Split sliding type width-adjustable fiber placement head method and device

A technology of laying head and sliding type, which is applied in the field of split sliding adjustable width laying head method and device, which can solve the problem of uneven width of prepreg tape, influence on product quality, and difficulty in accurately matching the width of laying head And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

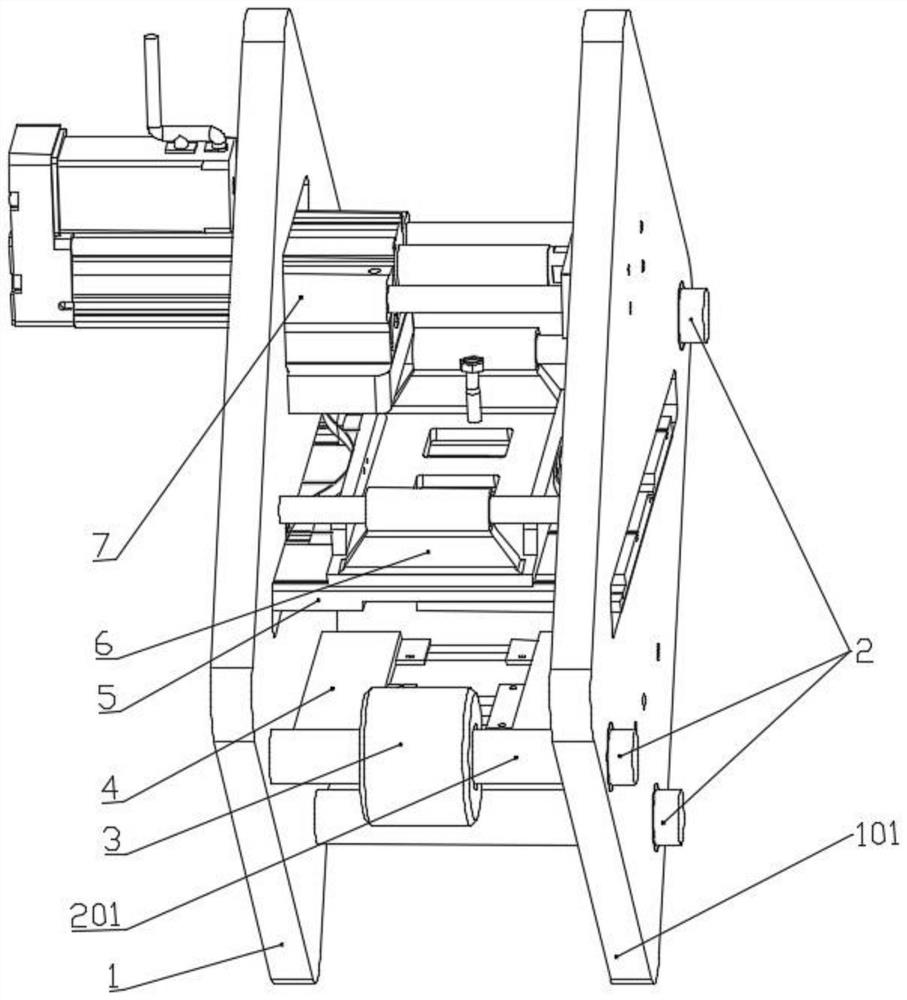

[0024] refer to figure 1 , a split sliding type adjustable width silk laying head device, comprising a left mounting frame 1 of the silk laying head, an electric cylinder 7 is installed on the upper part of the left mounting frame 1 of the silk laying head, the output of the electric cylinder 7 and a right mounting frame of the silk laying head 101 connection, optical axis 2, slidable channel 4, and slidable support 5 are installed between the left mounting frame 1 of the silk laying head and the right mounting frame 101 of the silk laying head, and the pressure roller shaft 201 connected to the optical axis 2 at the bottom is installed There is a pressure roller 3, and the pressure roller 3 cooperates with the slidable channel 4 above it, and the slidable channel 4 cooperates with the cylinder module 6 installed on the slidable bracket 5 above it.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com