Base processing equipment for wooden pallet

A technology for processing equipment and wooden pallets, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as uneven laying, low work efficiency, and affecting product quality, and achieve accurate laying, high production efficiency, and high automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

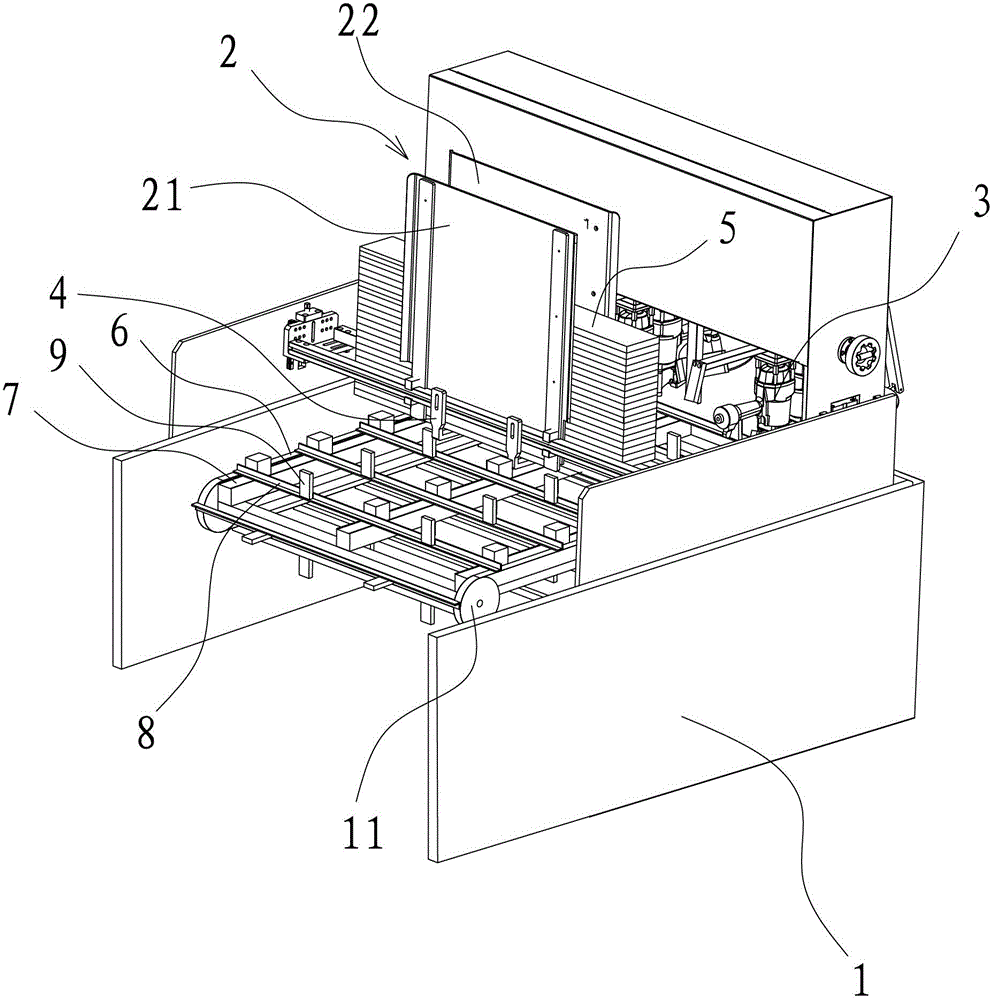

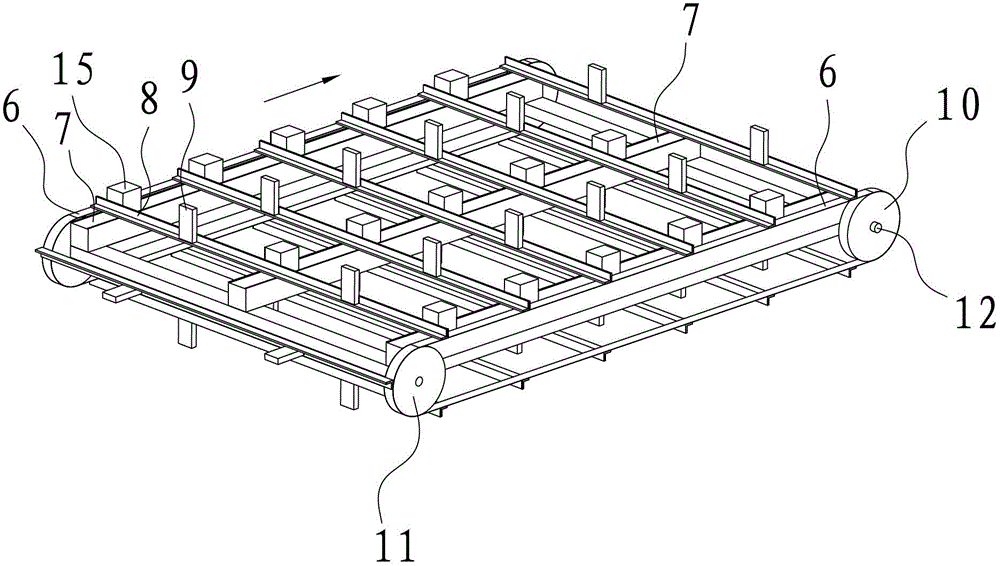

[0023] Such as figure 1 As shown, the base processing equipment of this wooden pallet includes a frame 1 and a conveying mechanism, and the upper part of the conveying mechanism is provided