Flattening and winding device of waterproof waterstop for bridge expansion joint

A winding device and waterstop technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as unfavorable smooth installation of waterstops, unstable installation, and no flattening of waterstops, and achieve fast and efficient filling. The effect of laying operation, uniform and orderly feeding, and high filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

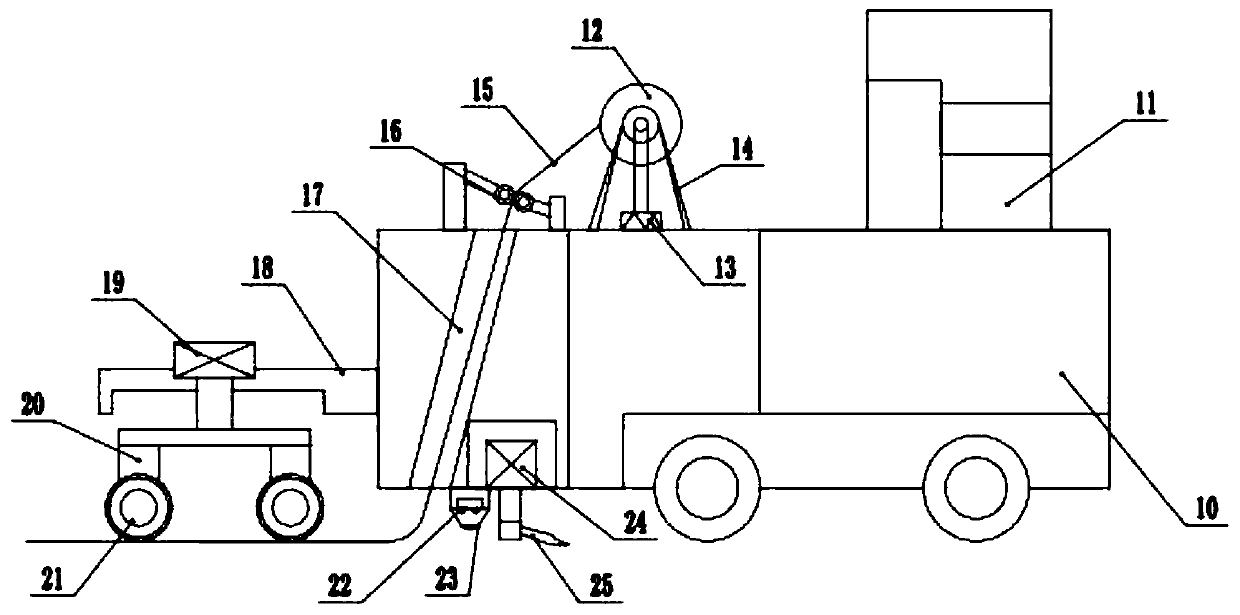

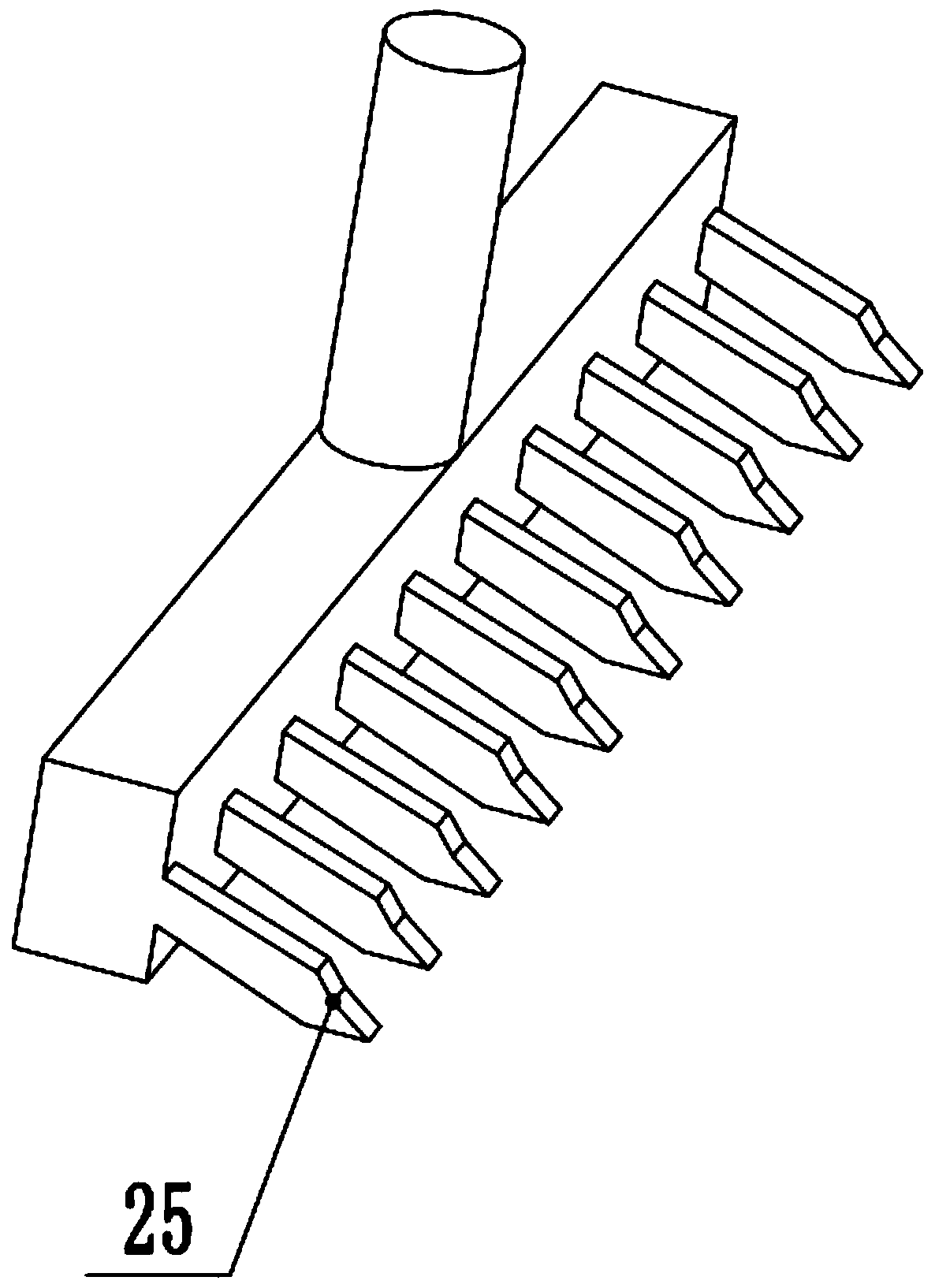

[0020] see Figure 1-3 , a waterproof waterstop wrapping device for bridge expansion joints, comprising a locomotive 10, a driving device 11, a waterstop roller 12, a waterstop 15, and a pressure roller 21; the top of the locomotive 10 is provided with a device for driving the locomotive 10 Mobile drive unit 11. The middle position of the top of the locomotive 10 is transitionally supported by a bracket 14 with a set of waterstop rollers 12, and the waterstop rollers 12 are wound with a waterproof waterstop 15 for sealing bridge expansion joints. The waterstop rollers 12 are The front side is rotatably connected with a rotating rod, and the rotating rod is downwardly connected with a rotating motor 13 fixed on the top of the locomotive 10 through the transmission belt. The rotating motor 13 is started to drive the water stop roller 12 to rotate through the connection of the transmission belt, thereby turning the water stop The waterstop 15 on the roller 12 is released outward...

