Assembly type ground leveling assembly, device and system

A leveling device and assembled technology, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of easy crushing of the screw teeth and poor support force of the supporting leveling device, so as to achieve difficult movement and accurate paving , good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

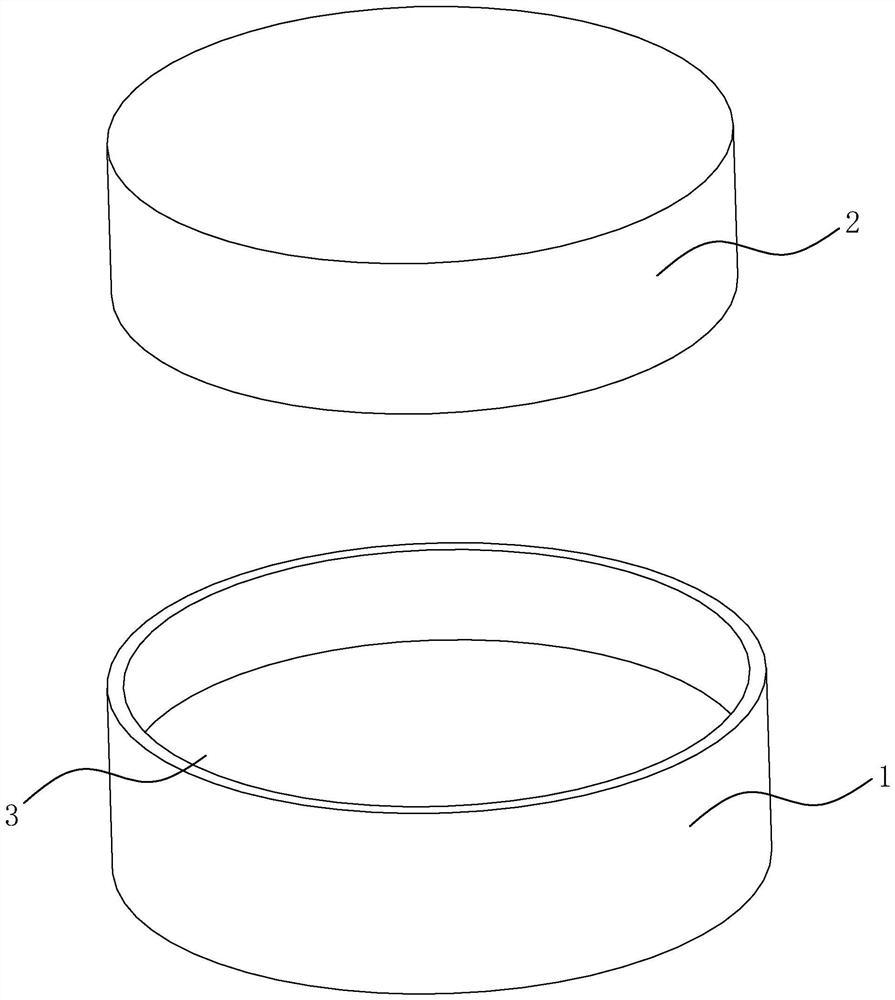

[0048] refer to figure 1 , the assembled ground leveling device includes a storage ring 1, a leveling piston 2 and a filler 3, the leveling piston 2 is inserted in the storage ring 1 and is slidably matched with the storage ring 1, and the filler 3 is set in the storage ring 1 for supporting Level piston 2. refer to Figure 1-3 , the storage ring 1 is a circular ring, a semicircular ring, a triangular ring or other polygonal rings, and correspondingly, the leveling piston 2 is a cylinder, a semi-circular cylinder, a triangular prism or other polygonal prisms adapted to the storage ring 1 . In different installation positions, you can choose the appropriate storage ring 1 and leveling piston 2, for example: when the assembled ground leveling device needs to be installed against the wall, the storage ring 1 can choose a semi-circular ring and a polygonal ring, and the leveling piston 2. Select the corresponding semi-cylindrical and polygonal prism; when the assembled ground le...

