Patents

Literature

39results about How to "Same shade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

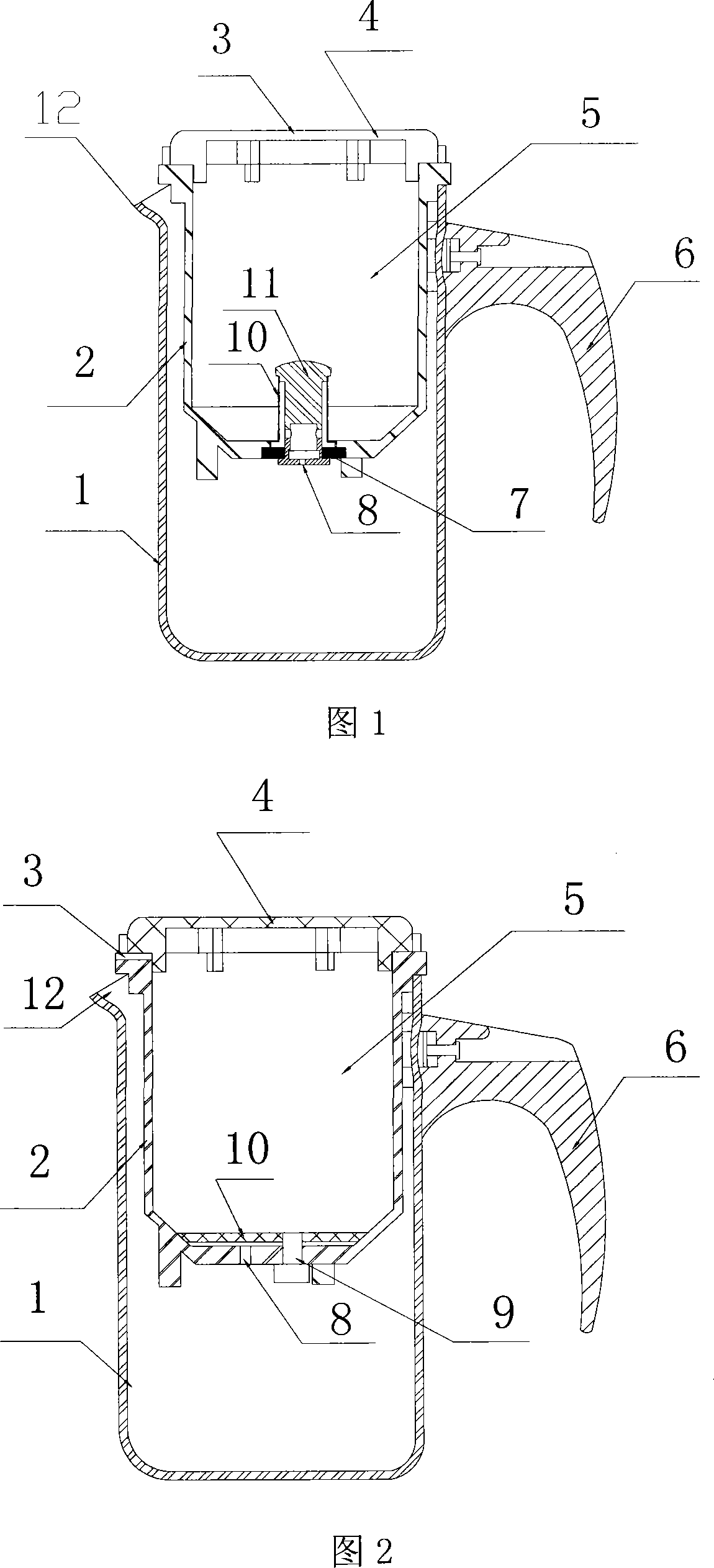

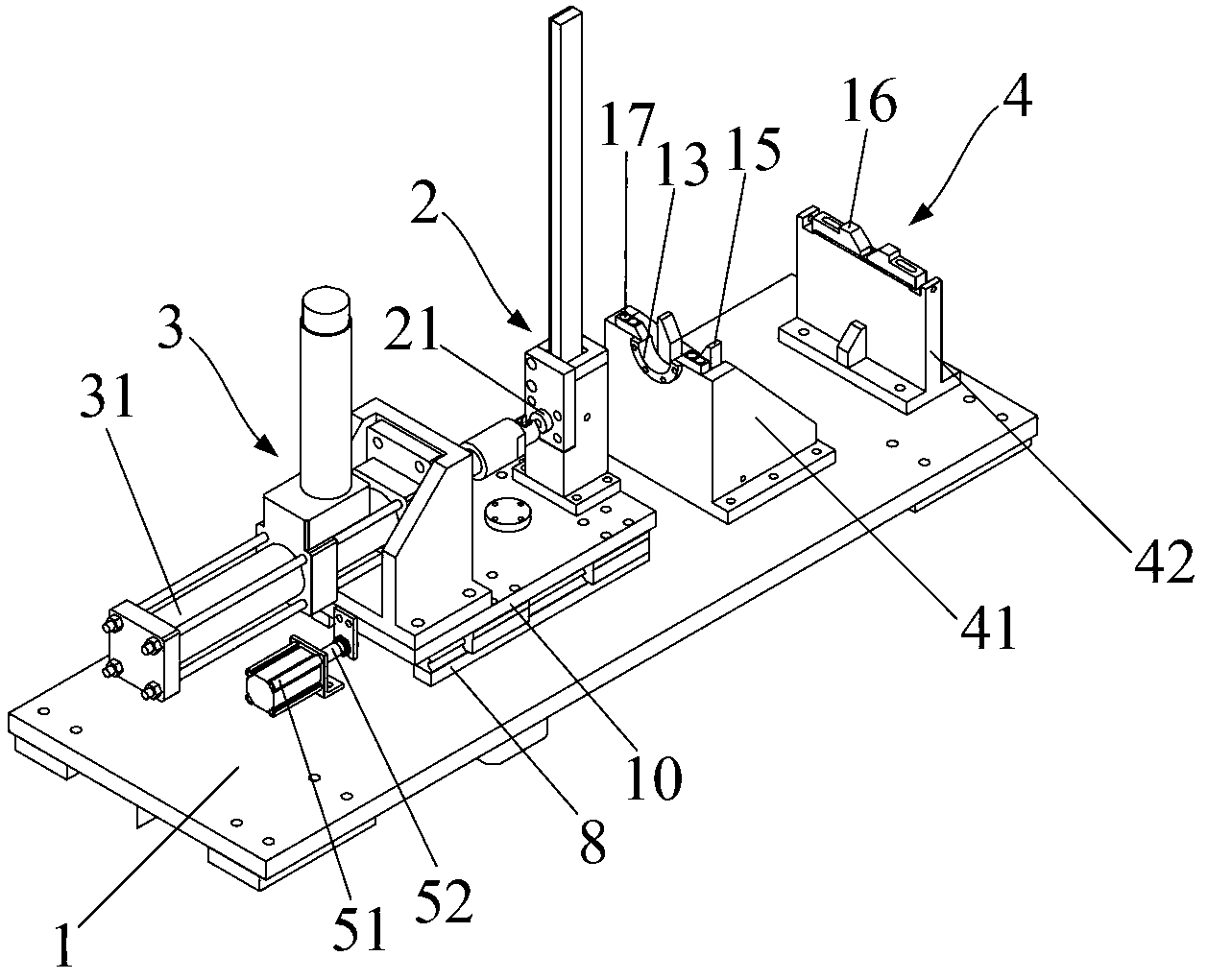

Full-automatic tea making cup

InactiveCN101194798ASimple structureAutomatic time controlDomestic vesselsDrinking vesselsAutomatic controlWater flow

The invention relates to an automatic tea-making cup, which comprises an outer cup and an inner cup inside the outer cup, wherein the inner cup bottom is provided with a timing hole in certain size and the upper side of the timing hole is fixed with a filter screen; the screen is in a cylinder shape provided with a screw rod inside and the screw rod passes through the inner cup bottom and is fixed on the inner cup through screws; the filter screen is in a flat shape and is fixed on the inner cup through screw bolts; inner cup ventilating holes are arranged on the upper side of the cup to duct the tea water flow into the outer cup; the inner cup and the outer cup are connected movably and the inner cup top is provided with an edge folding outside; the timing hole has a diameter of 1 to 3mm. The invention has the advantages that: the tea leaves and the tea water can be separated automatically with a constant gradation; no handle operation is needed and the time of the tea-soaking in the boiled water can be automatically controlled; the invention has simple structure, convenience and utility, simple operation and can be widely popularized and applied.