with a feed bin 2 and a nailing device in sequence along the conveying direction of the pier 15, and the feed bin 2 and the nailing device are fixedly arranged on the machine. On the shelf 1, wherein the nailing device includes multiple sets of nail guns 3 and sensors.

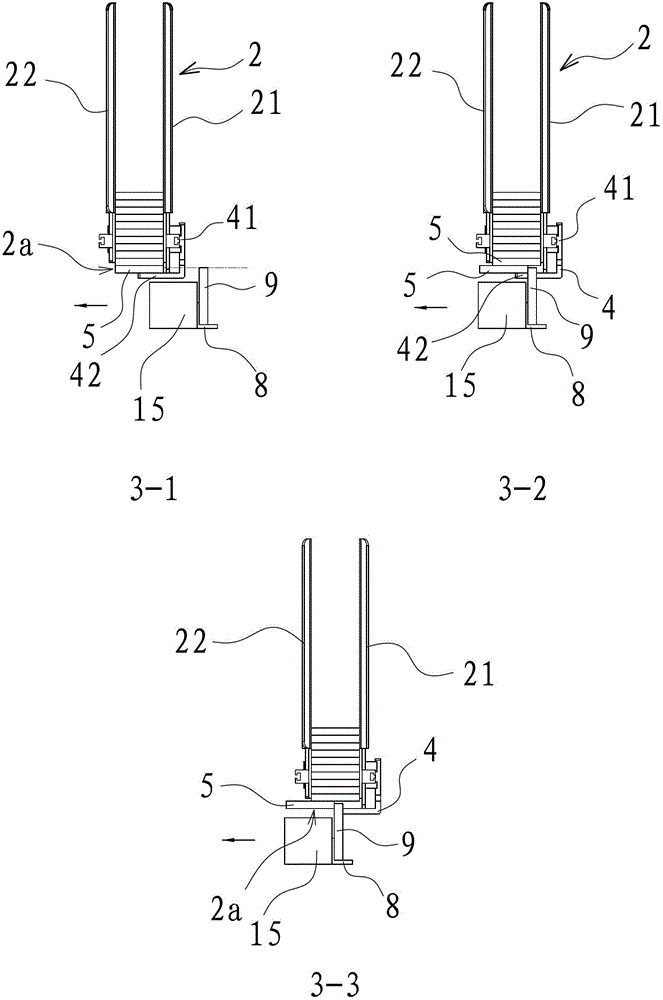

[0024] The silo 2 includes a front side plate 21 and a back side plate 22 arranged vertically in parallel. The bottom of the silo 2 is provided with two "L" shaped stoppers 4, and the stoppers 4 are composed of a vertically arranged connecting portion 41 and a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com