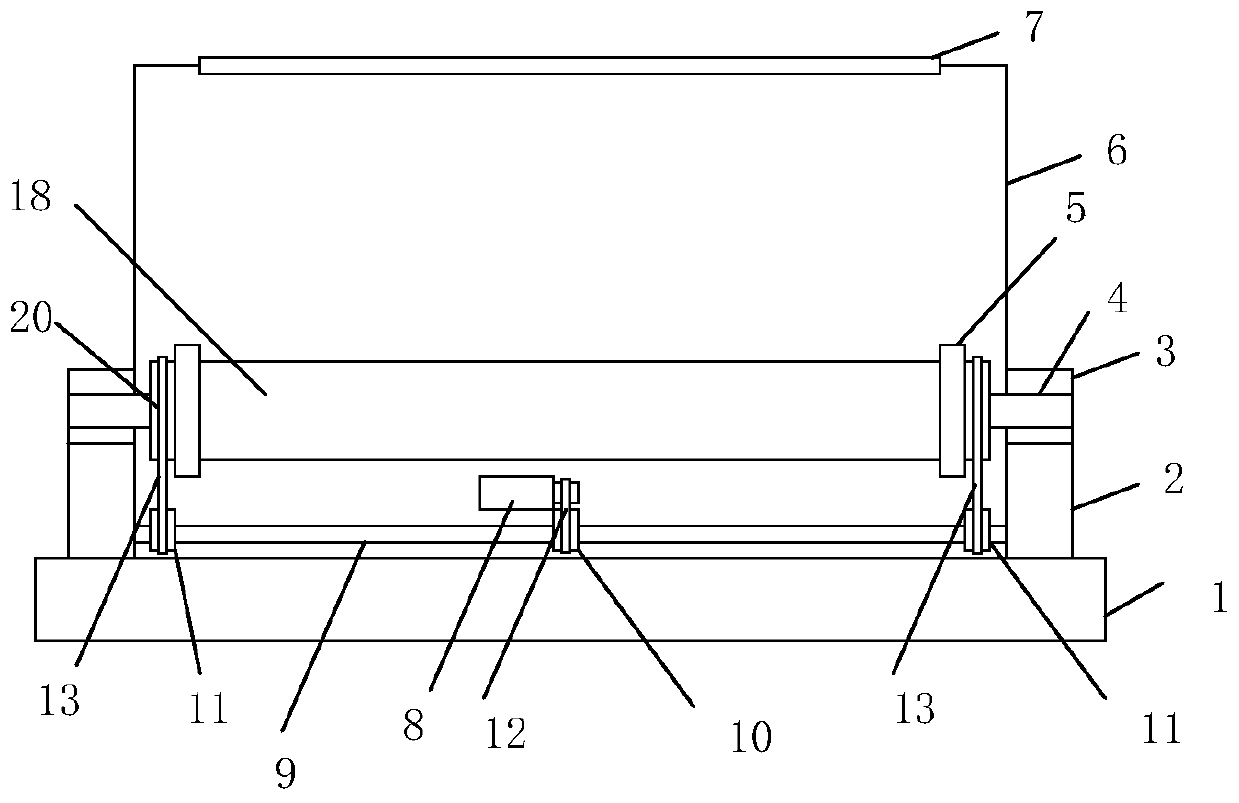

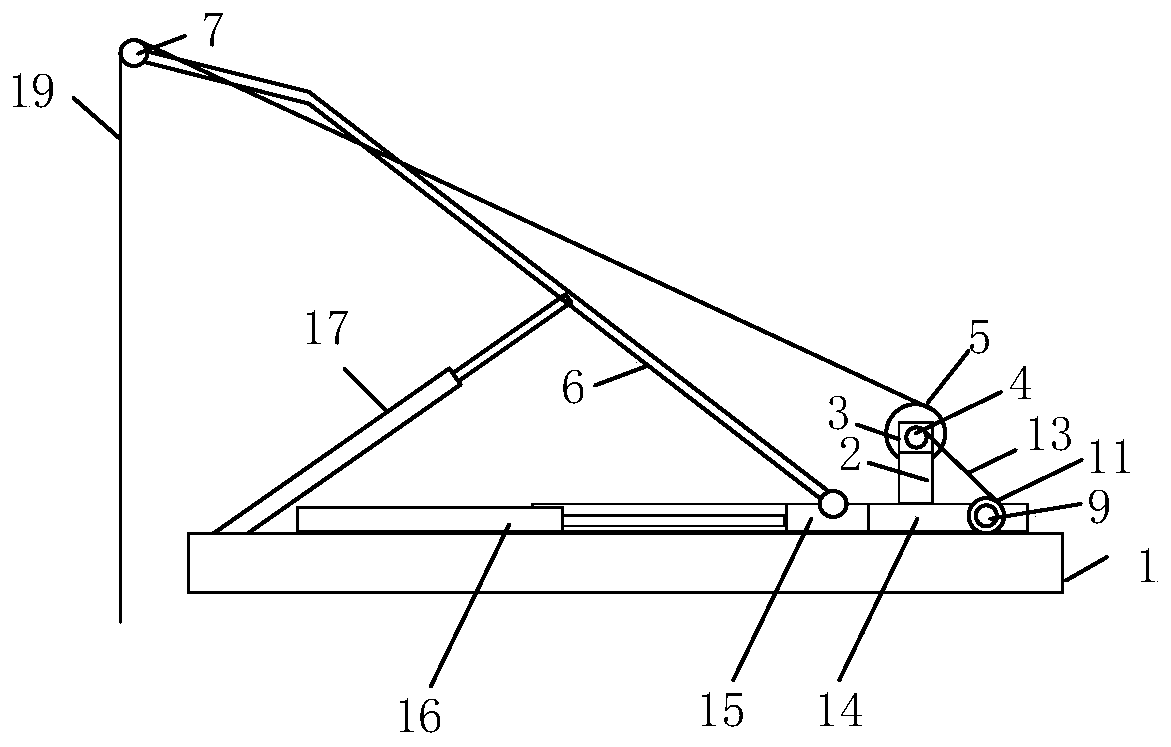

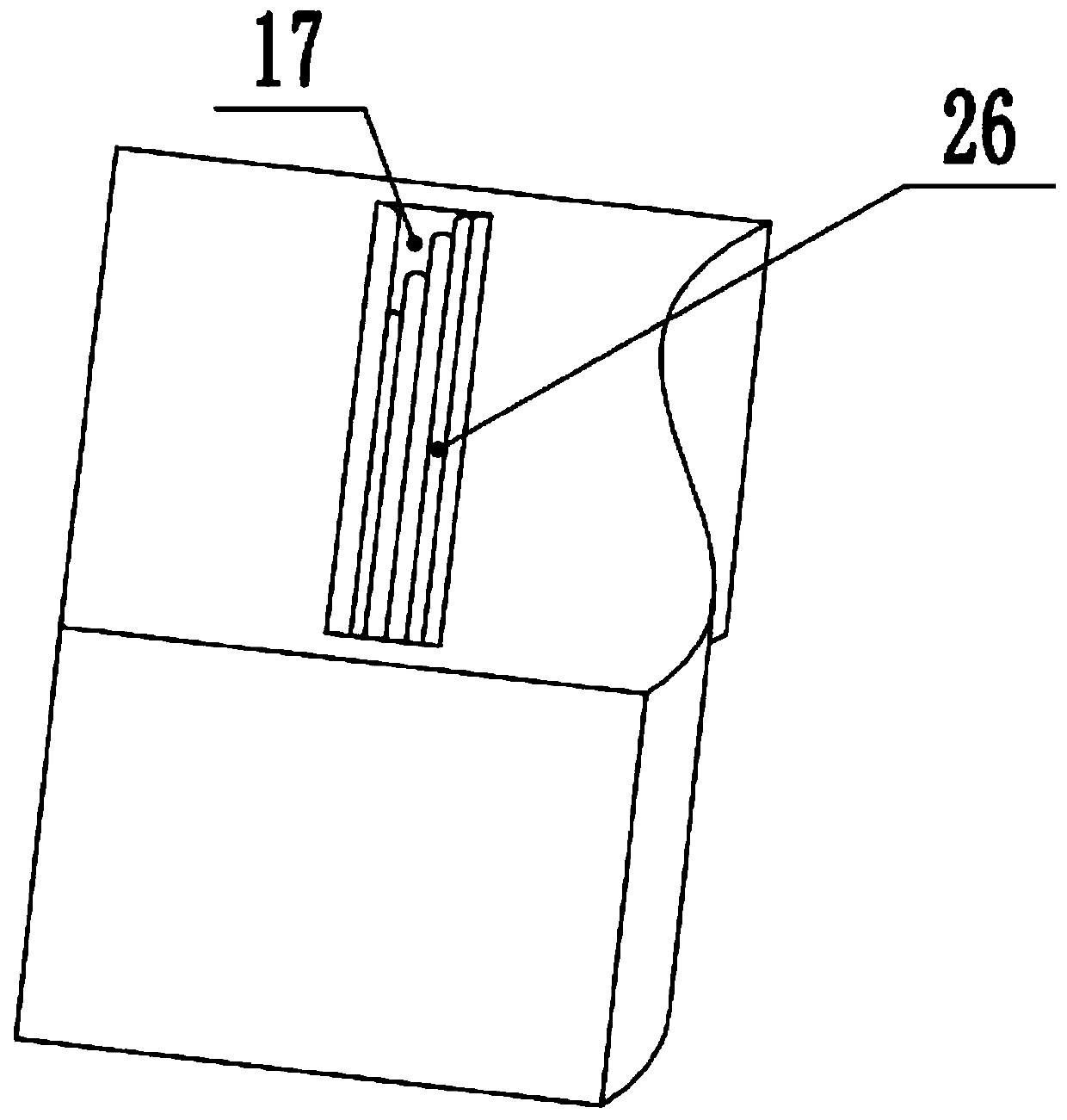

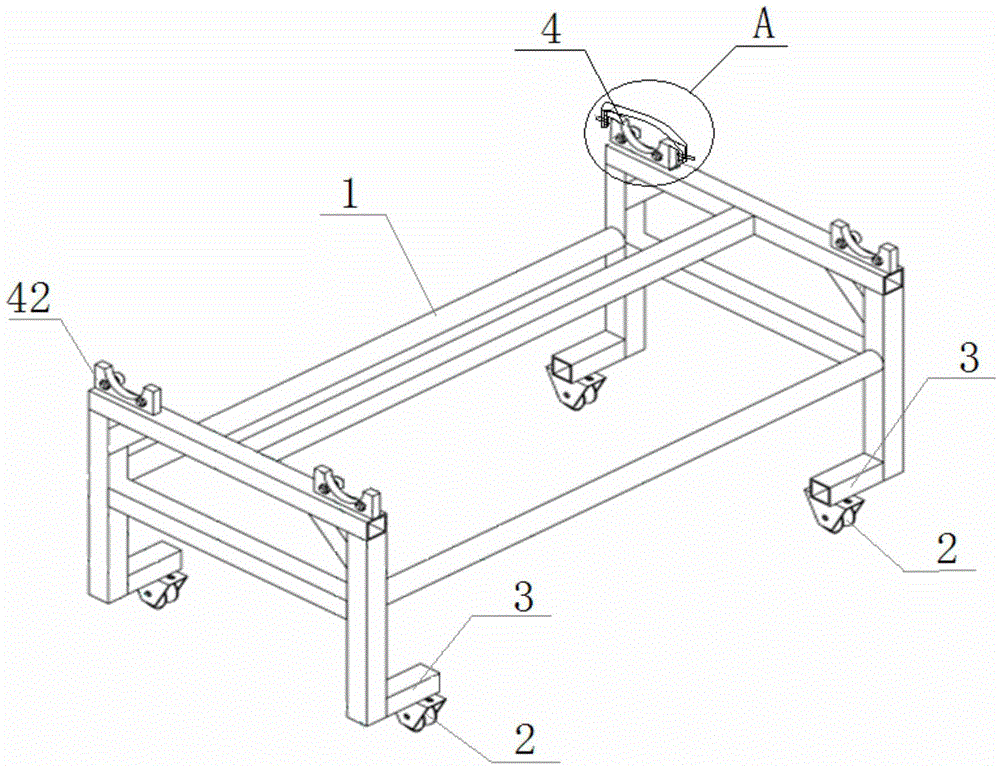

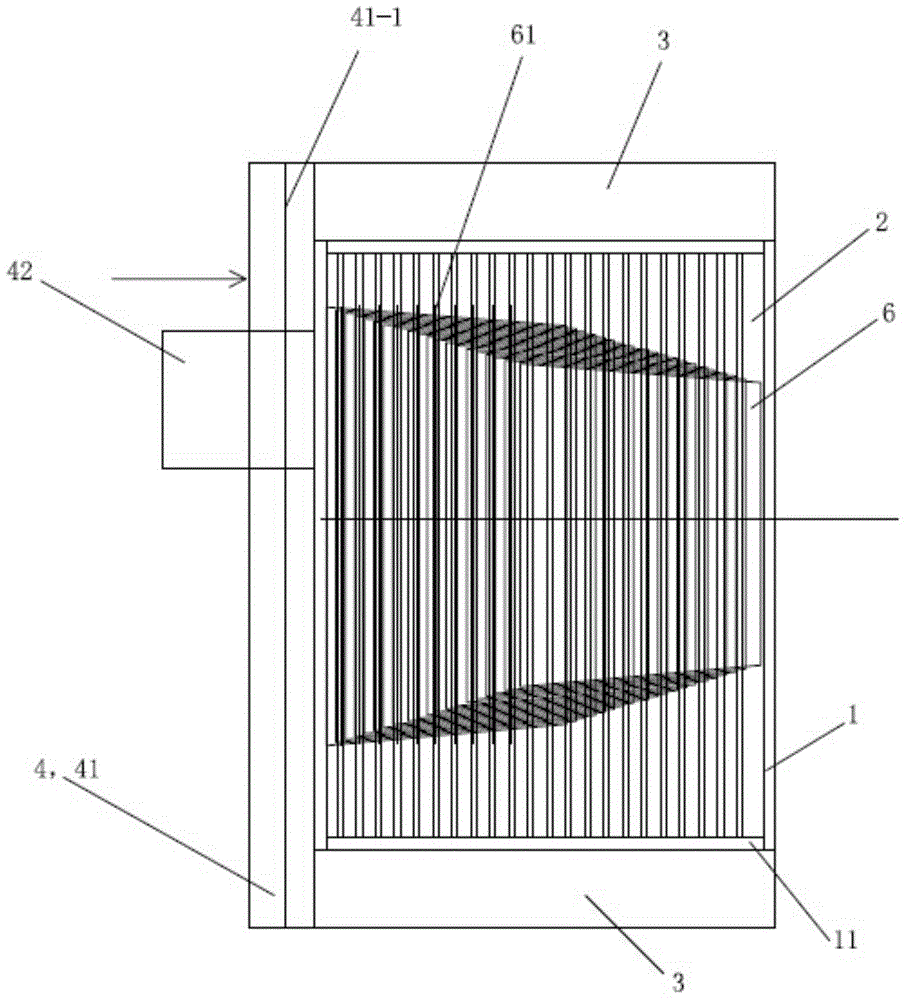

