Reciprocating type ultrathin laminated filter press

A reciprocating, filter press technology, applied in filtration and separation, membrane filters, mobile filter element filters, etc., can solve the problem of large floor space, strict equipment motion control requirements, and not suitable for small-scale workshops, etc. problems, to achieve the effect of saving area, good protection, good precision and rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

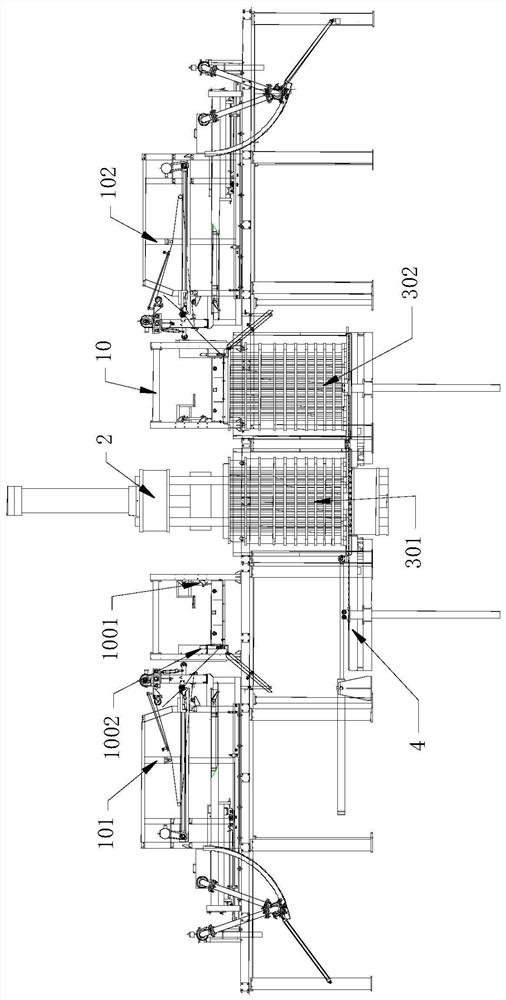

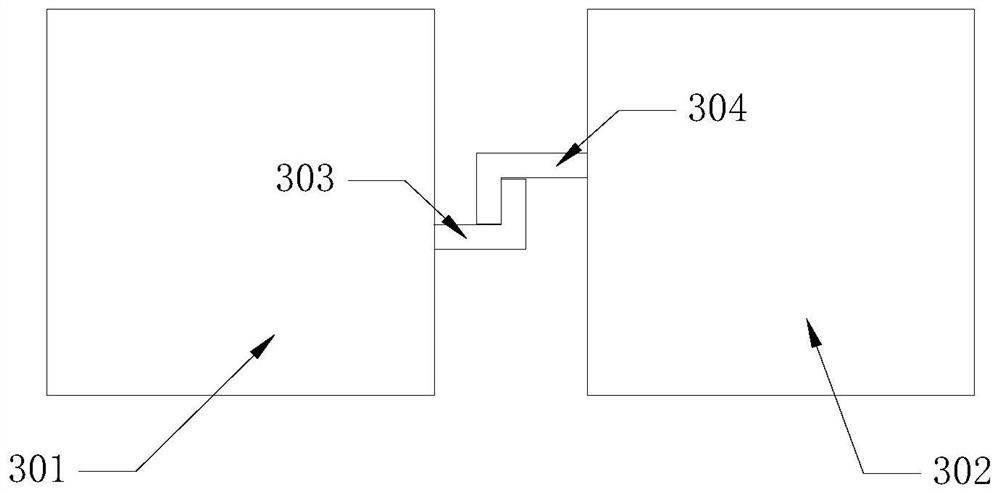

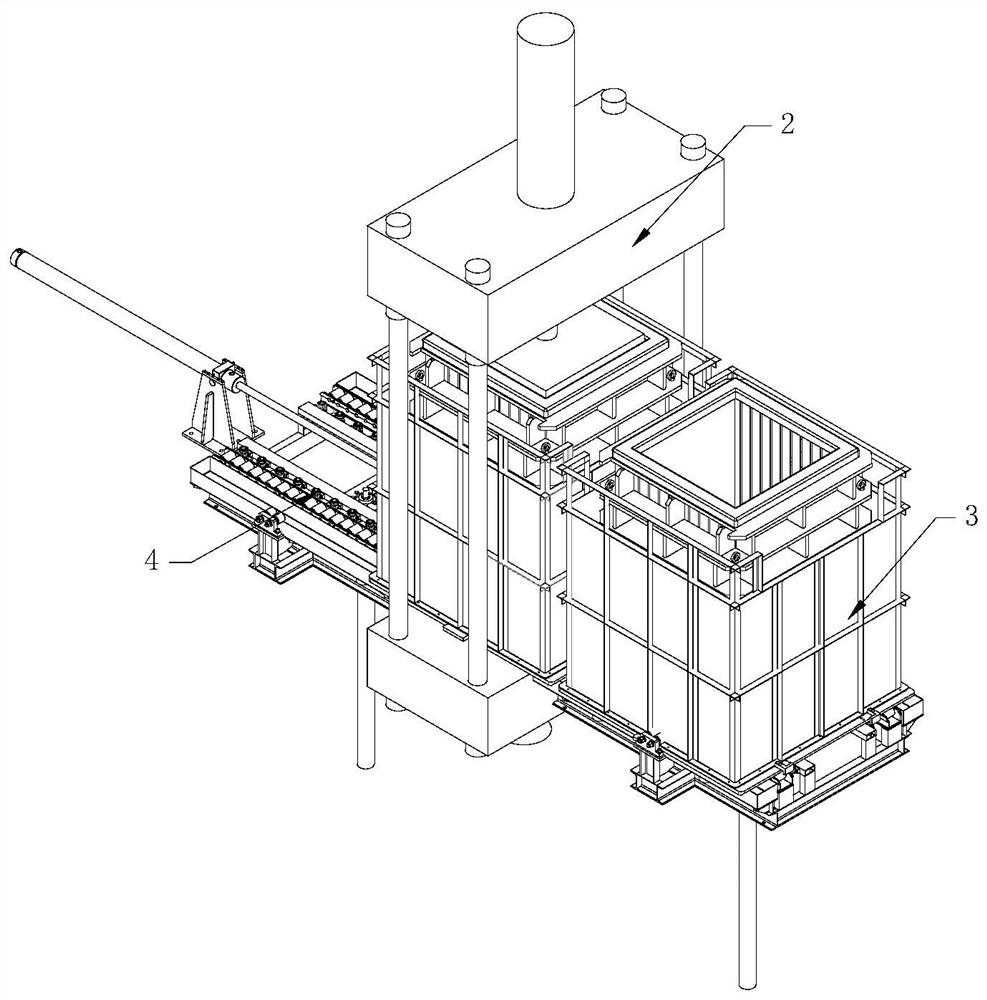

[0052] Such as figure 1 As shown, a reciprocating ultra-thin laminated filter press includes a material laying and discharging part, a pressing part 2, a water filter frame basket 3, and the water filter frame basket 3 has a first position and a second position, and the water filter frame The basket 3 makes a linear reciprocating motion between the first position and the second position. In the first position, the water filter frame basket 3 is between the laying material discharge part and the pressing part 2, and the water filter frame basket 3 is arranged near the pavement. One end of the material discharging part; in the second position, the filter basket 3 is located directly below the pressing part 2.

[0053] The laying and unloading part comprises a first laying and unloading device 101 and a second laying and unloading device 102, and the filter basket 3 is arranged between the first laying and unloading device 101 and the second laying and unloading device 102 , the...

Embodiment 2