Owner:沈斌

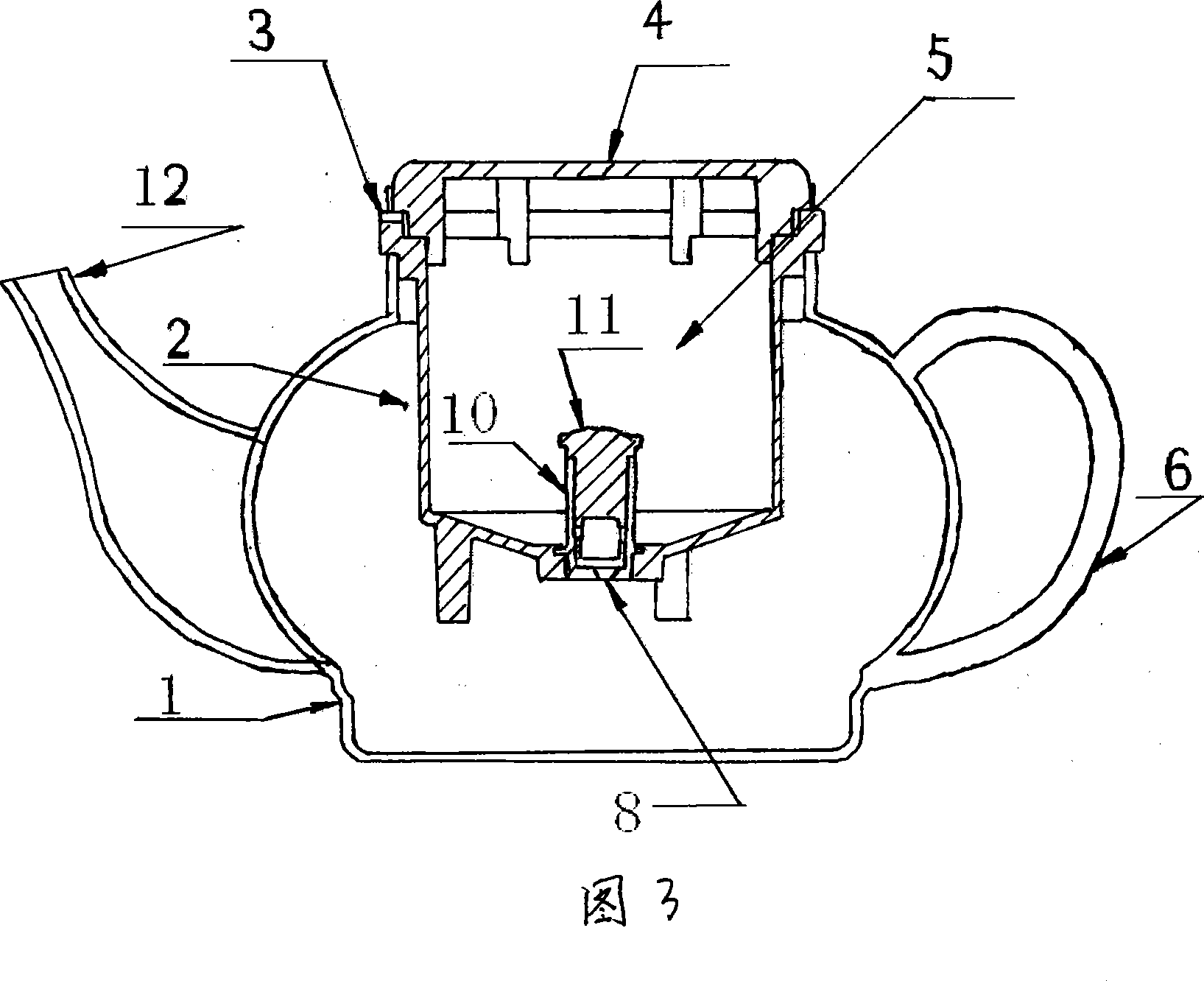

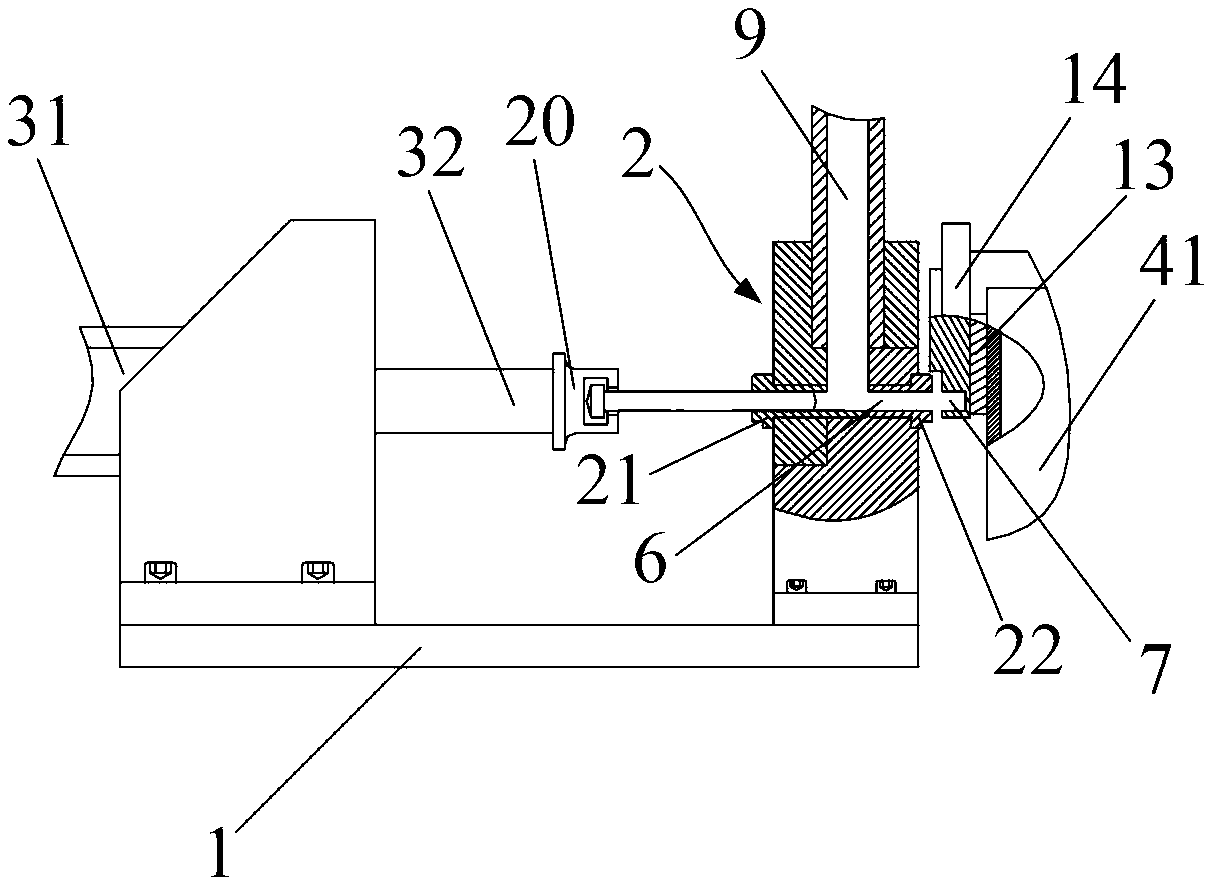

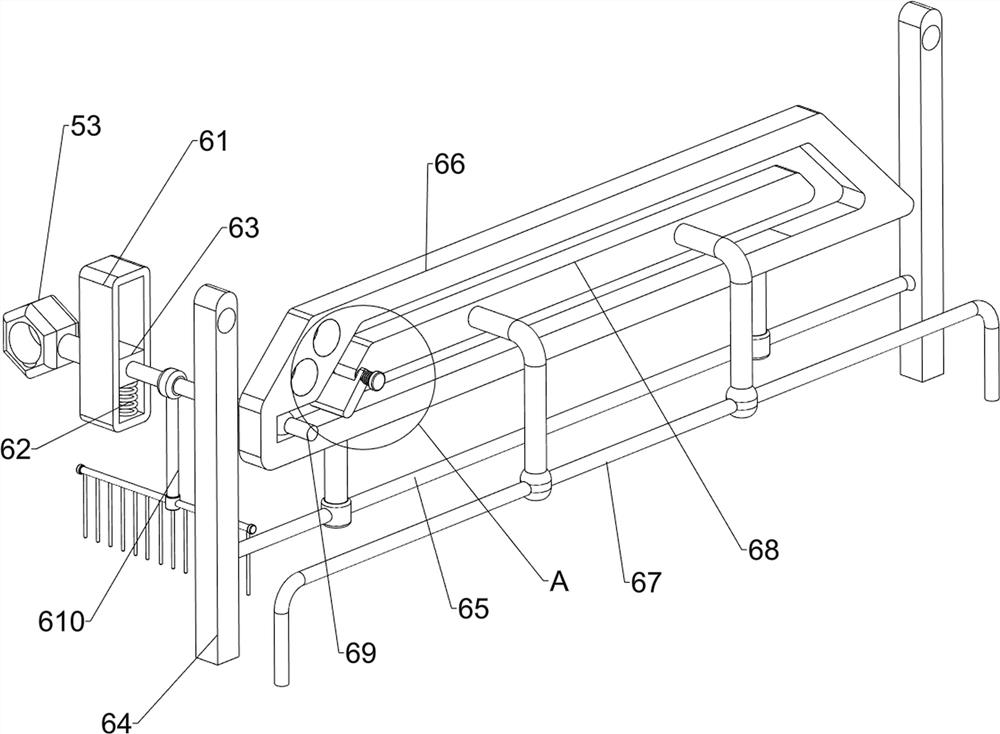

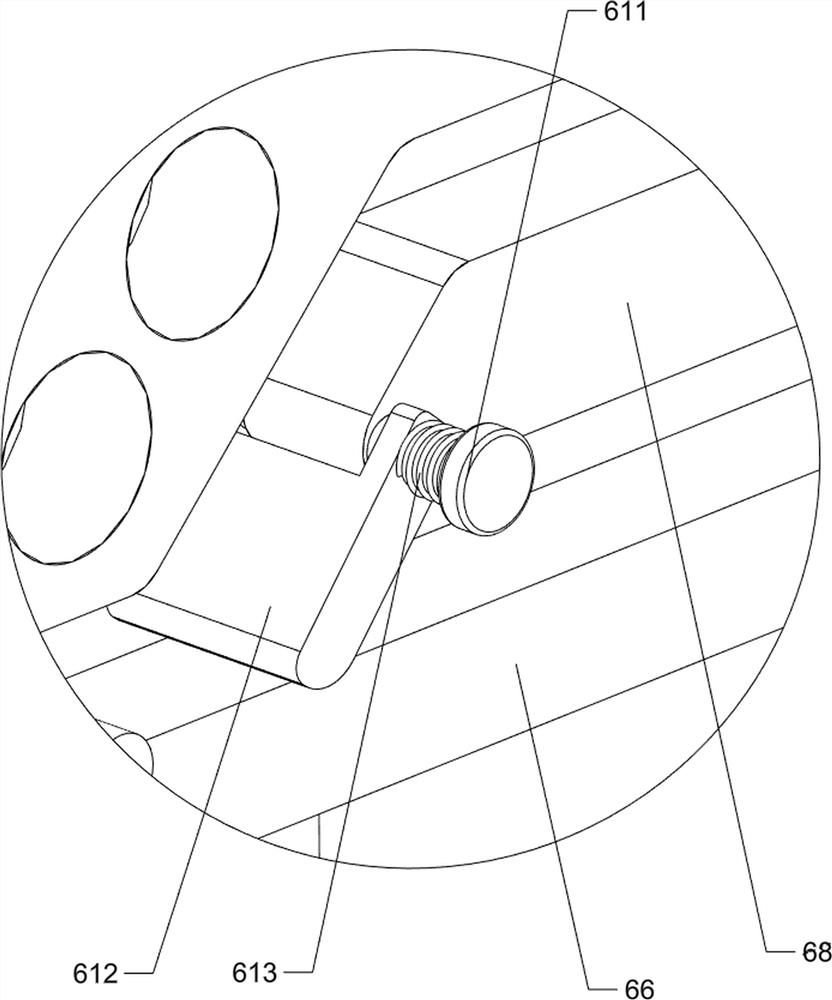

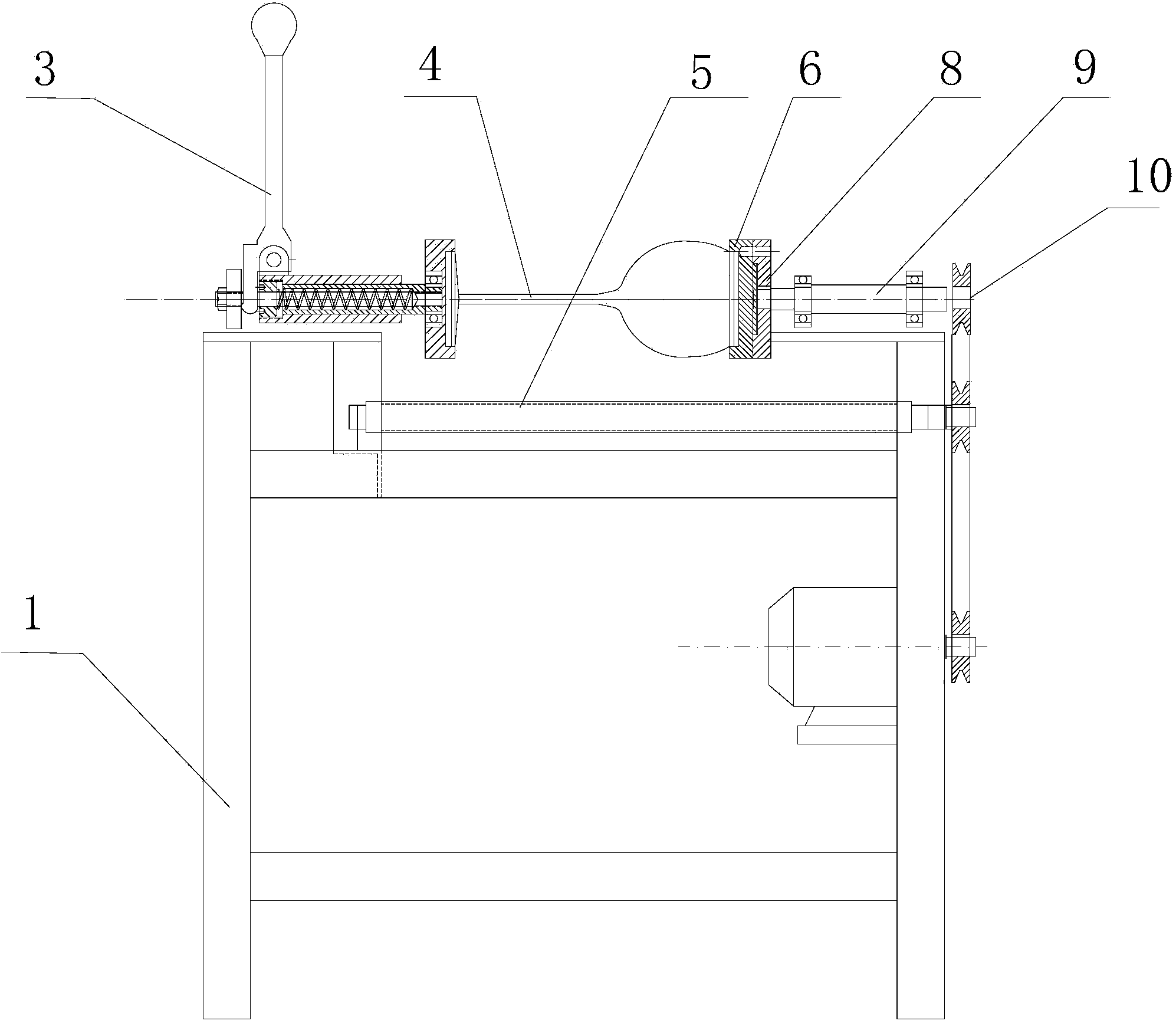

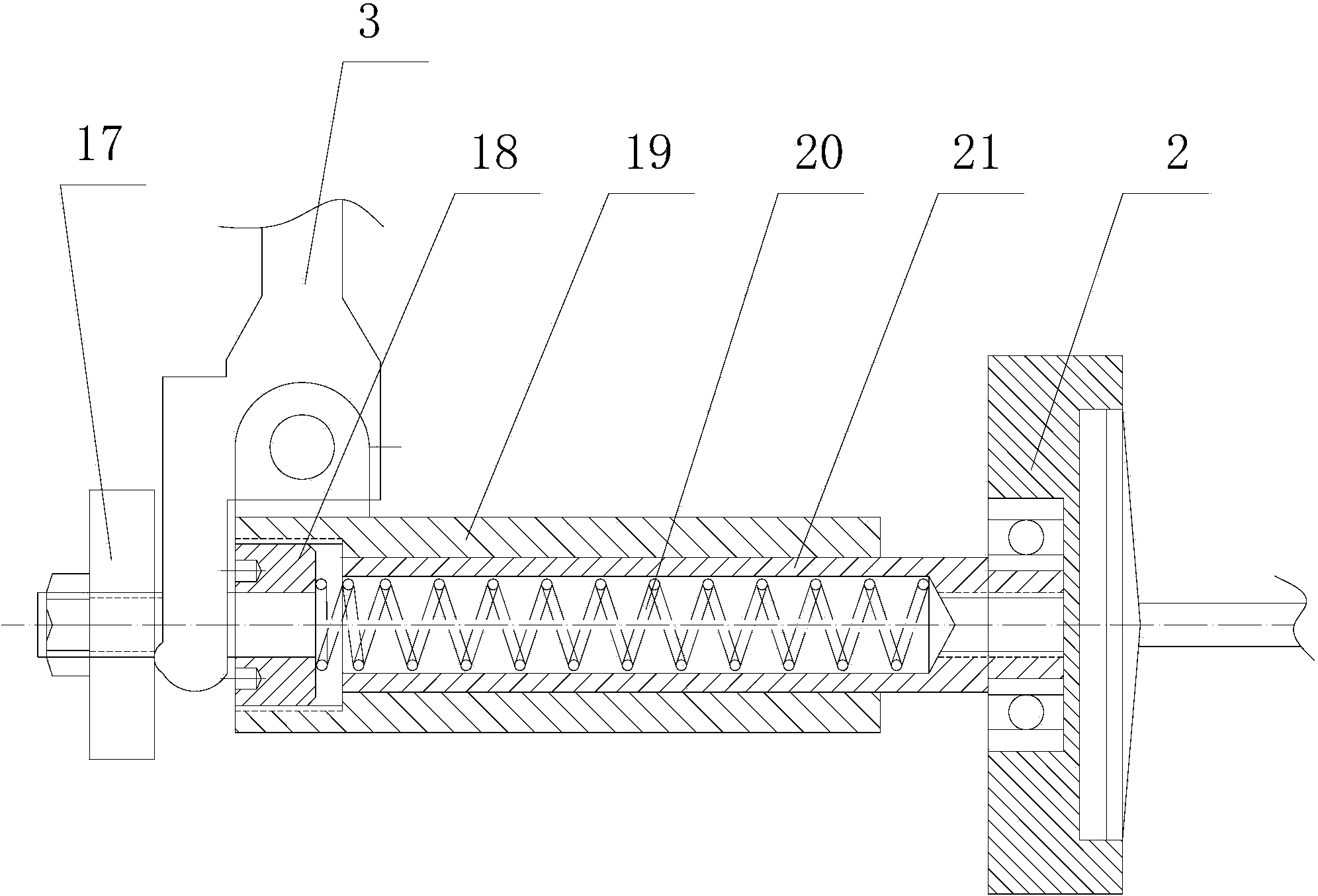

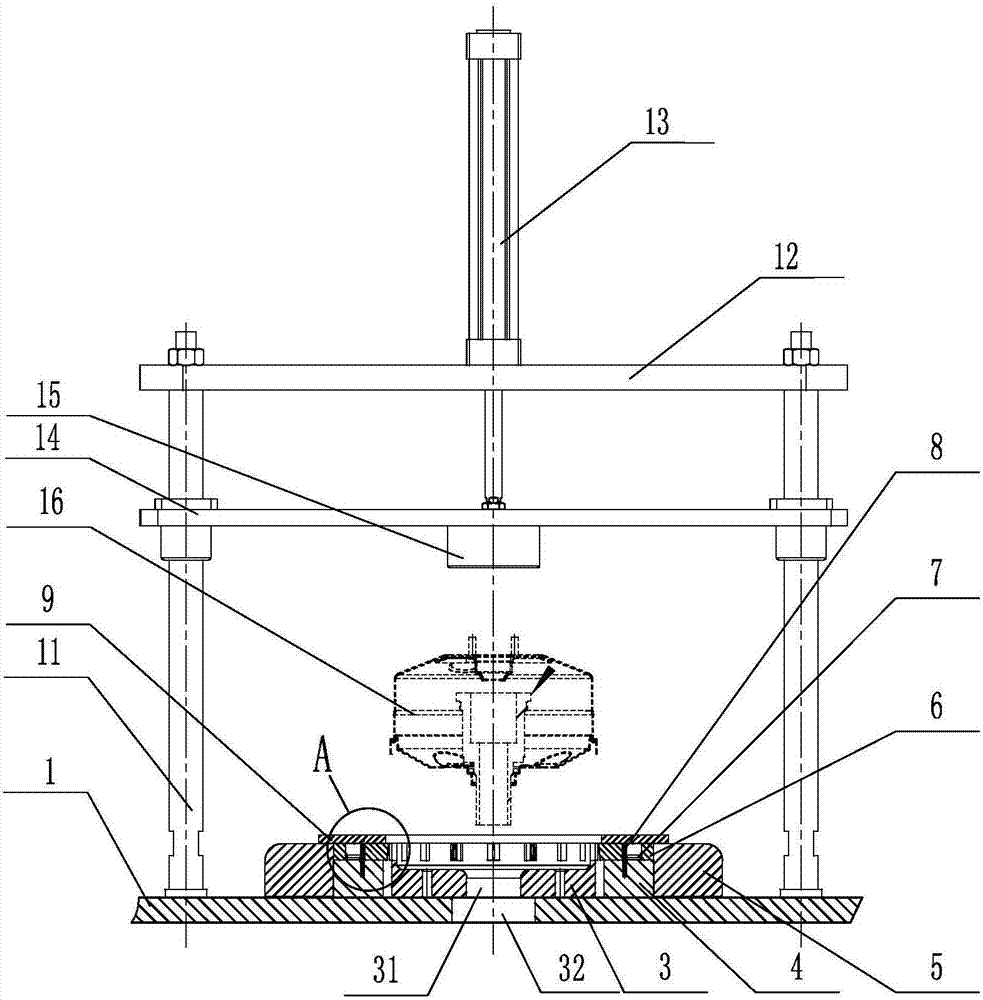

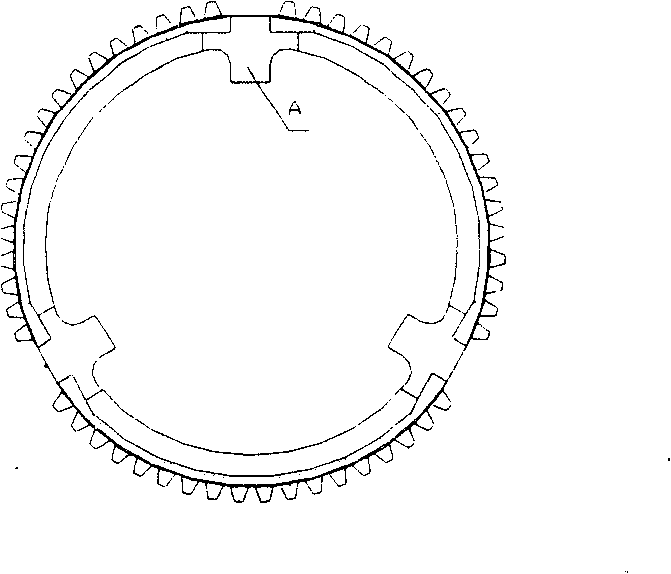

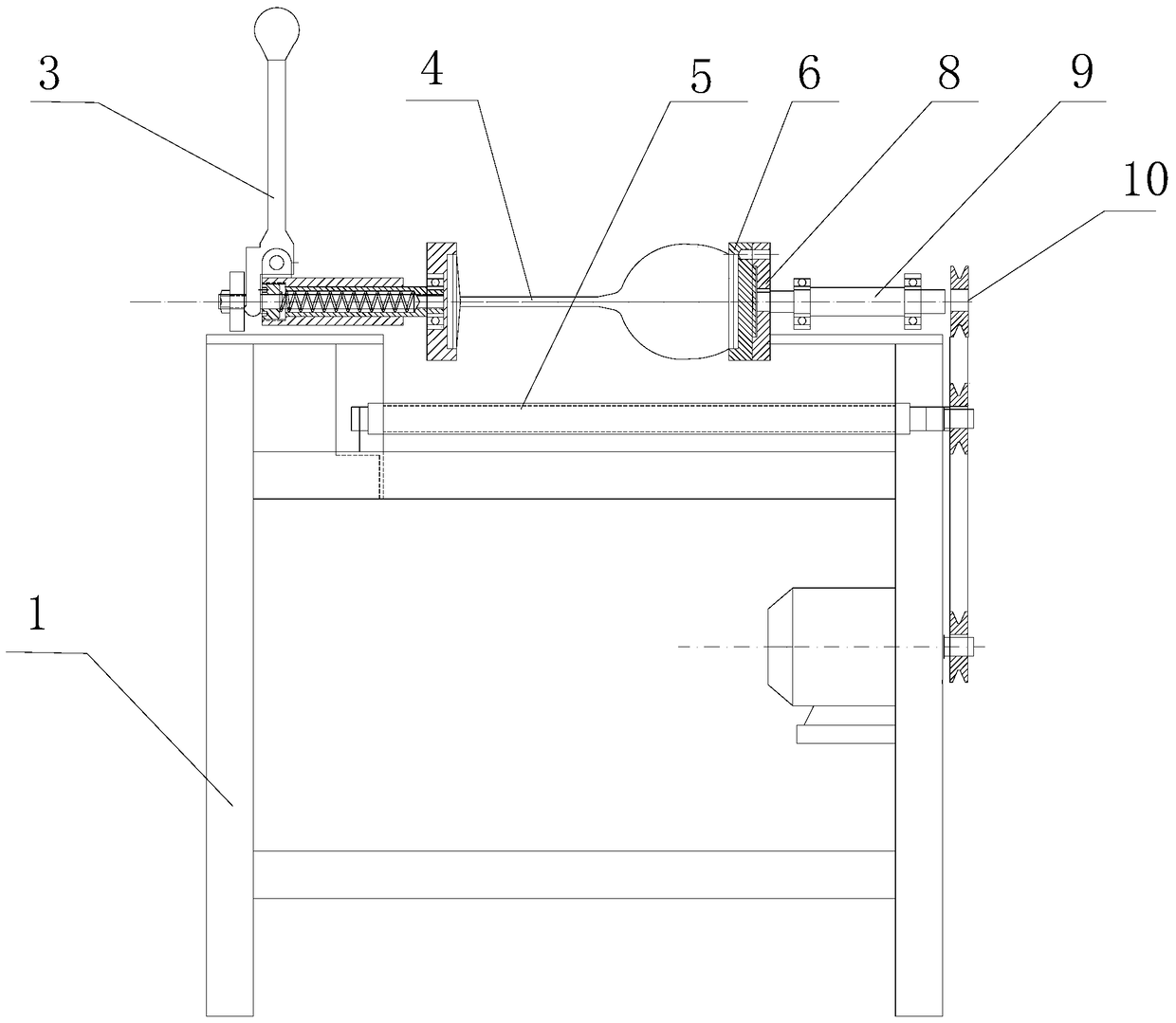

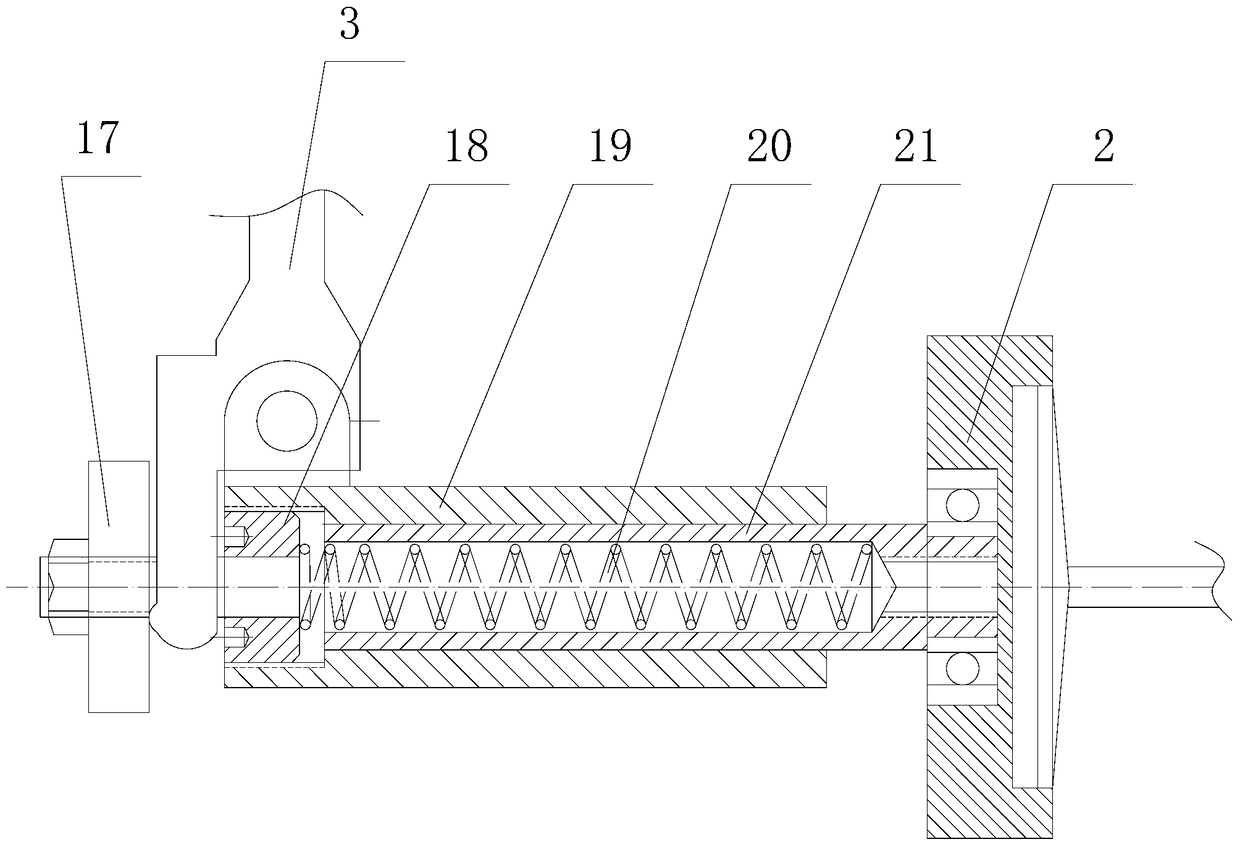

Crankshaft positioning pin pressing-mounting tool

ActiveCN103231238AGuarantee the quality of pressingDoes not destroy roundnessMetal working apparatusReciprocating motionEngineering

The invention relates to the technical field of automobile production tools and discloses a crankshaft positioning pin pressing-mounting tool. The crankshaft positioning pin pressing-mounting tool comprises a guiding mechanism, a pressing-mounting mechanism and a fixing mechanism, wherein the pressing-mounting mechanism comprises a pressing-mounting piston cylinder and is used for substituting for manpower and providing pressing-mounting force, accordingly the requirements for manual skills are reduced, and labor intensity is reduced. A guiding through hole is arranged on the guiding mechanism and is matched with a piston rod of the pressing-mounting piston cylinder to enable the piston rod of the pressing-mounting piston cylinder to perform reciprocating motion on one straight line and not to be influenced by self weight. When a positioning pin is pressed and mounted, a crankshaft is fixedly placed on the fixing mechanism. The guiding mechanism is installed between the fixing mechanism and the pressing-mounting mechanism to enable the piston rod of the pressing-mounting piston cylinder to press the positioning pin into a pin hole along the axis direction of the pin hole, the roundness of an excircle face of a crankshaft flange is not damaged, and the pressing-mounting quality of the crankshaft positioning pin is ensured.

Owner:长城汽车股份有限公司平湖分公司

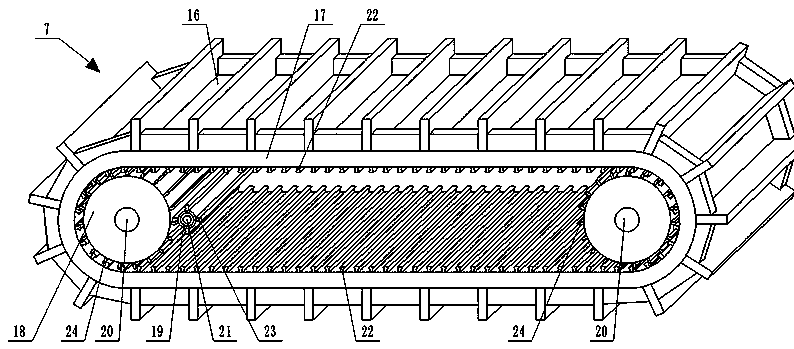

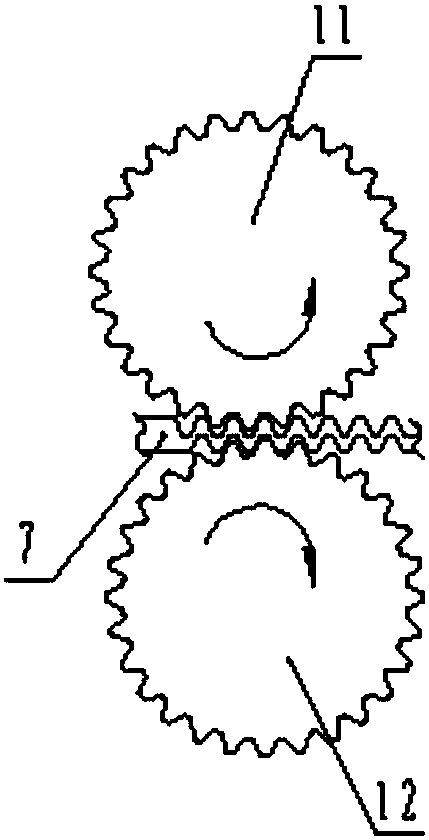

Packaging printing ink transfer roller

ActiveCN110341305ASolve the phenomenon of inconsistency between the front and backQuality assurancePrinting press partsEngineeringPrinting ink

The invention provides a packaging printing ink transfer roller. The ink transfer roller comprises an outer executing unit and an ink transfer mechanism; the outer executing unit is of a left-right symmetric structure; and the ink transfer mechanism is arranged on the outer executing unit through a bearing. According to the ink transfer roller, the phenomenon that in an ink transfer process, ink cannot be transferred to a printing plate due to the fact that parts of ink holes of an existing ink transfer roller are blocked frequently, so that printing products are different in front and back color shade is avoided; and the problem that the surface of the existing ink transfer roller is in contact with an ink scraping knife and is seriously worn after a long time, the ink cannot be stored and transferred, the ink supply is not in time, and the printing quality is influenced is solved.

Owner:浙江朗讯印刷新材料有限公司

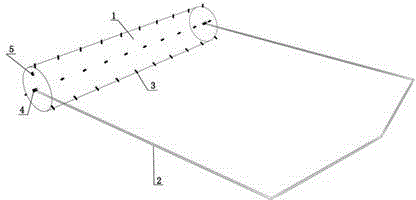

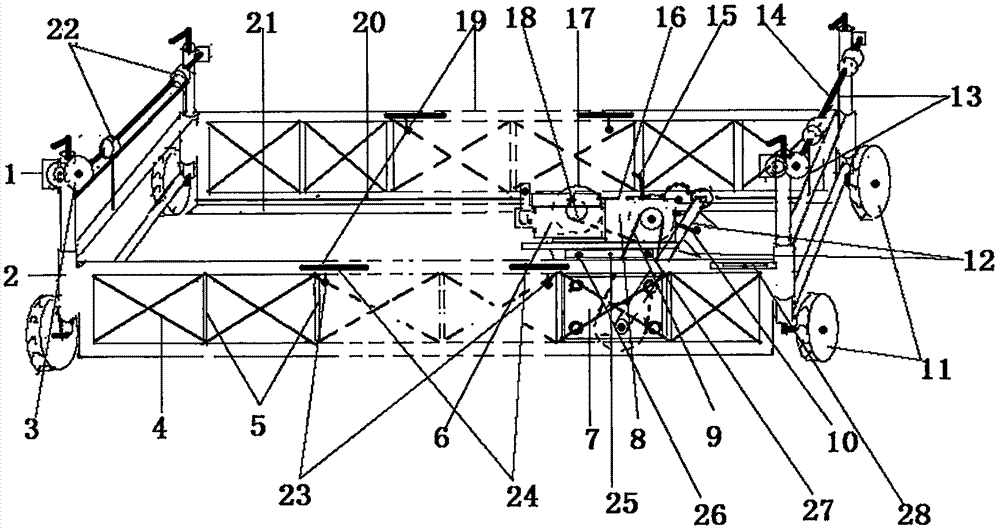

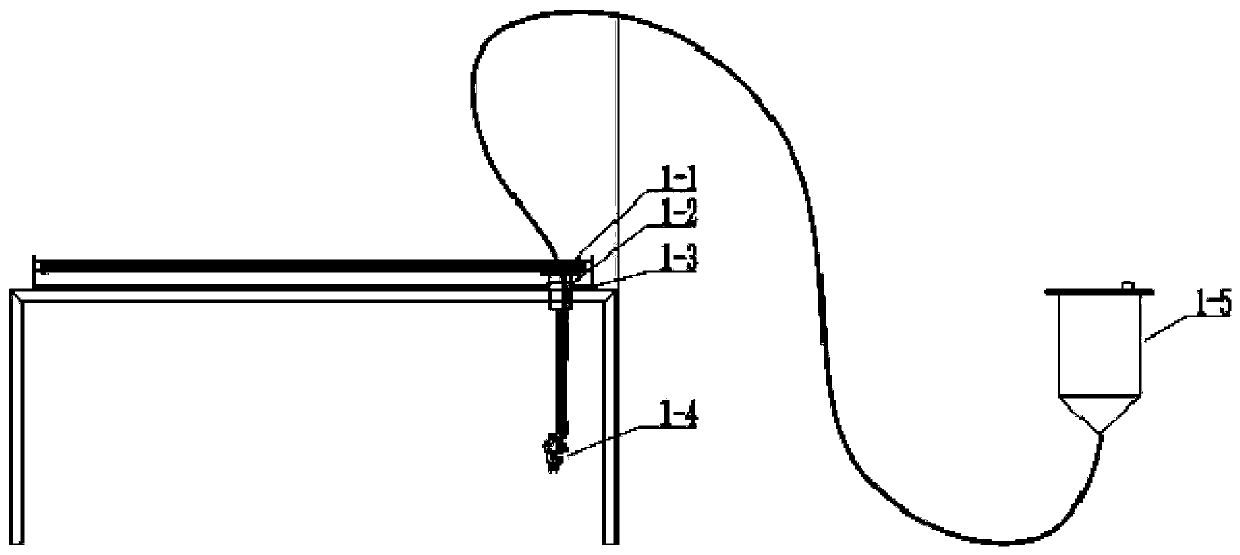

Dibber for crop breeding and exact cultivation test

InactiveCN101480125AUniform spacingSame shadeFertiliser distributersHand sowing implementsEngineeringRebar

The invention discloses a dibbler for crop breeding and exact culture test, which comprises a framework and a vessel used for storing seeds, wherein a plurality of steel pipes are evenly distributed at the bottom of the framework, reinforcing steels capable of being inserted into the steel pipes are arranged on all the steel pipes, the lengths of the reinforcing steels are more than those of the steel pipes, the reinforcing steels penetrate through the steel pipes for motion, all the reinforcing steels are connected together through a transverse pipe which is connected with a rod part through a bent plate, the length of the rod part more than that of the framework, the rod part slides up and down in the center of the framework to drive the reinforcing steels to move up and down in the steel pipes, an inclined pipe is also arranged on the side surface of each steel pipe, a pipeline is connected to the inclined pipe, and the pipeline is connected with a seed outlet opening at the bottom of the vessel; the vessel is arranged above the framework, and a seed metering device is arranged at the bottom of the vessel. The invention can ensure that the interplant spacing, the row pitch and the depth are basically consistent for the crop seed seeding and ensure the single-seed sowing and can especially perform the anti-drought sowing. The dibbler has the advantages of simple structure, convenient operation and higher efficiency.