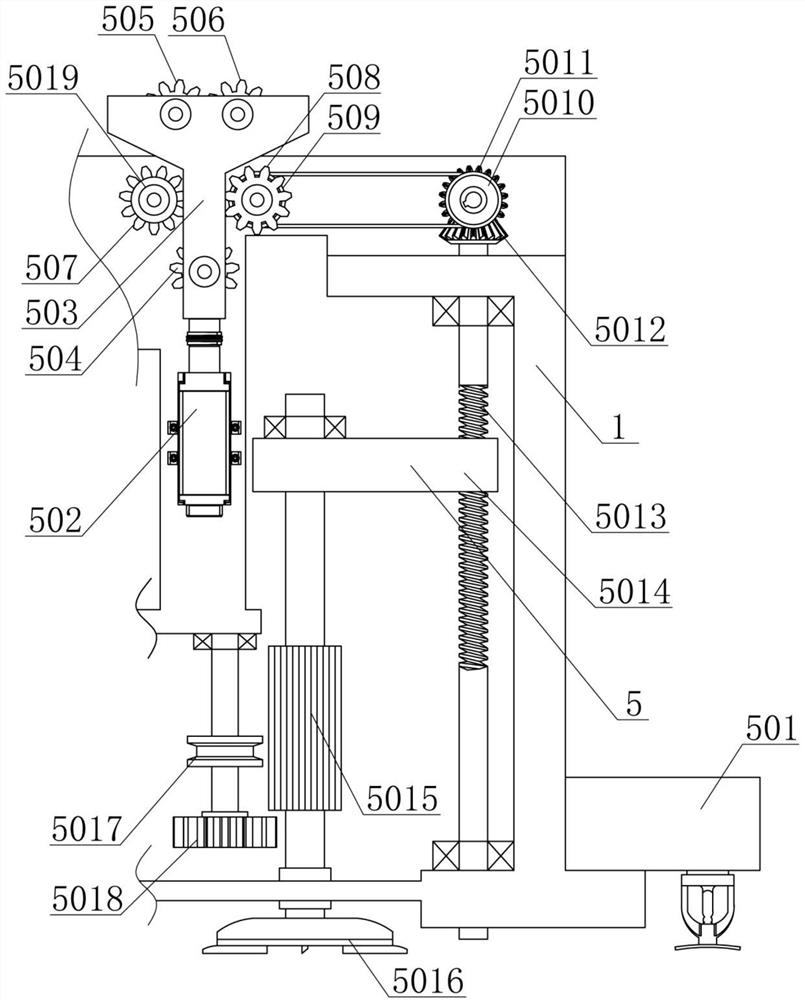

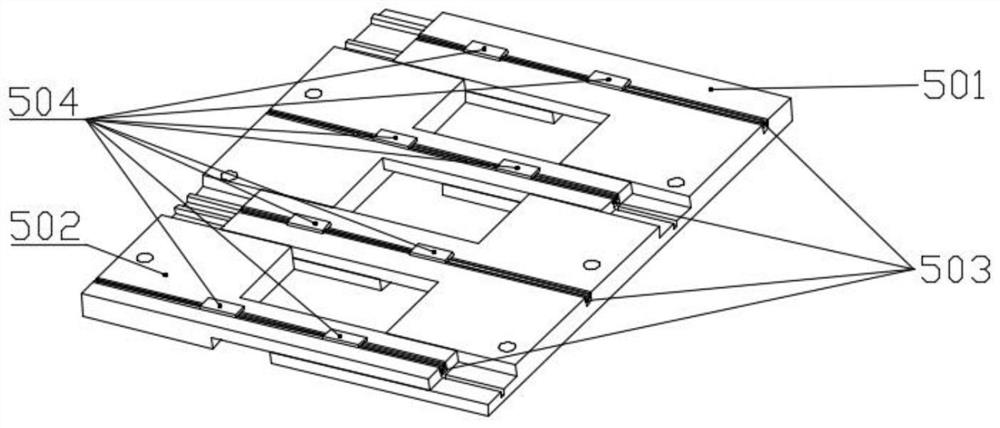

Layer paving device and layer paving method for main girder glass fiber cloth used for wind power blade production

