Moving plate machining method and moving plate machined through moving plate machining method

A processing method and technology of moving plates, which are applied in the field of moving plates, can solve the problems of asymmetric counterbores, difficulty in ensuring concentricity, and uneven height of plates, and achieve the effects of improving strength and service life, good fixing effect, and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1...A processing method for moving plates applied in shifting vehicles

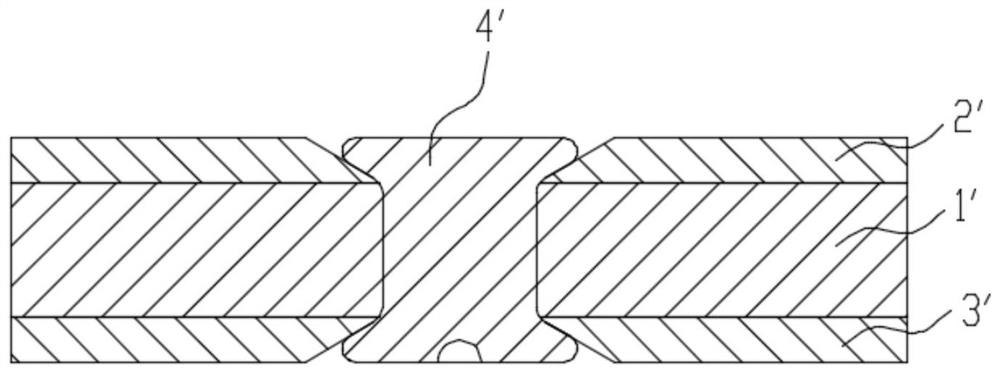

[0042] like Figure 4 As shown, the mobile plate includes an intermediate support plate 1, a panel 2 and a bottom plate 3, and has a three-layer structure; the panels and the bottom plate are thin metal plates, and the panels and the bottom plate are riveted on the upper surface and the lower surface of the intermediate support plate by rivets 4 ; The panel and the bottom plate are aluminum alloy plates, and the middle support plate is selected from one or a combination of stainless steel plates, cardboards, and plastic plates. The thickness of the middle support plate, panel and bottom plate are 3mm, 1mm, 1mm in turn;

[0043] Specifically, the mobile plate processing method includes the following steps:

[0044] (1) Opening of rivet holes on the plate:

[0045] Rivet holes 11, 21, 31 are provided at the corresponding positions of the middle support plate, the panel and the bottom pl...

Embodiment 2

[0055] Embodiment 2 is applied to the mobile plate in the shifting car

[0056] The moving plate is processed by the moving plate processing method of embodiment 1.

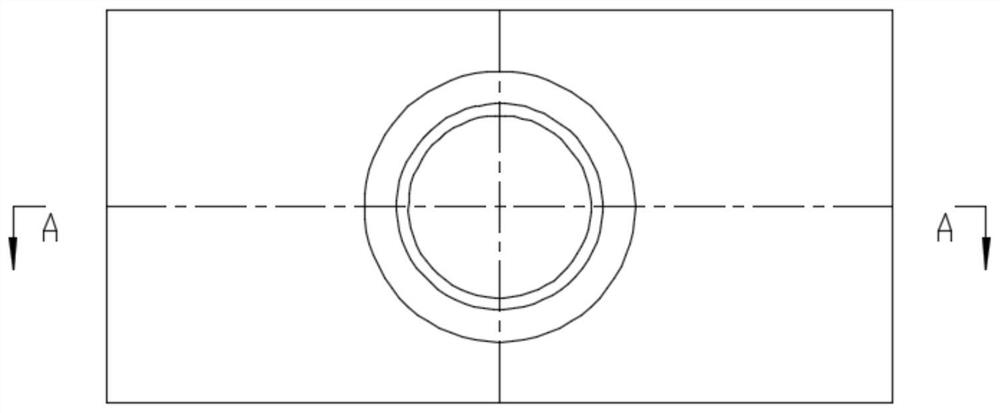

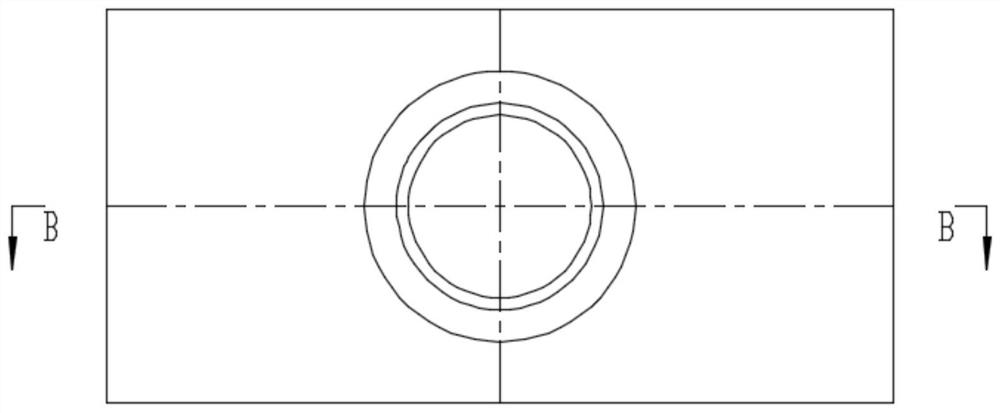

[0057] Specifically, as shown in Figures 3-7, the structure of the moving plate is as follows: the moving plate includes an intermediate support plate 1, a panel 2 and a bottom plate 3; 4 riveted on the upper surface and the lower surface of the intermediate support plate; the intermediate support plate, the panel and the bottom plate are provided with concentric rivet holes 11, 21, 31; the rivet holes on the intermediate support plate are provided with up and down facing The first funnel-shaped counterbore 12, the first funnel-shaped counterbore is formed by the surface of both sides of the plate is sunken toward the middle; the rivet holes on the panel and the bottom plate are provided with the second funnel-shaped counterbore 22,32, the second funnel-shaped counterbore The outer counterbore protruding from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com