Embodiment 2

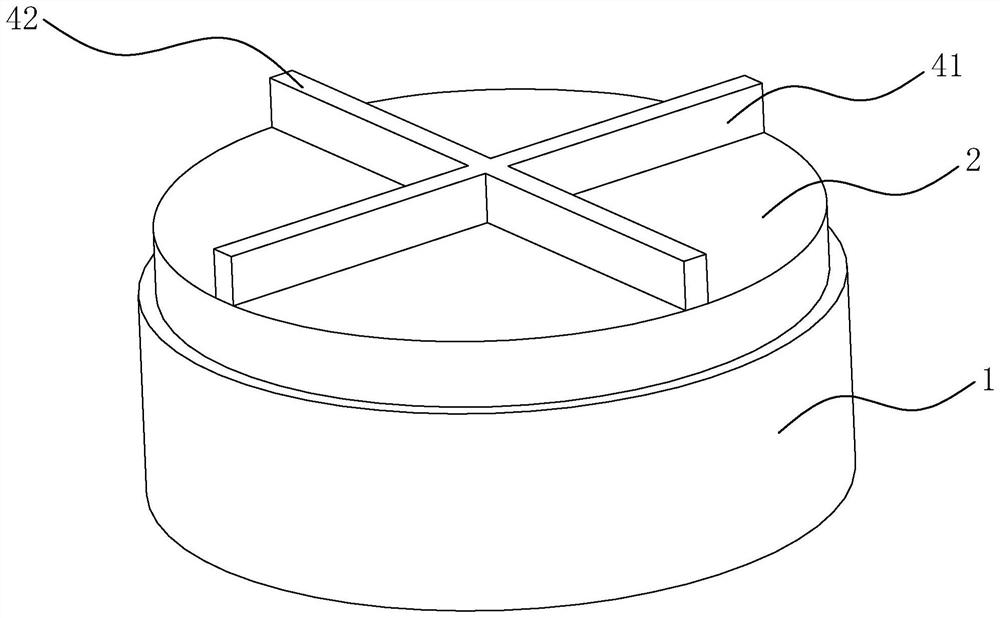

[0053] refer to figure 2 The difference between this embodiment and Embodiment 1 is that the assembled floor leveling device also includes a positioning protrusion arranged on the upper end of the leveling piston 2, and the positioning protrusion is used for positioning the floor, so as to improve the efficiency of laying the floor. In this embodiment, the receiving ring 1 is a circular ring, and the leveling piston 2 is a cylinder.

[0054] The positioning protrusion includes a positioning horizontal bar 41 and a positioning vertical bar 42, and the positioning horizontal bar 41 and the positioning vertical bar 42 intersect in the middle and are perpendicular to each other. The positioning horizontal bar 41 and the positioning vertical bar 42 divide the upper end of the leveling piston 2 into four areas equally. When in use, the assembled ground leveling device is arranged between four adjacent floors, and the corners of the four floors are respectively pressed on the four ...

Embodiment 3

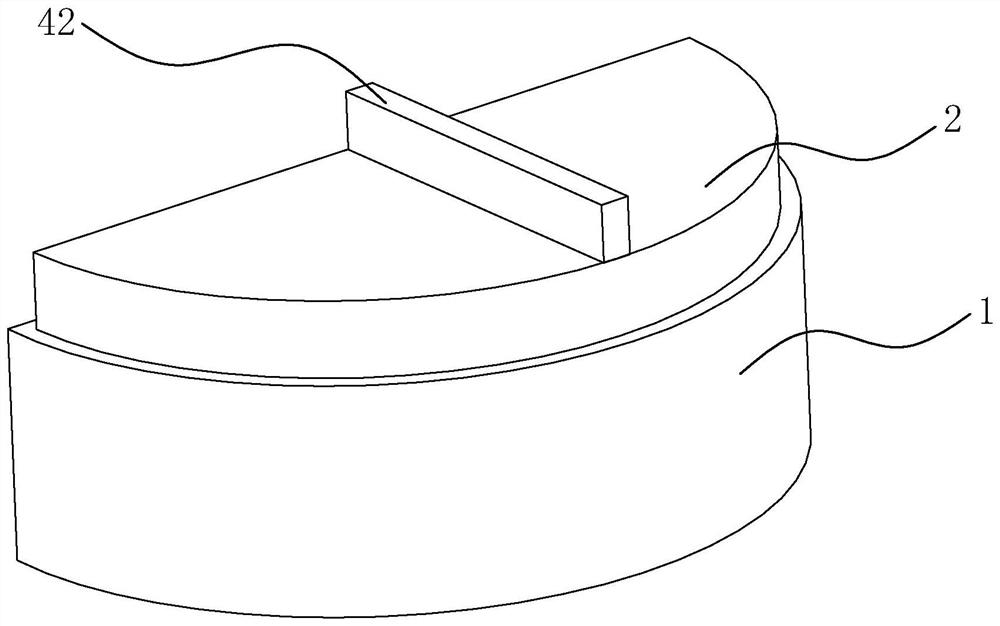

[0056] refer to image 3 The difference between this embodiment and Embodiment 1 is that the assembled ground leveling device also includes a positioning protrusion arranged on the upper end of the leveling piston 2, and the positioning protrusion is used to position the floor to improve the efficiency of laying the floor . In this embodiment, the receiving ring 1 is a semi-circular ring, and the leveling piston 2 is a semi-cylindrical cylinder.

[0057] The positioning protrusions include positioning vertical bars 42 . The positioning vertical bar 42 divides the upper end of the leveling piston 2 into two areas equally. When in use, the assembled ground leveling device is arranged between two adjacent floors, and the two floors are respectively pressed on the four areas of the upper end of the leveling piston 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com