The invention discloses a layer paving device for main girder glass fiber cloth used for wind power blade production. The layer paving device comprises a frame body and a supporting structure, wherein wheels are arranged at the bottom of the frame body, the supporting structure consists of four sets of fixing frames, each set of fixing frame comprises an upper fixing frame and a lower fixing frame, two sides of the lower fixing frame extend outwards to form right-angled folding ears, G-shaped clamping devices are arranged at parts corresponding to the right-angled folding ears on two sides of the upper fixing frame; the invention also discloses a layer paving method of the layer paving device for main girder glass fiber cloth used for wind power blade production, by placing the layer paving device on a guide rail and moving the layer paving device to one end of a mould, a glass fiber cloth roll is placed, and then glass fiber cloth is pulled out and fixed at one end of the mould, the layer paving device for main girder glass fiber cloth is pushed to the other end of the mould, and the operation is repeated until all layer paving is completed; and the layer paving device and the layer paving method which are disclosed by the invention can pave glass fiber cloth into the mould rapidly, accurately and smoothly, so that the subsequent manual adjustment is reduced, the time and manpower for adjustment of glass fiber cloth after laying are saved, and the laying efficiency is improved while guaranteeing the laying quality.

Owner:迪皮埃风电叶片大丰有限公司

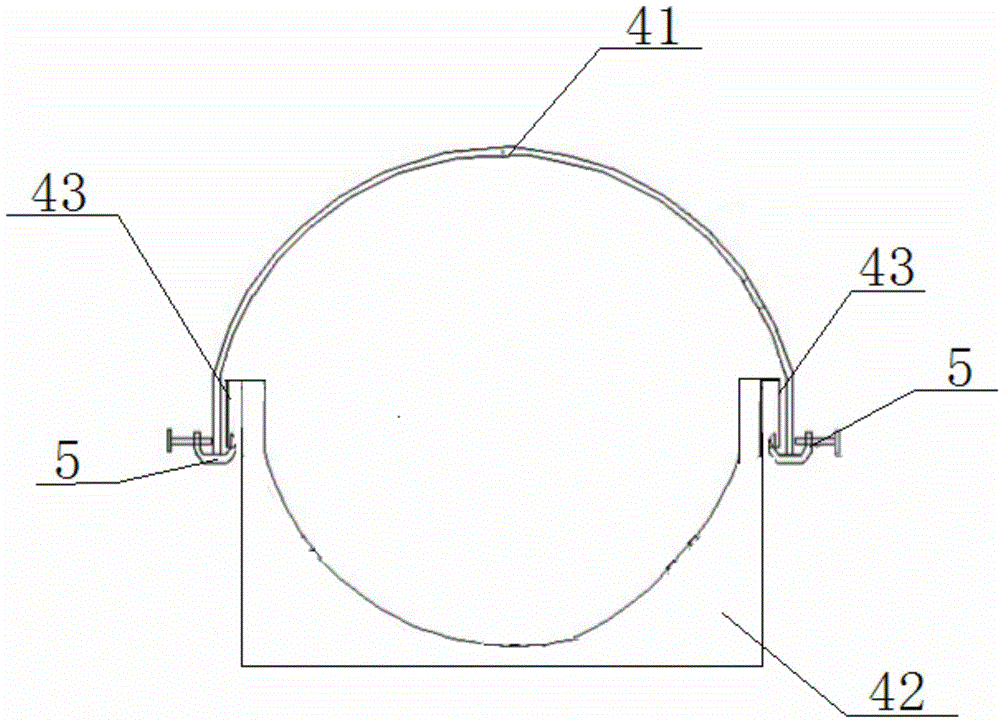

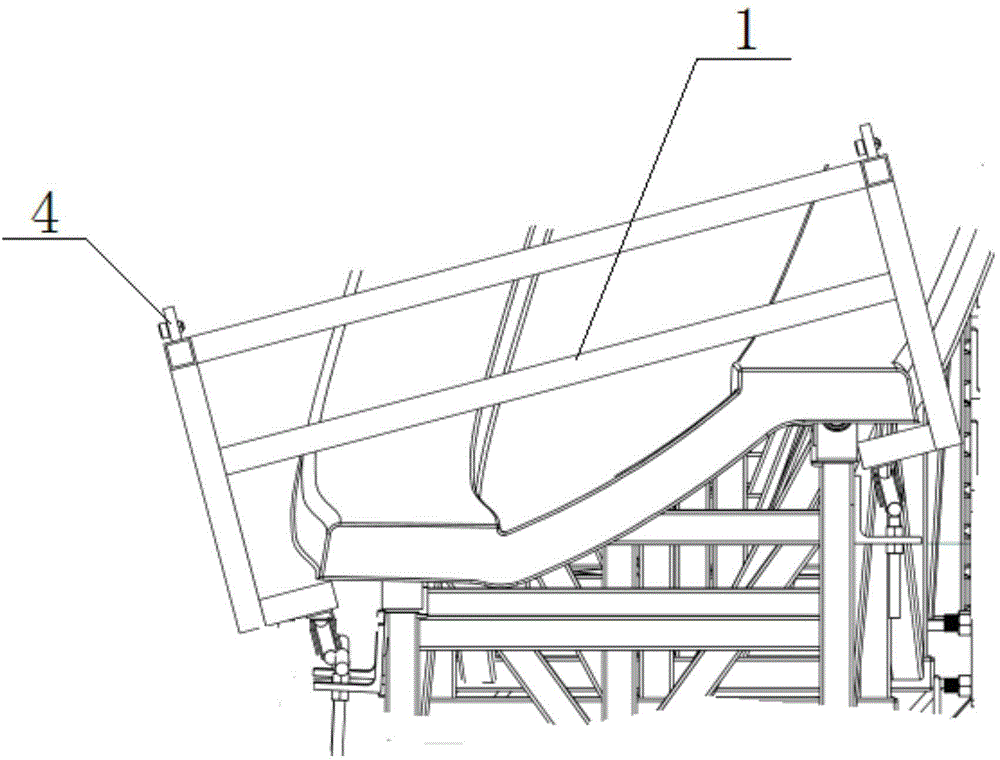

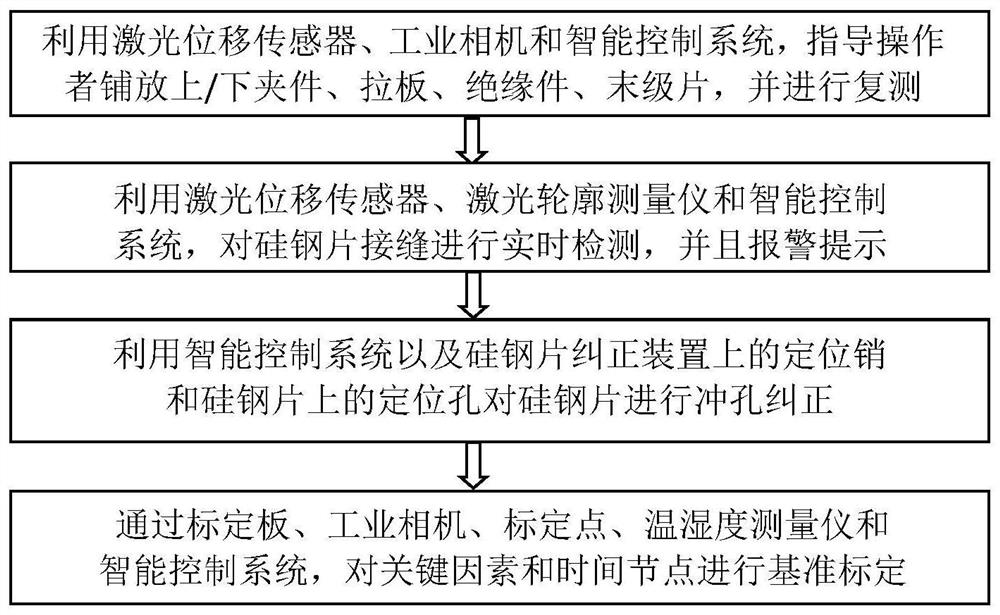

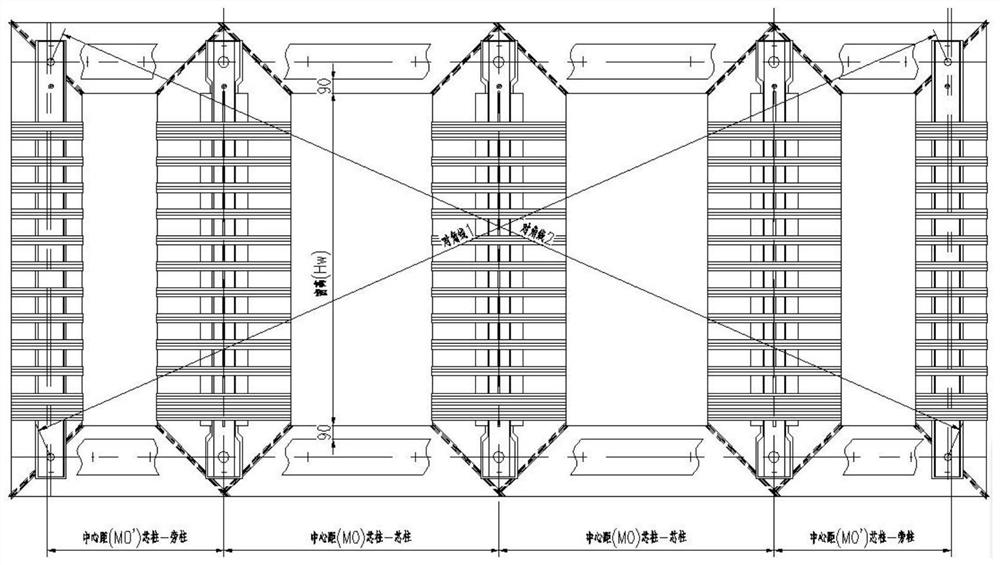

Auxiliary process method for automatically stacking iron cores

PendingCN113903581AFast layingAccurate layingMagnetic core manufactureEngineeringMechanical engineering