Owner:NORTHWEST A & F UNIV

Spot sowing device for crop breeding and cultivation precision tests

InactiveCN105638038AUniform spacingSame shadeSeed depositing seeder partsSingle grain seedersSteel barEngineering

The present invention discloses a spot sowing device for crop breeding and cultivation precision tests. The spot sowing device comprises a frame and a container for placing seeds, wherein a plurality of steel pipes are uniformly distributed on the bottom portion of the frame, each steel pipe is provided with a steel bar capable of inserting into the steel pipe, the steel bar performs penetrating movement in the steel pipe, all steel bars are integrally connected through a horizontal pipe, the horizontal pipe is connected to a rod member with a length of larger than the length of the frame through a bending plate, the rod member slides up and down in the middle of the frame so as to drive the steel bar to move up and down in the steel pipe, the side surface of the steel pipe is provided with an inclined pipe, the inclined pipe is connected to a pipeline, the pipelines are connected to seed outlets on the bottom portion of the container, the container is arranged above the frame, and the bottom portion of the container is provided with a seed discharging device. With the spot sowing device of the present invention, the basic uniformity of the plant spacing, the row spacing and the depth of the crop seed sowing can be ensured, the single seed sowing can be ensured, especially drought-resistant sowing can be ensured, and the spot sowing device has characteristics of simple structure, easy operation, and high efficiency.

Owner:重庆市涪陵区渝杨榨菜(集团)有限公司

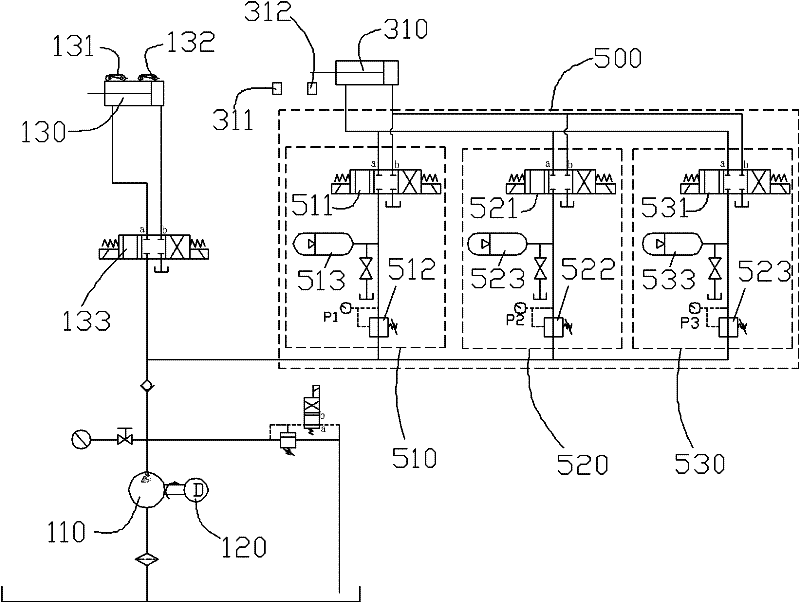

Full-automatic silk-screen printing machine

InactiveCN111791579AReduce volatilityImprove qualityScreen printersProcess engineeringPrinting press

The invention relates to the technical field of printing equipment, and discloses a full-automatic silk-screen printing machine. The full-automatic silk-screen printing machine comprises a printing table. A printing and dyeing screen plate, a doctor blade and an inking knife are mounted at the upper end of the printing table, all of which can ascend and descend independently. An ink feed part usedfor intermittently and linearly releasing ink is mounted between the doctor blade and the inking knife. According to the full-automatic silk-screen printing machine, quantitative ink adding is carried out while the inking knife moves, ink is sealed all the time before being added, ink volatilization is reduced, the use dosage of ink additives is reduced, and the printing cost is reduced; in the printing process, the ink quality is stable, the mixed proportion of ink and additives is ensured through a flow control valve, meanwhile, ink is dynamically mixed in the flowing process, the automation degree is high, and manual participation is reduced; on one hand, ink is instantly prepared and instantly used, the containing time of prepared ink is greatly shortened, and volatilization is reduced; and on the other hand, the ink quality keeps consistent in the whole printing process.

Owner:广州威品技术研发有限公司

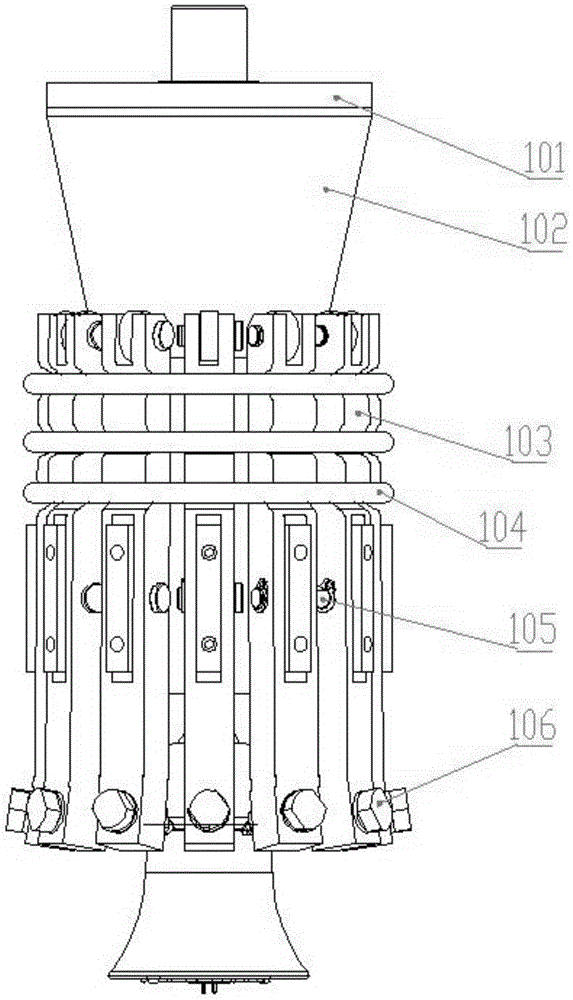

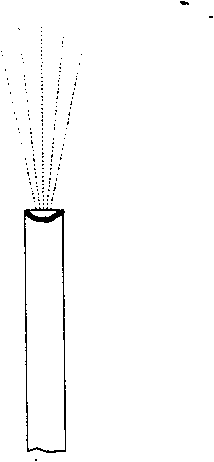

Edible fungus inoculation device

InactiveCN110915551AReduce the chance of infectionRealize fully enclosed punching and inoculation operationCultivating equipmentsMushroom cultivationBiotechnologyEngineering

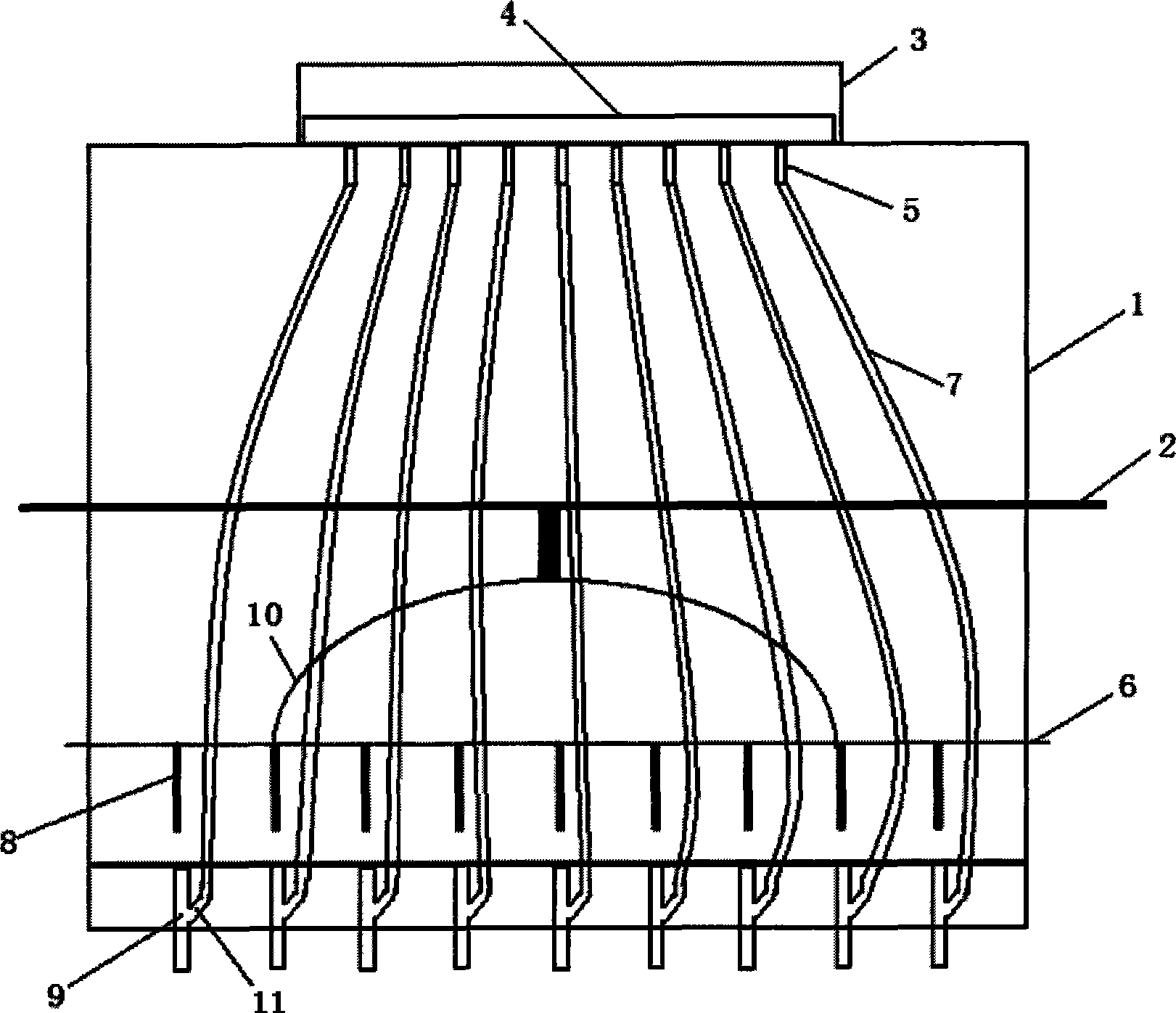

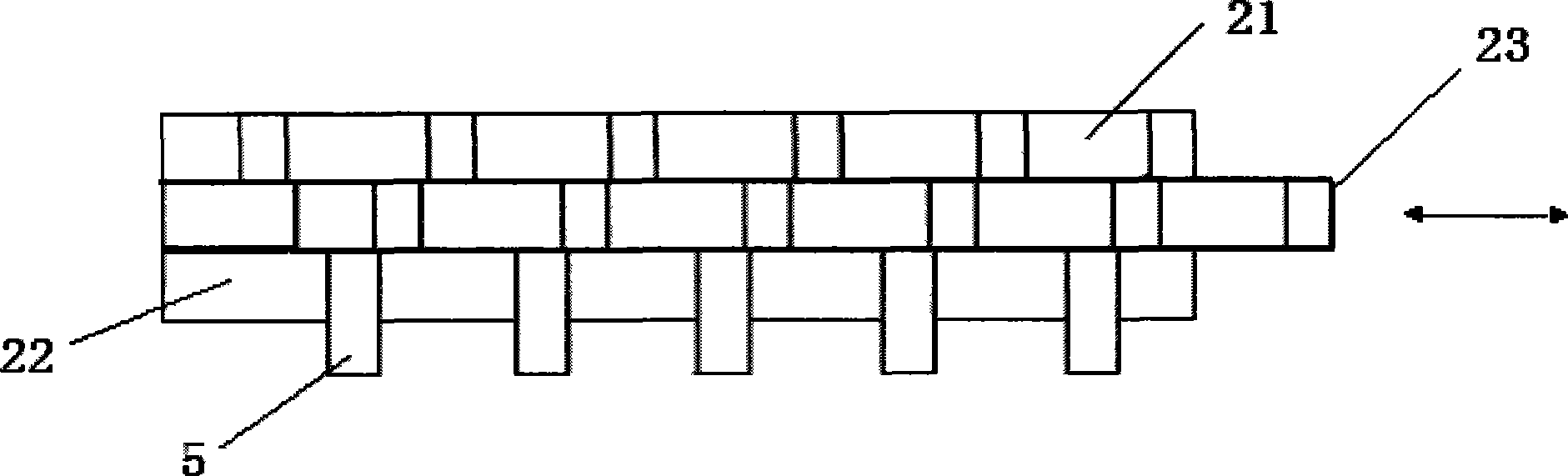

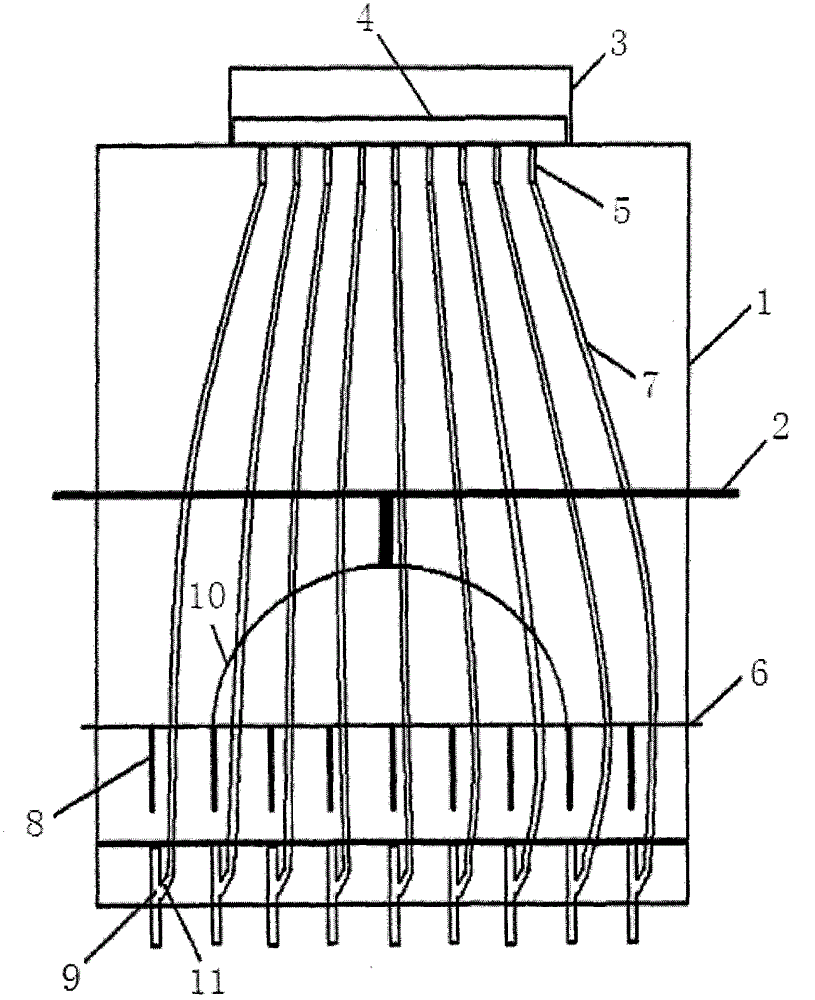

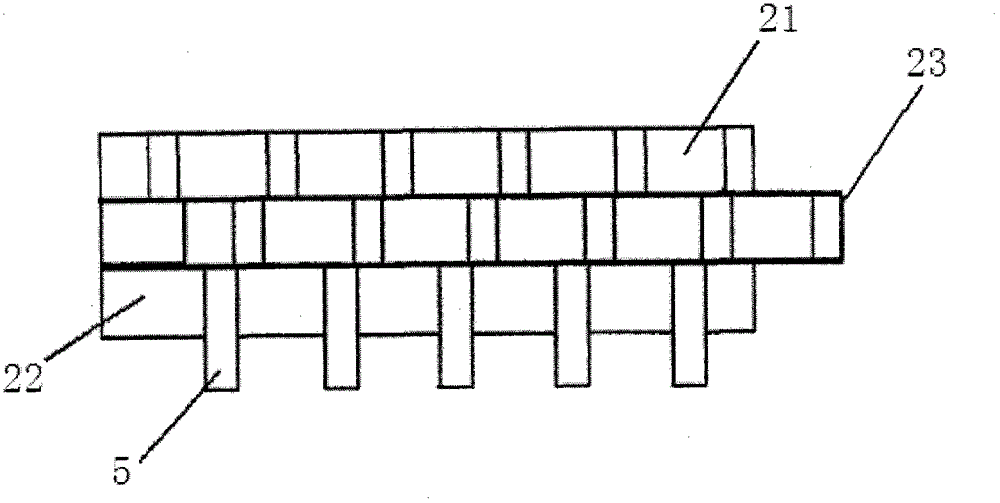

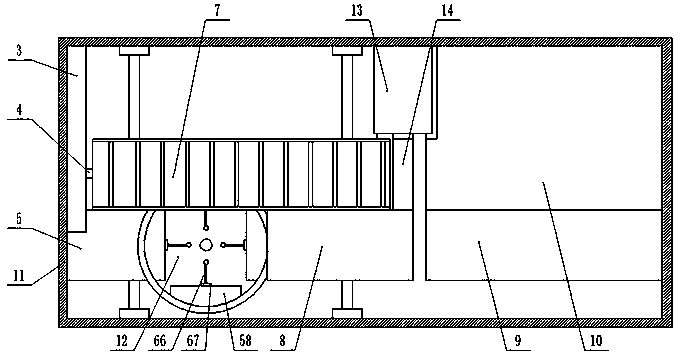

The invention discloses an edible fungus inoculation device. The edible fungus inoculation device comprises a machine body, a fungus stick disinfection box, a strain box, a fungus stick conveying device, a fungus stick channel, a fungus stick longitudinal pushing device, a fungus stick punching device, an inoculation device and a fungus stick transverse pushing device, the fungus stick disinfection box is arranged at the upper end of the machine body, and a fungus stick discharging outlet is formed in the bottom of the fungus stick disinfection box; the fungus stick conveying device is arranged on the lower end of the fungus stick disinfection box, the fungus stick punching groove is arranged on the lower end of the fungus stick conveying device, the fungus stick transverse pushing deviceis arranged on the rear side of the fungus stick punching groove, the fungus stick channel is arranged on the front side, the fungus stick punching device is arranged on the right side, the fungus stick longitudinal pushing device is arranged on the right side of the fungus stick channel, and the inoculating device is arranged on the left side of the fungus stick channel. An inoculating head is arranged on the rear side of the inoculating device. The full-automatic edible fungus perforating and inoculating machine has the advantages that automatic perforating and inoculating of edible fungus cultivation are achieved, labor intensity is greatly reduced, operation efficiency is improved, full-closed perforating and inoculating operation is achieved in the machine body, the infection probability of infectious microbes is greatly reduced, the perforating depth is consistent, and the inoculating number is the same.

Owner:吕辉

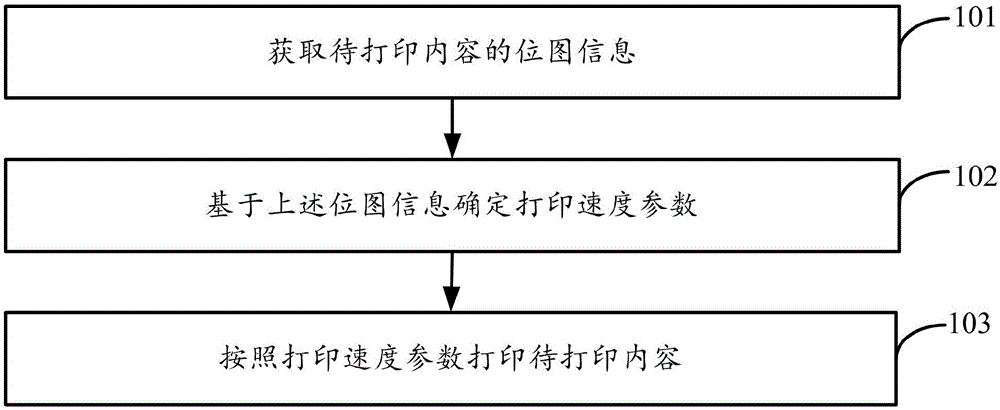

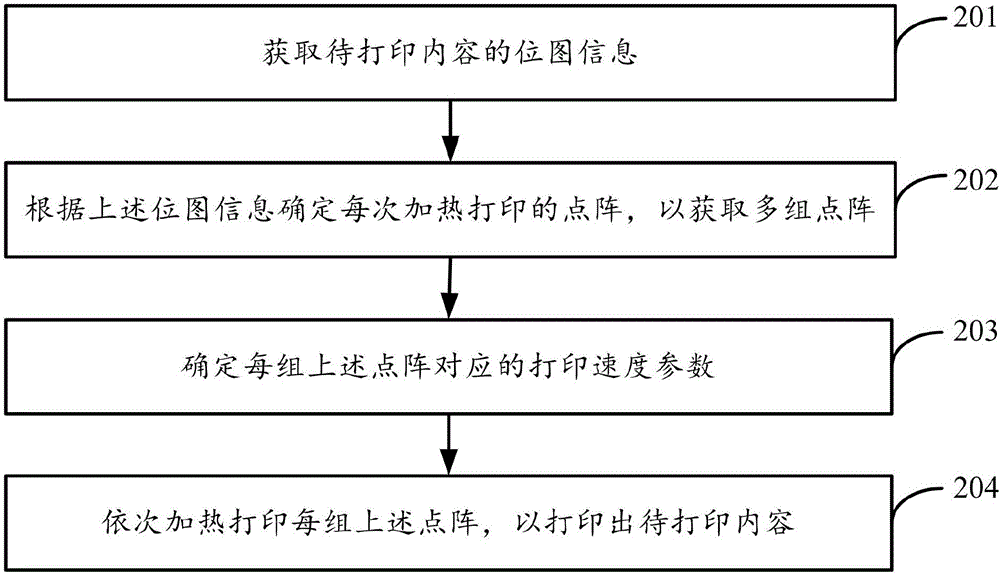

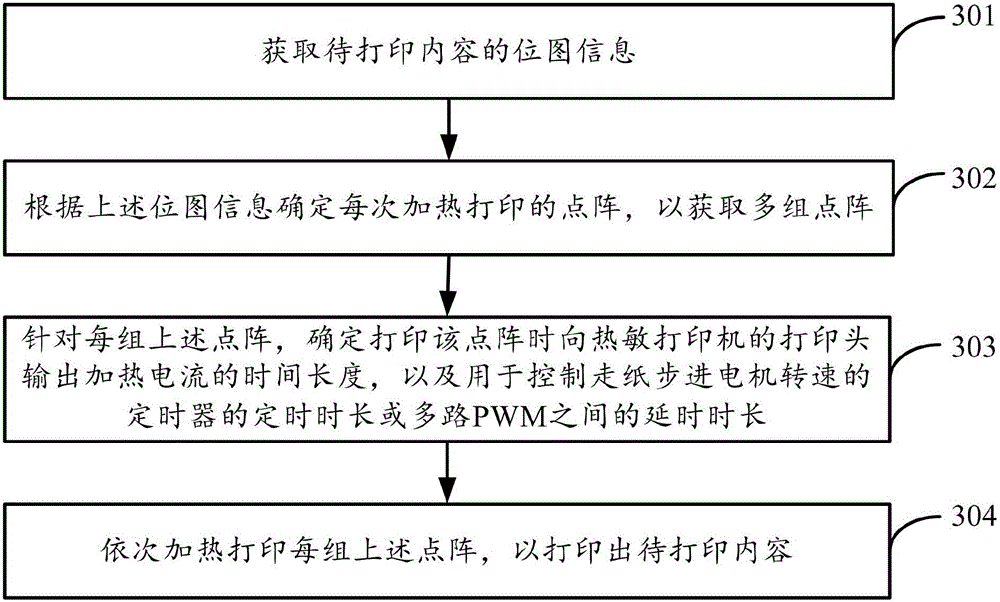

Printing control method, printing control device, and printer

The application provides a printing control method, a printing control device, and a printer. According to a specific embodiment, the method comprises the steps of acquiring the bitmap information of to-be-printed content, determining printing speed parameters based on the bitmap information, and printing the to-be-printed content in accordance with the printing speed parameters. According to the embodiment, the printing speed can be adjusted according to the bitmap information of the to-be-printed content, so that a printed graph is of uniform color and consistent color depth.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

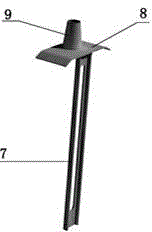

Seed-production onion seedling reservation drilling machine

The invention provides a seed-production onion seedling reservation drilling machine, relates to farm machinery, especially to machinery for seed-production onion seedling reservation drilling. The seed-production onion seedling reservation drilling machine comprises two parts such as a drum and a pulling rod, wherein regularly-aligned film-breaking projections are designed on the outer surface of the cylindrical drum, a rotation shaft is designed at the circle center positions on both bottom surfaces of the drum, the pulling and the drum are subjected to matched use through the rotation shaft, and a switch door capable of filling a material is designed on one bottom surface of the drum. Compared with the existing film-breaking drilling tool, the seed-production onion seedling reservation drilling machine of the present invention has the following characteristics that the seedling-reserving seed-production onion seedlings have characteristics of uniform row spacing, same depth and regular growth, and the field management is easily achieved.