[0060] Such as Figure 4-Figure 6 As shown, in this embodiment, on the basis of Embodiment 1, a protective part 5 is provided under the track 4 , and the protective part 5 includes a receiving groove 501 for placing the track 4 , and the depth of the receiving groove 501 is greater than the height of the track 4 . It also includes a lifting part 502 for the rail 4 to move up and down in the receiving groove 501, and the lifting part 502 includes several lifting cylinders.

[0061] When this embodiment is in use, when the pressing part 2 performs pressure filtration on the water filter basket 3, in order to protect the track 4, the track 4 is lowered into the receiving tank 501, and the water filter basket 3 is not pressed on the track 4, but Be pressed on the protection part 5, when will use track 4 to play a role in transmission to filter frame basket 3, track 4 rises again.

[0062] It can be understood that the track 4 is divided into three sections, and only the middle se...

Embodiment 3

[0065] On the basis of Example 1, the present embodiment further explains the structure of the laying and unloading section, as Figure 7 and Figure 8 As shown, the material spreading and unloading part includes a main frame 6, and the main frame 6 is provided with a material spreading device 103, a filter cloth frame 7, a filter cloth rectifying device 8 and a filter cloth traction device 9, and the material spreading device 103 is arranged on the main frame 6 The lower end of the filter cloth frame 7 is set on the main frame 6 near the end of the water filter basket 3, the filter cloth frame 7 is provided with a cloth roll 701, and the filter cloth correction device 8 is used for the cloth roll 701 to extend its axial direction To move horizontally, the filter cloth traction device 9 includes a traction roller 901 , and the traction roller 901 is arranged between the cloth winding roller 701 and the material laying device 103 . The main frame 6 is provided with a guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com