The invention relates to an auxiliary process method for automatically stacking iron cores. The method comprises the following steps of guiding an operator to lay an upper / lower clamping piece, a pulling plate, an insulating piece and a final-stage piece by using a laser displacement sensor, an industrial camera and an intelligent control system, and retesting after laying; using the laser displacement sensor, a laser profile measuring instrument and the intelligent control system for detecting the seam of the silicon steel sheets in real time, and if the seam distance exceeds the tolerance range or the two silicon steel sheets are overlapped, alarming and prompting; using the intelligent control system, a positioning pin on a silicon steel sheet correcting device and the positioning holes in the silicon steels sheets to punch and correct the silicon steel sheets; carrying out reference calibration on the key factors and time nodes through a calibration plate, an industrial camera, a calibration point, a temperature and humidity measuring instrument and the intelligent control system. According to the invention, auxiliary accessories for iron core stacking are more quickly and accurately laid, the condition that the seam size meets the process requirement is ensured, and the automatic correction of the positions of the silicon steel sheets in the iron core stacking process is realized.

Owner:SHANDONG POWER EQUIP

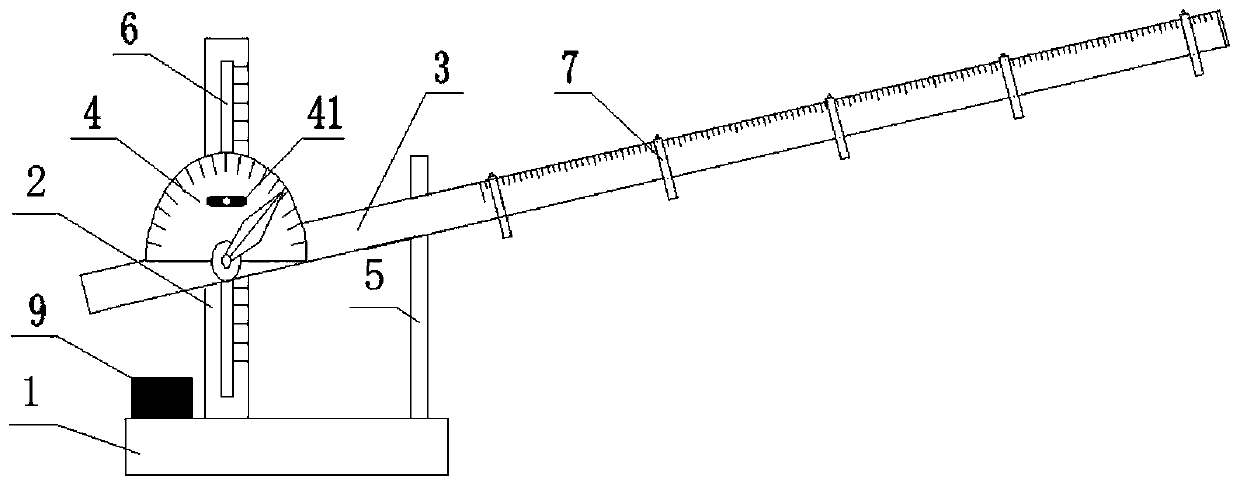

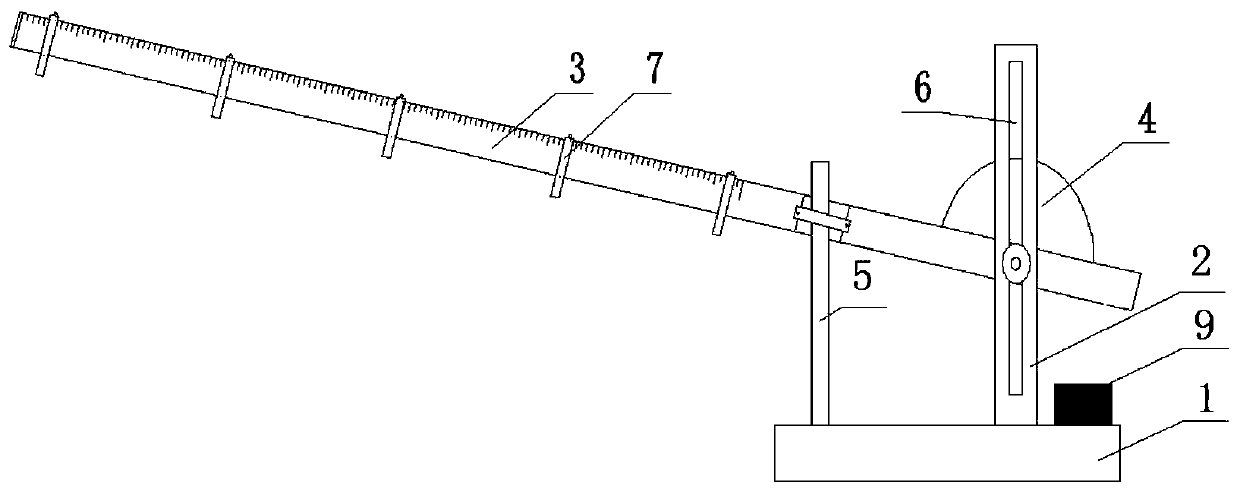

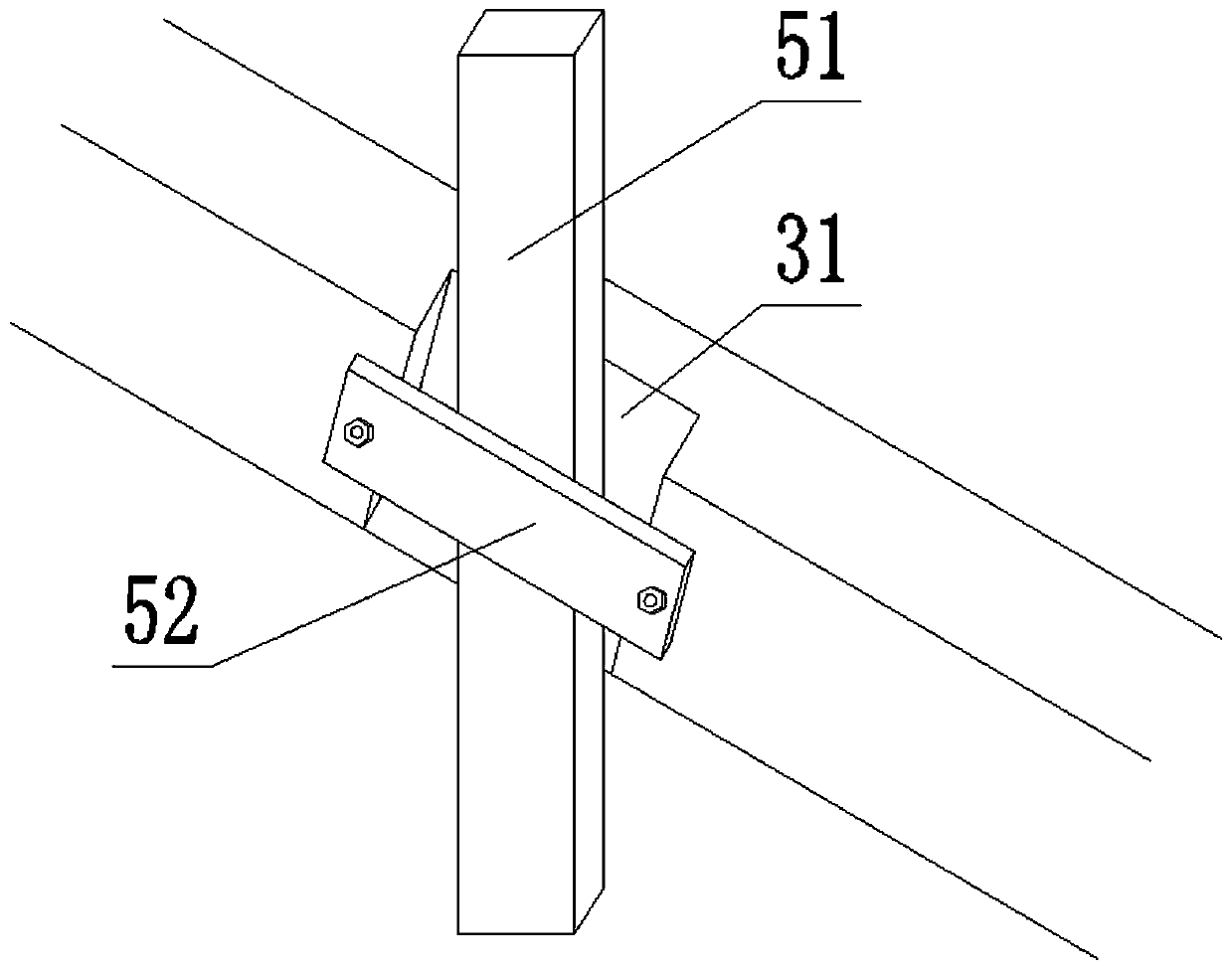

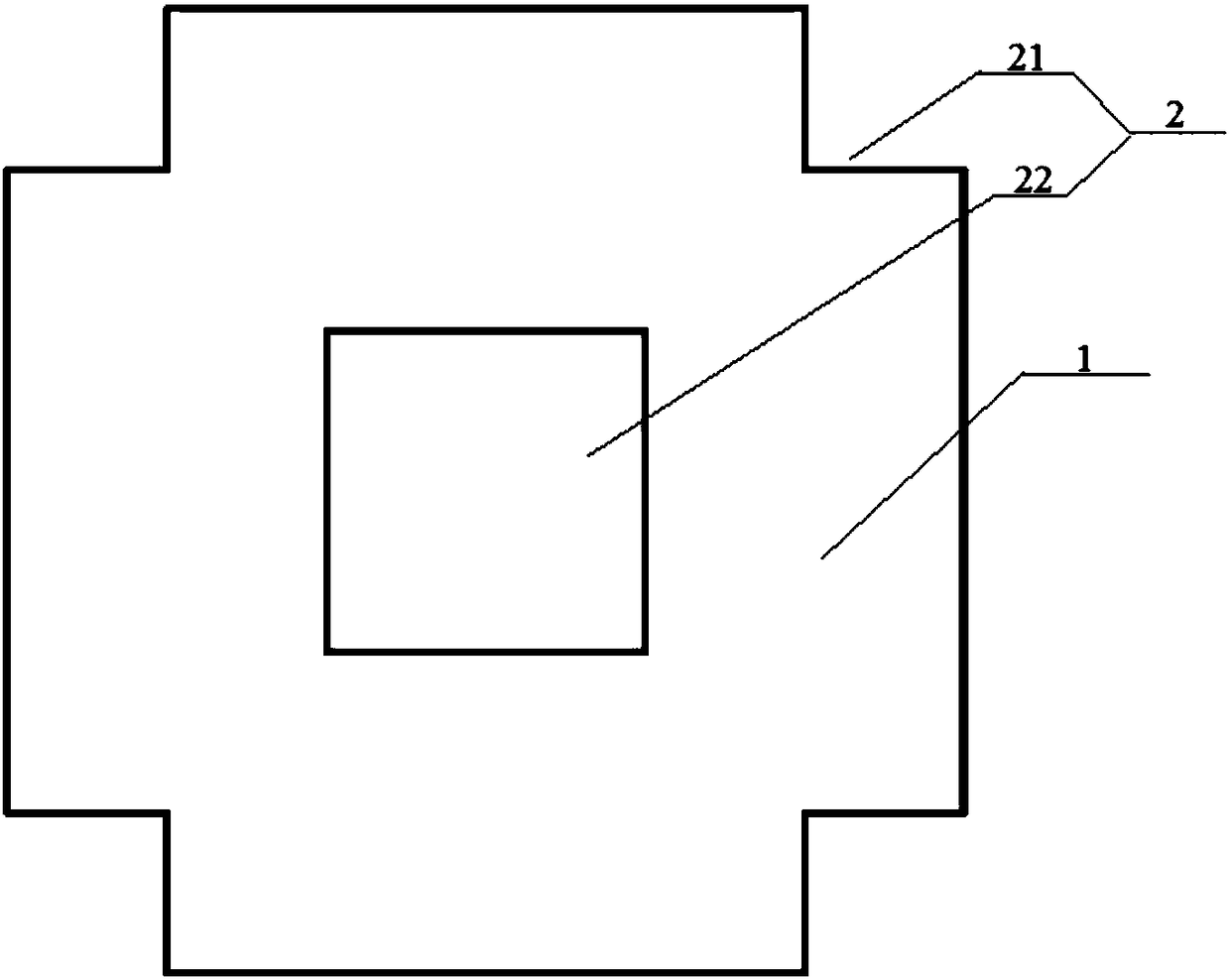

Device and construction method for guaranteeing slope and interseam of acid proof ceramic tile paving

PendingCN110259072AEfficient layingAccurate layingBuilding constructionsCeramic tilesBuilding construction

The invention provides a device and construction method for guaranteeing the slope and the interseam of acid proof ceramic tile paving. The device comprises a bottom seat, a stand column, a measure gauge, an angle scale and an angle locking device, the stand column is perpendicularly fixed to the bottom seat, a sliding groove is formed in the stand column in the vertical direction, and measure gauge and the angel scale are connected to the sliding groove through an adjusting bolt and the stand column; the angle locking device comprises a longitudinal rod fixed to the bottom seat, the longitudinal rod is slidably connected with the measure gauge, the longitudinal rod is provided with a limiting part, the longitudinal rod and the measure gauge are locked through the limiting part, thus relative sliding is avoided, a plurality of sliding cushion blocks sleeve the measure gauge, the sliding cushion blocks are moved and fixed, a clamping groove is formed through every two adjacent sliding cushion blocks to assist paving of acid proof ceramic tiles. According to the device and construction method for guaranteeing the slope and the interseam of acid proof ceramic tile paving, the requirements of experiences and skills of construction personnel are low, the acid proof ceramic tiles can be effectively and accurately paved by the construction personnel, the whole slope is guaranteed, and the situation that accumulated liquid occurs in the using process of later stage is prevented.