Owner:杨斌

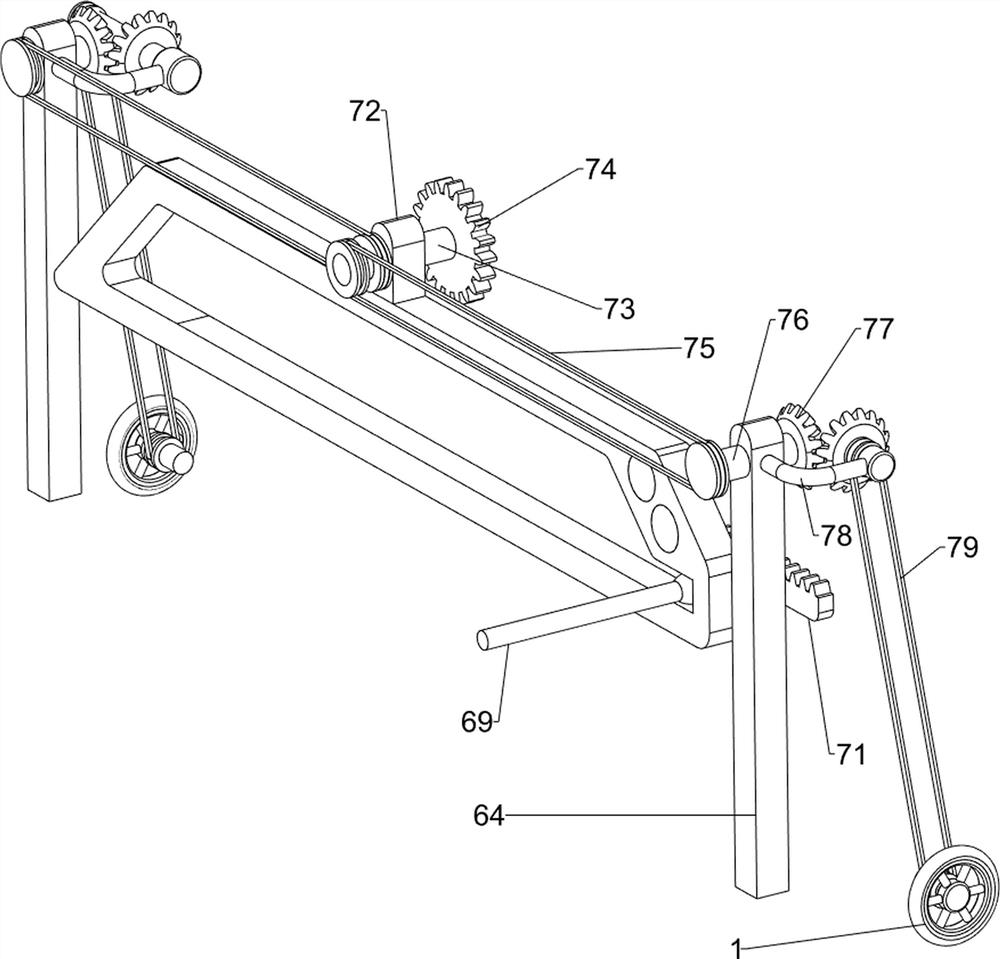

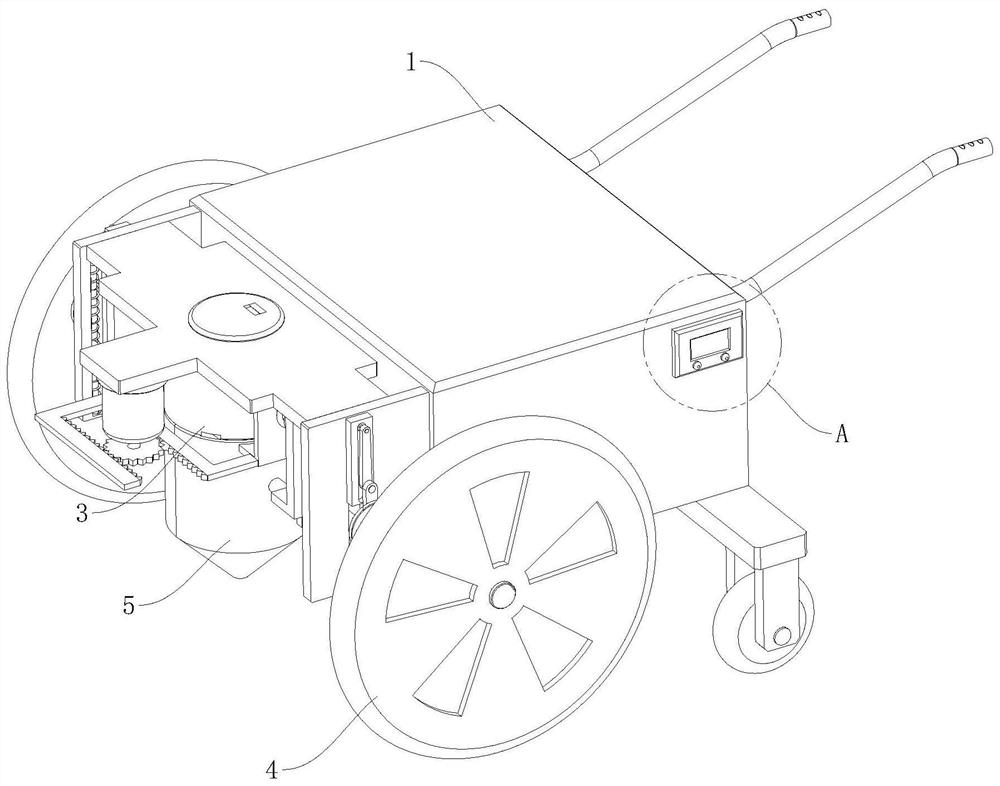

Galling device for paving cement road

ActiveCN112030679ASpecification of nap spacingSmooth textureRoads maintainenceStructural engineeringRoad surface

The invention relates to a galling device, in particular to a galling device for paving a cement road. According to the galling device for paving the cement road, provided by the invention, a cart isnot manually pushed by people, and the galling pattern is smooth and the quality is high. The galling device for paving a cement road comprises wheels and a mounting plate, and the wheels are arrangedon the mounting plate; the device also induces first brackets symmetrically arranged on the mounting plate, a mounting seat arranged on one of the first brackets. a moving mechanism arranged on the mounting plate, and a scraping mechanism arranged on the mounting plate. Through cooperation of the moving mechanism and the scraping mechanism, the scraping plate is driven to carry out galling treatment on the road surface, the galling distance is standard, and lines are smooth; and by arranging a walking mechanism, the walking mechanism is matched with the scraping mechanism; when the scraping plate moves upwards and is not in contact with the road surface, the walking mechanism drives the whole device to move to the next road surface needing galling, time and labor are saved, and the working efficiency is improved.

Owner:山东鹿德驰机械有限公司

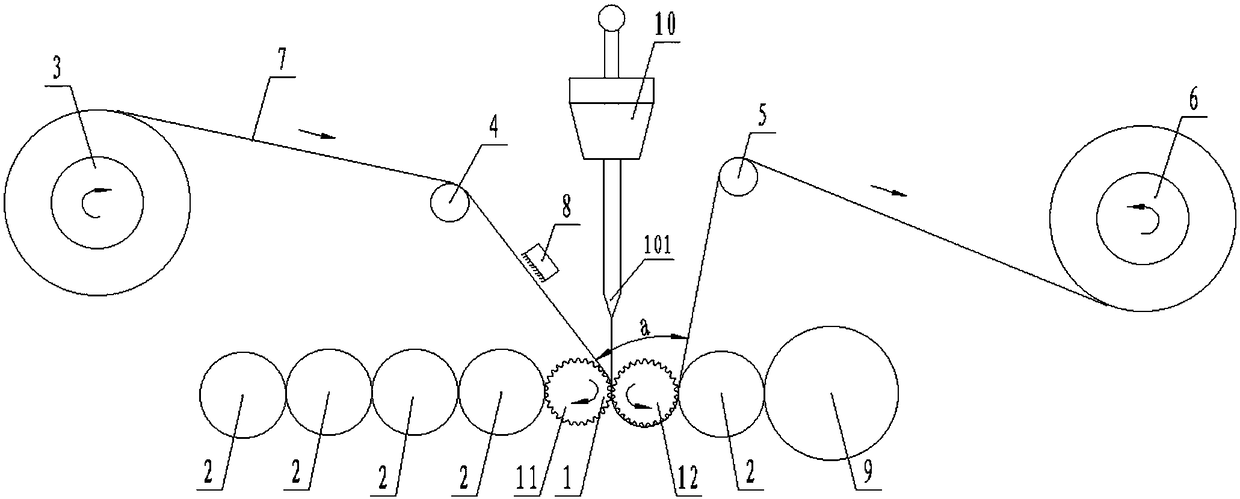

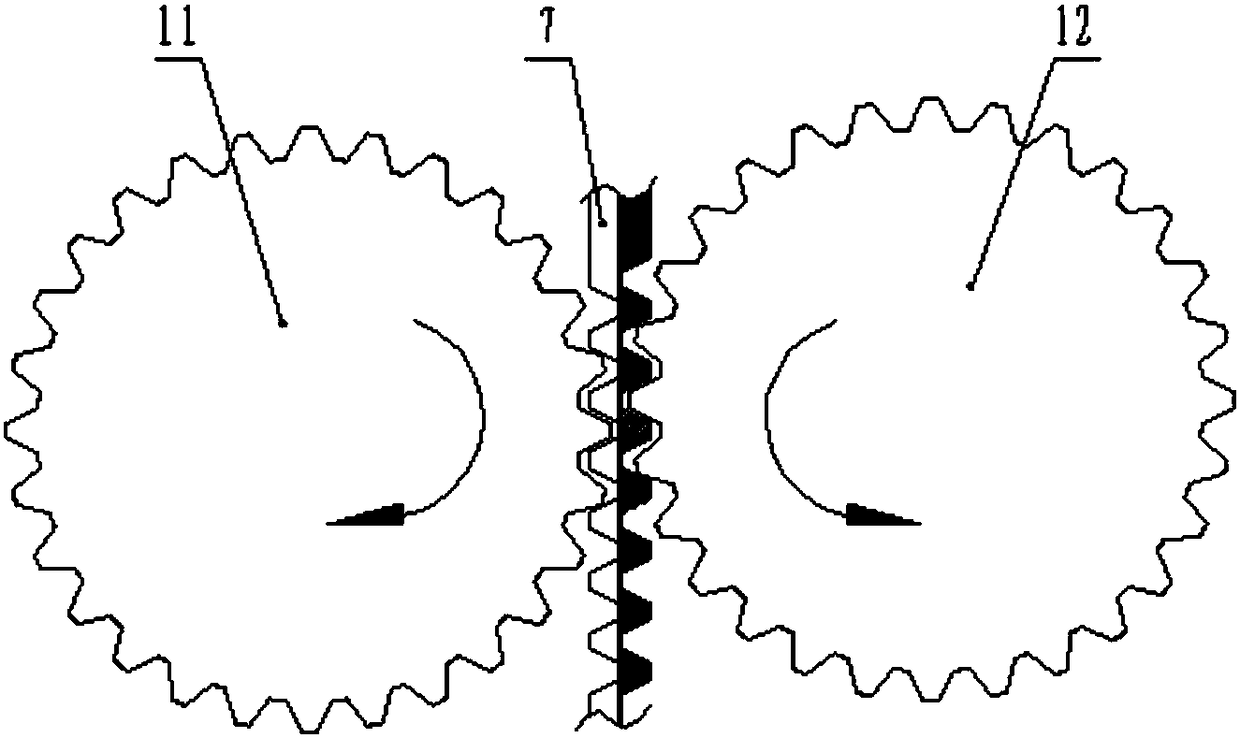

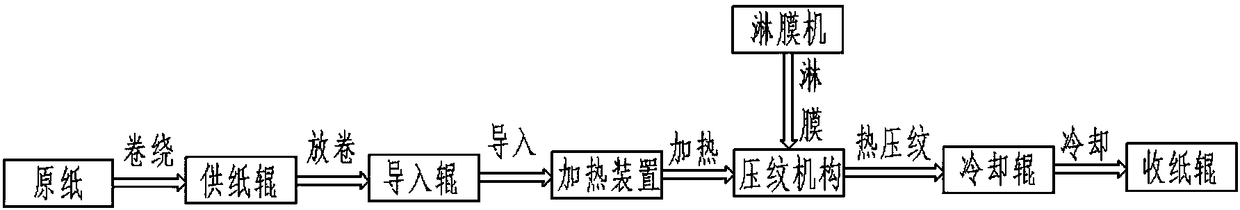

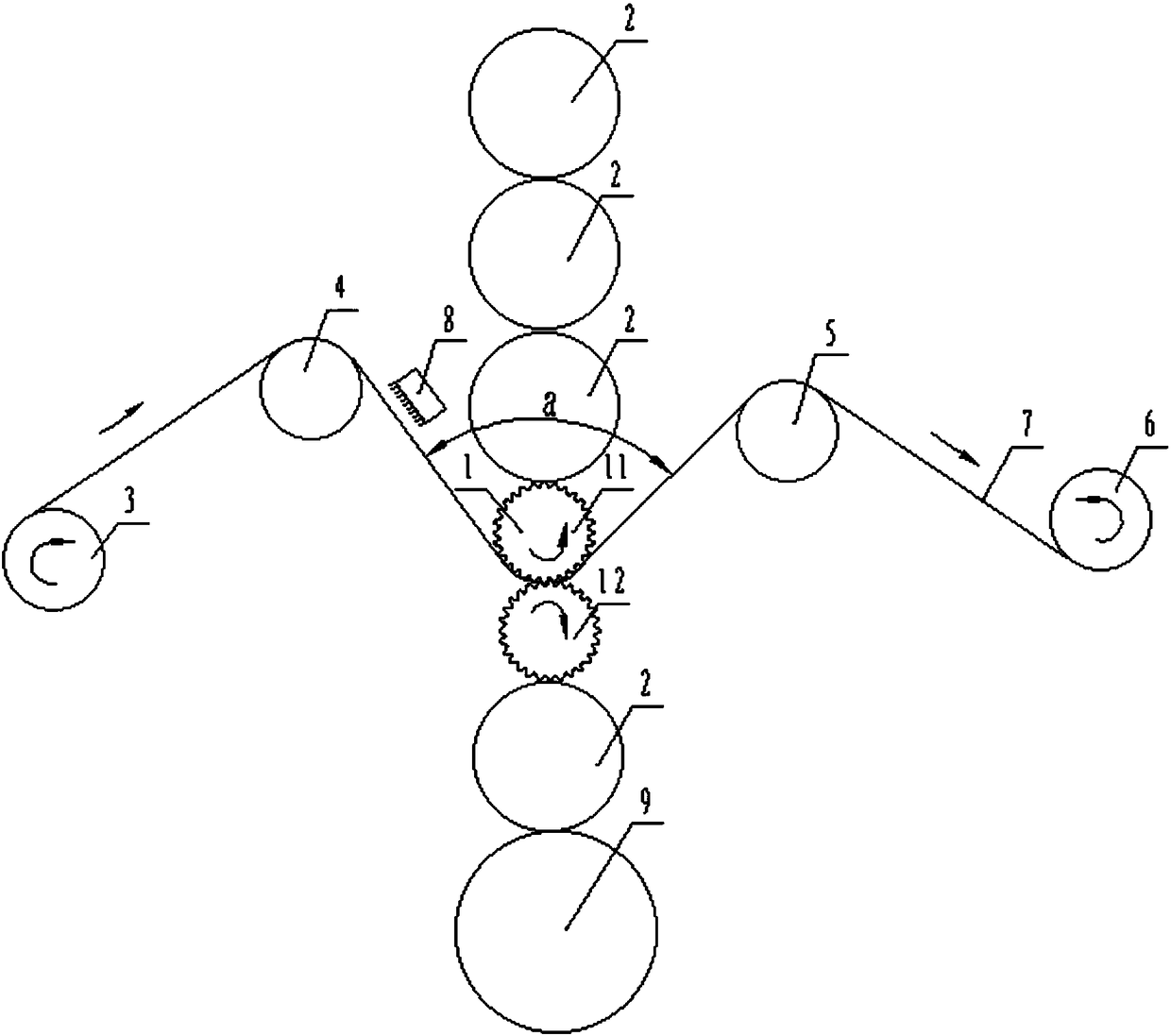

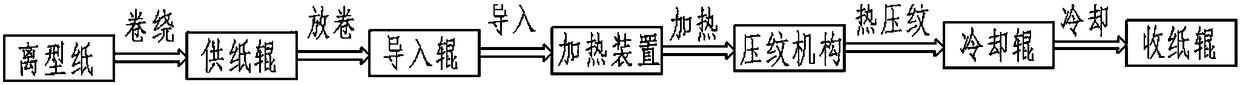

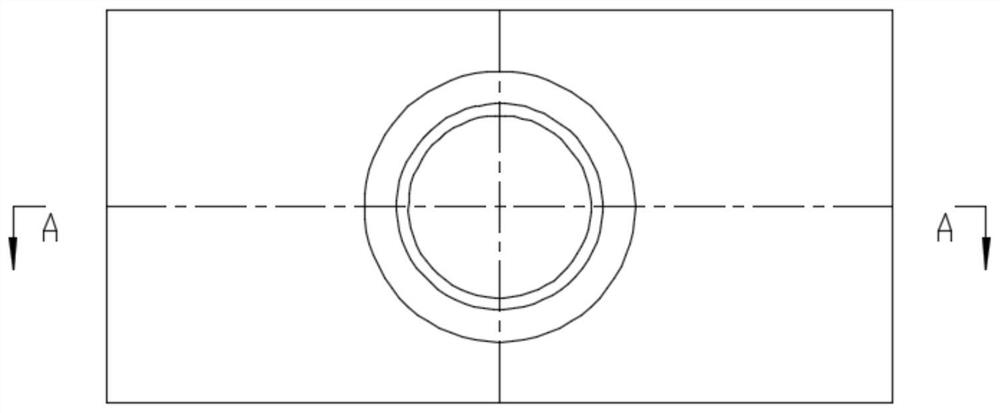

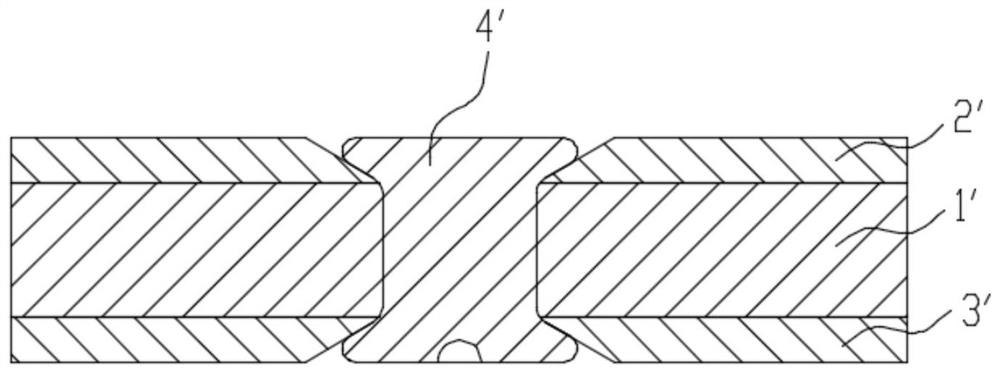

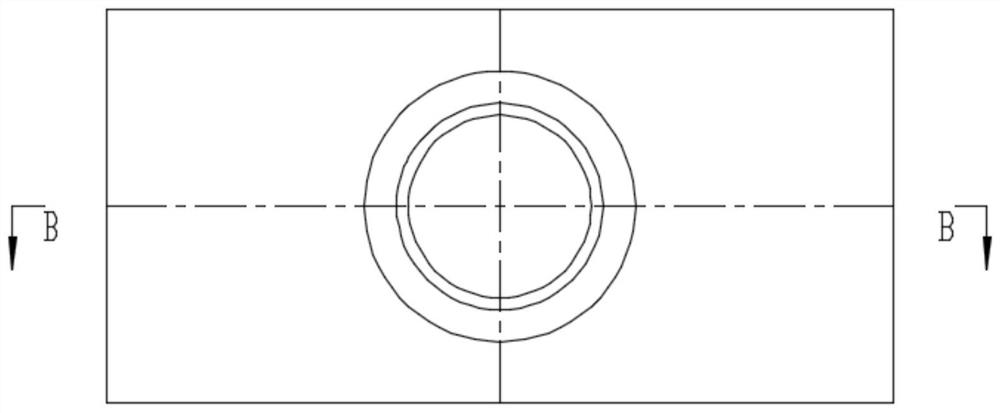

Online film-coating embossing device for raw paper and use method for online film-coating embossing device

InactiveCN108532368AQuality assuranceEasy to useMechanical working/deformationPaper/cardboardComing outPulp and paper industry

The invention discloses an online film-coating embossing device for raw paper. Raw paper is wound on a paper supplying roller, an introduction roller is arranged in front of an embossing mechanism, aheating device is arranged between the introduction roller and the embossing mechanism, a film coating machine is arranged just above the embossing mechanism, a cooling roller is arranged behind the embossing mechanism, paper comes out from the cooling roller and is wound and collected by a paper winding roller, and auxiliary rollers are arranged at the left and right of the embossing mechanism. Ause method of the online film-coating embossing device comprises the steps: the raw paper is wound on the paper supplying roller, is unwound through the paper supplying roller and is heated by the heating device, then, the heated raw paper is introduced into the embossing mechanism, the film coating machine carries out film coating on the raw paper, meanwhile, the embossing mechanism carries outdouble-sided thermal embossing on the raw paper, and then, the paper is cooled by the cooling roller and finally is wound and collected by the paper winding roller. According to the online film-coating embossing device for the raw paper, the coating quality is good, the coating is thin, the cost is low, the patterns are clear and uniform, the paper sheets are smooth, and the use performance of embossed release paper is improved. According to the use method for the online film-coating embossing device for the raw paper, the efficiency is increased, the coating quality is good, and the pattern forming is clear and uniform.