Embodiment 2

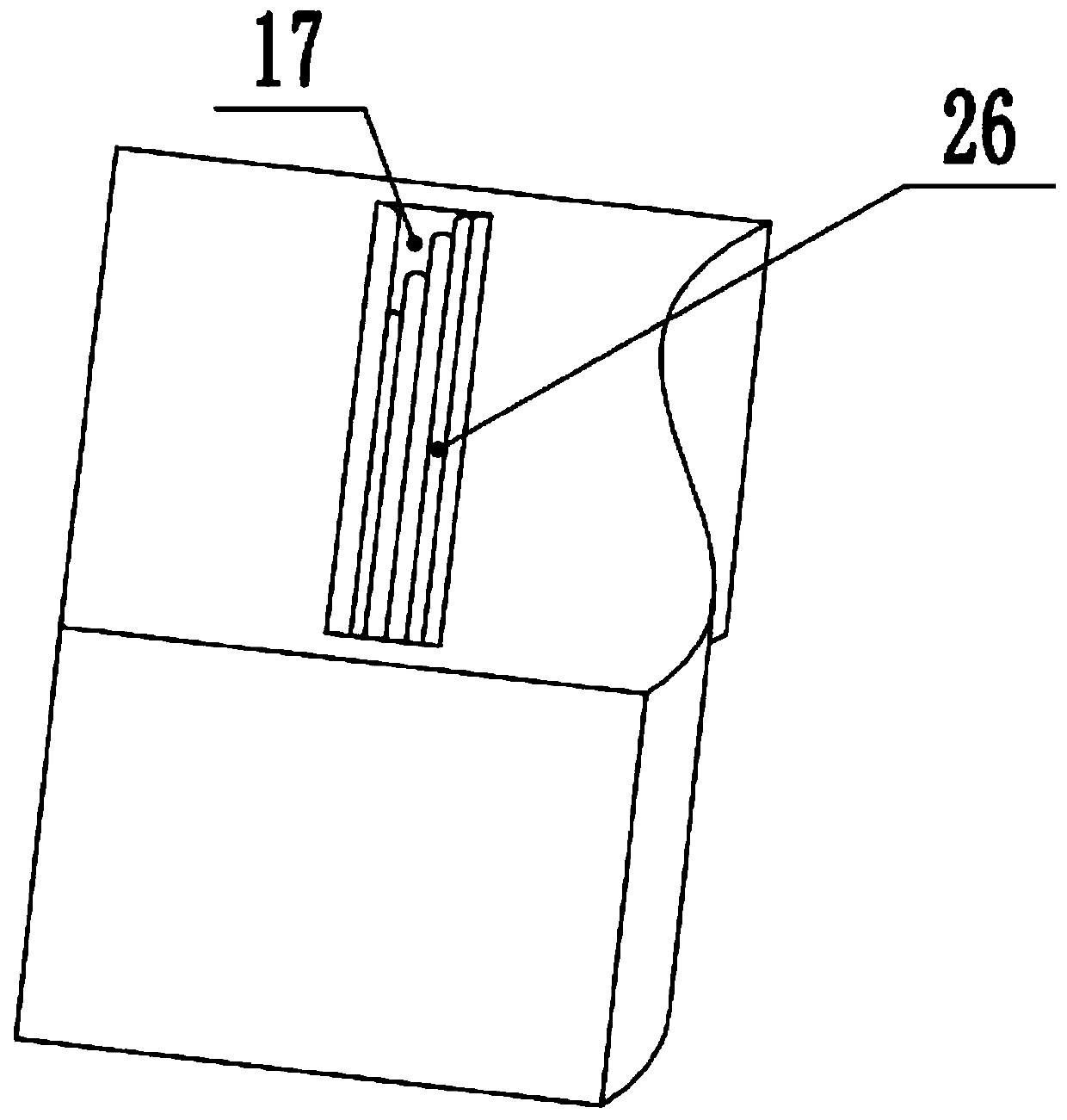

[0024] On the basis of Embodiment 1, the upper and lower sides of the cutting trough 17 are all arranged in an arc-shaped structure, so that the waterstop 15 will not be worn by the edges and corners of the upper and lower sides of the cutting chute 17 when entering and leaving. The inner bottom of the feeding chute 17 is rollingly connected with several groups of equally spaced rollers 26, and the setting of the rollers 26 is used to reduce the friction between the waterstop 15 and the inner surface of the feeding chute 17, thereby increasing the downward movement. speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com