Owner:MCC TIANGONG GROUP

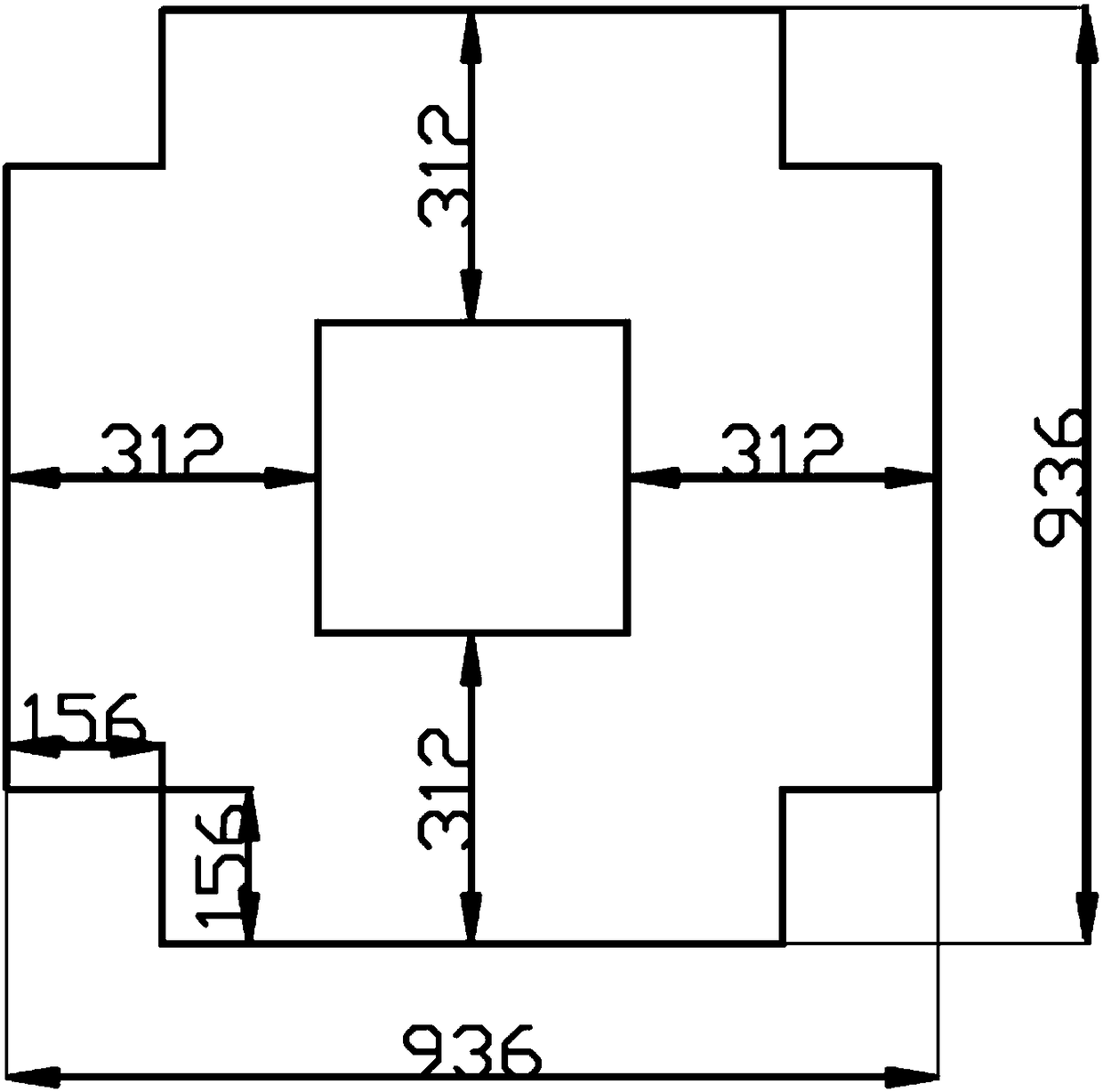

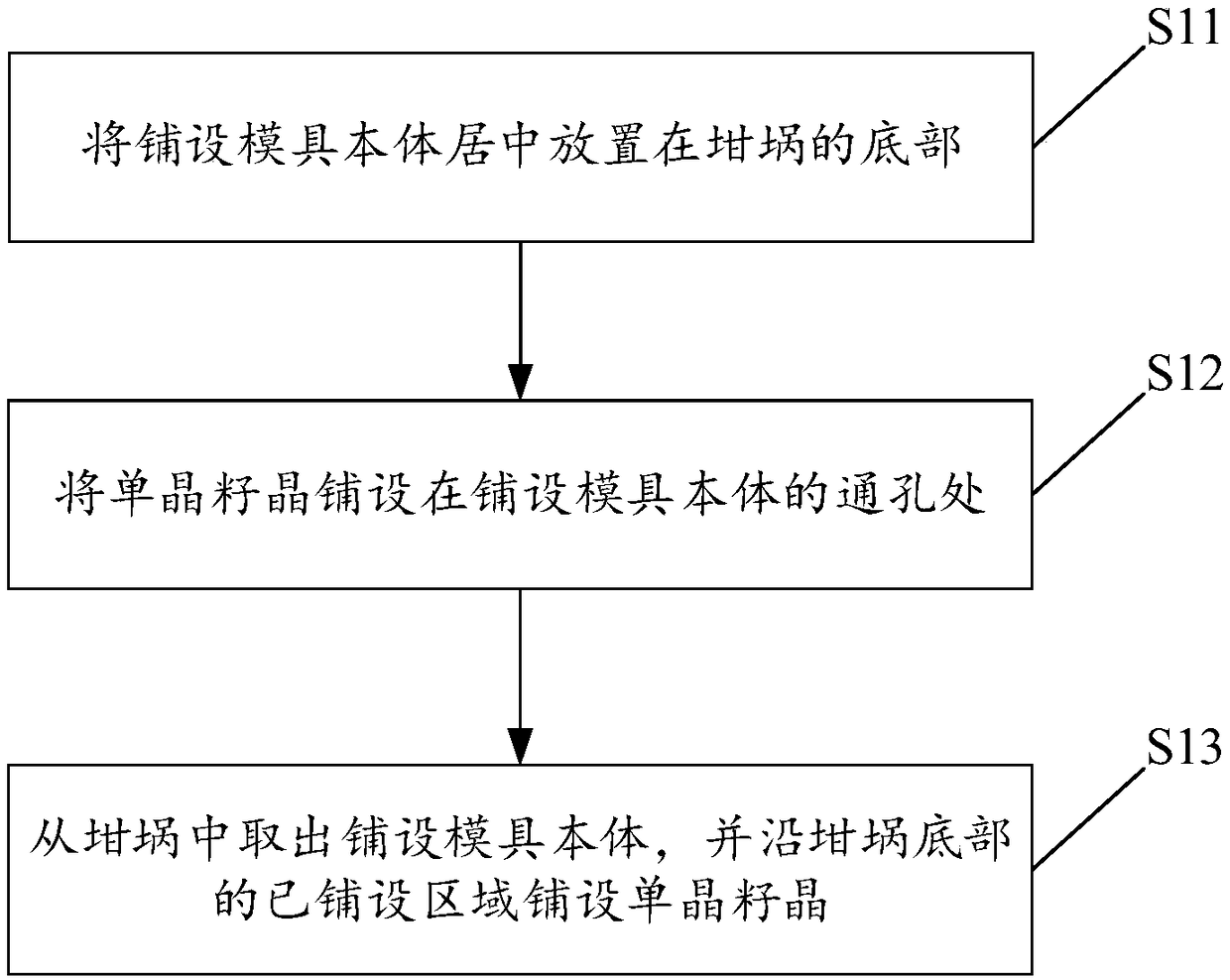

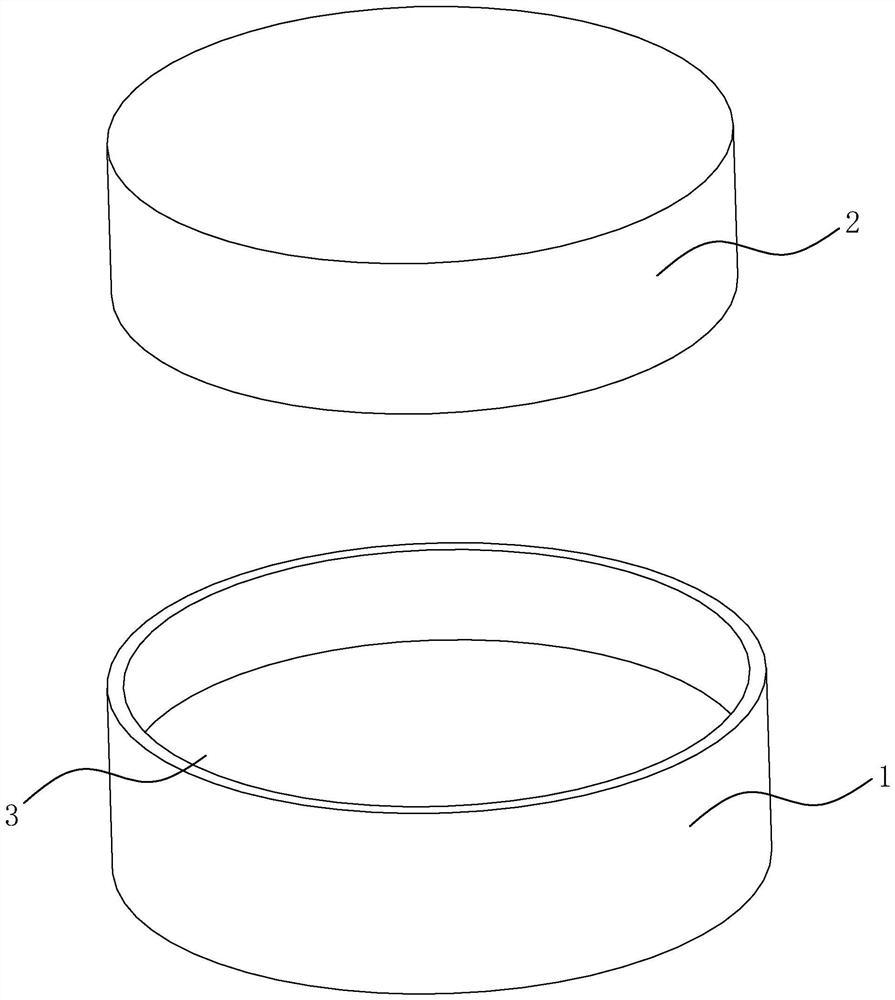

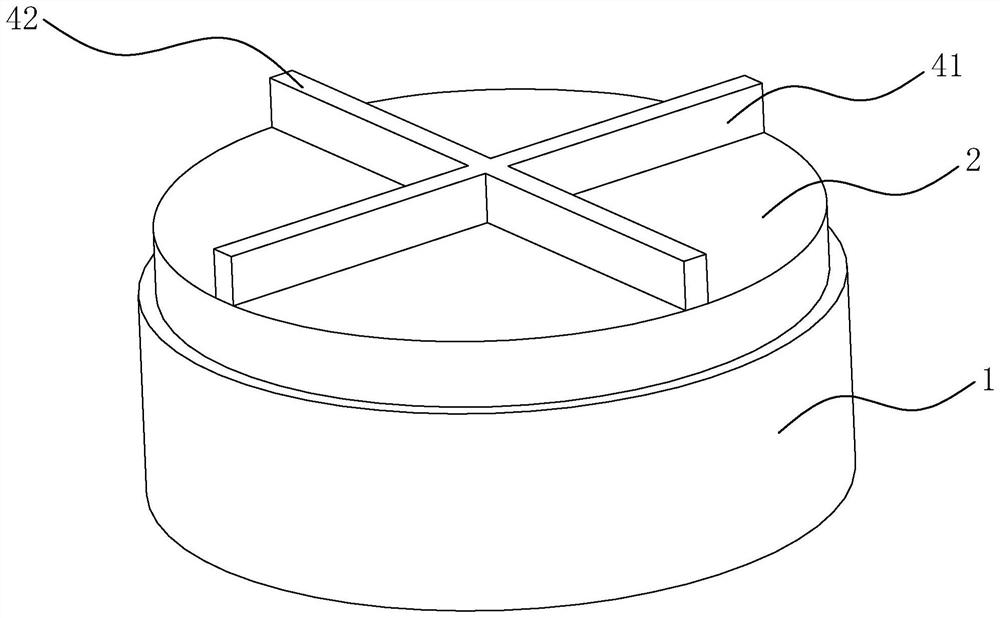

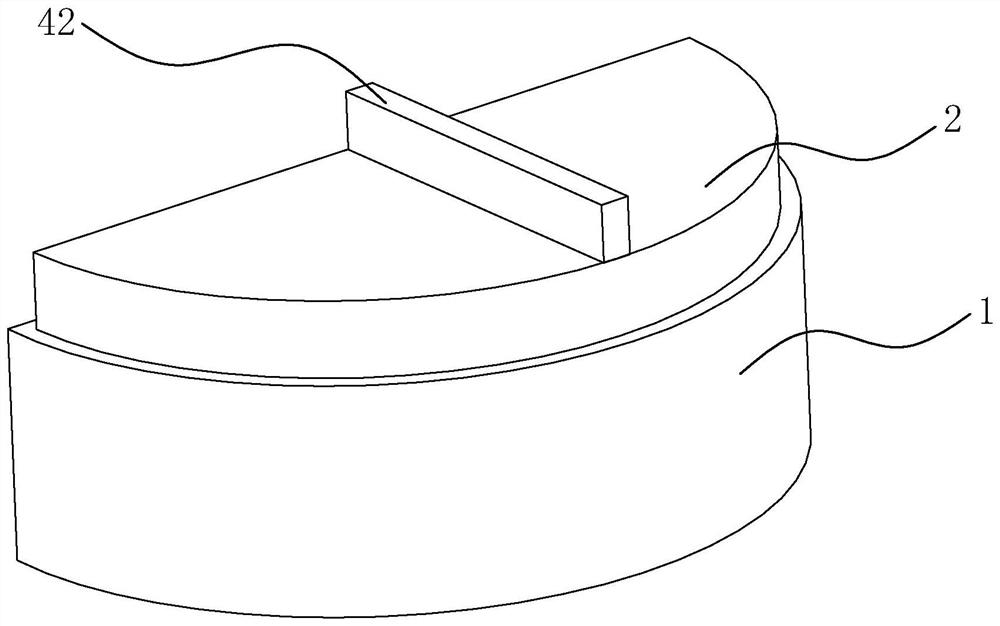

Mold and method for laying monocrystal-like seed crystals

InactiveCN108531977AIncrease the proportionReduce laying deviationPolycrystalline material growthFrom frozen solutionsBriquetteSeed crystal