Owner:浙江池河科技有限公司

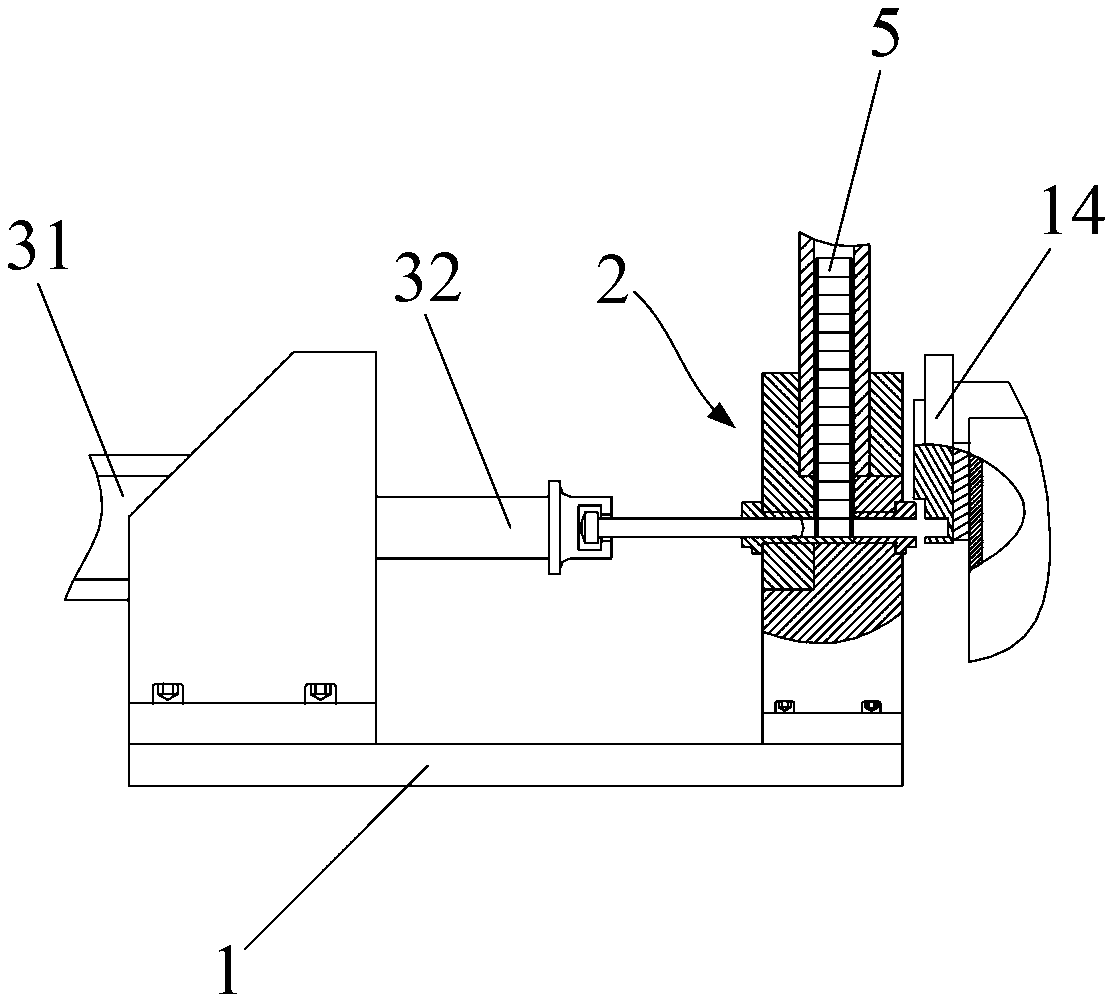

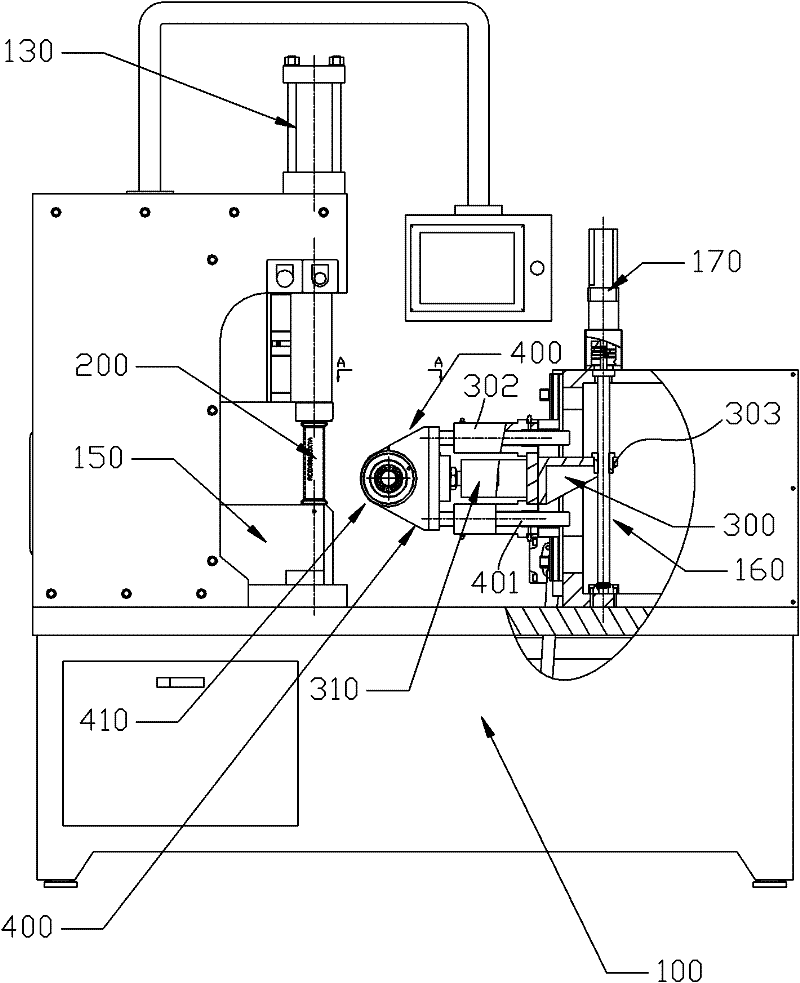

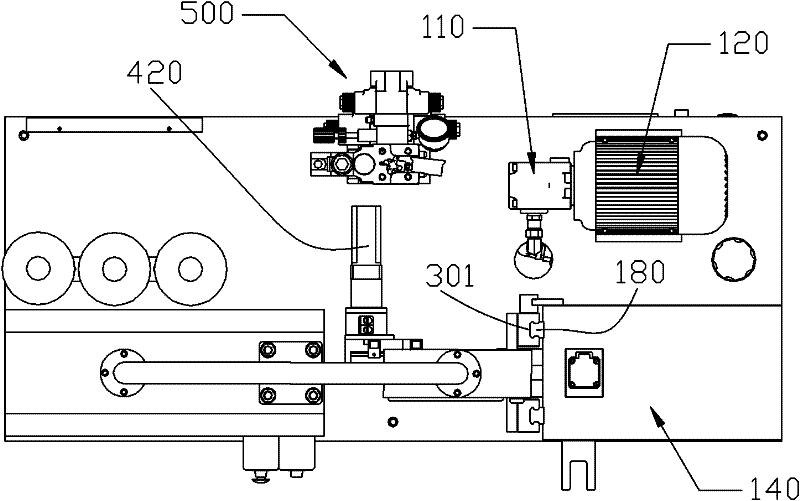

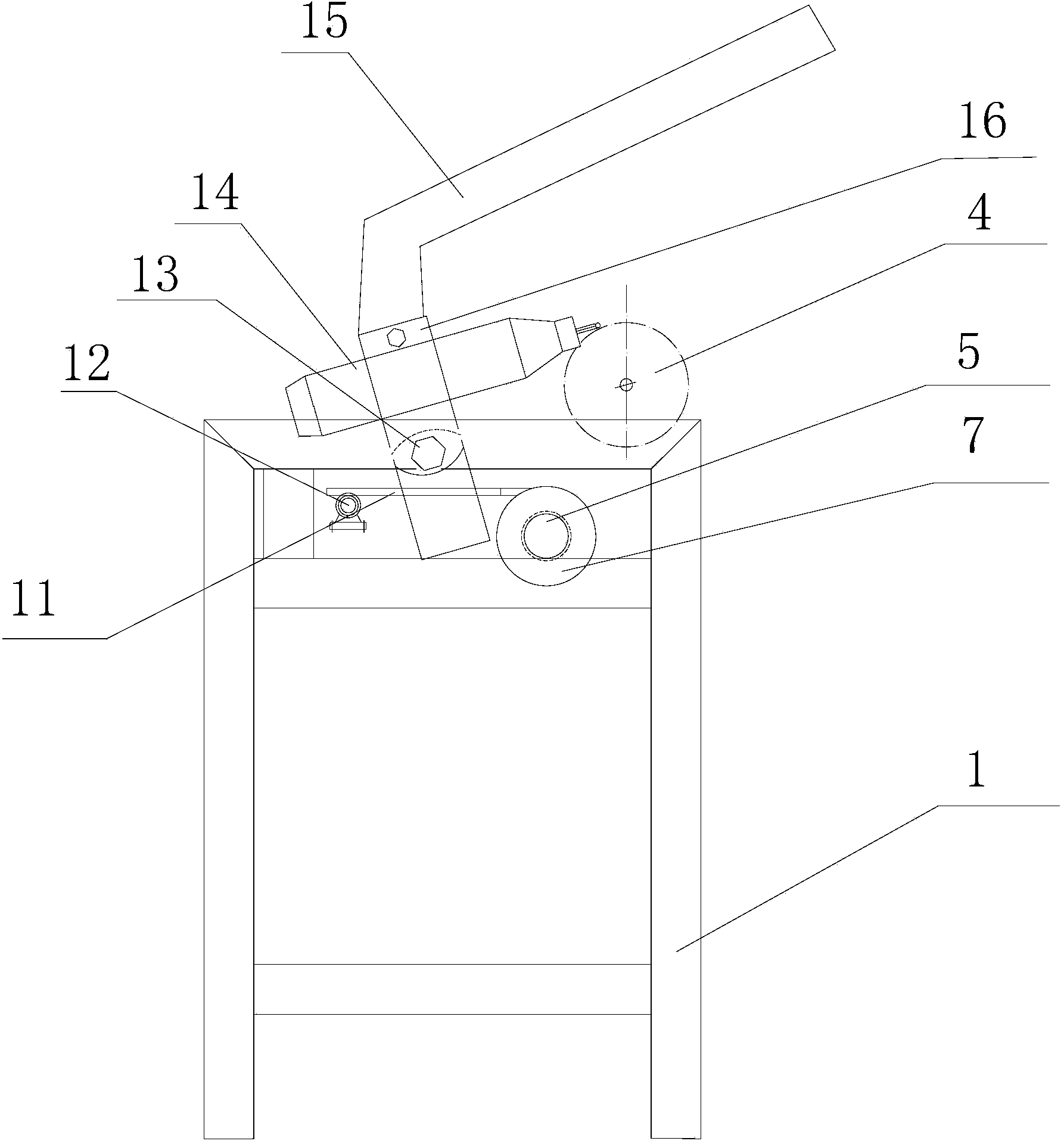

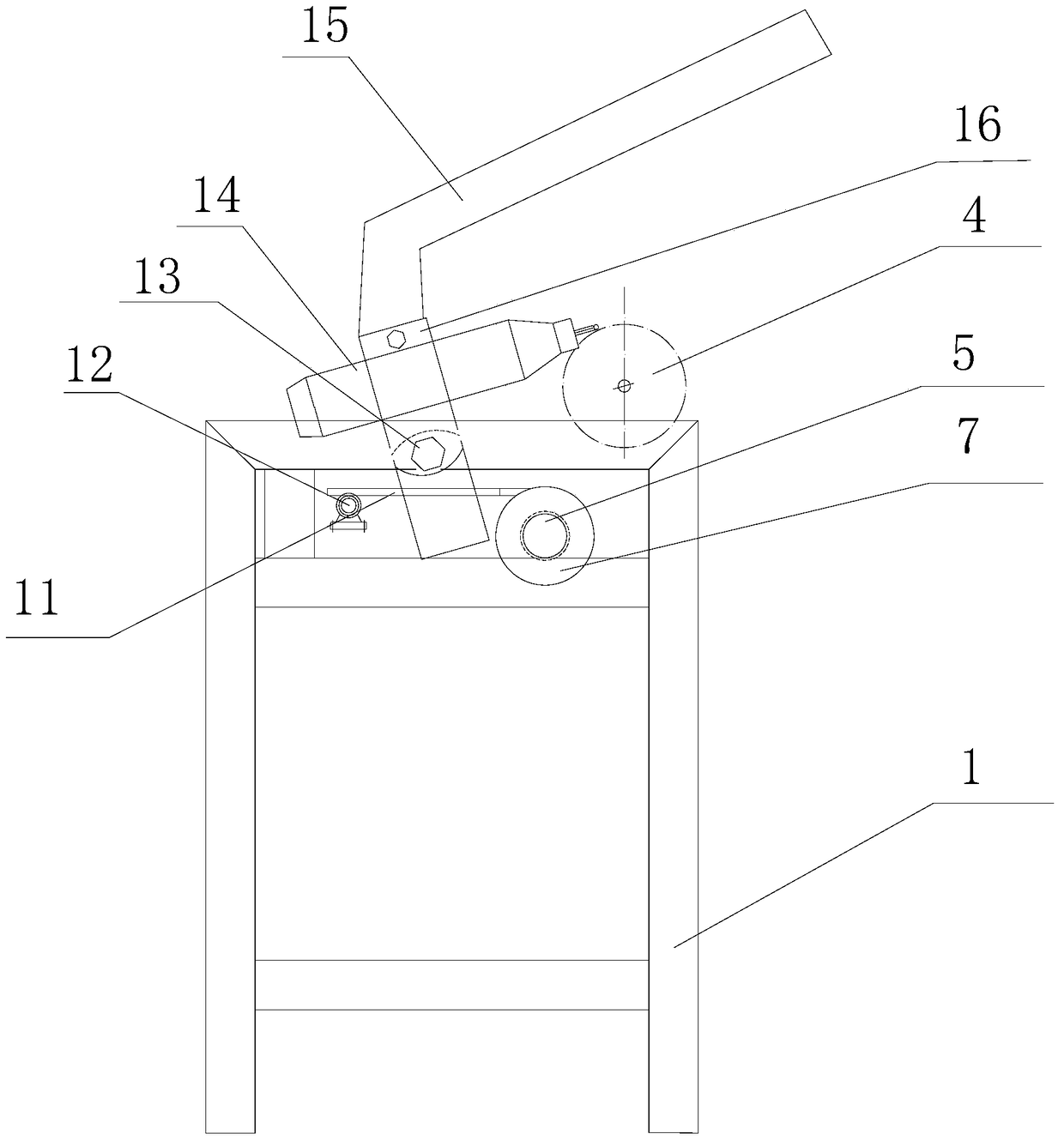

Motorcycle frame number code pressing machine and method

The invention relates to a motorcycle frame number code pressing machine and method. The code pressing machine comprises a code disc and a driving device for driving the code disc, wherein the code disc is provided with a plurality of steel seal matrixes, each steel seal matrix corresponds to a character, the driving device has multiple stamping pressure outputs, and each steel seal matrix corresponds to a preset stamping pressure according to the frontal projected area of the character of the steel seal matrix; and when number codes are stamped, each steel seal matrix performs the stamping operation with the preset stamping pressure, so that the depths of prints of codes formed by stamping of the steel seal matrixes are approximately consistent. The code pressing method is characterized in that: when number codes are stamped, each steel seal matrix performs the stamping operation with the preset stamping pressure according to the frontal projected area of the character of the steel seal matrix, so that the depths of prints of codes formed by stamping of the steel seal matrixes are approximately consistent. The code pressing machine and method provided by the invention can ensure that the depths of the prints of the codes obtained by stamping of the steel seal matrixes are approximately consistent, and frame numbers with consistent depths can be obtained.

Owner:SHENZHEN NEW CANGHAI MACHINERY

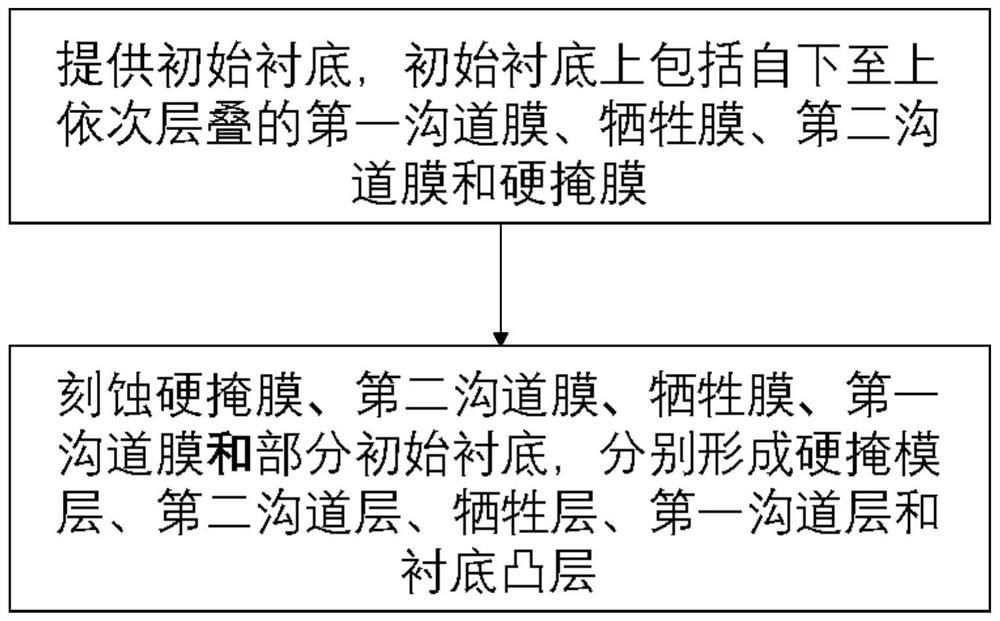

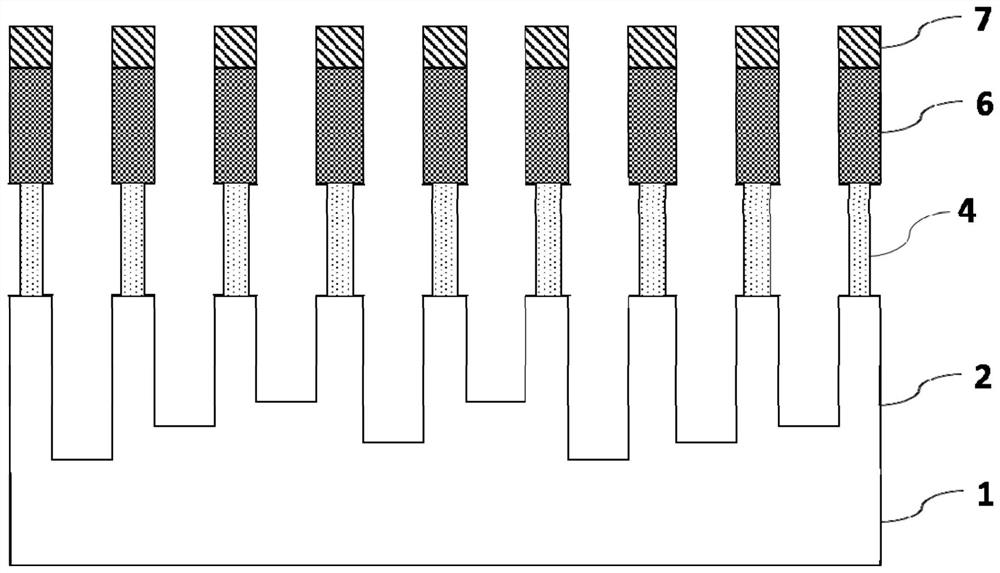

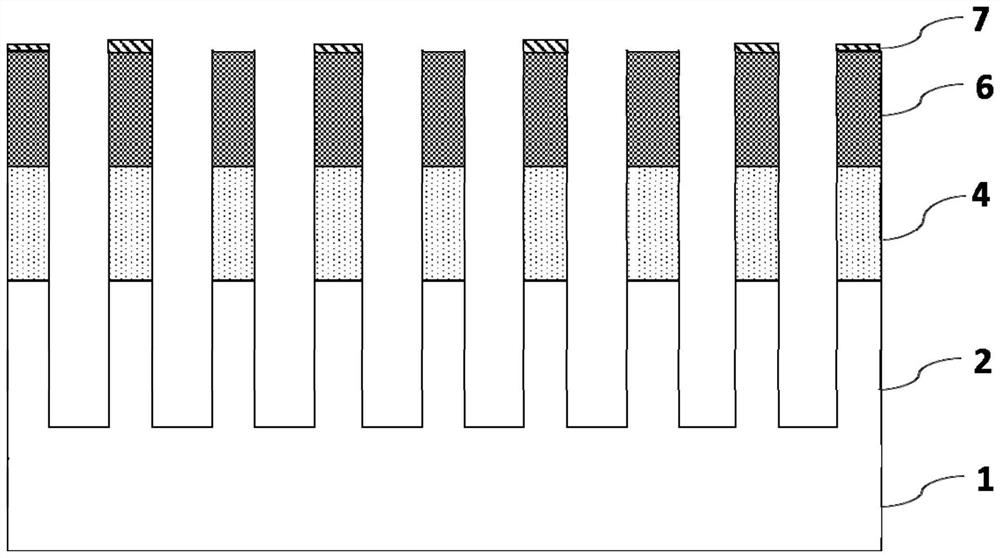

Semiconductor structure and forming method thereof

ActiveCN113539823AReduce typesRealize isolation protectionTransistorSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

The invention discloses a semiconductor structure and a forming method thereof. The method comprises the steps that: an initial substrate is provided, wherein the initial substrate comprises a first sacrificial film, a first channel film, a second sacrificial film, a second channel film and a third sacrificial film which are sequentially stacked from bottom to top; the third sacrificial film and the second channel film are etched until the surface of the second sacrificial film is exposed to form a third sacrificial layer and a second channel layer; a first protection layer is formed on the side wall of the second channel layer; the second sacrificial film and the first channel film are etched until the surface of the first sacrificial film is exposed to form a second sacrificial layer and a first channel layer; a second protection layer is formed on the side wall of the second channel layer, the side wall of the second sacrificial layer and the side wall of the first channel layer; and the first sacrificial film and a part of the initial substrate are etched to enable the first sacrificial film to form a first sacrificial layer. According to the semiconductor structure and the forming method thereof disclosed by the invention, the CFET manufacturing process is improved, and the performance of the semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

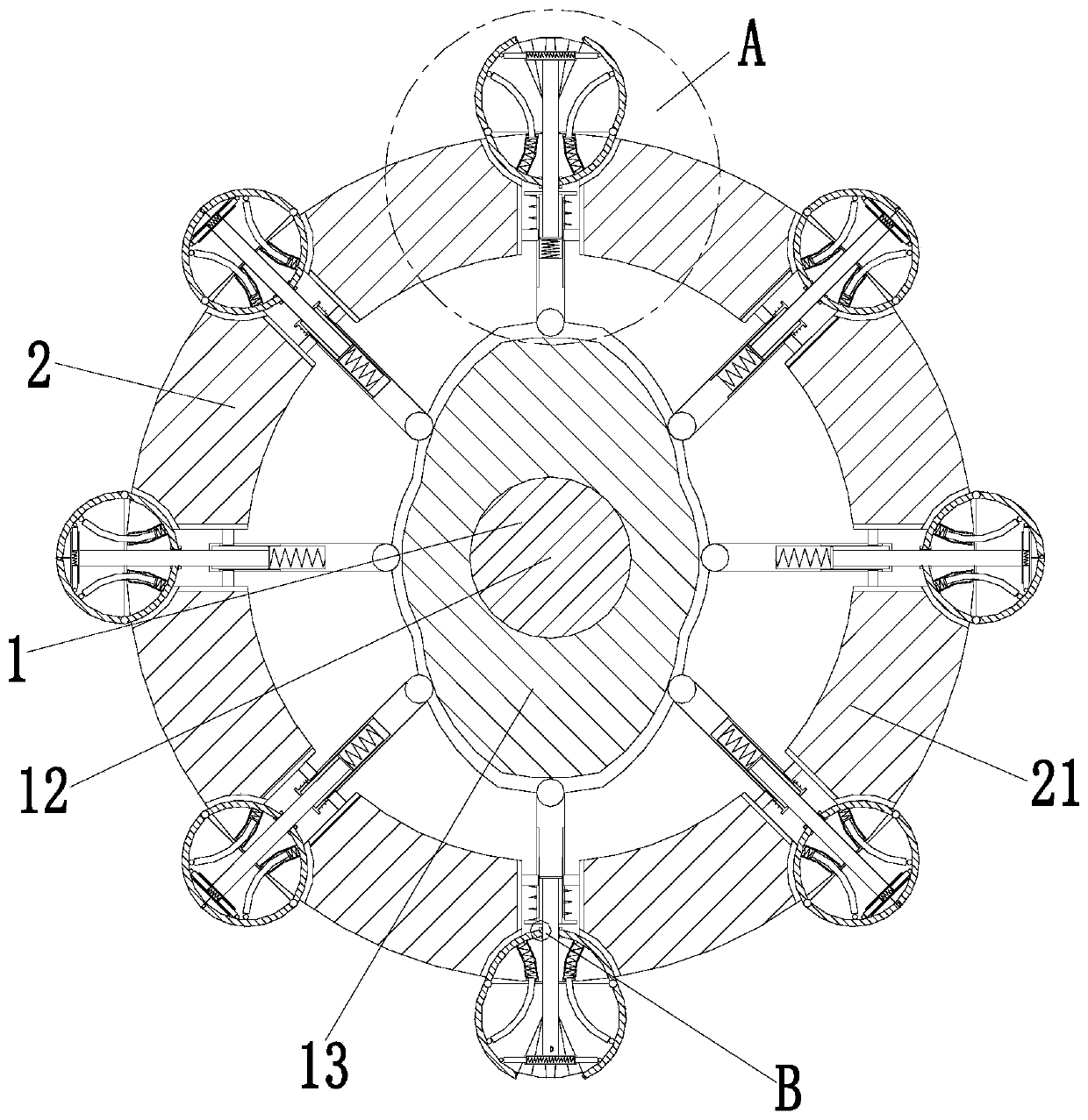

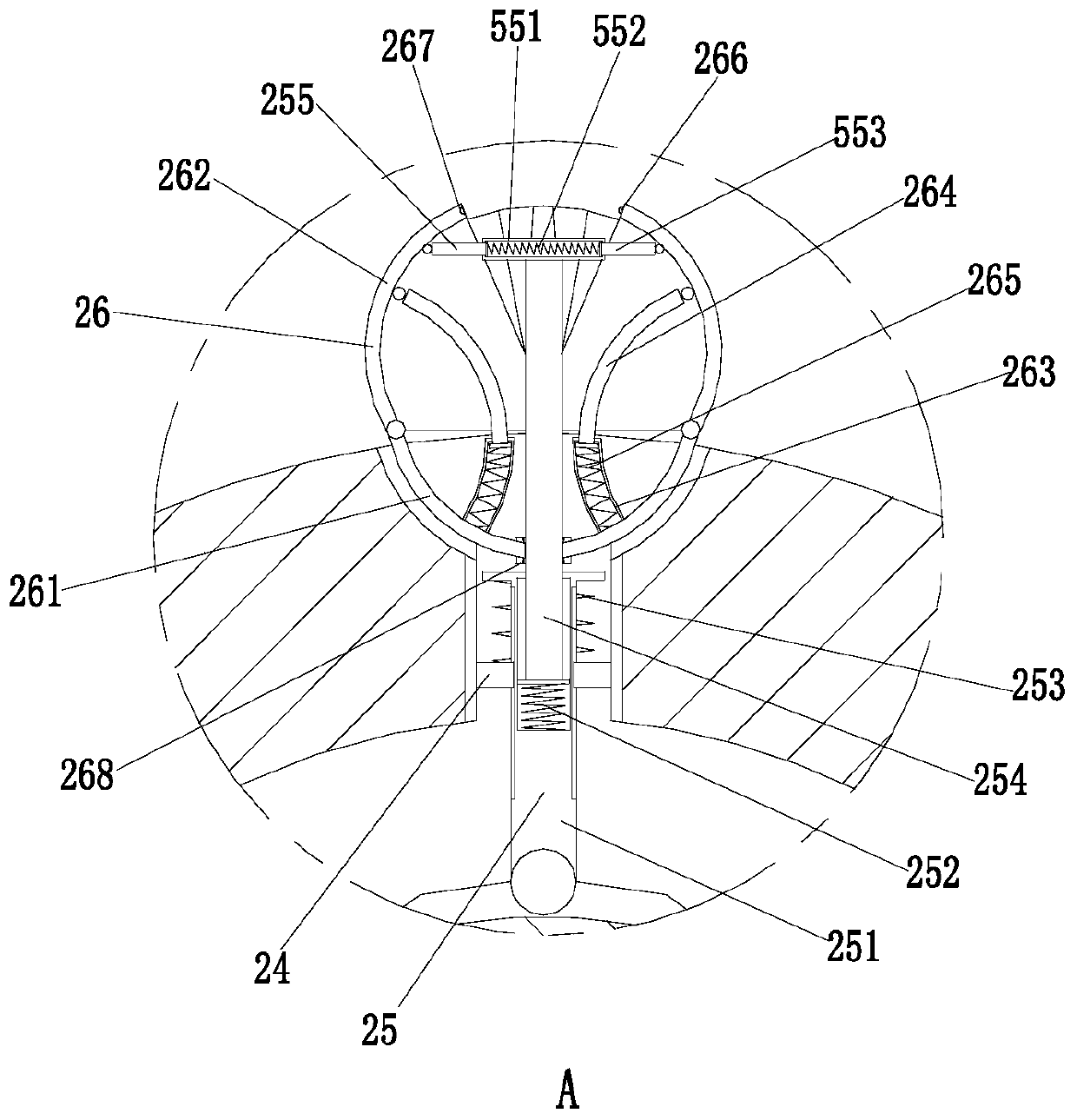

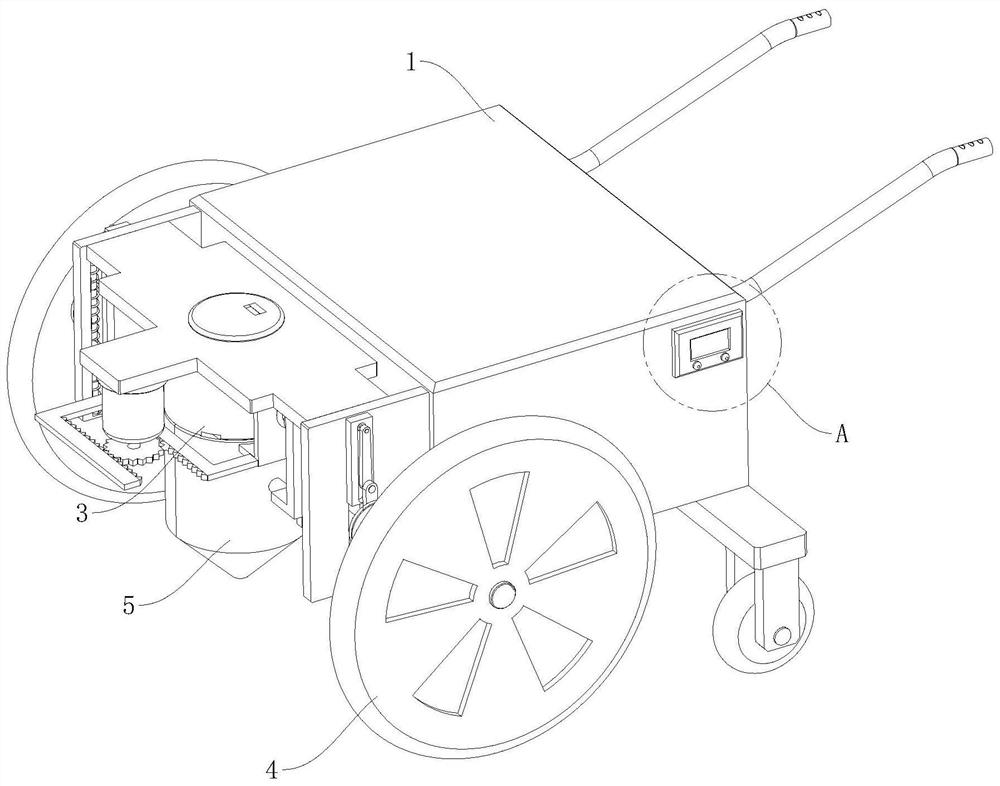

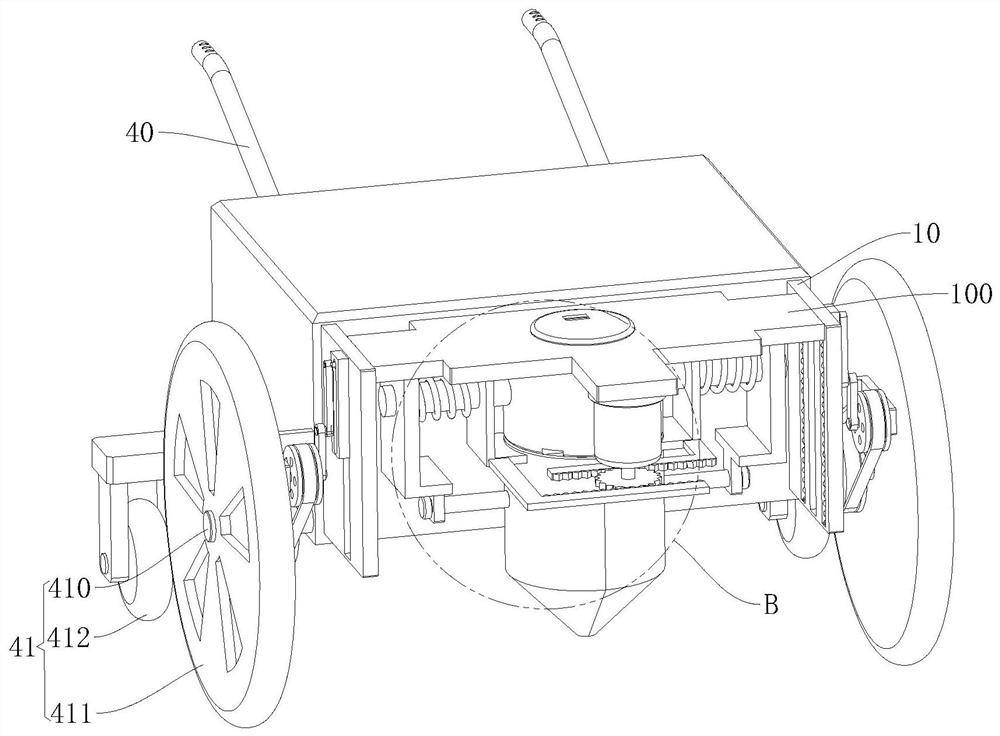

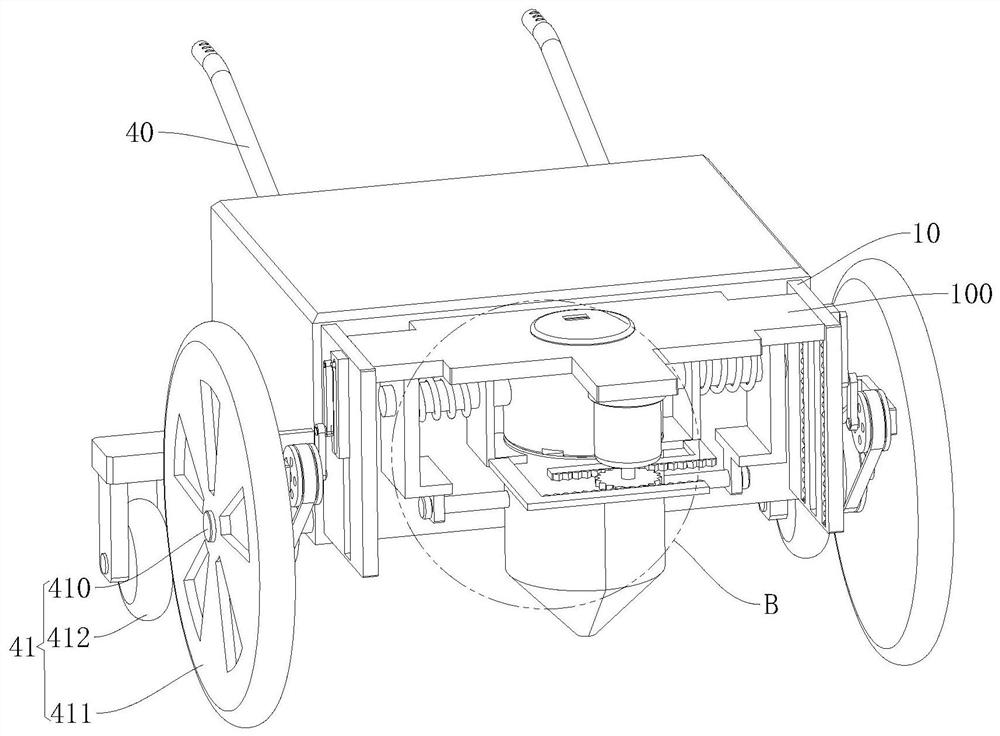

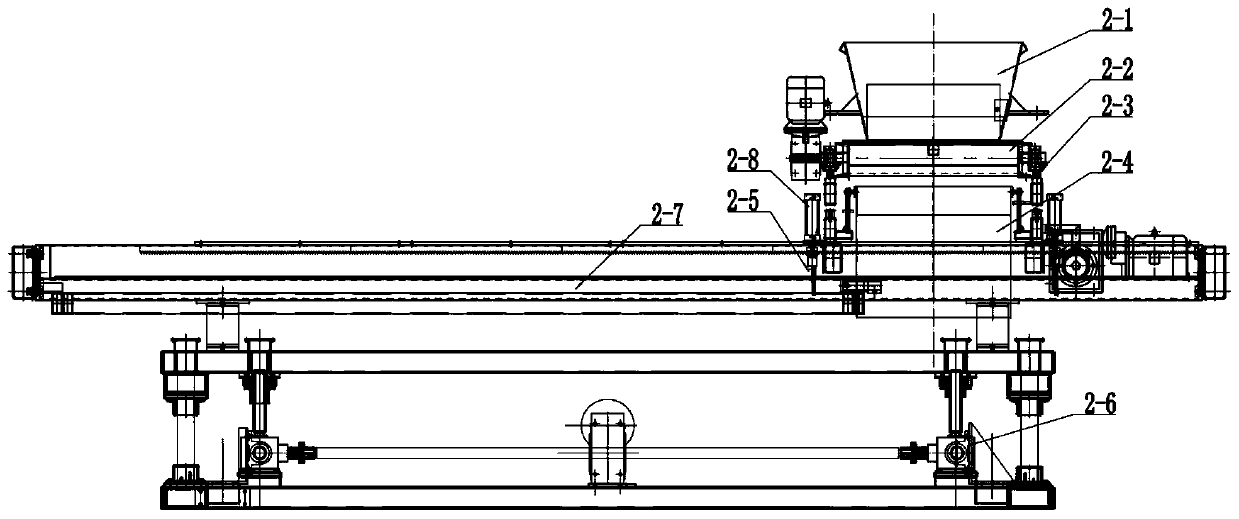

Agricultural sowing equipment

ActiveCN112772058AReduce labor intensitySame shadePlantingDibble seedersAgricultural scienceAgricultural engineering

The invention relates to the field of agricultural machinery, in particular to agricultural sowing equipment. The equipment comprises a vehicle body, a controller, a sowing mechanism, walking mechanisms and a soil expanding mechanism, the walking mechanisms are arranged on the two sides of the vehicle body to support the equipment to walk, and each walking mechanism comprises a push handle and a rolling assembly. The soil expanding mechanism is arranged at the bottom of the sowing mechanism and used for digging holes, the soil expanding mechanism comprises a driving assembly, two conical digging shovels, two transverse sliding assemblies and two longitudinal sliding assemblies, the sowing mechanism is arranged on the outer wall of the vehicle body and used for sowing seeds, and the sowing mechanism comprises a feeding assembly and a sensing assembly. The driving assembly, the sensing assembly and the controller are all electrically connected, according to the equipment, manual work is replaced, the seeding efficiency is high, quantitative seeding can be achieved, waste is avoided, the labor intensity is small, meanwhile, fixed-distance seeding can be achieved, crop growth and subsequent seedling transplanting are facilitated, and the seeding cost is conveniently reduced.

Owner:芜湖星之原工业设计有限公司

Glass scribing device

The invention provides a glass scribing device and solves the problems of low production efficiency and nonuniformity in spacing, thickness and depth of lines scribed on glass products in the prior art. The glass scribing device comprises a support and an engraving machine, a first motor and a second motor are disposed on the support, the first motor drives a rotating shaft to rotate, the rotating shaft is connected with a fixed plate which is connected with a locking plate, and a telescoping mechanism is arranged on one side of the locking plate and fixed onto the support. The engraving machine is disposed on a connection plate, one end of the connection plate is connected with a nut while the other end of the connection plate is connected with a guide rod which is arranged on the support through a bearing seat, the nut is matched with a screw rod which is driven by the second motor, and the engraving machine is connected with a position adjusting device. The glass scribing device has the advantages that the first motor controls rotation of glass products while the second motor drives the engraving machine to move horizontally, and consequently scribed lines are uniform in thickness and depth, and scribing within different diameter ranges of a same product can be realized; further, widths of the scribed lines are controllable, and tracing is not needed.