The invention discloses a mold and a method for laying monocrystal-like seed crystals. The mold comprises a mold body. The size of the mold body is matched with the sizes of crucibles; a mounting portion is arranged on the mold body, the size of the mounting portion is matched with the sizes of monocrystal seed crystals, and the monocrystal seed crystals can penetrate the mounting portion when laid at the bottoms of the crucibles. According to the technical scheme, the mold and the method have the advantages that the mold comprises the mold body, the size of the mold body is matched with the sizes of the crucibles, the mounting portion is arranged on the mold body, the size of the mounting portion is matched with the sizes of the monocrystal seed crystals, the monocrystal seed crystals canpenetrate the mounting portion, central regions in which the monocrystal seed crystals are about to be laid can be quickly determined by the aid of the mold body, accordingly, the spent laying time can be shortened, and the laying efficiency can be improved; the monocrystal seed crystals further can be accurately laid in the central regions of the crucibles as much as possible by the aid of the mold body, accordingly, laying deviation of the monocrystal seed crystals can be reduced, and the proportions of monocrystals in monocrystal-like silicon briquettes can be increased.

Owner:JINKO SOLAR CO LTD +1

Reinforced fabric sewing device and sewing method

ActiveCN104947330AImprove bindingReduce deformationTextiles and paperEngineeringWind power generation

The invention discloses a reinforced fabric sewing device and a sewing method. The device includes a sewing platform, pressure plates, guide rails and a sewing machine, wherein the upper surface of the sewing platform is a hollow frame; the pressure plates include an upper pressure plate and a lower pressure plate, and a plurality of strips of sewing zones are uniformly arranged on the pressure plates; the guide rails are arranged at the two ends of the sewing platform in the lateral directions; the sewing machine includes a sewing machine stand and a sewing machine head; the sewing machine stand spans across the guide rails longitudinally and is connected with the guide rails in a sliding manner; the sewing machine head is arranged on the sewing machine stand, and can move along the sewing machine stand longitudinally. The frame type sewing platform is arranged and used for laying fabric, the fabric is placed between the upper pressure plate and the lower pressure plate, and the suture line is sutured in the sewing zones of the upper and lower pressure plates, so that the laid center line can be easily calibrated, and the production time of the whole process is reduced; in addition, all layers of reinforced fabric can be pressed tightly, the combination degree among all layers of reinforced fabric is high, and little deformation is caused, therefore, high-performance wind power generation used blade roots can be obtained.

Owner:NEWTRY COMPOSITE

curb paving machine

A road calculus paving machine, mainly composed of a car body mechanism, a hoisting mechanism, a laser guidance mechanism and a dust scraping mechanism. On one side of the car body, it is composed of a three-dimensional platform and a lifting clamp. The laser guidance mechanism is composed of a laser discharger and a laser receiver. The laser receiver is a light target structure. The laser target is installed on the side of the lifting clamp and moves together with the lifting clamp. . The dust scraper is driven by a DC motor. The invention adopts laser setting-out, the battery power supply of the whole machine, is matched with modern road construction machinery, and can be laid accurately and quickly, with low noise and no pollution.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

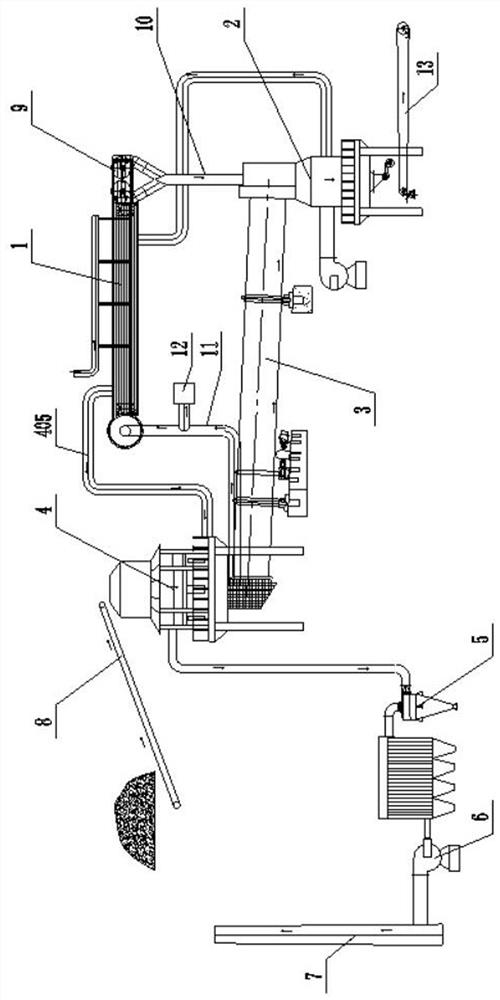

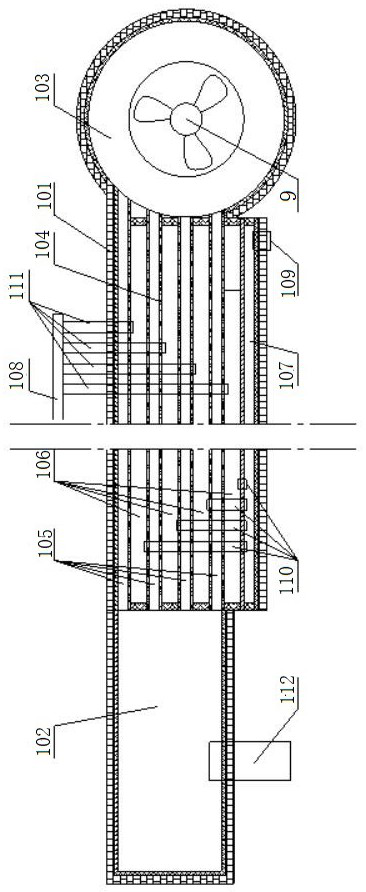

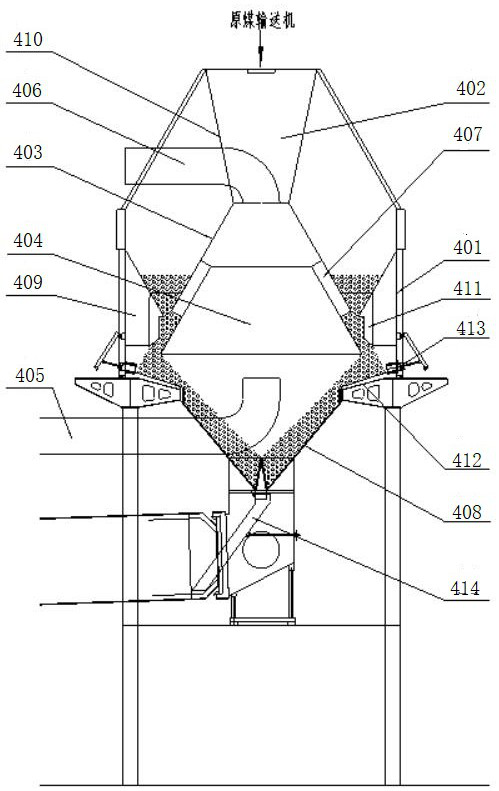

Low-rank coal anaerobic upgrading, grading and grading system

PendingCN111961487AReduce manufacturing costReduce consumptionSpecial form destructive distillationHeat carrierThermodynamics

The invention discloses a low-rank coal anaerobic upgrading, grading and grading system, and belongs to the technical field of raw coke oven gas production. The technical problem to be solved is to provide the low-rank coal oxygen-free upgrading, grading and grading system, low-rank coal is subjected to oxygen-free cracking to generate raw coke oven gas, the production cost is saved, and the production quality is improved. The adopted technical scheme is as follows: the system comprises a heat exchange furnace, a cooler, a rotary kiln, a raw coal preheater, a cyclone dust collector, a main fan, a desulfurizing tower, a raw coal conveyor and a carrier output fan. The heat of the high-temperature combustion gas is transferred to the raw coke oven gas carrier in a heat conduction manner; theraw coke oven gas carrier enters the rotary kiln in a closed oxygen-free environment and is subjected to cracking reaction with the low-rank coal to generate a large amount of raw coke oven gas, and the heat carrier is the same product and is doped with few impurities, so that the influence of burning coal impurities and air impurities on the product is avoided, the low-rank coal on the market isconsumed, and enterprise benefits are formed.