Owner:SHANXI DAHUA GLASS IND

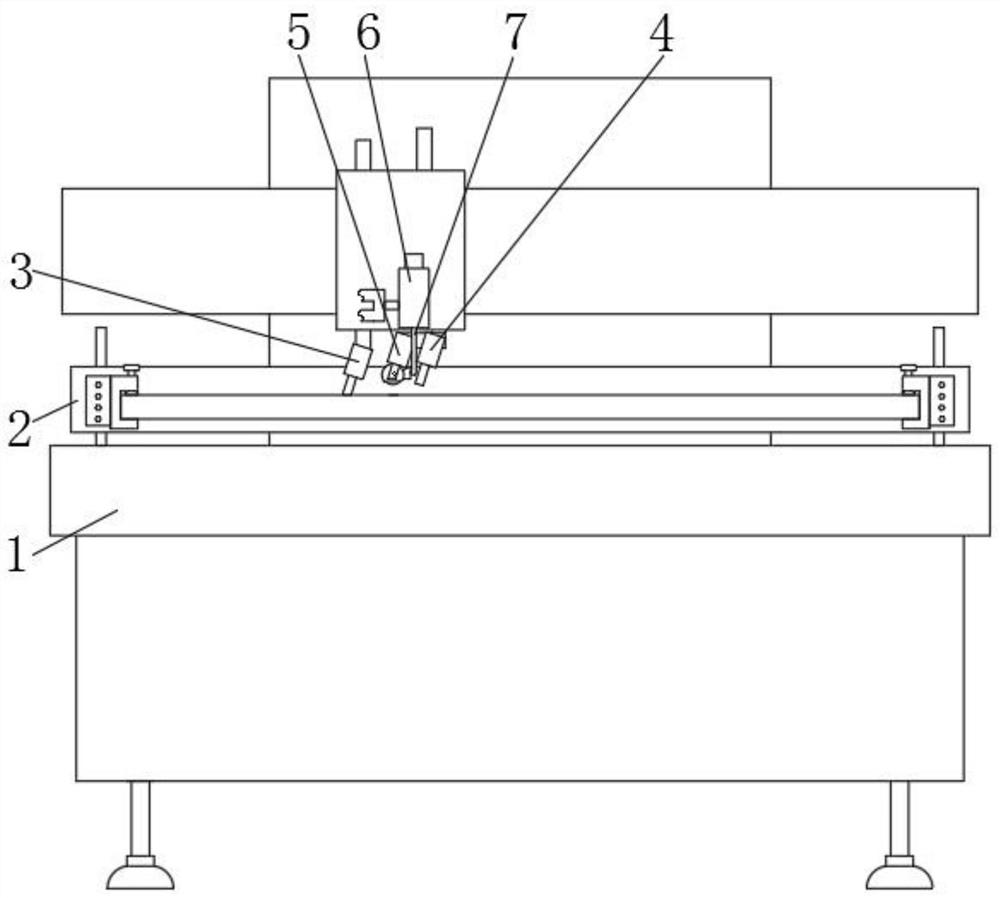

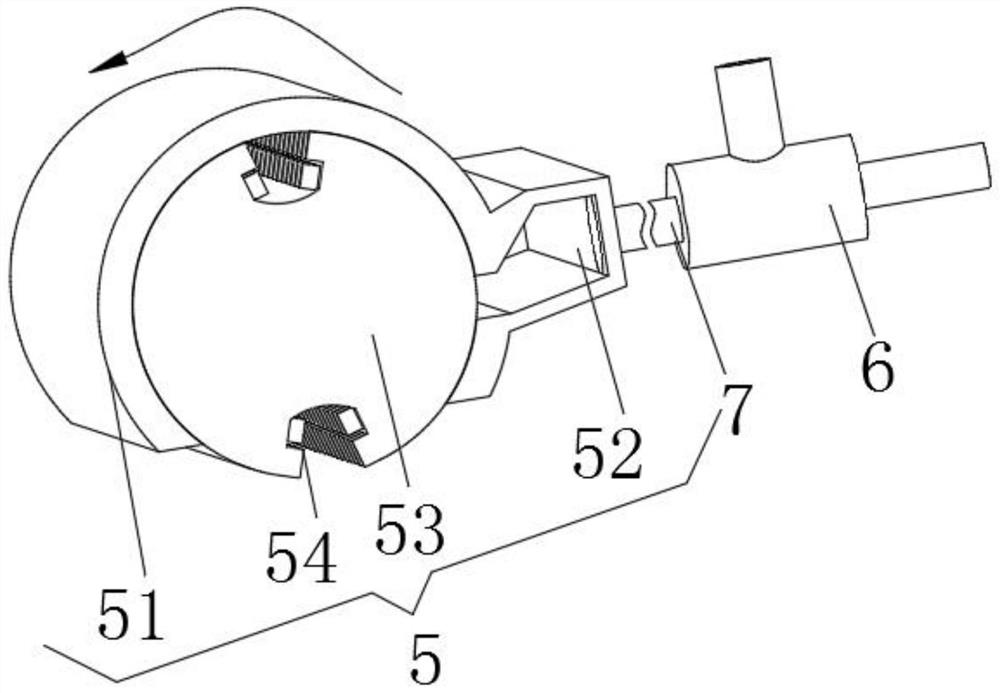

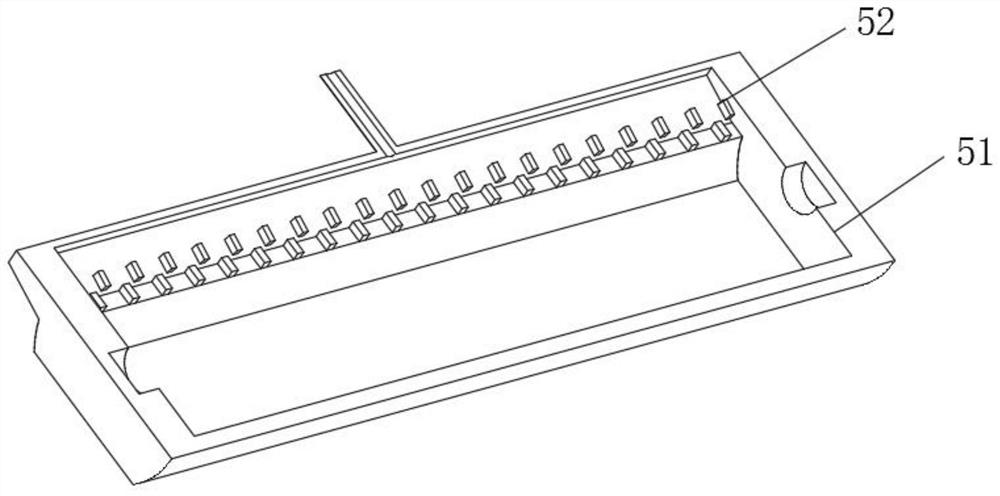

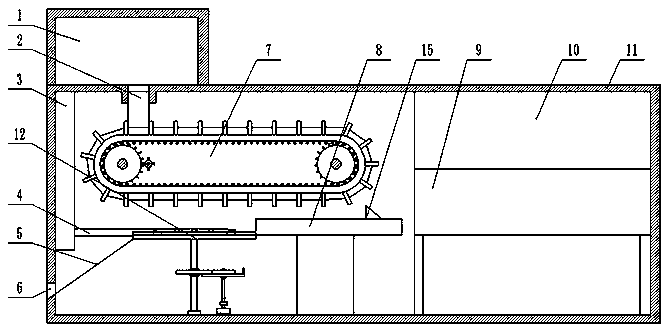

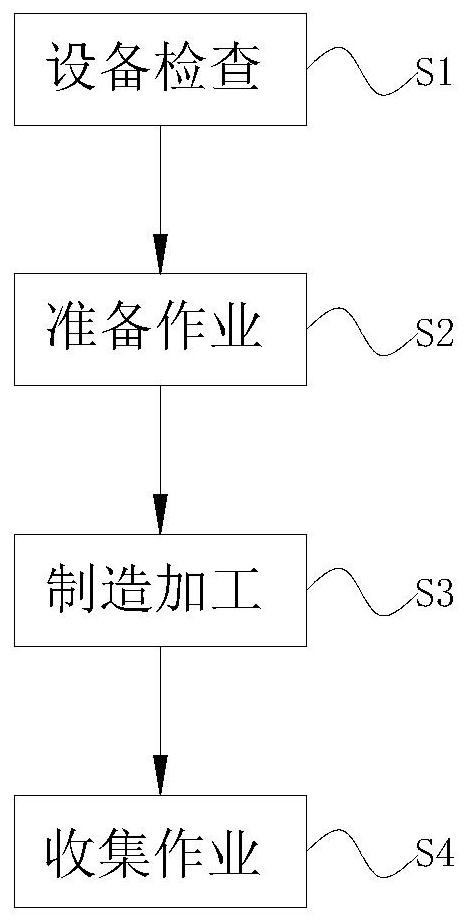

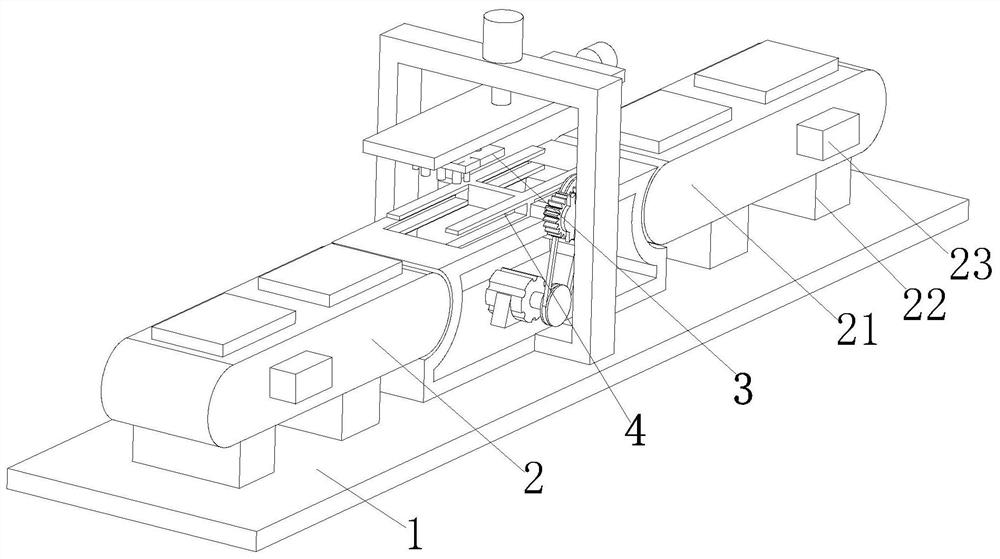

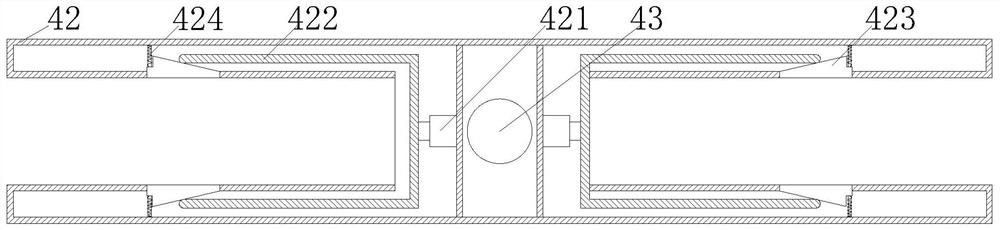

Flame-retardant waterproof sound-absorbing plate manufacturing and processing process

InactiveCN112518865AEfficient deliveryIncrease productivitySound proofingBuilding insulationsMachine buildingMachining process

The invention discloses a flame-retardant waterproof sound-absorbing plate manufacturing and processing process, and relates to the field of mechanical manufacturing and processing. The flame-retardant waterproof sound-absorbing plate manufacturing and processing process comprises a bottom plate, a conveying device, a processing device and a turnover device, wherein the conveying device is fixedlymounted on the bottom plate; the position, close to the middle part, of the conveying device is fixedly equipped with the processing device; and the turnover device is arranged below the processing device. The flame-retardant waterproof sound-absorbing plate manufacturing and processing process can effectively solve a slot line bending phenomenon when existing equipment forms slots, and also canguarantee consistent slotting depth, so that a processing qualification rate is further increased; and through efficient treatment of the turnover device, the yield can be greatly increased, so that production efficiency of the products is improved.

Owner:冒鹏飞

Release paper embossing device and embossing method thereof

InactiveCN108515735ALow costNot easy to curlMechanical working/deformationPulp and paper industryPaper sheet

The invention discloses a release paper embossing device. Release paper is arranged on a paper supply roller, a guide-in roller is arranged in front of an embossing mechanism, the embossing mechanismcarries out dual-face embossing on transmitted release paper, a heating device is arranged between the guide-in roller and the embossing mechanism, a transmission roller drives the embossing mechanismand an auxiliary roller, a cooling roller is arranged behind the embossing mechanism, and the release paper is guided out of the cooling roller and is wound and collected by a paper receiving roller.An embossing method of the release paper embossing device comprises the steps that the release paper is wound on the paper supply roller, the release paper is unwound through the paper supply roller,the heating device carries out heating, the paper is guided into the embossing mechanism to be embossed, the cooling roller caries out rolling, and finally, the paper is wound and collected by the paper receiving roller. According to the release paper embossing device, the release layer is subject to dual-face embossing, a coating layer is thin, the cost is reduced, figures are easily formed, thefigures are clear and uniform, and paper is flat; and according to the embossing method of the release paper embossing device, the release paper is subject to dual-face embossing, figure forming of the release paper is good, the figures are clear and uniform, a certain strength is kept for the paper, and the repeated use frequency is high.

Owner:浙江池河科技有限公司

A kind of agricultural seeding equipment

ActiveCN112772058BReduce labor intensitySame shadePlantingDibble seedersAgricultural scienceAgricultural engineering

The invention relates to the field of agricultural machinery, in particular to an agricultural seeding device, which includes a body, a controller, a sowing mechanism, a traveling mechanism and a soil expansion mechanism. The mechanism includes a push handle and a rolling assembly. The soil expansion mechanism is located at the bottom of the spreading mechanism for digging holes. The soil expansion mechanism includes a drive assembly, two conical excavating shovels, two lateral sliding assemblies and two longitudinal sliding assemblies. , the sowing mechanism is arranged on the outer wall of the vehicle body for sowing seeds, the sowing mechanism includes a feeding component and an induction component, and the driving component and the induction component are electrically connected to the controller. The present invention relates to an agricultural The seeding equipment, instead of labor, has high seeding efficiency, can achieve quantitative seeding, avoid waste, and has less labor intensity.

Owner:芜湖星之原工业设计有限公司

Track type greenhouse tunnel furrowing machine

The invention relates to agricultural machinery, in particular to a track-type greenhouse arch shed ditching machine; it solves the problem of high labor intensity and low efficiency of manpower ditching by vegetable farmers; it includes a track frame, and the four corners of the track frame have lifting sleeves, which are movable on the vertical pipes , a thin tube is inserted in the tube, and the lower end of the thin tube is equipped with a universal wheel (the rear wheel of an electric vehicle can be used); the upper part of the vertical tube is equipped with a two-way deceleration small motor, and the gear of the small motor is engaged with the lifting drive wheel to drive the traction sheave. The rail frame is raised or lowered; the ditch opener main shaft frame is installed on the track, and two ditch shares are installed on it, and the rotation power is provided by the diesel engine through the clutch and gearbox device and the conveyor belt; The sprocket set has a chain above the track, which is engaged with the sprocket. When the main shaft of the ditching splitter rotates, it drives the sprocket to rotate. Through the action of the sprocket and the chain, it moves in the track frame and simultaneously opens two grooves; press the motor power The switch can make the trencher lift and shift; there is a level on the track frame.

Owner:郭兆岗

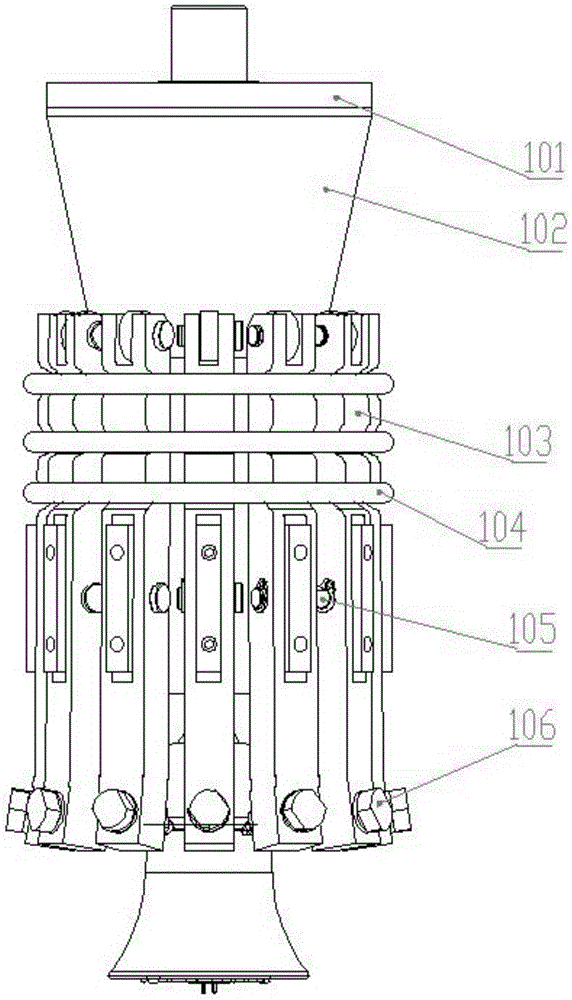

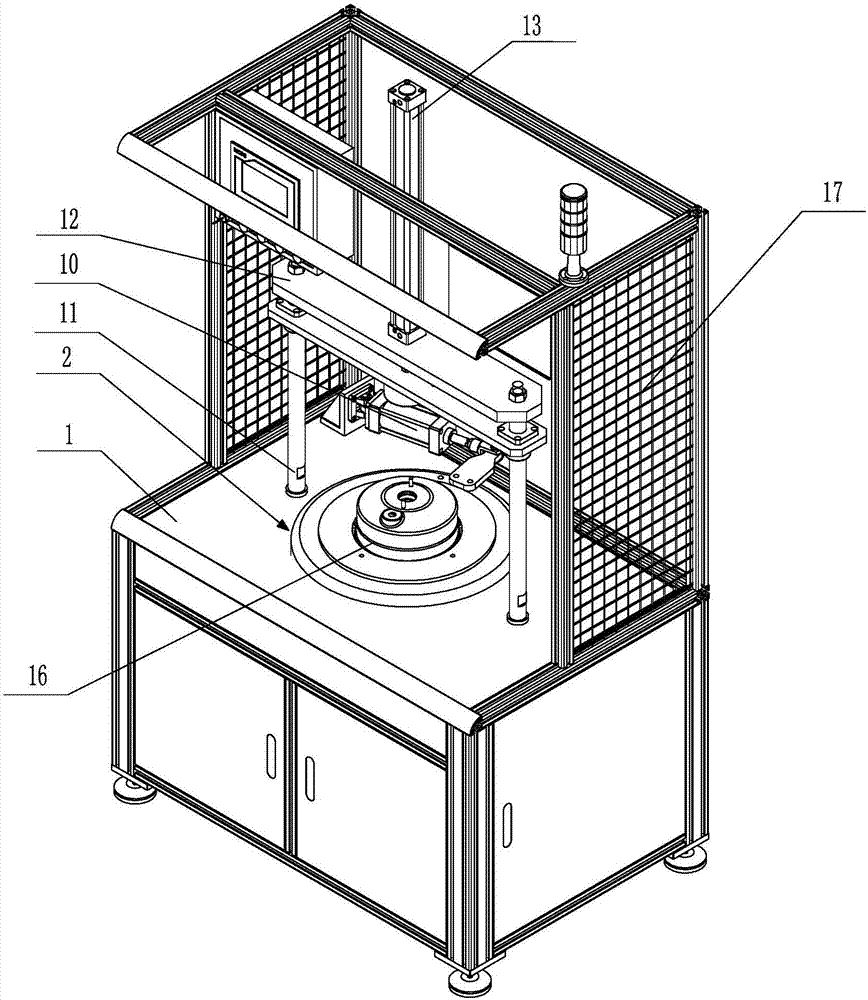

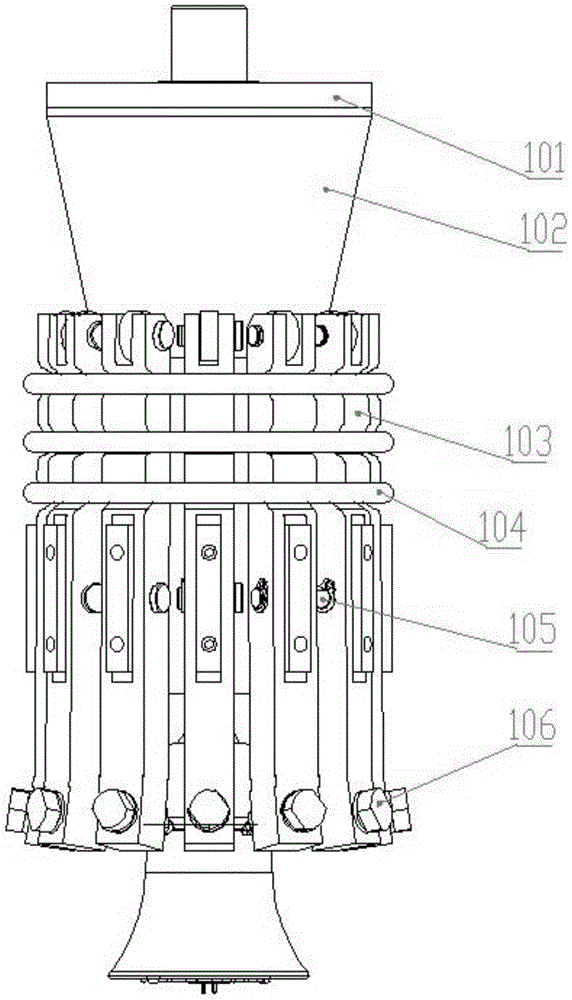

Automatic lamp holder riveting pressure device

The invention discloses an automatic lamp holder riveting pressure device, belongs to the field of mechanical machining equipment, and relates to a riveting mechanism. The automatic lamp holder riveting pressure device comprises a polyformaldehyde sleeve, a conical table, long-bar-shaped levers, a tension spring, round pins, riveting pins, a fixing shaft seat and small blocks, wherein the polyformaldehyde sleeve is fixedly connected with the conical table, the upper end of the fixing shaft seat is sleeved with the polyformaldehyde sleeve, the small blocks are fixedly arranged on the fixing shaft seat, each round pin is formed in the middle of corresponding small block, each corresponding long-bar-shaped lever is hanged on corresponding round pin, the lower end of each long-bar-shaped lever is fixedly provided with the corresponding riveting pin, and the upper end of each long-bar-shaped lever is wrapped and sleeved with the small extension spring. The automatic lamp holder riveting pressure device can provide a certain holding force for a lamp holder to make the depths of riveting points have no difference and make the riveting points be distributed uniformly during riveting pressure of the riveting pins; meanwhile the riveting pins can be stable when the riveting pin riveting pressure is turned on, and excursion of the lamp holder driven by the riveting pins is avoided.

Owner:MAANSHAN LIANBANG INTELLIGENT EQUIP

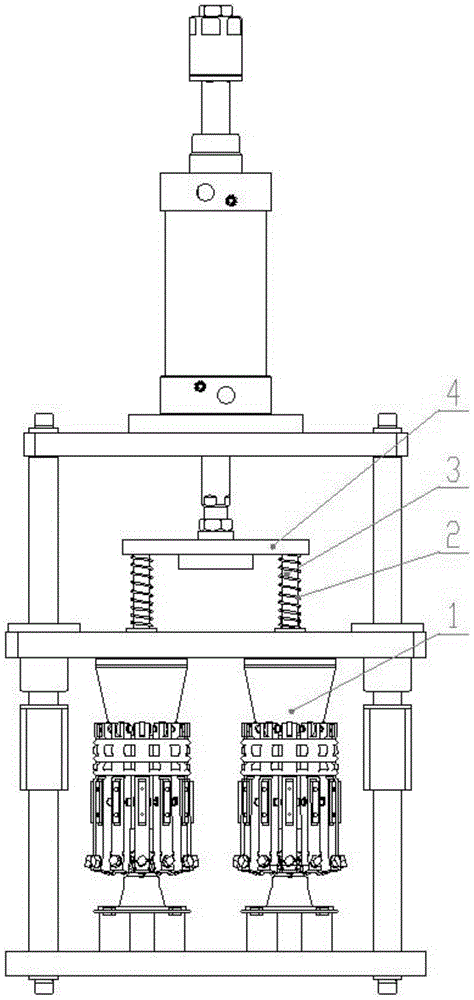

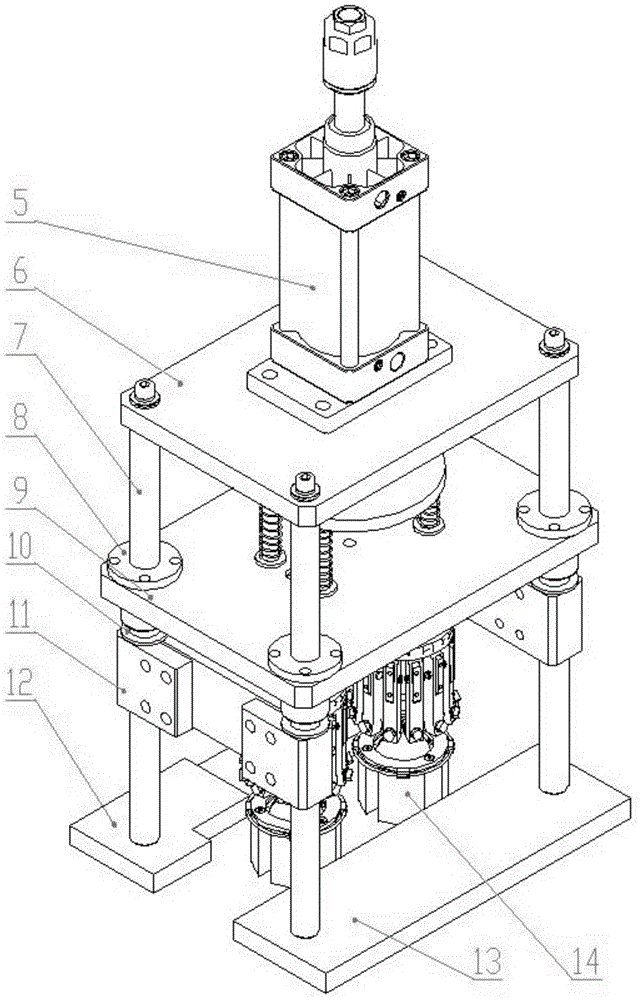

A special machine for automatic lamp cap riveting

The invention discloses a special and automatic lamp holder point riveting machine, belongs to the field of machining equipment, and relates to a lamp holder riveting machine. The special point riveting machine comprises a rivet pressing device, compression springs, connecting rods, a connecting disk, a cylinder, a top plate, stand columns, a lifting plate, limiting clamping plates, a front bottom plate and a rear bottom plate, wherein the rivet pressing device comprises a polyformaldehyde sleeve, a conical platform, long-strip-shaped levers, small tension springs, round pins, riveting needles, a fixing shaft base, small square blocks and a small compression spring, the polyformaldehyde sleeve and the conical platform are connected and arranged on the upper portion of the fixing shaft base in a sleeving mode, the round pins penetrate through the middles of the small square blocks fixed by the fixing shaft base, the long-strip-shaped levers are hung on the round pins, the riveting needles are fixed to the lower ends of the long-strip-shaped levers, the upper portions of the long-strip-shaped levers are sleeved with the small tension springs, the polyformaldehyde sleeve, the connecting rods and the connecting disk are fixedly connected with a cylinder piston, the compression springs penetrate through the middles of the connecting rods, and the fixing shaft base is fixed to the lifting plate. Through the special machine, riveting points are unified and uniform in depth, bad products are reduced, the structure of the machine is simplified, and meanwhile the machine adapts to assembly line conveying and improves riveting efficiency.

Owner:MAANSHAN LIANBANG INTELLIGENT EQUIP

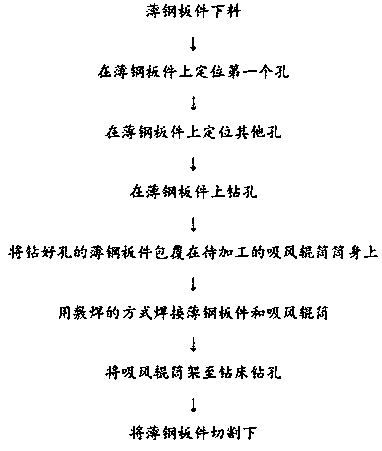

Manufacturing process of air suction holes of roller body of air suction roller

The invention discloses a manufacturing process of air suction holes of a roller body of an air suction roller, and relates to the field of mechanical drilling. The manufacturing process comprises thefollowing steps that according to the length and the diameter of the roller body of the air suction roller, blanking is carried out on a thin steel plate part; the position of the first air suction hole on the thin steel plate part is positioned; according to the product machining requirement, the positions of other holes are positioned; the needed holes are drilled in the thin steel plate part by using a drilling device; the thin steel plate part is coated on the roller body of the air suction roller to be machined; the thin steel plate part is enabled to be tightly attached to the roller body of the air suction roller by using a surfacing welding mode; then the air suction roller is erected to a drilling bed, and drilling is sequentially carried out according to the holes in the thin steel plate part; and after drilling is completed, the thin steel plate part is detached. According to the manufacturing process of the air suction holes of the roller body of the air suction roller, the requirement for the position degree of the air suction holes and an air guide groove is met, and the quality of the drilled holes is guaranteed.