Owner:稷山县金星煤焦有限公司 +1

Rubber floor pavement apparatus

ActiveCN111648574AAccurate layingImprove efficiencyBuilding constructionsArchitectural engineeringStructural engineering

The present invention relates to the field of rubber floors, particularly to a rubber floor pavement apparatus. The technical problem to be solved by the present invention is to provide the rubber floor pavement apparatus. The rubber floor pavement apparatus comprises a bracket, a rubber floor roller, a roller fixed frame, a glue coating mechanism, a floor protrusion leveling mechanism, a floor cleaning mechanism, a rubber floor cutting mechanism and a control screen; the rubber floor roller is arranged at the top of the left side of the bracket; and the left portion of the top end of the bracket is in inserted connection with the roller fixed frame. The rubber floor pavement apparatus in the present invention achieves the effects of high rubber floor pavement efficiency, safety and tidiness in use, saving of materials, accurate pavement and saving of human resources.

Owner:凤阳凯晨建设工程有限公司

Split sliding type width-adjustable fiber placement head method and device

ActiveCN113510945AAccurate layingAccurate placement of accurateElectrical and Electronics engineeringFiber

The invention discloses a split sliding type width-adjustable fiber placement head method and a device. The device comprises a fiber placement head left mounting frame, an electric cylinder is mounted at the upper part of the fiber placement head left mounting frame, the output of the electric cylinder is connected with a fiber placement head right mounting frame, an optical axis, a slidable channel and a sliding support are mounted between the fiber placement head left mounting frame and the fiber placement head right mounting frame, a compression roller is mounted on the optical axis at the bottom and matched with the slidable channel above the compression roller, and the slidable channel is matched with an air cylinder module mounted on a slidable support above the slidable channel. The electric cylinder operates to drive the fiber placement head right mounting frame to move on a polished rod, the slidable channel slides relatively, the width of the channel is changed to adapt to prepreg tapes with different widths, the slidable support slides relatively, the cylinder module freely slides on the guide rail, and it is guaranteed that the cylinder module is located in the center of the fiber placement head and is aligned with the channel below, according to the split sliding type width-adjustable fiber placement head method and the device, waste caused in the cutting process of the prepreg tapes can be reduced, and the influence of non-uniform width of the prepreg tapes caused by cutting is eliminated.

Owner:XI AN JIAOTONG UNIV

Assembly type ground leveling assembly, device and system

The invention relates to the field of building decoration engineering materials, and discloses an assembly type ground leveling assembly, device and system. The assembly type ground leveling device comprises a storage ring. One end of the leveling piston is connected with the storage ring in a sliding manner; and the filler is arranged in the storage ring to support the leveling piston. When ground construction is carried out, the height of the leveling piston can be adjusted by adjusting the amount of filler added into the containing ring, and therefore the leveling pistons of all the assembly type ground leveling devices are located at the same height. And after the filler is compacted, the bearing capacity is high, the floor can be well supported, and the floor is not prone to sinking due to the fact that the floor is subjected to weight.

Owner:BEIJING YANTONG BUILDING COMPONENTS PROD

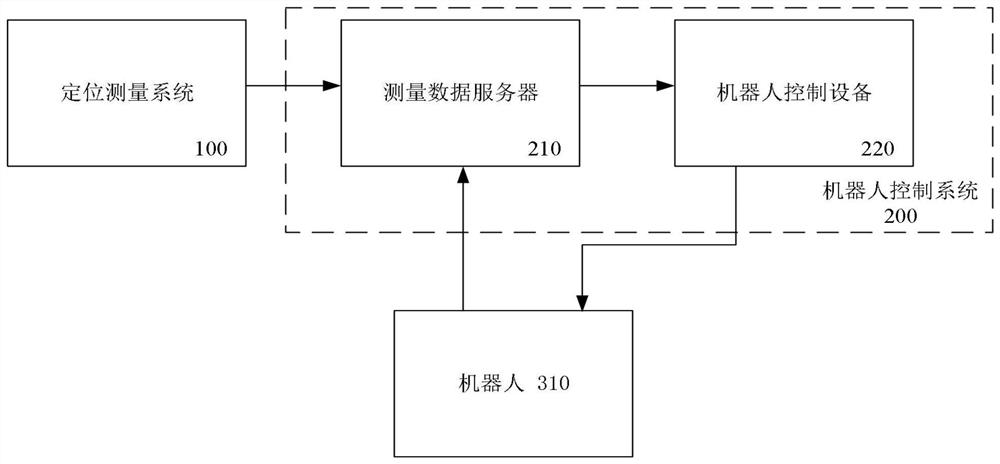

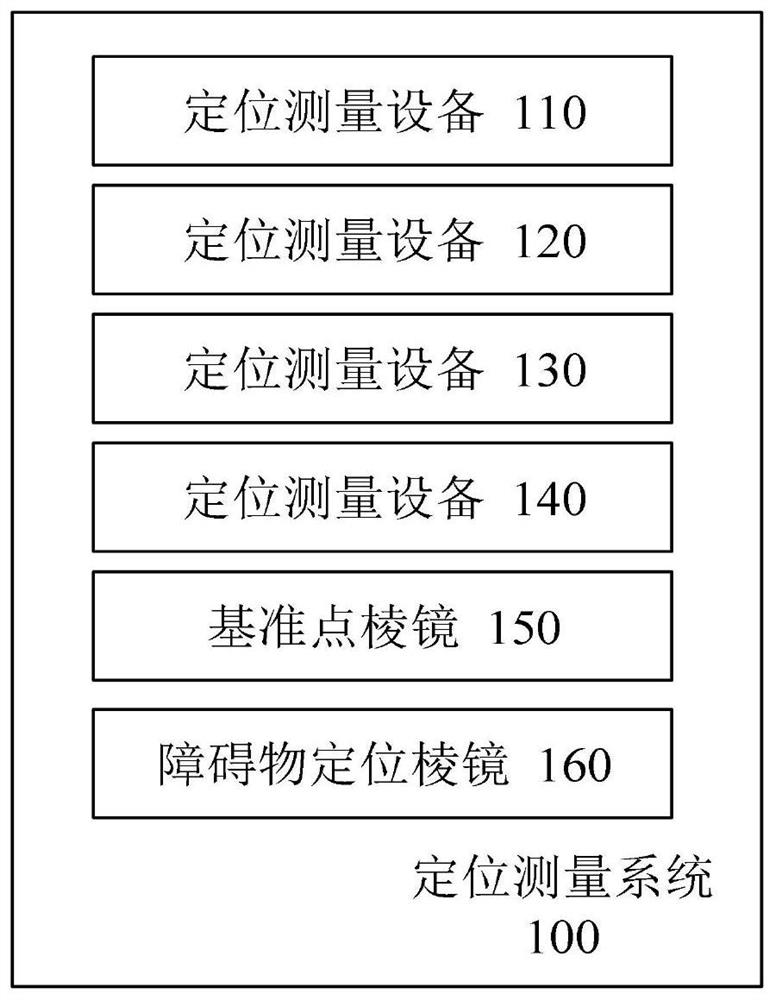

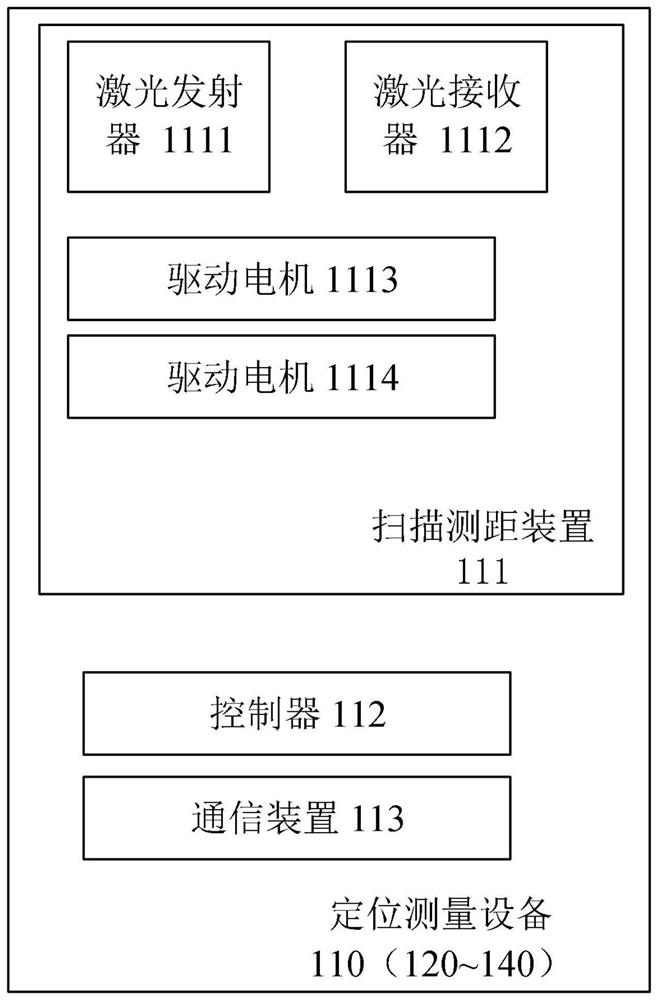

Movable brick laying robot system for building construction and control method

PendingCN112792825AHigh positioning accuracyAccurate layingBuilding constructionsManipulatorRobotic systemsControl system

The invention discloses a movable brick laying robot system for building construction and a control method. The system comprises a robot, a positioning measurement system, and a robot control system, wherein the positioning measurement system comprises at least one positioning measurement equipment; each positioning measurement equipment is arranged on the periphery of a preset site and used for determining first position information of the robot; the robot control system is used for controlling the robot according to the first position information; each positioning measurement equipment comprises a scanning distance measuring device used for measuring second position information of the robot relative to the positioning measurement equipment, and a controller connected with the corresponding scanning distance measuring device and used for determining the first position information of the measuring robot relative to the preset site according to the second position information; and a positioning prism is arranged on the robot and used for determining the position of the robot.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com