Owner:如皋市昌旭机械制造有限公司

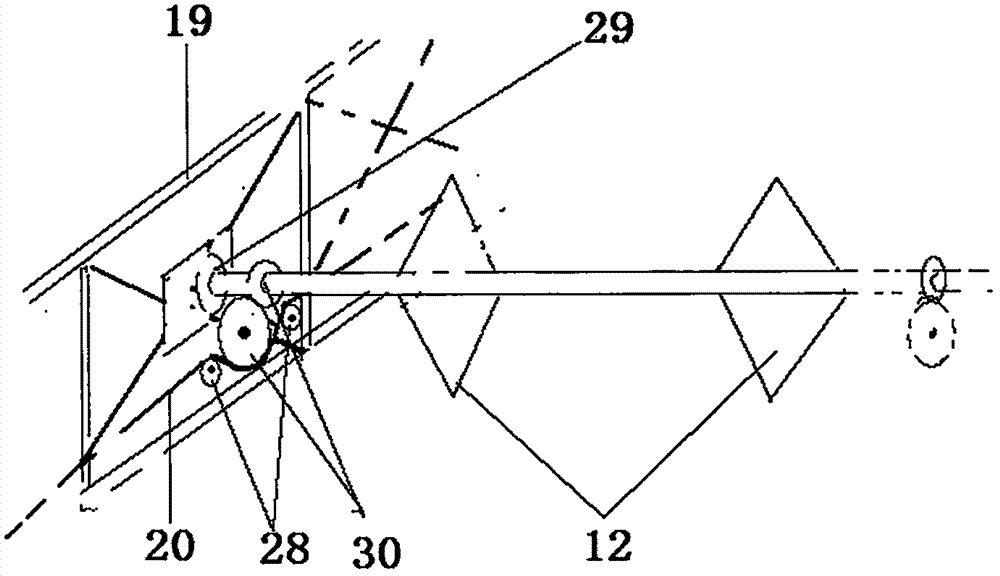

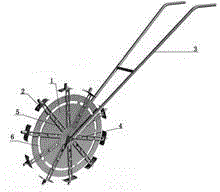

Adjustable seed-production and film-breaking cave digging device

InactiveCN105379473AUniform spacingSame shadePlantingFurrow making/coveringRolling diskAgricultural engineering

The invention provides an adjustable seed-production and film-breaking cave digging device, and relates to an agricultural tool, which comprises three parts such as a rolling disk frame, cave digging devices and pushing rods, wherein the pushing rods are connected to the rolling disk frame through a rotation shaft, the groove hole adjusting bracket on the cave digging device is fixedly arranged on the rolling disk frame through round hole openings and adjusting hole grooves, the circle center position of the rolling disk frame is provided with the rotation shaft, the round hole openings distributed in a round and dispersed manner are designed by adopting the circle center on the rolling disk frame as the fixed point, the outer edge position of the rolling disk frame is provided with the adjusting hole grooves distributed in an annular and dispersed manner, the cave digging device comprises three parts such as a hole digging cylinder, an arc baffle and the groove hole adjusting bracket, the convex surface of the arc baffle is fixedly connected to the hole digging cylinder, and the concave surface is fixedly connected to the groove hole adjusting bracket. With the adjustable seed-production and film-breaking cave digging device of the present invention, the characteristics of uniform plant interval, same depth, and rapid and regular seedling emergence of seed production crops can be achieved, the technical problems of seedling deficiency and non-uniform seedling size of seed production crops are effectively solved, and the seed production risk is substantially reduced.

Owner:杨斌

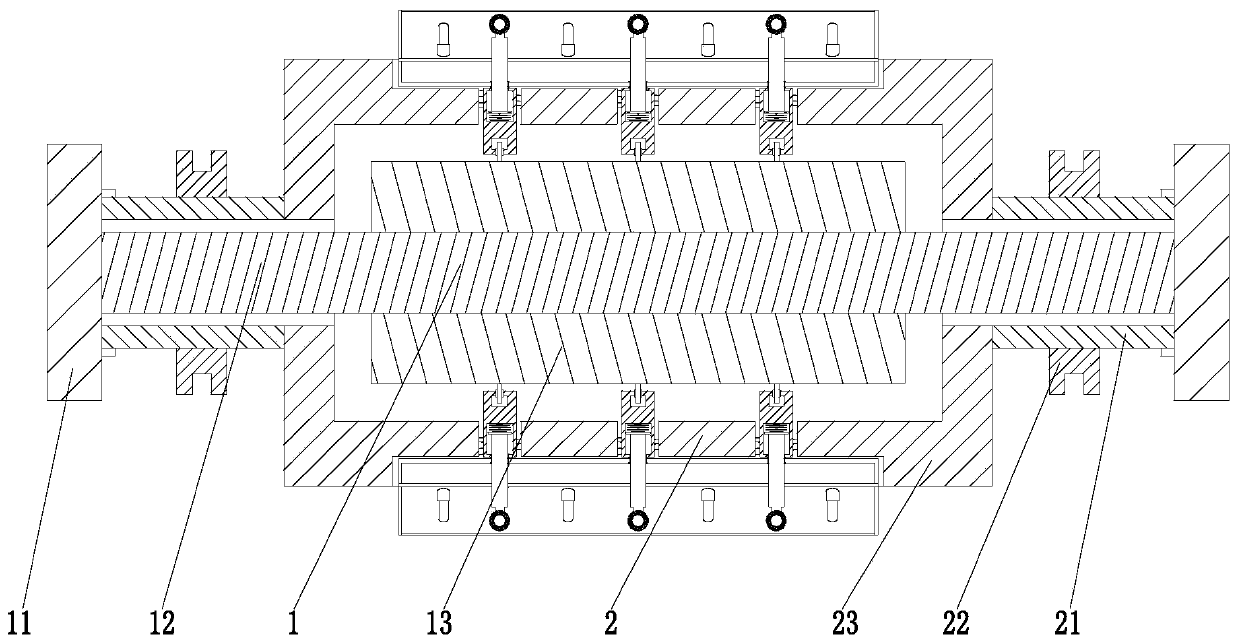

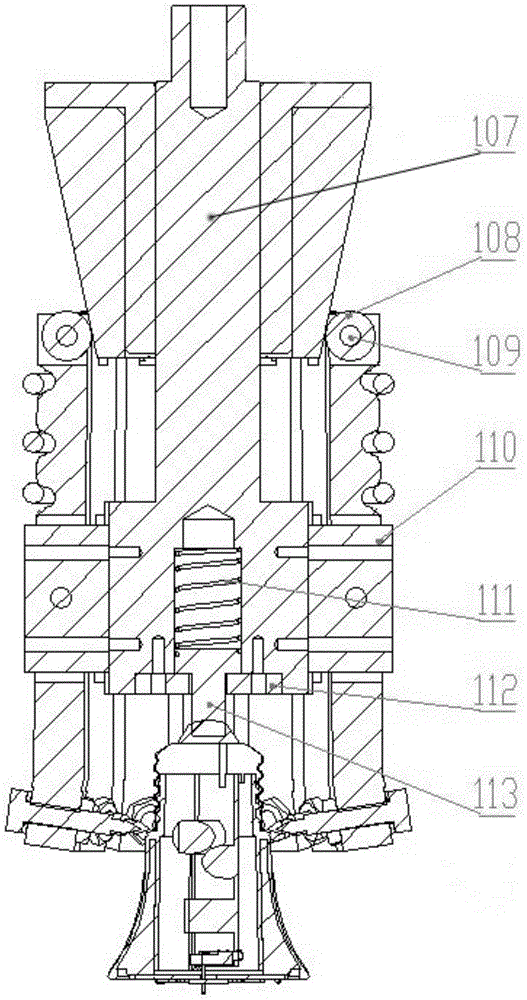

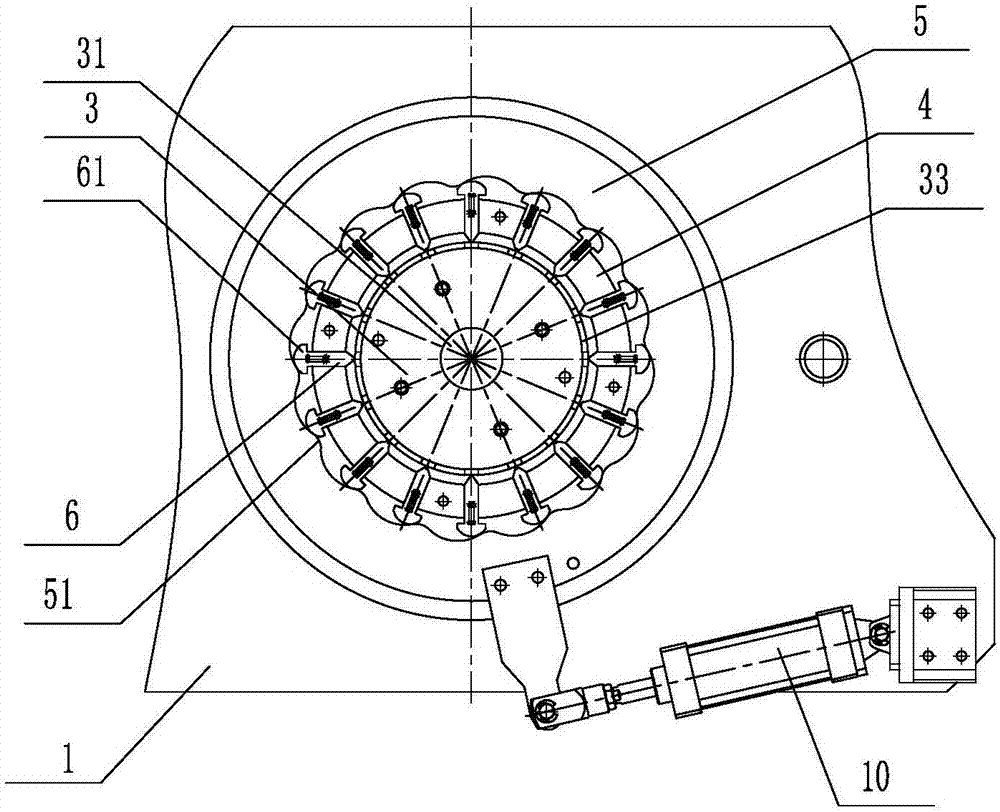

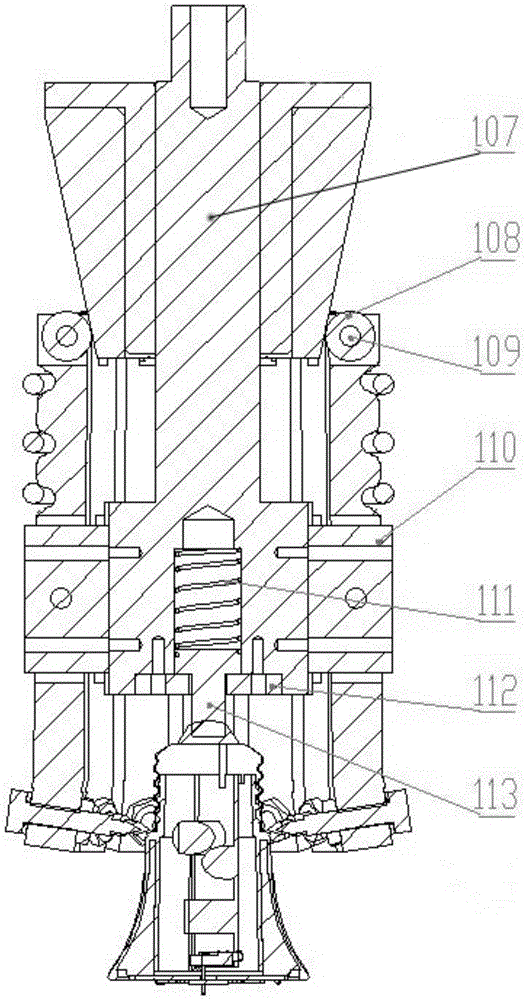

Special riveting machine for vacuum booster

The invention discloses a special riveting machine for a vacuum booster. The special riveting machine comprises a rack, wherein a riveting device is arranged on the rack; the riveting device comprises a location disc installed on the rack and used for placing the vacuum booster; a riveting guide device is fixedly installed at the outer side of the location disc in a sleeving manner; radially-sliding riveting knives are distributed on the riveting guide device in the circumferential direction; the riveting knives are connected with a return limit device; an outer riveting disc is rotationally installed at the outer side of the riveting guide device in a sleeving manner; riveting bulges corresponding to the outer ends of the riveting knifes are distributed on the inner circumferential wall of the outer riveting disc in a bulging manner in the circumferential direction; and a riveting propelling device is arranged between the rack and the outer riveting disc. The special riveting machine disclosed by the invention is capable of realizing simultaneous feeding of the riveting knifes, thereby ensuring the same riveting time for parts and the same depth of riveting points of riveting parts of a vacuum booster product, and effectively ensuring the sealing performance and the appearance quality of the riveting points.

Owner:SHANDONG AOYOU AUTOMOBILE BRAKING SYST

An automatic lamp cap riveting device

The invention discloses an automatic lamp holder riveting pressure device, belongs to the field of mechanical machining equipment, and relates to a riveting mechanism. The automatic lamp holder riveting pressure device comprises a polyformaldehyde sleeve, a conical table, long-bar-shaped levers, a tension spring, round pins, riveting pins, a fixing shaft seat and small blocks, wherein the polyformaldehyde sleeve is fixedly connected with the conical table, the upper end of the fixing shaft seat is sleeved with the polyformaldehyde sleeve, the small blocks are fixedly arranged on the fixing shaft seat, each round pin is formed in the middle of corresponding small block, each corresponding long-bar-shaped lever is hanged on corresponding round pin, the lower end of each long-bar-shaped lever is fixedly provided with the corresponding riveting pin, and the upper end of each long-bar-shaped lever is wrapped and sleeved with the small extension spring. The automatic lamp holder riveting pressure device can provide a certain holding force for a lamp holder to make the depths of riveting points have no difference and make the riveting points be distributed uniformly during riveting pressure of the riveting pins; meanwhile the riveting pins can be stable when the riveting pin riveting pressure is turned on, and excursion of the lamp holder driven by the riveting pins is avoided.

Owner:MAANSHAN LIANBANG INTELLIGENT EQUIP

Method for laser surface hardening treatment of local end surface of thin-wall piece by workpiece clamping

Owner:CHINA FIRST AUTOMOBILE

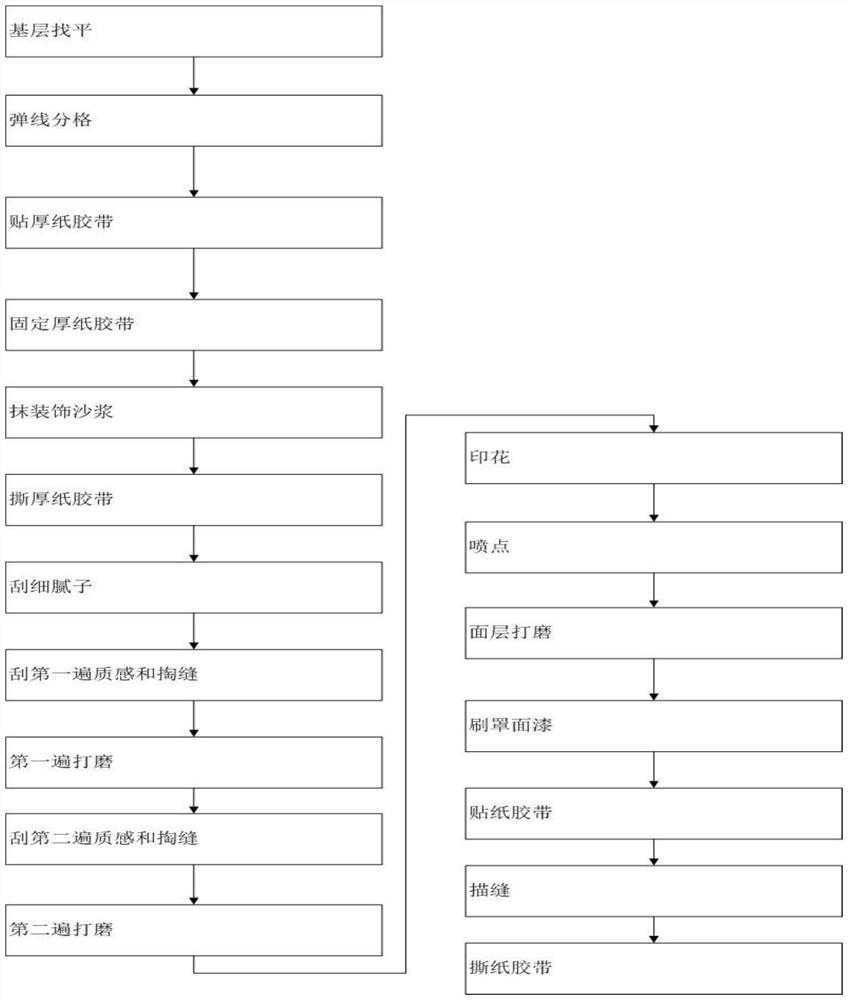

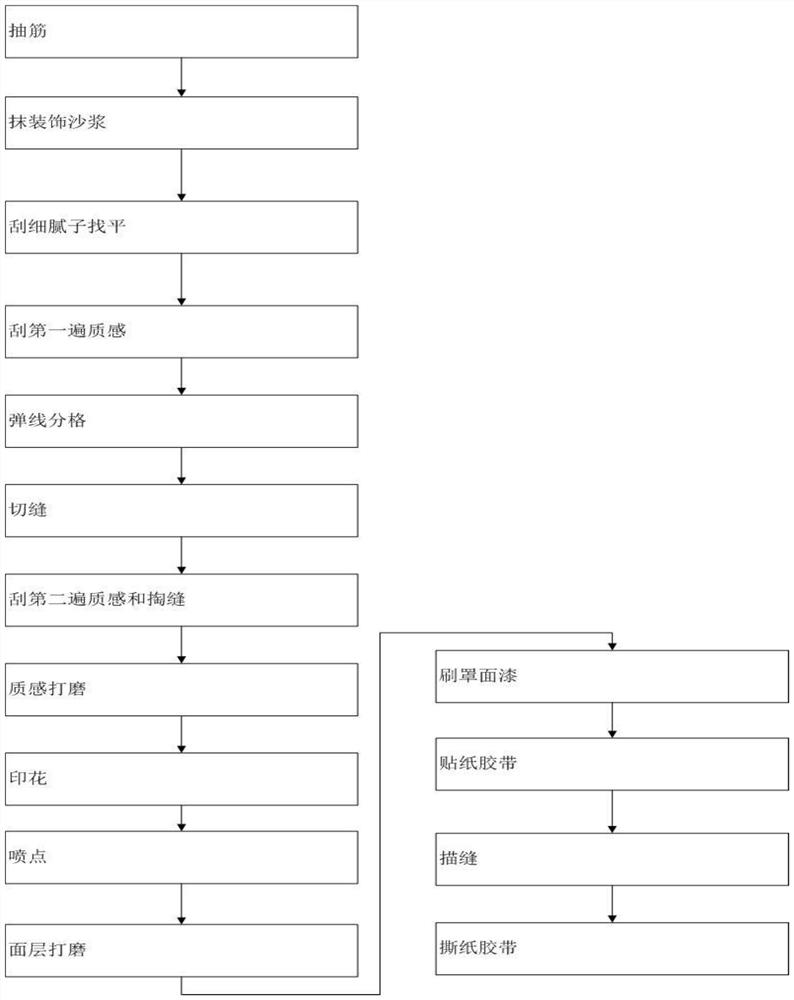

Dividing joint slotting process

InactiveCN112726983AGuaranteed flatnessGuaranteed to be straightCovering/liningsTextile printerPaper adhesive tape

The invention discloses a dividing joint slotting process. The dividing joint slotting process comprises the following steps of S1, pulling out tendons; S2, smearing decorative mortar for leveling; S3, scraping fine particles for repairing and leveling; S4, scraping the texture for the first time; S5, snapping lines and dividing grids; S6, slotting by a slotting machine; S7, scraping the texture for the second time and digging out seams; S8, texture polishing and grinding; S9, printing; S10, spraying points; S11, polishing a surface layer; S12, brushing finish-coat paint; S13, pasting a paper adhesive tape; S14, carrying out seam tracing; and S15, tearing the paper adhesive tape. By adopting the process, the working hours are greatly shortened, the working efficiency is improved, the quality is effectively improved, the flatness of a finished surface and the straightness, uniform size and consistent depth of the seams are ensured, and the cost of a thick paper adhesive tape is saved.

Owner:重庆永联达涂装工程股份有限公司

Moving plate machining method and moving plate machined through moving plate machining method

ActiveCN112974639AImprove flatnessIncreased strength and service lifeShaping toolsNursing bedsManufacturing engineeringStamping press

The invention discloses a moving plate machining method and a moving plate machined through the moving plate machining method. The moving plate machining method comprises the following steps of (1) forming rivet holes in plates, wherein the rivet holes are formed in the corresponding positions of the middle supporting plate, the face plate and the bottom plate; (2) punching counter bores in the face plate and the bottom plate, wherein a punching machine and a punching die are used for performing counter bore inclined surface extrusion on the face plate and the bottom plate which are provided with the rivet holes; and (3) riveting the three laminates, wherein the three laminates, namely the face plate, the middle supporting plate and the bottom plate are sequentially laminated, then rivets are placed in the rivet holes, and flat heads on the two sides of the punching machine are used for performing punching to form flat rivet heads. According to the production and machining method, the depth consistency of the counter bores can be guaranteed, the concentricity consistency of the counter bores and the rivet holes can also be guaranteed, the overall flatness of the moving plate is higher, the strength of the moving plate can be improved, and the service life of the moving plate can be prolonged.

Owner:GUANGZHOU ARCH INNOVATION TECH CO LTD

A glass marking device

The invention provides a glass scribing device and solves the problems of low production efficiency and nonuniformity in spacing, thickness and depth of lines scribed on glass products in the prior art. The glass scribing device comprises a support and an engraving machine, a first motor and a second motor are disposed on the support, the first motor drives a rotating shaft to rotate, the rotating shaft is connected with a fixed plate which is connected with a locking plate, and a telescoping mechanism is arranged on one side of the locking plate and fixed onto the support. The engraving machine is disposed on a connection plate, one end of the connection plate is connected with a nut while the other end of the connection plate is connected with a guide rod which is arranged on the support through a bearing seat, the nut is matched with a screw rod which is driven by the second motor, and the engraving machine is connected with a position adjusting device. The glass scribing device has the advantages that the first motor controls rotation of glass products while the second motor drives the engraving machine to move horizontally, and consequently scribed lines are uniform in thickness and depth, and scribing within different diameter ranges of a same product can be realized; further, widths of the scribed lines are controllable, and tracing is not needed.

Owner:SHANXI DAHUA GLASS IND

Quartz stone plate distribution device and distribution method

ActiveCN110466066ASame shadeImprove efficiencyWorking accessoriesStone-like material working toolsDistribution methodAgricultural engineering

The invention discloses a quartz stone plate distribution device and distribution method. The device comprises a pulp shooting machine, a filler machine and a grooving machine, all of which are sequentially arranged on a conveying belt. The pulp shooting machine comprises a guide rail, a spray gun, a pulp shooting tank and a transmission device. The pulp shooting tank is connected with the spray gun. The spray gun is in sliding connection with the guide rail through a transmission device. The filler machine comprises a filler mold frame and a filler trolley, and the filler trolley is arrangedabove the filler mold frame. The grooving machine comprises a first lifting mechanism and a grooving cutter. The grooving cutter is arranged on the first lifting mechanism. According to the fishbellywhite plate distribution device, in the procedures of distribution of two times and above, manpower is replaced, and efficiency is improved; due to the fact that unified molds and cutters are used inthe distribution process, pattern and line grain depths of produced quartz stone fishbelly white products can be consistent; and the technical problems that in manual distribution, production efficiency is low, pattern and line grain depths of the produced quartz stone fishbelly white products are different, and unification cannot be achieved are solved.

Owner:WANFENG COMPOUND STONE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com